SUMMARY RECORD OF THE 27 th MEETING OF STATE LEVEL EXPERT APPRAISAL COMMITTEE, CHHATTISGARH

The 27th meeting of State Level Expert Appraisal Committee, Chhattisgarh was held on 28/03/2009 at Conference Hall, SEAC, Secretariat, 1-Tilak Nagar, Shiv Mandir Chowk, Main Road, Avanti Vihar, Raipur at 12:00 noon. Dr. Harendra Kumar, Chairman, SEAC, Chhattisgarh chaired the meeting. The following members of SEAC were present in the meeting: - 1. Shri Ashok Masih Member, SEAC 2. Shri V.N. Singh, Member, SEAC 3. Dr. Piyush Kant Pandey, Member, SEAC 4. Shri Shailendra Kumar Trivedi, Member, SEAC 5. Shri Anant Prabhakar Rajimwale, Member, SEAC 6. Shri S.S. Bajaj, Secretary, SEAC

At the outset, the Nodal Officer, SEAC, Chhattisgarh welcomed the Chairman and Members of State Level Expert Appraisal Committee, Chhattisgarh. Agenda wise discussions were carried out as follows: -

Agenda Item No. 1 - Confirmation of minutes of the 26th meeting of SEAC, Chhattisgarh.

Minutes of the 26th meeting of SEAC, Chhattisgarh held on 13/03/2009 was presented before the committee. The Committee approved the minutes of the meeting.

Agenda Item No. 2 - Presentation on the proposals received for TOR/EC as per provisions of the Environment Impact Assessment Notification, 2006.

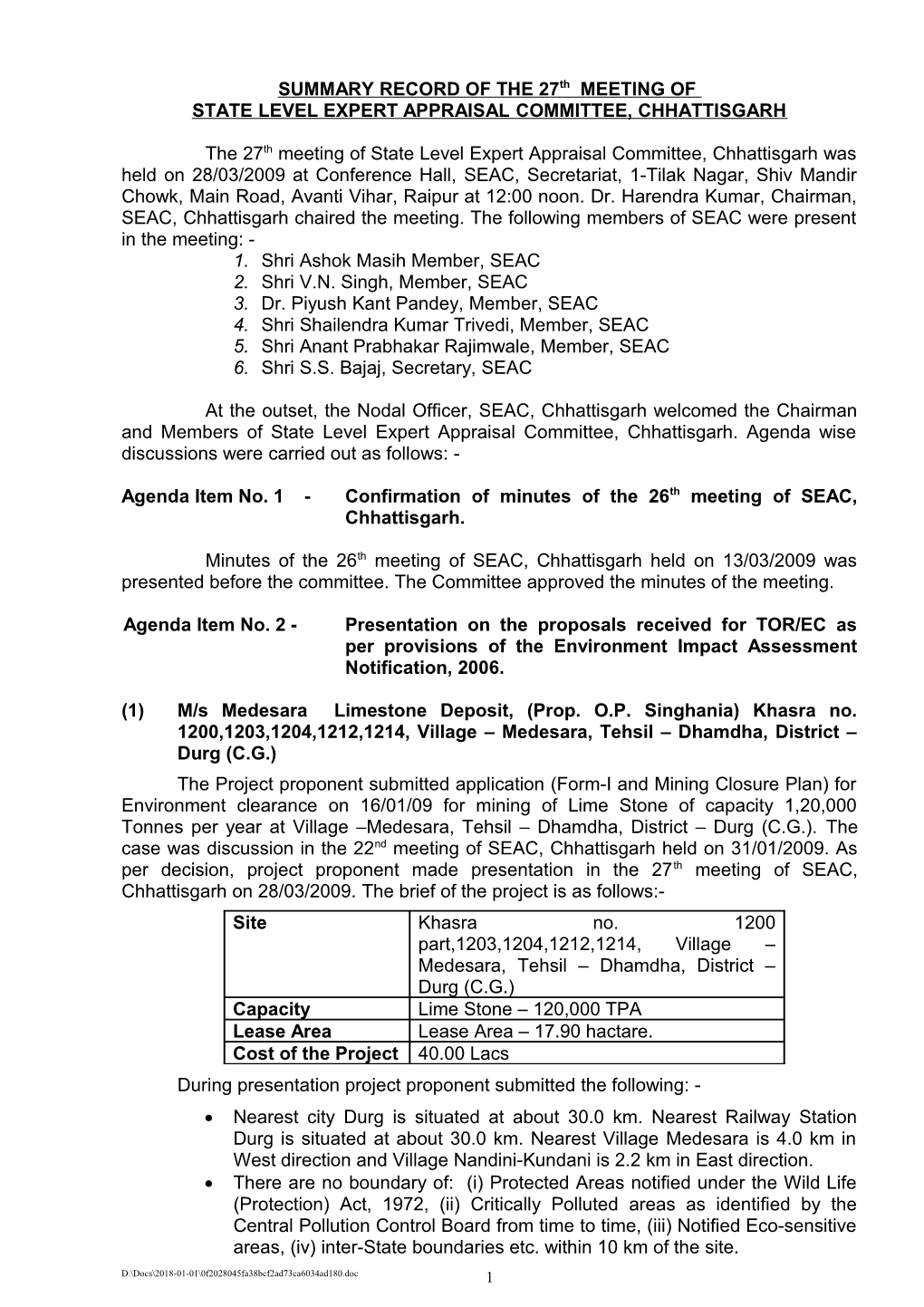

(1) M/s Medesara Limestone Deposit, (Prop. O.P. Singhania) Khasra no. 1200,1203,1204,1212,1214, Village – Medesara, Tehsil – Dhamdha, District – Durg (C.G.) The Project proponent submitted application (Form-I and Mining Closure Plan) for Environment clearance on 16/01/09 for mining of Lime Stone of capacity 1,20,000 Tonnes per year at Village –Medesara, Tehsil – Dhamdha, District – Durg (C.G.). The case was discussion in the 22nd meeting of SEAC, Chhattisgarh held on 31/01/2009. As per decision, project proponent made presentation in the 27th meeting of SEAC, Chhattisgarh on 28/03/2009. The brief of the project is as follows:- Site Khasra no. 1200 part,1203,1204,1212,1214, Village – Medesara, Tehsil – Dhamdha, District – Durg (C.G.) Capacity Lime Stone – 120,000 TPA Lease Area Lease Area – 17.90 hactare. Cost of the Project 40.00 Lacs During presentation project proponent submitted the following: - Nearest city Durg is situated at about 30.0 km. Nearest Railway Station Durg is situated at about 30.0 km. Nearest Village Medesara is 4.0 km in West direction and Village Nandini-Kundani is 2.2 km in East direction. There are no boundary of: (i) Protected Areas notified under the Wild Life (Protection) Act, 1972, (ii) Critically Polluted areas as identified by the Central Pollution Control Board from time to time, (iii) Notified Eco-sensitive areas, (iv) inter-State boundaries etc. within 10 km of the site. D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 1 Total mineable reserve is 21,29,500 Tonnes and the life of mine is 12.5 years. Date of agreement of mining lease is 19/06/2001. Date of permission for land entry is 31/10/2001. Mining operation started in November 2001. The mining operations include removal of overburden, drilling by Jackhammer, blasting and removal of fragmented limestone and sizing (semi- mechanized). There are three pits in the area (one old pit and two working pits). Crusher has also been installed at the site. Project proponent has obtained consent under Water (Prevention and Control of Pollution) Act, 1974 and Air (Prevention and Control of Pollution) Act, 1981 for lime stone crusher of 48000 metric tonne/year. Mining plan has been approved by IBM vide letter no. DRG/LST/MPLN – 751/NGP dated 14/05/2001 for 2700 metric tonne/year, subsequently modification approved on 30/03/05 for 70000 metric tonne/year lime stone mining. Current Mining Scheme has been approved by IBM, Nagpur vide letter no. DRG/LST/MPLN-751/NGP dated 23/10/2007. Mining lease has been granted from 19/06/2001 to 18/06/203. Mining lease area is not a part of forest land. Power is not required for mining activity. However, 70 HP load connection obtained for crusher motor within lease area.

