Design Projects Documentation

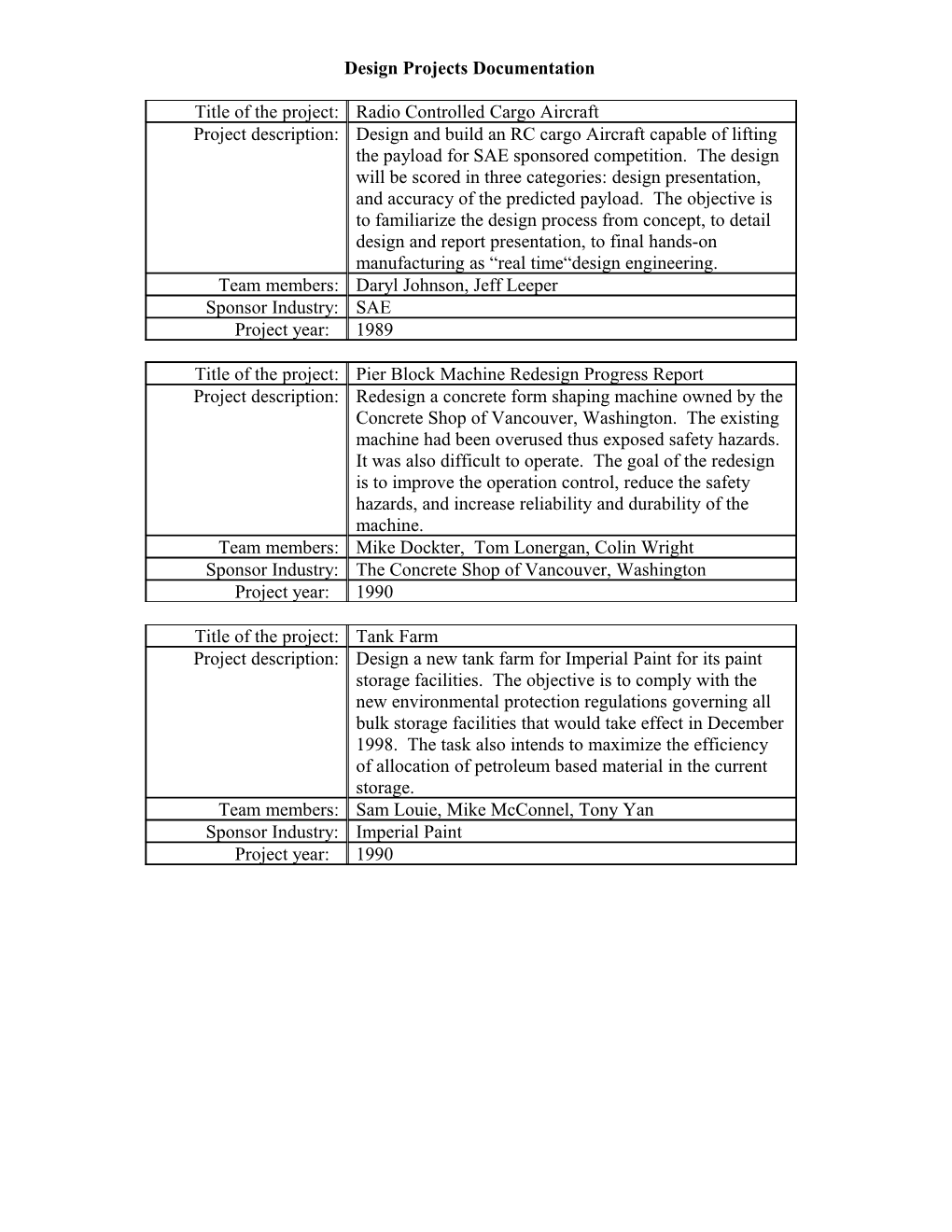

Title of the project: Radio Controlled Cargo Aircraft Project description: Design and build an RC cargo Aircraft capable of lifting the payload for SAE sponsored competition. The design will be scored in three categories: design presentation, and accuracy of the predicted payload. The objective is to familiarize the design process from concept, to detail design and report presentation, to final hands-on manufacturing as “real time“design engineering. Team members: Daryl Johnson, Jeff Leeper Sponsor Industry: SAE Project year: 1989

