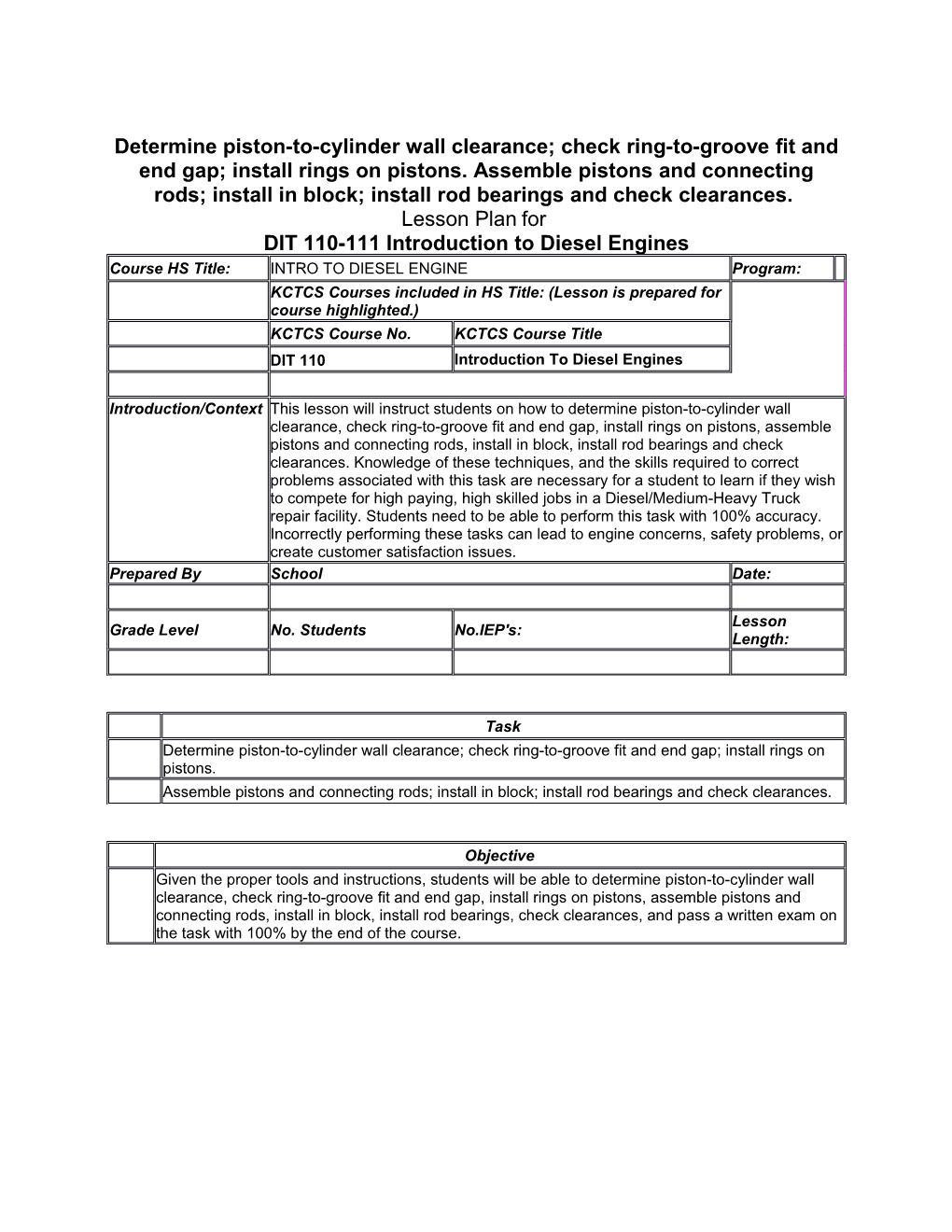

Determine piston-to-cylinder wall clearance; check ring-to-groove fit and end gap; install rings on pistons. Assemble pistons and connecting rods; install in block; install rod bearings and check clearances. Lesson Plan for DIT 110-111 Introduction to Diesel Engines Course HS Title: INTRO TO DIESEL ENGINE Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title DIT 110 Introduction To Diesel Engines