Production and Waste Generation

Production in Previous Years (During 01-02 to 05-06)

Year ROM (Tonnes) 2001-02 2,700 2002-03 17,700 2003-04 44,600 2004-05 77,800 2005-06 77,800 Total 2,20,600

Production and Waste Generation (During 06-07 to 10-11)

Year Limestone Soil Waste (Tonnes) (m3) (Tonnes) 2006-07 66,000 4200 6000 2007-08 66,000 250 6000 2008-09 66,000 280 6000 2009-10 88,000 3015 8000 2010-11 88,000 7080 8000 Total 374,000 14825 34,000

Action Taken for Pollution Control

Air Pollution Water sprinkling on the haul road by tanker mounted on truck. Wet drilling of blast holes.

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 2 Ambient Air Quality at Site (winter)

SPM RPM SO2 NOX Minimum (µg/m3) 104.0 24.4 5.6 8.2 Maximum (µg/m3) 128.0 44.7 7.7 14.9 Average (µg/m3) 115.2 34.3 6.5 9.7 10th Percentile 107.0 31.4 5.8 8.4 30th Percentile 110.0 33.0 6.1 8.9 50th Percentile 115.0 34.1 6.5 9.3 95th Percentile 125.0 41.2 7.5 13.6 98th Percentile 126.6 43.3 7.6 14.6 CO found to be <1 (µg/m3)

Water Pollution Garland drains with check dams would be constructed to prevent the suspended particles along with water coming out of the mine during rainy season. De-siltation of garland drain, check dam and settling pond would be cleaned before rainy season and during rainy season. No effluent is being discharge outside premises.

Noise Pollution Blasting is resorted in controlled manner to mitigate noise pollution. The bits of the drill are kept sharpened to have least noise at the time of drilling. Regular maintenance of the equipments is being done. The person employed in the drill have been provided with ear plugs, Glasses & Gloves.

Solid Waste Disposal Disposal of mine waste will be done partially manual and partially with the help of dumpers. The maximum height of the dump will be 3.0 m and spread of the dump would be approximate 2176 sqm. It is being stored as per mining plan at designated place. Entire overburden would be utilized for back filling. Hence, no waste dump is required. The sub-grade minerals including fines are used as construction material.

Afforestation Programme Along the boundary of lease area dense plantation is under progress. More than 1,500 trees will be planted in coming five years.

Socio Economic Aspect Project proponent will organize regular medical camps once in a month. Project proponent will distribute free medicine to needy people in medical camp. Project proponent will execute eco development/community welfare works of maximum Rs 1.5 Lac/year or about 5% of royalty every year. Based on the consideration of the documents submitted and discussion held, the committee recommended for the filing of court case against the project proponent as per rule at appropriate level as this is a case of existing mine and project proponent has not obtained environment clearance as per the applicable notification. The Committee decided that proposal would be considered after submission of the following information/documents in writing as asked vide letter dated 28/02/2009:-

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 3 Layout plan and area map of 10 km radius showing major topographical features such as land use, drainage, location of habitats, major construction including railways, highways, pipelines, major industries / mines, stone crushers and other polluting sources etc. All above major topographical features should be clearly marked on the map and distance from mine site should be given. Copy of duly approved Mining Plan issued by IBM, Nagpur vide letter dated 14/05/2001 along with amended mining plan approved by IBM, Nagpur vide letter dated 30/03/2005 for mining of lime stone – 1,20,000 tonnes per annum. Details regarding annual return submitted to IBM for production/mining operations. Submit the copy of the same. Declaration of the occupier (managing Director/Director who has control over the mine premises) regarding the existing/proposed activities on land adjoining to the land of existing/proposed activity.

In addition to above, following information should also be submitted :- Clarification regarding the production capacity. Project proponent has applied for lime stone mining 120,000 tonnes per annum; where as the mining plan/scheme has not been approved for this capacity. Project proponent should revise the application as per the capacity mentioned in mining plan/scheme (lime stone mining ROM 88,000 tonnes per annum). Detailed de-watering scheme of mine pit water.

Project proponent should be informed accordingly.

(2) M/s Salasar Balaji Ispat Private Limited, Village – Sondra, Tehsil & District – Raipur The project proponent submitted application (Form-I and Pre-feasibility Report) for Environment Clearance on 16/12/2008. The Project Proponent has proposed a Rolling Mill of capacity 90000 tonnes per year at village – Sondra, near phase- II, Siltara Industrial Area, Tehsil & District – Raipur. The project cost is Rs. 9.80 Crores. The case was discussed in the 22nd meeting of SEAC, Chhattisgarh held on 31/01/2009. As per decision, project proponent was available for presentation in the 27 th meeting of SEAC, Chhattisgarh on 28/03/2009. Project proponent not submitted the desired information as asked vide letter dated 28/02/2009 and 13/03/2009. At the outset of presentation, project proponent could not furnish the information as asked vide letter dated 28/02/2009 and 13/03/2009. The desired information/documents were not included in the presentation also. Project proponent asked more time for compilation of the information/documents and for presentation. Committee decided that after receipt of the desired information/documents as asked vide letter dated 28/02/2009 and 13/03/2009, project proponent should be asked the present the case along with the alternate sites and the criteria for selection of the site for proposed project. Project proponent should be informed accordingly.

(3) M/s. Shankar Hari Agrawal, Works: Village – Chandi, Tehsil – Berla, District- Durg (C.G.) The Project proponent submitted application (Form-I, and Pre-Feasibility Report) for Environment Clearance on 25/08/08 for Limestone mining of 3,375 metric tonnes per annum capacity in 17.95 ha area. SEAC, Chhattisgarh considered the application in 12th meeting held on 12/09/2008. Committee then decided to ask the project proponent to submit the additional information/documents. Project proponent submitted the information on 05/01/2009. The proposal was reconsidered in 23rd meeting on 07/02/2009 of SEAC, Chhattisgarh. After deliberation, the Committee then decided to ask the project proponent to submit the additional information/documents and present the case. D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 4 Project proponent did not come for presentation in the 27th meeting of SEAC, Chhattisgarh on 28/03/2009. SEAC, Chhattisgarh decided that after receipt of the requisite information/documents and formal request for presentation from project proponent proposal should be considered. Project proponent may be informed accordingly.