Title of the project: Pier Block Machine Redesign Progress Report Project description: Redesign a concrete form shaping machine owned by the Concrete Shop of Vancouver, Washington. The existing machine had been overused thus exposed safety hazards. It was also difficult to operate. The goal of the redesign is to improve the operation control, reduce the safety hazards, and increase reliability and durability of the machine. Team members: Mike Dockter, Tom Lonergan, Colin Wright Sponsor Industry: The Concrete Shop of Vancouver, Washington Project year: 1990

Title of the project: Tank Farm Project description: Design a new tank farm for Imperial Paint for its paint storage facilities. The objective is to comply with the new environmental protection regulations governing all bulk storage facilities that would take effect in December 1998. The task also intends to maximize the efficiency of allocation of petroleum based material in the current storage. Team members: Sam Louie, Mike McConnel, Tony Yan Sponsor Industry: Imperial Paint Project year: 1990 Title of the project: Redesigning The Tensioning System For An I.D. Silicon Wafering Saw Project description: Redesign a wafer I.D. saw to improve the slicing process in terms of throughput and wafer quality for Wacker Siltronic, Inc. The target is to develop a system that enables rapid blade changeover (5 to 10 minutes) while improving the wafer quality as less than 30 microns of run-out at 3 standard deviations. The project includes two separate phases, 1) a remote tensioning system, and 2) a device easy and efficient for mounting the pre- tensioned blade to the saw. Team members: Paul K. Durant, Chris Burkle, Brent Running Sponsor Industry: Wacker Siltronic Inc Project year: 1995

Title of the project: Metal Building Assembly Fixture Project description: Redesign the current building assembly fixture to improve its performance and increase its usability. The fixture design will include 12 – 16 ft wide buildings, allow different framing member spacing between building sizes, and allow installation of doors and windows anywhere around the building perimeters. The redesigned fixture will be able to work on the same site where the job is. The fixture size will be adjusted to 8 ft long and 4 ft wide for transportation. Team members: Russel Reigel, Steve Rothe, Ali Kashi Sponsor Industry: Reigel Buildings, Inc Project year: 1994

Title of the project: Design of a Ground Ambulance Gurney Project description: Design a Ground Ambulance Gurney (a medical emergency wheeled cot or stretcher) for Life Port to stay in competition on the gurney market. The design model NE-31 must meet the following constraints: 18” (height) x 76” (length) x 22” (width). Able to carry 500lb patient with maximum deflection of 1”. The four wheel casters must be free to allow the gurney to maneuver around corners. Compatible with the existing attachment systems used in ambulances. Team members: Richard Berney, David Graham, Mike Rusch Sponsor Industry: Life Port, Inc Project year: 1990 Title of the project: A Method to Rebuild Delaminated Color Printer Heads Project description: Designing a procedure to rebuild the delaminated color printer heads so that the returned defective heads can be reused. The rebuilt heads not only need to be functional, but also need to meet the following goals: The built head will have a service life of 7 years. The head rebuilding must use the existing equipment at Tektronix as much as possible. The process must complete by June 9, 1989. Four phases are developed for the rebuilding process: 1. Disassembly and sorting. 2. Surface preparation. 3. Adhesive selection. 4. Reassembly. Team members: Mark Erickson, Eric Muhvy Sponsor Industry: Tektronix Project year: 1989

Title of the project: Unwind Stand for James River Corp Project description: Design an unwind stand for James River Corporation. The design focuses on areas of self loading, brake, and tension controls. The targets are to increase productivity, eliminate paper breakage, ensure the edge alignment, ensure self loading, and properly position the bulk rolls. Utilizing the latest technology in paper tension control and brake devices, the design also includes a scissor lift mechanism mounted in the floor, and a hydraulic actuator integrated with a photo-electronic senor for lateral adjustment. Team members: Peter Arola, Kevin O’Connell, Man Wah Poon, Arthur Miller Sponsor Industry: James River Corporation. Project year: 1987 Title of the project: Warn Vacuum Locking Hub Group Project description: Design and prototype a remotely-actuated mechanisms which can engage and disengage the clutch ring with the inner drive gear for Warn Industries, Inc. The design objectives focus on the mechanism itself as follows, The remote actuation will be accomplished by way of vacuum or pressure delivered through the spindle. The design must allow the clutch ring to move to the locked and unlocked positions repetitively and reliably. It must survive the exposed location of a front wheel hub in a four-wheel drive vehicle. The mechanism must fit into approximately the same internal cavity of the hub as found on Warn’s current design.

