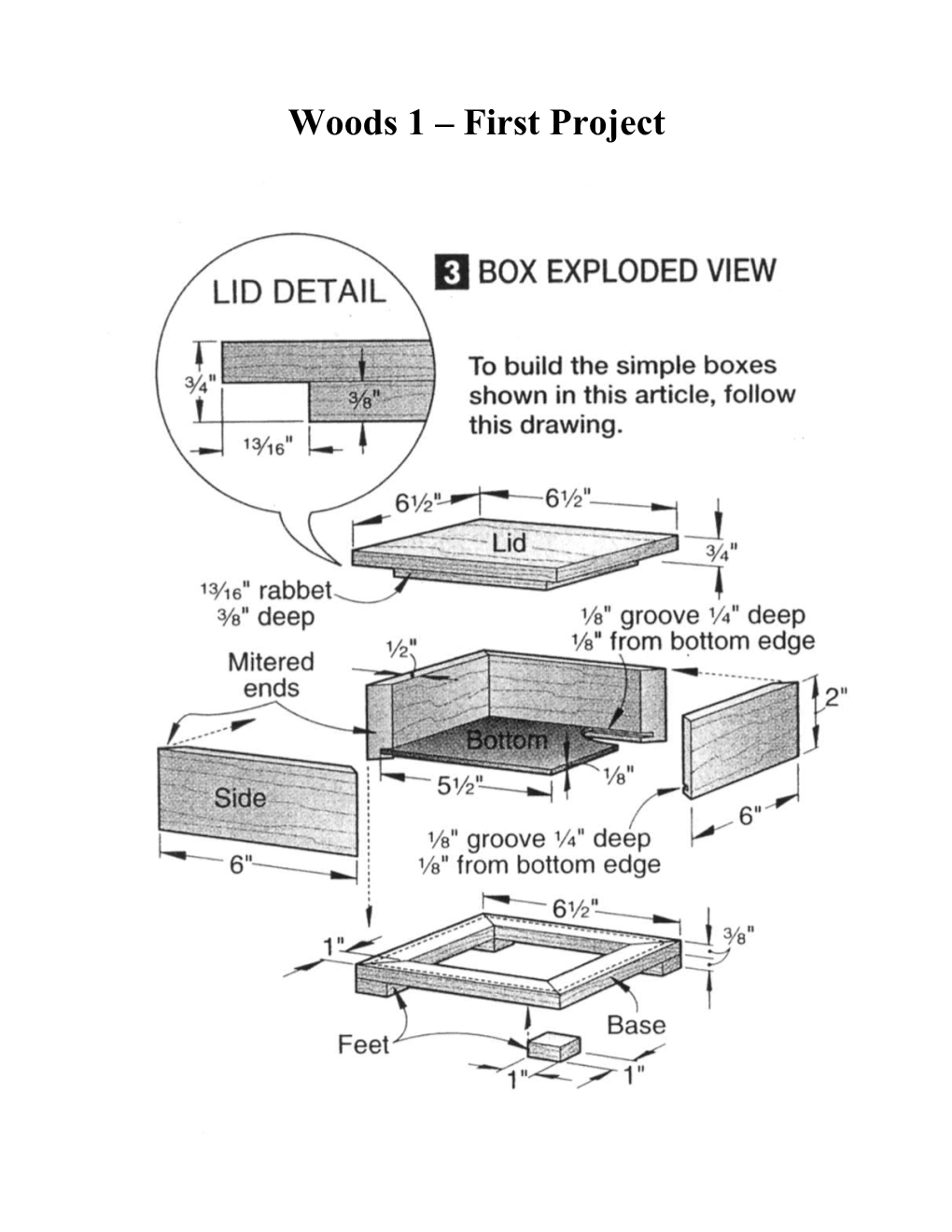

Woods 1 – First Project Project Cut List

Part No of Pieces Measurements Sides 4 6” x 2” x ½” Base 4 6½ “x 3/8” x 1” Feet 4 1” x 1” x 3/8” Bottom 1 5½” x 5½” x 1/8” Lid 1 6½” x 6½” x 3/4” Project Directions

NOTE: Read and understand all directions before starting this project. Depending on the size of wood, multiple parts may be made from one plank if the cut list and steps are coordinated correctly. Constantly refer back to the 3D Exploded View to help visualize each step. Sides

Steps 1 Plane a plank of wood, at least 2½” wide by 26” long, down to ½” thick. 2 Joint one edge of plank. 3 Rip plank to 2”. 4 Lower saw blade to ¼ and set fence to 1/8” to saw one groove for the bottom 5 Crosscut plank into 4 sections of 6¼” (trim one end first) 6 Miter cut each piece with opposing 45 degree angles on each end 7 Sand* and set aside.

Base and Feet

Steps 1 Plane a plank of wood, at least 1½” wide by 32” long, down to 3/8” thick (This should be the cut-off from the side plank of wood.). 2 Rip to 1”. 3 Crosscut 4 sections of 1” (trim one end first) for the Feet. 4 Crosscut remainder into 4 sections of 6¾” (trim one end first) 5 Miter cut each piece with opposing 45 degree angles on each end 6 Sand* and set aside

Bottom

Steps 1 Cut a piece of 1/8” Melamine to 5½“ square. 2 Lightly sand edges only and set aside. Project Directions cont.

Assembly * Sanding* For small pieces of wood, always use hand sand with a sanding block (a square block of scrap wood). Sand in 3 stages making sure to fully complete each stage before going on to the next stage. Always sand with the wood grain (the lines in the wood). Stage 1, 80-100 grit (rough sanding) Gets rid of tool & saw marks and burns. Stage 2, 120-180 grit (medium sanding) Smoothes and removes scratches from stage 1. Stage 3, 220-320 grit (fine/finish sanding) removes all scratches from stage 2 and prepares the wood for a finish.

Steps 1 Dry fit all the parts together and look for proper alignment and fit. Now is the time to make any adjustments or modifications. After the glue sets, it will be very difficult to make changes. 2 Start with the Sides and the Bottom. Lay all the pieces out in the order they will be put together 3 Have 4 small bar clamps ready for clamping the sides together once all the glue is applied. 4 Apply a thin layer of glue to all the mitered edges and in the 1/8” groove so that a small amount will ooze out when clamped together. 5 Carefully fit all the pieces together without getting glue on the surfaces. 6 Slightly clamp each corner. 7 When all clamps are on then gradually tighten each one until all are firm. 8 Wipe off any excess glue before it has time to dry. 9 Let sit undisturbed for 2-3 hours before unclamping 10 Next the Base. Follow the same process as with the sides. 11 After the base has dried completely, then glue the Feet using the same technique. 12 After everything has dried, glue the Base with Feet to the glued Sides. Refer to the dotted lines on the base in the Exploded View for proper placement. Follow the same gluing techniques as before. 13 When the entire project is dry, finish sand and apply stain and/or clear coatings.

Lid NOTE: Depending on which “Texturing Technique” you wish to use, the directions for making the lid will vary. The following steps are for the lid in the Exploded View.

Steps 1 Start with a piece of wood at least 7” wide and 7” long by ¾ thick. (In most cases it isn’t possible to find a piece of wood 7” wide, so gluing 2 narrower pieces together will be necessary.) 2 Once the wood is at 7” square, trim down to 6½” square. 3 Set up a 13/16” Dado blade on the table saw or a router with the same size bit. 4 Make a 13/16” cut on all sides of the bottom side of the lid 3/8” deep. 5 *Sand and modify (texture) if desired.