(4) M/s Gajanand Grinders, Village – Khouli Dabra, Tehsil- Tilda, District- Raipur (C.G.) The Project proponent submitted application (Form-I and Project Report) for Environment Clearance for proposed Grinding Mill (Mini Cement Plant) project on 09/09/2008. SEAC, Chhattisgarh considered the application in 16th meeting held on 23/10/2008. Committee then decided to ask the project proponent to submit the additional information/documents. Project proponent submitted the desired information on 01/01/2009. The proposal was reconsidered in 23rd meeting on 07/02/2009 of SEAC, Chhattisgarh. As per decision, project proponent made presentation in the 27th meeting of SEAC, Chhattisgarh on 28/03/2009. The brief of the project is as follows:- Proposed Site Village – Khouli Dabra, Tehsil- Tilda, District- Raipur (C.G.) Product and Production Capacity Cement : 21000 Bags/year Proposed Cost Rs. 40.00 Lacs Manufacturing Process Grinding of Clinker (with Slag, Gypsum etc.) for making Cement Water Consumption Source- Bore well. Water will be required for drinking, cleaning, washing, dust suppression & plantation. No effluent generation from the process. Activity falls under the Schedule of 3(b) EIA Notification, 2006 During presentation project proponent submitted the following: - Nearest Village- Mohrenga is situated at about 1.6 km and Khouli dabri 1.2 km. Khauli Dabri protected forest and Mohrenga protected forest are situated at 0.2 km and 1.8 km respectively. Nearest reserve forest Bilari is situated at 20 kms in NW direction. Water body Pindraon Tank and Kumhari Tank are situated at 2.40 km and 3.59 km respectively. The unit is based on dry process of clinker grinding. Site Justification Easy availability of raw material. Transport accessibility for raw material and finished good. The demand of cement in the area. The site has a connecting road and easy approachability.

Raw Material Requirement Raw Material Quantity/Day Quantity/Day Source (%) (wt.) Clinkers 40.00 20.00 T Near by Cement plants

Slag 57.00 28.50 T Near by Steel Plant

Gypsum 2.00 1.00 T Local Market D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 5 Coke + others 1.00 0.50 T Local Market

TOTAL 100.00 50.00 T -

Utility Requirement

Utility Requirement Source Water 1.7 KLD Ground Water [1.0 KLD for Dust Suppression 0.5 KLD for Green Belt 0.2 KLD for Domestic Requirement] Power 350 kW CSEB Man Power 15 Local Villagers

Environmental Management Plan

Air Environment

Raw Material Handling Area Dust Suppression during unloading of raw material (Water Spraying System with high pressure pump and spray nozzle at unloading points, transfer points, conveyor etc.) Conveying System Covered conveying system throughout the length. Raw Mill / Storage Hopper & De-dusting System (Suction Raw Mill / Blending Silo Storage Hopper & Blending Silo point & Bag Filter)

Water Environment

Purpose Requirement Waste Water Generation (KLD) (KLD) Dust Suppression 1.0 Nil Green Belt 0.5 Nil Domestic 0.2 0.14

There will be no process effluent generation (Dry Process). Sewage will be treated in septic tank / soak pits. Water conservations systems will be deployed. Rain water harvesting will be undertaken.

Noise Environment Ear muffs / ear plugs will be provided to the workers in noise prone areas. Provision of acoustic enclosures. Anti-vibrating pods will be provided. Green belt all along the boundary to attenuate noise levels.

Solid Waste Management There is no solid waste generation from the project. Fine cement dust collected in bag filter will be sent to packing mill.

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 6 Green Belt Development About 30% of total project area will be used for development of green belt. Local species /CPCB recommended species will be selected for plantation. Based on the consideration of the documents submitted and discussion held The Committee decided that proposal would be considered after submission of the following information/documents in writing :- The comparative study of alternate sites as only one acre land is available and the habitat is very near. More land should be acquired. There are two protected forests namely Khauli Dabri at 0.2 km and Mohrenga 1.8 km from the site. Details of protected forests (preferably authenticated by DFO) should be submitted. Clarification regarding source of slag (Raw material) should be submitted. Revised layout plan keeping the unit at maximum distance from the habitat should be submitted. Proposal for development of green belt in at least 33% of the total land should be submitted. The layout plan showing minimum 10 meter wide green belt should be submitted. The Noise control measures with complete technical details should be submitted. Commitment regarding expenditure of 5% of net profit for eco development and community welfare purposes should be submitted. Project proponent should be informed accordingly. (5) M/s Vandana Energy & Steels Private Limited, Village – Dhanras, Tehsil- Katghora, District - Korba M/s Vandana Energy & Steels Private Limited has proposed to set up a 2 x 35 MW Coal/Washery Reject/ Dolochar Based Power Plant. Project proponent has applied for Environmental Clearance to Ministry of Environment and Forests, Government of India, New Delhi on 09/08/2007 and 22/12/2007. The proposal was considered by Expert Appraisal Committee (Thermal & Coal Mining Projects) on 11-13/02/08. TOR was issued to Project proponent on 12/03/07. Public Hearing was held on 04/10/2008 at Tehsil Office Parisar, Katghora, District-Korba (C.G.). Public Hearing proceedings were received by SEIAA Chhattisgarh on 27/10/08 from CECB, Raipur. Ministry of Environment and Forests, Government of India, New Delhi transferred the original file of M/s Vandana Energy & Steels Private Limited vide their letter no. J-13012/207/2007-IA(T) dated 07/10/2008. Project proponent has applied to SEIAA Chhattisgarh on 30/10/2008 for the grant of Environmental Clearance. The application submitted was considered in 20 th meeting of SEAC, Chhattisgarh held on 27/12/2008. Committee then decided to ask the project proponent to submit the additional information/documents. Project proponent submitted the desired information on 04/02/2009. The proposal was reconsidered in 23rd meeting on 07/02/2009 of SEAC, Chhattisgarh. As per decision, project proponent made presentation in the 27th meeting of SEAC, Chhattisgarh on 28/03/2009. The brief of the project is as follows:- Proposed Site Village – Dhanras, Tehsil- Katghora, District – Korba Capacity Coal/Washery Reject/ Dolochar Based Power Plant of 2 x 35 MW Fuel Washery Rejects = 1604 TPD Dolochar = 295 TPD Coal = 290 TPD Water Source River Hasdeo Area of the Project Land requirement has been optimized and reduced to 29.54 ha from 33.0 ha.

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 7 Description Area (ha) Power Plant and 05.0 Ancillaries Coal Storage Yard 01.54

Raw Water Reservoir 01.00 Greenbelt 10.0 Ash Disposal Area 11.0 Road, Drainage, open 01.0 areas etc. Total 29.54 Proposed Cost Rs. 24000 lacs During presentation project proponent submitted the following: - Nearest city Katghora is situated at about 7.0 km. Nearest Air port Raipur is situated at about 225km. Nearest Village Chhuri khurd is 1.0 km in West direction. Nearest National Highway is NH- 111 Ambikapur – Bilaspur is 7.0 km. from the site. Hasdeo and Ahiran Rivers are flowing at a distance of about 3 km and 3.5 km respectively. There is no railway line within 10 km radius. There are no National Parks/Sanctuaries/Biosphere reserve/Notified. Archaeological site/Defence installation, inter-state border and historic places within the 10 Km. radius. The Ministry of Environment & Forest, Government of India, New Delhi issued TOR on 13/02/2008. The study carried out in the month of December 2007 to February 2008. The fuel (Washery Rejects = 1604 TPD, Dolochar = 295 TPD, Coal = 290 TPD) and ash for beneficiary uses shall be transported through road. Two CFBC boilers of 150 TPH (maximum continuous rating) will be provided.