Team members: Brian Baker, Mike MacGregor, Ken Millard, Daniel Morrow Sponsor Industry: Warn Industries, Inc. Project year: 1995

Title of the project: The Densification of Energy Wood Material for Economical Transpiration to Distant Energy Markets Project description: The objective of the design is to propose and evaluate a method to densify (bale) waste wood materials for convenient and economical long range transportation to distant energy markets. The design focuses on two areas of processes, the method of densifying waste wood and means of transportation for shipping waste wood. Team members: Richard Allen, Steve Ringous, Roger Doolin, Ali Khashab Sponsor Industry: USDA Forest Service Pacific Northwest Research Station. Project year: 1995 Title of the project: Tillamook Cheese Project Project description: The objective is to design an automated cheese trimming system to replace manual operation that causes injuries due to repetitive motion. Eliminating manual operation in this trimming process reduces the medical cost due to the injuries. Along with the savings from medical costs and recycling the excessive cheese from oversized cheese block, this project would ultimately bring $80,000- $10,000/yr savings to Tillamook Cheese Corporation. The automated cheese trimming system would be integrated into the existing conveyor system at Tillamook Cheese Corporation. Team members: Jim Jackson, Fred Frey, Jerry Stole, Terry Daugherty Sponsor Industry: Tillamook Cheese Corporation. Project year: 1992

Title of the project: Bonnelville Navigation Lock Project description: The design proposes a new navigation lock gate actuating mechanism. The existing navigation lock that has not been replaced in the last twenty years has a long downtime in the event of mechanical failure. The long downtime could be up to 3 weeks that disrupts the traffic on the entire Columbia River. The components of the existing lock were custom made that takes longer time and expensive to replace. The new navigation lock would be less expensive in maintenance and shorter downtime that would ease the bottleneck condition developed on the Columbia River. Team members: Jim Jackson, Fred Frey, Jerry Stole, Terry Daugherty Sponsor Industry: US Army Corps of Engineers, Mechanical Design Section, Portland Oregon. Project year: 1986 Title of the project: Design of Condensate Return System Project description: This is a preliminary design and economic evaluation of a steam condensate recovery system that will serve Ballast Water Treatment Plant for Portland Ship Repair Yard. One of the Ship Yard services is the separation and treatment of a mixture of water and crude oil, known as ballast water. The separation process utilizes steam from a nearby boiler house to heat and separate the mixture. After repeated cycles, the oil will be skimmed and the water will reach its purity level accepted to return to sewage or the Willamette River. Before this project, none of the condensate generated in the whole process was recovered. The water and its remaining heat all lost along with the chemicals in the water to prevent the corrosion in the boiler. The design objective is to capture the maximum amount of steam condensate possible and return it to the boilers at the highest temperate possible with free maintenance and reasonable cost. Team members: Scott Hewitt, Bill McKay, Dan Watson Sponsor Industry: Portland Ship Repair Yard, Port of Portland, Swan Island Project year: 1990

Title of the project: Pneumatic Switch Project description: Redesign a pneumatic switch, an HVAC valve used in a cab of a truck for Sprague Aristo-Aire to meet their customer needs. Driven by the cost (under $8.00), the redesign report discussed two alternatives, use of the spool valve operated by a cam, and an adaptor allowing the current product to fit an Eaton style rocker arm switch, and picked latter as its final decision. The report gathered information of existing valve mechanisms, and did analysis including valve body, cam piston, bulking, pressure vessels, heat transfer, and rocker plunger. The report presents discussions of quality, decision matrix, and drawings Team members: Michael Pepelaskov, Danny Yuwono, Scott Hartell, Tom Lee Sponsor Industry: Sprague Aristo-Aire Project year: Dec., 1995 Title of the project: Freightliner Twin Steer Project description: The Twin Steer system is used in heavy duty truck to increase the load carrying capacity. Freightliner’s Twin Steer system poses problems when navigating uneven byways and rugged terrain. Using QFD (Quality Function Deployment) techniques, the project focuses on the front suspension used universally on various models of Freightliner trucks that will distribute the loading evenly over both the front axles. The proposal for the new suspension offers improved steering geometry over the current design and free of interference of the tire and the steering linkage. The intent is to solve the problem of 1) possible overloading on one axle; 2) interference of the right tire with the steering linkage. The final design uses a mix of exiting Freightliner components and new parts manufactured in house from standard Freightliner materials. The redesign has achieved equalization, and has been recommended to be a standard option for Freightliner heavy duty truck. Team members: Doug Johnson, Eric Kominek, Chris Phimister, Dilan Silva Sponsor Industry: Freightliner Corporation. Project year: unknown