Introduction/Context This lesson will instruct students on how to determine piston-to-cylinder wall clearance, check ring-to-groove fit and end gap, install rings on pistons, assemble pistons and connecting rods, install in block, install rod bearings and check clearances. Knowledge of these techniques, and the skills required to correct problems associated with this task are necessary for a student to learn if they wish to compete for high paying, high skilled jobs in a Diesel/Medium-Heavy Truck repair facility. Students need to be able to perform this task with 100% accuracy. Incorrectly performing these tasks can lead to engine concerns, safety problems, or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Determine piston-to-cylinder wall clearance; check ring-to-groove fit and end gap; install rings on pistons. Assemble pistons and connecting rods; install in block; install rod bearings and check clearances.

Objective Given the proper tools and instructions, students will be able to determine piston-to-cylinder wall clearance, check ring-to-groove fit and end gap, install rings on pistons, assemble pistons and connecting rods, install in block, install rod bearings, check clearances, and pass a written exam on the task with 100% by the end of the course. Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 New Common Core Standards: RST 11-12 3 A-CED-4 N-Q.1 Common Core Technical Standards: TD-OPS 2 TD-SYS 2 New Generation Science Standards: HS-PS2-1

INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts Instructor may use the content section of this plan to create a handout for the students.

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Various Diesel Engines Test T2 Fourth Delmar 36 Sean Bennett Medium/Heavy Duty Truck Engines. Second Delmar 84

Equipment Quantity Item Source As Needed Feeler Gauges Various As Needed Inside Micrometer Various As Needed Micrometer Various

Content/Presentation/Demonstration Outline Instruct students to use a micrometer to measure the piston diameter at right angles to the piston pin bore and 1 inch below the bottom edge of the lowest ring groove. Tell students to compare these measurements to the bore diameter of the parent bore, and let them know that the difference between these two values becomes the piston-to-cylinder wall clearance. Inform students that the average running clearance on larger engines is 0.006 in. (0.152 mm), but not less than 0.002 in. (0.050 mm). Explain that insufficient clearance will cause premature piston or cylinder/liner failure. Tell students that they will measure cam ground pistons at right angles (90 degrees) to the piston pin. Explain that the running clearance of all pistons can be measured using a spring scale with a feeler gauge attached to its end. Instruct students to insert the 0.006 in. (0.152 mm) feeler gauge in the cylinder (liner), and then lubricate the piston with oil and install it (with no rings) bottom up, with the feeler gauge between the cylinder and the piston. Tell them to position the piston about 2 in. (50 mm) below the block deck with the piston pin bore in line with the crankshaft. Explain that when the spring scale indicates the specified force in pounds as the feeler gauge is being withdrawn, the running clearance is correct. Instruct students to ensure the rings have the proper end gap before installing them on the piston. Inform students that this measurement is taken with the rings in the cylinder. Tell students to slide each ring into the cylinder, level using a ringless piston, and measure the gap using a feeler gauge. They should then remove rings from the cylinder and follow manufacturer’s instructions for installing these specific rings on the piston. Explain to students that when installing the piston in the cylinder, ensure the ring gaps are spaced 90 to 120 degrees apart depending on the total number of rings. Let them know that ring gap specification is usually 0.003 in. to 0.004 in. per 1 inch of diameter. Instruct students that ring side clearance is the installed clearance between the ring and the groove it is fitted to, and that dimension is measured using thickness (feeler) gauges. Instruct students that the installation of semi-floating piston pins into an aluminum piston can be made easier by preheating the piston in 200°F (93°C) water. Tell students to slide the piston pin through bosses in the piston and connecting rod and install retaining rings. Inform them to clamp the connecting rod in a soft-jawed vise to support the assembly while installing the piston rings. Tell students to ensure the rod number is correct for the cylinder bore in which it is being placed. Have them protect the rod bearing and journal by covering rod bolts with plastic caps or rubber hose, and then carefully guide the rod onto the journal until the bearing shell seats. Instruct them to verify that bearing clearances are within specification using a Plastigage and connecting rod. Also, tell them to check that the rod cap numbers match their cylinder. Finally, instruct students to sequentially torque the rod cap bolts.

Applications/Practice 1 Refer to Content

Evaluation and feedback Prior to Testing or Lab Work Objective 1/ Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist should be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1/ Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required.

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)