Statutory Clearances Status

No. Description Status 1 Land Govt. Land (23.358 ha) : Letter of Intent issued by the CSIDC & payment total Rs. 1,33,04,600/- made. The lease dead agreement under process. Private Land (6.182 ha) : Rs. 36,69,590.00 deposited to the CSIDC as compensation.

2 Water Allocation for 2.24 MCM/Annum allotted by Water Allocation Resource Department, Government of Chhattisgarh. Commitment charges of Rs. 56000.00 paid.

3 Coal Linkages Duly recommended by Ministry of Power and in the final stage of sanction. 5 forest blocks exist in 10-km radius area.

Forest Area Distance and Direction from Site Boranala Protected Forest 6.5 km, NNE Pantha Protected Forest 4.5 km, NE

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 8 Protected Forest Near 10.0 km, E Kharku Village Protected Forest Near 7.5 km, WSW Kasaniya Village Tanakhar Protected Forest 8.5 km, WNW

No forest land is involved within the site. Water Requirement No. Units Quantity of water (m3/hr) Actual Water System Wastewater Requirement Loss/ Evaporation Loss 1 Cooling Tower 281* 221 60 2 DM Water 20 19 1 A) For steam generation B) Potable water 3 Service Water 15 12 3 Total 316 252 64

281* m3/hr includes 237 m3/hr makeup water & 44 m3/hr recycled water from RO plant. Withdrawal of river water will be 277 m3/hr, after considering loss due to desludging, evaporation etc. (277-5 = 272 m3/hr) Zero discharge concepts will be adopted. Annual water requirement has been optimized to 2.2 MCM form 2.4 MCM as per TOR. Environment Management Plan Air Environment High Efficiency ESP (99.89%) to control particulate matter. One 110-m high single flue stack for wider dispersion of gaseous emission. Control of stack emission within 50 mg/Nm3 for particulate matter through regular monitoring & control measures as per norms. Regular ambient air quality monitoring in and around project during operational period. Dust extraction and suppression systems in Coal handling plant and coal stock yards Black topping of internal roads & loading unloading areas, avenue plantation and mist type fixed and mobile water sprinkling system and to reduce fugitive emissions. Development of greenbelt and green cover in and around the plant. Water Environment Plant has been designed for zero effluent discharge. Effluent treatment plant proposed for treatment of effluent generated due to operation of plant. Treated effluent will be recycled and reused for greenbelt development, dust suppression and other industrial applications. Regular water and effluent monitoring for control of pollution as per norms.

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 9 Total 64 m3/hr wastewater will be generated and will be recycled and utilized within the plant premises for plant operations and ancillary uses.

Utilization Quantity (m3/hr)

Cooling Tower 44

Greenbelt 14

Ash Handling 6

Total 64

Impact on Water Resources: - Water requirement of 277 m3/hr to be drawn from Hasdeo River. No major impact on Hasdeo river downstream users has been envisaged. Ash pond will be lined to avoid ground water contamination. Noise Environment Provision of acoustic enclosure and hoods for noise generating equipments wherever possible. Development of greenbelt all along the boundary to attenuate noise levels. Personnel protection equipment for plant personnel.

Solid Waste Management Annual fly ash generation will be about 0.4 million tones. Dry fly ash collection system envisaged for ash utilization. Annual bottom ash generated will be about 0.1 million tones. The fly ash will be disposed off to nearby cement manufactures, Brick manufacture’s and for various construction works. Ash pond will be lined with appropriate material to be designed based on the soil testing studies & guidelines. Long term tie-up for fly ash supply to the cement plant has been planned. With the above arrangements, it is expected to achieve 100% flyash utilization during 9th year of commencement of plant operation. Green Belt For greenbelt development 10 ha with 20 -30m width (33% of the project land area) has been allocated. Local species for development of greenbelt/green cover to be planted in consultation with Forest Department/any other expert agency Total no. of plant 15000 @ 1500 tress per ha to be planted on 10 ha land as per schedule given below:

Year No. of Plants

1st Year 3000

2nd Year 3000

3rd Year 3000

4th Year 3000

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 10 5th Year 3000

Socio Economic Environment No rehabilitation involved as there is no displacement of population for the land acquired. Employment opportunity for local community both directly & indirectly will be created. Training for skill up-gradation for self employment and local jobs opportunities will be imparted. Development of social infrastructure & facilities in surrounding area.

Financial Provision for CSR Activity

CSR Programs for villages around the One Time Recurring project Financial Annual Provision Financial (in Rs. Provision Lacs) (in Rs. Lacs) Education and Skill up gradation A) Construction of class rooms and toilet 4.0 B) Skill upgradation training programs 0.5 Health Care A) Construction of health center room 2.0 B) Health checkup and awareness camps 0.5 Community Welfare A) Construction dug well/tubewell 3.0 B) Drainage and sanitation 2.0 C) Community Plantation 1.0 D) Repair and maintenance of community 0.5 assets and infrastructure Total 12.0 1.5

The affected farmers and local people will be provided employment and cost for their land will be paid as per the Government Rules. As a part of CSR activities the management will arrange pure drinking water and health facilities to the near by villagers. If the Industrial Training Institute (ITI) established by Government in Katghora block, the project authority will provide financial support. Commitment for issues raised in Public Hearing

High efficiency and high capacity electrostatic precipitators shall be provided to limit the stack emission with in stipulated norms. Suitable bag filters and dust extraction / suppression systems shall be provided at all the fugitive emission point. The preventive measure will be adopted for dust emission. The vehicles will be cover by tarpaulin. The affected farmers and local people will be provided employment and cost for their land will be paid as per the Government rules. Land will be acquired as per rule. Unitization/ disposal of the fly ash shall be done as per the notification dated 14/09/1999 (amended) of MoEF, New Delhi.

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 11 The impact will be minimized by implementing EMP judiciously. High efficiency ESP, suitable bag filters and dust extraction / suppression systems and water sprinklers will be provided. This will prevent fly ash deposition on land and vegetation. A 20 – 30 m wide greenbelt will be developed along the plant premises and road side. Approximately 1500 trees per ha will be planted in consultation with the local Forest Department. As a part of CSR activities the management will arrange pure drinking water and health facilities to the near by villagers. Re-habitation/ employment facilities will be provided. For each project affected family in the villages 5 nos. fruit bearing trees will be provided. Coal used in the proposed power plant contains low sulphur (0.7 %), hence no control system for SO2 has been envisaged. A provision of 110 m high stack as per the guidelines of CPCB has been followed for dispersion of emissions. If the ITI is established by Government in Katghora block the project authority will give financial support. Based on the consideration of the documents submitted and discussion held The Committee decided that proposal would be considered after submission of the following information/documents in writing :- The ash dyke area shall not be more than 10 ha as against 11 ha. The balance 1 ha should be utilized for green belt development. Green belt area should be 11 ha. Detailed calculation to verify the adequacy of proposed one 110-m high single flue stack for use of fuel mix in worst case should be submitted. Analysis of washery reject and dolochar to be used as fuel should be submitted. Local species Mahua, karanj, Neem, Jamun, Aam, Arjun etc. should be given preference for green belt. Selection of broad leaf local plant species for the development of green belt should be ensured. Minimum COC shall be maintained as five. Justification and details regarding availability of water in Hasdeo River should be submitted. Transportation route map for the transportation of fuel and ash should be submitted. GLC for SPM should be verified. Financial provision for CSR activities should be increased to Rs. 25.00 lacs. Commitment for construction of pucca approach road from main road to power plant should be submitted. Possibility of railway siding should be explored. Feasibility for air condenser in place of water condenser should be explored to minimize the water consumption. Justification for not selecting the monitoring station in upwind direction should be submitted. High concentration slurry disposal system should be adopted. Project proponent should be informed accordingly.