Title of the project: Refrigeration Update Design Project description: The project presents the design and analysis of a retrofit kit for semi-trailer refrigeration unit to replace earlier style of Thermo King model SNWD units and subsequent reinstallation into the glider kit to produce a unit which is a comparable in design and performance to late model Thermo King SB style units. The accomplishment also includes the update that is less than half of the cost of a new refrigeration unit. The design features include a flush mount evaporator section, improved evaporator fan design, and the conversion from CFC based refrigerant to an EPA approved HFC based alternative. The project consists four major tasks, 1) frame design and analysis; 2) evaporator fan selection and analysis; 3) alternative refrigerant selection and analysis; and 4) construction of the prototype Glider kit. The project also covers cost analysis of building the prototype and recommended testing procedure for determining the refrigeration performance of the prototype under actual operation condition. Team members: Andrew Gorman, Dodd Juenemann, Scott Basom Sponsor Industry: Thermo King Corporation Project year: June, 1994 Title of the project: Final Report Prototype Air Burst Screen Cleaning System Project description: The objective of the project is to develop a functional prototype of an air burst system to remove debris from two selected dewatering screens, as means of studying an effective replacement to the mechanical systems at the new JBS (Juvenile Bypass System) at Bonneville Dam. The project is to meet the request from the National Marine Fisheries Service (NMFS) to improve the survival rate of the young salmon during downstream migration. Team members: Dwayne M. Weston, Jeff Howard, James N. Rawlinson Sponsor Industry: U.S. Army Coprs of Engineers, Portland District Project year: June 1997

Title of the project: Large Building Monitoring Project description: The project is about the development of an energy monitoring procedure for large commercial buildings. The project presents a method that substantiates and pinpoints the savings attained in monitoring the various energy loads from the retrofits. The project derived the answers about the reason of monitoring a particular load, the measurement precision, recording frequency, the duration of the monitored load, the method of gathering ambient weather information, power quality analysis versus monitoring accuracy, monitoring procedure versus multiple-load testing, data acquisition system being stationary versus portable, and compatibility between procedure and the retrofit system. Team members: Dryan D. Babcock, Kevin C. Fish Sponsor Industry: Microgrid Inc. Project year: June 1993 Title of the project: IDC Fab Chiller Project Project description: The project analyzes the alternative sources of energy for facility cooling. These alternative energy sources are the use of natural gas and absorption driven chillers instead of electricity driven to cool the incoming air or remove the water vapor. The project focuses on reducing electrical energy costs for a chiller plant by using heat recovering from gas-engine-driven (GED) chillers to power absorption chillers. The design requirements are 10000 ton maximum required cooling load, payback period of 1 ½ to 2 years, inside dry bulb temperature of 70 F, inside relative humidity of 42-45%, and use off- the-shelf components. Additional requirements are space constraints, use of heat recovery, chilled water temperature, system reliability, maintenance downtime, system life, system cost, and fab location and ambient conditions (Austin, Texas). Team members: David Bueffel, Doug Crombie, Tony Hunt, Danny Wilhelmi Sponsor Industry: Industrial Design Corporation (IDC) Project year: June 1997

Title of the project: Human Powered Hydrofoil Design Report Project description: The project investigates the propeller and foil theories, and presents programs to predict a ten foot diameter air propeller and a wing tapering from a 2” to a 4 “ chord length. The project studied ergonomics and evaluated the data from the riders who were tested for their horsepower output (0.9 to 1 horsepower output is expected for an athlete pedaling at 100 rpm. The project presents a drive train system design that supplies the power to propeller from the rider using standard bicycle components. Using FEA, the project presents the design of the hull and tubular structures to support the foils and propeller. Team members: Craig Ulrich, Robert Ray, James Oliver, Gerald Knrdonowy, Linda Jackson, Paul Giuffrida Sponsor Industry: The International Human Powered Vehicle Association, Inc Project year: June 1992 Title of the project: 1996 SAE Mini Baja Final Report Project description: The project is of an SAE sponsored annual Mini Baja competition. The ultimate goal of the project is to design and build a prototype of an off road vehicle. The intent of the prototype was the acquisition of suspension and drive train loading data, as well as information leading to the improvement of the overall design. The maximum vehicle size is 60” wide x 96” long, 8hp, and 4 cycles Briggs and Stratton engine. The competition is intended to simulate an industrial engineering situation in the form of prototype development, and is limited to a maximum production cost of $2500 per vehicle in a 4000 vehicle run. In addition to the technical specifications, SAE sets strict safety regulations. Vehicles conforming to safety and technical regulations are subjectively judged by practicing engineers based on marketability, design innovation, aesthetics, and cost effectiveness. The cars then compete in dynamic events intended to evaluate their performance characteristics. Dynamic events consist of a maneuverability slalom course, a hill climb, a drag race, and a four hour endurance event. Team members: Chris Aspmo, Dave Hort, Bill Hayhurst Sponsor Industry: Society of Automotive Engineers Project year: June 1996