(6) M/s Maruti Clean Coal & Power Limited, Village – Bandhakhar, Tehsil – Pali, District – Korba (C.G.) M/s Maruti Clean Coal & Power Limited has proposed to set up a Thermal Power Plant project of 2 x 135 = 270 MW capacity. Project proponent has applied for Environmental Clearance to Ministry of Environment and Forests, Government of India, New Delhi vide letter dated 25/12/2007. The proposal was considered by State Expert Appraisal Committee (Thermal & Coal Mining Projects) in 16th meeting on 11-13/02/08. TOR was issued to project proponent on 18/03/08. Public Hearing was held on 06/08/2008 at Tehsil Office Parisar, Katghora, District-Korba (C.G.). Public Hearing D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 12 proceedings were received by Ministry of Environment and Forests, Government of India from CECB Raipur vide letter dated 21/08/08. Ministry of Environment and Forests, Government of India New Delhi transferred the original file of M/s Maruti Clean Coal & Power Limited vide their letter no. J-13011/MISC/2008-IA.II(T) dated 26/08/2008. Project proponent has applied to SEIAA Chhattisgarh on 05/11/08 for the grant of Environmental Clearance as per schedule five of EIA Notification 2006. The application submitted was considered in 20th meeting of SEAC, Chhattisgarh held on 27/12/2008. Committee then decided to ask the project proponent to submit the additional information/documents. Project proponent submitted the desired information on 06/02/2009. The proposal was reconsidered in 23rd meeting on 07/02/2009 of SEAC, Chhattisgarh. As per decision, project proponent made presentation in the 27th meeting of SEAC, Chhattisgarh on 28/03/2009. The brief of the project is as follows: - Name of the Project M/s Maruti Clean Coal & Power Limited, Proposed Site Village – Bandhakhar, Tehsil – Pali, District – Korba (C.G.) Production Coal Based Thermal Power Plant of 2x135 = 270 MW Capacity Fuel Coal rejects will be used as primary fuel. The fuel shall be mixture of ROM coal (40%) and washery rejects (60%) and shall be consumed at the rate of 1.05 kgs per KWH, totaling to 6800 TPD (2720 TPD ROM coal and 4080 TPD washery rejects). The washery reject shall be available from the washery of M/s Maruti Clean Coal and Power Ltd. located at a distance of about 6 km. The washery reject shall be transported to the proposed power plant through pipe conveyor. Raw coal transport shall be through road. Cooling System The steam turbine will be of 3000 rpm, tandem compound single re-heat condensing type, air cooling, condensing machine with extraction for regenerative feed water heating. Area of the Project 174.50 Ha During presentation project proponent submitted the following: - Nearest railway station Korba is situated at about 16.0 km. Nearest Air port is Raipur. Nearest National Highway is Bilaspur to Raigarh 57.0 km and Nawapara- Kathghora road is 8 km from the site. There is no National Park, Sanctuary, Elephant / Tiger Reserve (existing as well as proposed), migratory routes, within 10 km of the project site as certified by the Office of Divisional Forest Officer, Katghora, vide letter no. MAP/2008/3149 dated 24/04/08 as well as by the Chief Conservator of Forest, Raipur vide their letter no 1865 dated 30/07/08. 343.04 acres of Govt. barren land and 87.97 acres of private un-irrigated agricultural land will be converted to industrial land use. Ash dyke of 91 acres area will be constructed. R & R plan is not applicable for the project since no person would be displaced. Only agricultural land under private ownership will be acquired besides the government land. The private owners will be compensated as per the market rates and given employment as per qualification. A common railway corridor by SECL is under planning stage. Steam Generators and Accessories Circulating Fluidized Bed Combustion (CFBC) boiler for utilization of rejects as fuel will be installed.

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 13 Coal will be transported from the beneficiation plant to the project site by pipe conveyor. Coal will be transported to the site by road, unloaded in coal yard with the help of suitable Stacker Re-claimer system and will be fed to the in-plant belt conveyor by plough feeders or vibrating feeders. Independent and dedicated air cooled condensers with auxiliary system for each turbine unit. This will ensure reduction in water consumption by 2/3 as against conventional water cooling system. The condensing plant will convert the exhaust steam to condensate in the air cooled condenser and then deliver the condensate to feed water cycle. Air Environment During Construction Fugitive dust will be controlled by regular sprinkling of water. Construction equipments and transport vehicles shall be maintained as per manufacturers specification to minimize source emissions Roads shall be paved at the earliest within the plant. During Operation Electrostatic precipitators (ESP) with an efficiency of 99.9% will be installed to control the particulate emission so as not to exceed 50 mg/Nm3. A stack of 220 m height will be constructed as per applicable standards for plant of < 500 MW capacity. Water spraying system will be provided in washery rejects and coal fines yard to suppress dust at suitable location including transfer points, loading and unloading points. Bag filters will be installed at silo for dry ash extraction. Water Environment Water requirement is 353 cum/hr to be sourced from anicut on Lilagarh River. In principle, 3.09 MCM of water has been allocated by Water Resources Department, Government of Chhattisgarh vide letter no 2397/F/4-34/31/S-2/IWD/7 dated 03/05/2008. Project proponent informed the committee that preliminary feasibility report for availability of water in Lilagarh River has been submitted to Water Resources Department, Government of Chhattisgarh. Surface water bodies Project area falls in the catchment area of Hasdeo River. One seasonal drain originates from the plant site and carries the monsoon run-off to the Lilagarh River. The major drains in the study area are Lilagarh river, Pitni nala, Goknai nala, Ganjar nala, Hathi nala, Karra nala, Tuma nala and Sundhara nala. Apart from the seasonal drains, there are a number of ponds/lakes in the study area. The Khalari reservoir located near the proposed plant is used partially for water supply for irrigation purpose. Impact & management The seasonal nala flowing through the plant site will have to be diverted along the plant boundary to avoid any impact on the downstream flow and drainage pattern. No impact is envisaged due to this diversion since the diversion will be in a small area and the volume of flow within the nala will be maintained. Ground water The wells present in the area can sustain a low yield ranging between 2 to 3 LPS.

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 14 The depth of water table over the study area ranges between 3 to 8 m during pre- monsoon season. The annual fluctuation of water table range between 3.5 to 4.5 m depending upon rainfall. The rainfall is the only source to recharge the groundwater storage. Impact and management No ground water withdrawal has been envisaged Ash will be dumped over 91 acres of area in the form of high concentration slurry within the plant premises where only rainfall can cause leaching of heavy metals into subsurface strata. The ash dyke area will be lined with impermeable material (HDPE – High Density Polyethylene). The leachate will be collected through drain and will be passed to the treatment plant. Hence, ground water contamination will not occur from the ash dumps. Waste Water Management Sources of waste water : • Run-off water from coal yard. • Run off water from ash dyke area during rainy season. • Oily waste water. • Boilers blow down. • Clarifier sludge. • Cooling tower blow down. • DM plant resin regeneration effluent. • Sewage from toilets and effluent from canteen. The project has been designed on 100% recirculation and reuse of waste water to prevent wastage of water. Hence, no waste water discharge or effluent discharge from industrial activities has been anticipated. Waste water from DM plant resin regeneration will be neutralised and reused in CHP dust suppression and in plant horticulture via CMB. Water from cooling tower blow down will be used for ash disposal. The effluent from the industrial activities, after proper treatment in oil/grease separator and sedimentation of SS, will be collected in the central monitoring basin (CMB) and then used for ash disposal. The domestic effluent from colony and plant will be treated in sewage treatment plant and after treatment water will be used for irrigating green belt while sludge will be used as manure. The plant will operate on 100 % recirculation of waste water. All the effluent generated will be treated and re-circulated in the system. Make up water will be required only for compensating the evaporation and other losses. On rainy days, the water allocated to greenbelt will not be used completely and therefore some portion will be discharged. Rain Water Harvesting Rain water falling on the roof tops will be harvested and used for charging of ground water. The rain water falling within the remaining area of the plant will flow into the raw water reservoir, from where it will be utilized in power generation. Noise Environment

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 15 During the observation, it was found that noise level in the study are ranged between 43.0 to 54.4 dB(A) during day time while it ranged between 37.0 to 43.6 dB(A) during night. Impact & Management Increase in noise level during construction due to construction machinery. The impact will be temporary and reversible. The noise level at sources like the generator is anticipated to go as high as 95 dB (A). Provision and maintenance of green belt to screen noise. Restriction of construction to day time. Periodic maintenance of noise generating machinery and vehicles. Provision of air silencers on machines/equipments. Reducing the exposure time of workers to the higher noise levels. Encasement of noise generating sources will be done to control noise level. Besides, ear muffs/plugs will be provided to the workers in the close vicinity of noise source. Provision has to be made for special vibration dampeners and monitor to prevent propagation of vibration to surrounding areas. All workers working in noise borne area will be posted on rotation basis and regularly subjected to medical check-up for detecting any adverse impact on their TLV of hearing. Impact & Management of Traffic There will be additional movement of trucks for transportation of coal to the plant site through covered trucks. It is anticipated that 40 trucks shall be used. The coal transportation from SECL mines to projects site shall be through road which is maintained by SECL (South Eastern Coalfield Ltd.). Impact of the project on the local road network will be 136 trips (40 T) which will not require the construction of any new road. 60% of the fuel which will be washery rejects shall be transported through pipe conveyor which will help in substantially reducing the load on traffic and related pollution. Provision and maintenance of avenue plantation. Periodic maintenance of vehicles. Provision of air silencers on vehicles. Covering of the trucks. Regular PUC checks to ensure emissions are within limits. Maintenance of roads so as to minimise potholes and have smooth ride leading to lesser fuel consumption. Solid Waste Management Ash content in the fuel mix will be around 55%. Ash generation about 3848 tonnes/day. 20% bed ash in dry granular form and 80% fly ash will be collected in RCC silos in dry form. High concentration slurry disposal system will be adopted for disposal of unused ash. In the first 9 years of operation, about 6067526 Tonnes of ash will be utilized by supplying to the cement manufacturers and brick manufacturing units. It is proposed to set up a fly ash brick and aggregate manufacturing plant commensurate with the quantity of fly ash generation. No ash will be utilized for road filling. From the 10th year of operation, 100% ash utilization will be achieved. The total un-utilized ash during the first 9 years of operation will be about 4045018 Tonnes at 80% PLF. The ash dyke has been designed to contain 10 years of ash generation.

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 16 Suitable impermeable HDPE lining shall be done in the ash dyke area to prevent the seepage. Concreting of the land surface of coal pile area will prevent the seepage into the ground. The company is looking for the possibility of getting permission from concerned authorities for abandoned coal mine filling. Green Belt Development A green belt of three layer system in 141 acres area has been proposed all around the plant premises. Plantation will be done along the plant boundary, road sides, office building and stretches of open land with a density of 1500 trees/ha. Fast growing of local species and predominant abundance with proven survival rate plants will be planted. Occupational Health and Safety Measures The workers engaged will be equipped with appropriate protective equipment. All safety measures such as provision of safety appliances, imparting training, giving-of safety awards, display of posters with slogans related to safety will be taken. The workers exposed to noisy sources will be provided with ear muffs/plugs. Adequate facilities for drinking water and sufficient toilets will be provided for the employees. Medical facilities will be provided to the employees and to their family members and will also be extended to the villagers. Periodic check up of workers at OHC for blood, sputum, chest x-rays, audiometric tests, etc. Employment During operation, plant will generate a direct employment for 200 persons. Preference will be given for local population for employment in the semi-skilled and unskilled category. Indirect employment is created by the plant for supply of daily domestic goods. Corporate Social Responsibility The CSR activities will constitute formation of motivational forums, organizing training programs for cooking & catering, tailoring, carpentry, computers, masalas, dairy, poultry, first aid and other training, establishment of middle school in Bandakhar village, providing drinking water in villages, improving drainage system & sanitation systems, repair of roads and construction of culverts, providing elementary Health Check up camp twice in a year, mobile Medical Van to reach out to the villages during night & emergency and others in the Bandakhar, Nonberra, Ratija, Ramtarai, Nonera etc. villages. Under DUTTAK PUTRI YOJNA at least 5 girl students in primary classes from above noted villages will be adopted. One orphan child from each village to be adopted for his overall growth. Funds to the tune of Rs 01 Crore are proposed to be made available per year. (This being 0.5% of our expected profit). Commitment for issues raised in Public Hearing Direct/indirect employment shall be ensured for the project affected people as per their qualifications and skills. Separate budgetary allocation for Community welfare and eco development has been planned and committed as per the direction and requirement of topical District Authorities. Various welfare and eco development activities will be carried out. As a part of CSR activities the management will arrange pure drinking water for the near by villagers. Major part of the fuel shall be transported through closed pipe conveyor being installed in between the coal benefication plant and the proposed project site. D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 17 Balance of the required coal shall be transported though closed tarpaulin covered trucks, thus, reducing fugitive dust. Dedicated road built by SECL shall be used up-to Bandhakhar village. Plant Water sprinkling shall be done on the roads near the villages. 33% of plant area shall be covered with greenbelt with a tree density of 1500 trees/ha. High efficiency and high capacity electrostatic precipitators shall be provided in both the units to limit the stack emission within stipulated norms. Suitable bag filters and dust extraction / suppression systems shall be provided at all the transfer points and storage yards. Utilization / Disposal of the fly ash shall be done as per the notification dated 14 September 1999 (amended) of MoEF, New Delhi. 91 acres ash dyke has been provided for disposal of unutilised ash. Plant construction shall be planned keeping in view the preservation of trees so that there are no detrimental affects on the environment. Based on the consideration of the documents submitted and discussion held The Committee decided that proposal would be considered after submission of the following information/documents in writing :- Local species Mahua, karanj, Neem, Jamun, Aam, Arjun etc. should be given preference for green belt. Selection of broad leaf local plant species for the development of green belt should be ensured. Justification and details regarding availability of water in Lilagarh River should be submitted. Copy of Preliminary Feasibility Report for availability of water in Lilagarh River submitted to Water Resources Department, Government of Chhattisgarh should be submitted. Transportation route map for the transportation of fuel and ash should be submitted. Undertaking for financial provision of Rs. 100.00 lacs or 5% of net profit (whichever will be heigher) per annum for CSR activities should be submitted. Possibility of railway siding should be explored. Commitment for providing financial support for establishment of ITI should be submitted. Justification for not selecting the monitoring station beyond 5 km should be submitted. Coal linkage recommendation letter should be submitted. Action plan for utilization of fly ash as per Ministry of Environment & Forest, Government of India, New Delhi Notification should be submitted. Authentic information regarding no historical importance monument within 10 km radius should be submitted. Commitment for construction for approach road from the already existing road of SECL to the plant site and its proper maintenance. Project proponent should be informed accordingly. (7) M/s Godawari Power & Ispat Limited, Siltara Industrial Growth Centre, Village-Siltara, Tehsil & District-Raipur The project proponent submitted application (Form-I and Project Report) for Environment Clearance on 14/11/2008 for proposed 1x20 MW Bio Mass Based Power Plant. The application submitted was considered in 20th meeting of SEAC, Chhattisgarh held on 27/12/2008. Project is proposed in Siltara Industrial Growth Center, Village- Siltara, Tehsil & District- Raipur. Government of Chhattisgarh has banned the coal-based power plant in this area vide order dated 16/03/2007. The biomass-based power plants use coal (25 – 30 %) during non-availability/ non-supply season (during rainy season) of biomass. After deliberation, Committee then decided that project proponent should be asked to submit the additional information/documents. Project proponent submitted the D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 18 desired information on 04/02/2009. The proposal was reconsidered in 23rd meeting on 07/02/2009 of SEAC, Chhattisgarh. As per decision, project proponent made presentation in the 27th meeting of SEAC, Chhattisgarh on 28/03/2009. The brief of the project is as follows: - Name of the Project M/s Godawari Power & Ispat Limited Proposed Site Siltara Industrial growth Centre, Village-Siltara, Tehsil-Raipur, District-Raipur Production Capacity 1x20 MW = 20 MW Bio Mass Based Power Plant Proposed Cost Rs. 79.76 Crores

During presentation project proponent submitted the following: - Project comes under notified industrial area, Siltara. Site is located within the existing plant premises. No National Park/Wildlife Sanctuary, Tiger Reserve/Elephant Reserve/Turtle Nesting Ground, Core Zone of Biosphere Reserve, Habitat for migratory birds, Notified Archaeological sites, Defense Installation within 10 km radius. Mandhar railway station is about 1.5 km. NH-200 is about 4.5 km. Kharun River is flowing about 7.0 km. Rice husk, wheat biomass, oilseeds & maize biomass will be transported by road. Na ash dyke shall be constructed for storage of ash. Land Requirement Sr. No. Description Area (Ha) 1 Plant Area 0.75 2 Ash Storage Area 0.60 3 Water Storage Area 0.10 (2 days) 4 Rice Husk Storage Yard 0.50 5 Greenbelt/Green Cover 0.70 6 Roads and Open Area 0.10 Total 2.75 Fuel Requirement Blend of rice husk, wheat biomass, oilseeds & maize biomass – 0.14 MTPA. Water Requirement Water required for the proposed power plant will be around 1500 m3/day, which will be supplied by Chhattisgarh Ispat Bhumi Limited from Kharun River. Particular Water System/Evaporation Waste Requirement loss Generation (m3/day) (m3/day) (m3/day) Cooling Tower 1296 1050 246 Potable 2 - 2 DM Plant 85 79 6 Service Water 30 30 - Back Wash 12 12 12 Total 1425 1171 266 Air Environment Regular water sprinkling on road and storage areas would be ensured. Conveyor belts would be covered with enclosures. 73 m tall stack with continuous emission monitoring system would be installed. High Efficiency (99.8%) ESP to limit particulate matter emission to less than 50 mg/Nm3 with one field out would be installed. D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 19 Water Environment Septic tank and soak pit will be constructed for treatment of domestic effluent. Closed circuit cooling system with COC 05 will be installed. Boiler blow down, cooling blow down, DM plant resin regeneration plant effluent will be treated and reused. Zero discharge shall be mentioned. Rain water harvesting will be implemented during operation phase. Noise Environment Equipments will be selected to meet statutory noise standards. Development of Green belt around plant. Exposure to high noise level would be restricted as per the exposure period specified in factories act (Job rotation, use of ear plugs & other PPE where necessary). Acoustic enclosures will be provided as per requirement. Plantation Development of green belt. Tree plantation will be done in consultation with forest department. Solid Waste Management Particular Quantity (TPA) Management/Utilization Fly Ash 19420 Used partially in cement industries and partially in land leveling. Bottom Ash 4856 Used in road construction & land levelling Total 24276 Corporate Social Responsibility A budgetary allocation of Rs. 10.0 lacs shall be earmarked for CSR activities. A fund of Rs. 1.0 lacs shall be allocated towards recurring expenditure each year. Based on the consideration of the documents submitted and discussion held The Committee decided that appropriate decision will be taken after submission of the following information/documents in writing :- Water conservation measures such installation of Reverse Osmosis system or by other means should be explored. Air monitoring stations should be relocated based on metrological conditions. Project proponent informed that the monitoring has already been started from 3rd week of March. Committee of the view that monitoring should be started after prescribing TOR by SEAC, Chhattisgarh. During presentation project proponent informed that coal will not be used as fuel under any circumstances. Only biomass will be used as fuel. Commitment in this regard should be submitted. It was also informed that supplier has also given guarantee for running the plant on 100% biomass. A copy of the letter issued by supplier should be submitted. The quantity of biomass required for three months should be assessed and based on this; the actual space requirement for storage of such a huge quantity of fuel should be calculated. It should be ensured that there is land/space available for construction for covered storage of biomass for non supply season (three months). The quantity of air pollutants emission (particulate matter, SO2, NOx, CO, volatile matters etc.) in case of 100% use of biomass and 100% use of coal should be submitted. Project proponent should be informed accordingly.

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 20 (8) M/s Clean Coal Enterprises Private Limited, Village – Baloda, Tehsil – Baloda, District- Janjgir-Champa (C.G.) M/s Clean Coal Enterprises Private Limited has proposed to set up a Coal Washery project of 0.9 Million Tonnes/Year capacity (throughput of coal). Project proponent has applied for Environmental Clearance to Ministry of Environment and Forests, Government of India, New Delhi on 20/04/2007. The proposal was considered by Expert Appraisal Committee (Thermal & Coal Mining Projects) on 29-30/08/07. TOR was issued to project proponent vide letter no. J-11015/513/2007-IA-II(M) dated 03/10/07. Project proponent submitted the application to CECB, Raipur for conducting Public Hearing on 21/02/2008. Public Hearing was held on 04/07/2008 at Middle School Thadgabahra, Baloda, District-Janjgir-Champa (C.G.). Public Hearing proceedings were received by SEIAA, Chhattisgarh on 01/08/08 from CECB Raipur. Ministry of Environment and Forests, Government of India, New Delhi has transferred the proposal of M/s Clean Coal Enterprises Private Limited vide their letter no. J-11015/513/2007- IA(M) dated 17/09/2008. Project proponent has applied to SEIAA, Chhattisgarh on 22/10/2008 for the grant of Environmental Clearance as per schedule five of EIA Notification 2006. The proposal was discussion in 20th meeting on 27/12/2008 of SEAC, Chhattisgarh. As per decision, project proponent made presentation in the 27th meeting of SEAC, Chhattisgarh on 28/03/2009. The brief of the project is as follows: - Name of the Project M/s Clean Coal Enterprises Private Limited Proposed Site Village – Baloda, Tehsil – Baloda, District- Janjgir- Champa (C.G.) Production Capacity Coal Washery of capacity 0.9 Million Tonnes Per Annum (throughput of coal). Washed coal - 6,30,000 TPA Middling/ Reject-2,69,700 TPA Shale picked – 300 TPA Area of the Project 11.25 acres

Particulars Area (m2) Built-up Area 3378 Internal Roads 7000 Green belt 15120 Storage 3200 Slime Ponds 1242 Rationalization/Open Area 14,460 Total 45,600 Proposed Cost Rs. 1240.00 Lacs During presentation project proponent submitted the following: - The project is located on Bilaspur-Seepat-Baloda-Hardibazar-Dipika road. A PWD road connecting Baloda to Dipika (Korba coalfield) via the proposed site already exists & is being strengthened and widened. Project site has a mild slope towards S-E. It has a flat terrain. Nearest Village Birgahni 2.5 Km Nearest Town Baloda 4 Km Nearest River Lilagar 6-7 Km On North side, about 2 Km away, Forest Land starts which extends northwards, away from project area. The nearest railway station is akaltara, about 20 kms from the proposed project on howrah – mumbai line. NH-200 is about 20 km away from project site. D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 21 There is no National Parks, Sanctuaries and Tourist Important Places within 10 km radius. There are no major industries / mines and other polluting sources within a radius of 5 km from the project site. There is no forest land within the project site. Some forest land of Baloda forest range falls within the study area. No rehabitation & resettlement is required as the land has been purchased through sale deed. Heavy media cyclone based washing technology will be adopted. Raw coal will be sourced from Dipika and Gevra open cast coal mine about 20 km and 25 km respectively from site. Raipur Handling Infrastructure Private Limited, Raipur (RHIPL) is a consortium of 9 sponge iron plants located in Raipur, Bilaspur and Raigarh area. These sponge iron plants have coal linkage from SECL. The company has already entered in an agreement with RHIPL for washing of their linkage coal. Primary baseline data on environmental quality – air (SPM, RPM, SOx & NOx), noise, water (surface & ground water) and soil was collected for one season (non- monsoon season) between mid October, 07 to mid January, 08. Input Coal Quality Moisture (%) - 3.5% - 3.9% Ash (%) - 39 - 40 Fixed Carbon (%) - 31.5 - 32.5 GCV - 3600-3700 KCal/Kg Washed Coal Quality Ash - 28 + 2% Moisture - < 12% Fixed Carbon (%) - >36% GCV - 4683 K Cal/Kg Power Requirement Machinery installed shall require 850-900 KVA of power. Hourly consumption of power, during operation, would be 775 Kwh. LPG/HSD Requirement - HSD for raw coal transportation - 2.5 KLD. - HSD for washed Coal transportation - 8 KLD. - LPG for cooking in the canteen - 2 Cyl./month Impact on Existing Road Network Raw coal transportation of 3000 T/day would mean an additional traffic density of 100 truck-trips /day. Considering cycle time of trucks as 6 hours, around 25 trucks would be deployed over a distance of 20-25 km. The traffic density comes to 1 truck/ km. A black topped 22.5 m wide road from Dipika-Gewra to Baloda is presently under construction. Increase in traffic density of 1 truck/km for transportation of raw coal, clean coal & middling would not have any impact on road network.

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 22 Air Pollution Control Measures Dust suppression in ROM coal receiving section shall be ensured by high pressure water spray and, if required, by addition of coal set (liquid), or coal guard (powder). Dust suppression in crusher cum screen house shall be ensured by enclosing this section totally with brick-cum-sheet walls and covering it with sheet roofing, and provision of dust suppression system with atomized water spraying arrangement. Dust suppression in coal stock yard shall be ensured by covering the stock yard from three sides with 3 m high GI sheeting, and provision of dust suppression jets at intervals. Water Pollution Mitigation Measures (-) 10mm coal (around 35 % of the feed) will be mixed directly with clean coal. Initial requirement of water has been estimated as 2900 KL. Estimated quantity of waste generated by the washery would be 1820 KL. Ground water will be used. The permission for drawl of the ground water from Central Ground Water Board has been sought. Industrial waste water coming from the washery (having fine content of around 20 gm./liter, generated on account of degradation in washing circuit ) will be treated in a series of three slime ponds, 1st to receive waste water, 2nd for settling and 3rd for drying and cleaning. All effluents from the system, floor washings & leakages will lead to the slime ponds. Coagulating agent (Poly Electrolytes) shall be added for coagulation/thickening of the slurry. Clarified water from slime ponds shall be recycled back to the washery circuit. Domestic effluent (3cum/day) generated will be treated in septic tank/soak pit. The project is designed in such a way that the water requirement is optimized by zero effluent discharge system. Zero discharge condition shall be maintained all the time. Noise Pollution Control Measures Ear plugs, mufflers shall be provided to the workers in noise prone areas. Green belt shall be developed in and around plant premises to control noise emission from going out of the plant premises. Rain Water Harvesting Rain water harvesting structures will be constructed to harvest the run-off water from roof tops by laying a separate storm water drainage system leading to a storage tank. Water collected will supplement the ground water source for meeting the water demand for washery. Development of Green Belt 5 to 10 meters wide green belt shall be developed in planned manner along the haulage & service roads of the proposed site, all around the premises, raw coal stock yards etc. Safety Measures First aid facilities will be provided within the washery premises. Periodical medical examination of employees at nearby Occupational Health Centre (OHC). D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 23 The medical records of each employee will be maintained separately. Pre employment medical examination will be conducted. All workers shall be medically tested at the end of his term of employment. A rest room with canteen facilities and toilet shall be provided within washery complex for use of truck operators. Community Development Measures Furniture will be provided for one class room to middle school, Thadgabahra to strengthen its teaching facilities. A first-aid centre established within the washery premises would provide emergent help to the local people. One hand-pump will be established. The site of the same would be finalized in consultation with local people. Stones for road building would be provided free of cost to the local people. Commitment for issues raised in Public Hearing All activities will be undertaken ensuring no damage to agriculture land around the washery. Employment to local people will be considered. Employment of educated person as per need & suitability will be considered. The trucks for raw coal transportation will not cause any problems. All trucks will be covered. Based on the consideration of the documents submitted and discussion held The Committee decided that proposal would be considered after submission of the following information/documents in writing :- The permission for drawl of the ground water from Central Ground Water Board should be submitted. Project proponent should explore the use of surface water to reduce the dependability on ground water as Lilaghar River is about 5 to 6 km away from the plant. The quantity of rain water to be harvested to recharge ground water and quantity for utilization of stored rain water should be submitted. Thickner should be proposed for treatment of industrial effluent. Project proponent should submit the technical details (size, detention period, hydraulic loading etc.) of slime ponds and thickner. Action to be taken for the compliance of the fugitive emission standards, effluent discharge standards and code of practice for coal washer issued by Ministry of Environment & Forest, Government of India, New Delhi should be submitted. Project proponent should be informed accordingly.

Meeting concluded with thanks.

Secretary, SEAC Chairman, SEAC

D:\Docs\2018-01-01\0f2028045fa38bcf2ad73ca6034ad180.doc 24