Title of the project: Water Heater Design Project: Out for the Long Run Project description: The project researches the causes of the tank failure of residential water heaters and presents a new design of hot water heater with longer life (35 years versus 5-12 years of conventional water heater lives). The result of the project is a design that employs an anodic protection system and a sediment removal system to protect the tank from failure and thus increase tank life to at least 35 years. Schematics of the design were created such that a prototype can be constructed. The prototype can then be used to test the concepts generated. Team members: Jake Abraham, Peter Villanueva, Samarith Loeung Sponsor Industry: American Water Heater Group Project year: Unknown Title of the project: Condensate Recovery System Project description: The project was to evaluate the economic feasibility of recovering lost energy and /or water from the Tall Oil area steam condensate. The team concluded that the Tall Oil area under utilized the heat value from condensate produced. The condensate collection tank was under sized and only returned a portion of the available condensate for boiler water preheat. The project proposed Liqui-Mover collection/pumping system that would have a larger capacity and return more condensate. A new plate and frame heat exchanger is presented to replace with the shell and tube heat exchanger thus the heat transfer would be more effective from returned condensate to the boiler feed water. The new heat exchanger combined with the Tall Oil return system would cost Hercules $27,600 and save $40,000, that yields 103% return on cost (ROC). Team members: Art Utter, Fred Imayoshi, Randy Mathieu, Susan Grant Sponsor Industry: Hercules, Inc Project year: June, 1995

Title of the project: UHMW-PE Parts Welding Project description: The project involves the development and design of an improved process for joining ultra-high molecular weight polyethylene (UHMW-PE) hubs to sprockets. To spin- welded the hubs to the sprockets, Solidur used a lathe to spin the hub against the stationary sprocket, generating enough heat from friction to weld the parts. The complexity of the lathe requires skilled labor intensity from the machinists. The molten plastic being thrown from the parts also became safety concerns. The project recommends an improved form of spin-welding through the use of automation that would reduce the skill level required to run the lathe, and free the lathe for other uses. Based on the economic analysis of costs, the team determined the configuration of the spin-welding fixture from the two alternatives, a dual-spindle welder that could weld two hubs at once, and conversion of an out- of-tolerance milling machine, and decided to use the conversion of an out-of-tolerance milling machine. Team members: Brian Bonn, John Calderbank, Larry Coon, Rich Rampone Sponsor Industry: Solidur Pacific Co. Project year: June, 1993 Title of the project: Tri-County Metropolitan Transportation Project description: The project was to develop an alternative wheelchair restraint system for the physically challenged riders of the Tri-County Metropolitan Transportation District of Oregon (Tri-Met) that reduces the company’s liability for injuries sustained by the restrained passengers and the drivers that must insure the safety of the regarded passengers. Tri-Met had been able to accommodate the wheelchairs before the change of modern wheelchair styles such as varied sizes of tires between front and rear, and 3 tires instead of 2. Tri-Met previous restraint system could not work as intended. The project provides the development of a universal wheelchair restraint system to be installed on the buses to replace the outdated system for all styles of wheelchairs to meet ADA (American with Disabilities Act) and FTA (Federal Transit Administration) requirements. Team members: Brad Grabo, Loren Morris, Kellie Reid, Eric Tubbin Sponsor Industry: Tri-Met. Project year: January, 1996

Title of the project: Step-Chair Project Project description: Initiated by the chair of Electrical Engineering Department of PSU, Dr. Scghaumann, the project was a joint development between both the electrical and mechanical engineering senior students. The objective was to build an electro-mechanical device that would attach to a wheelchair, regardless of configuration, providing a means of traversing a step or a curb. The project presents the design focusing on the constraints of weight, size, automation, safety, efficiency of power use, ease of retrofittability, and climb time. The final deliverable includes a proof-of-concept prototype and a written report containing a recommendation, conceptual CAD drawings, and FEM analysis. Team members: Joe Brackin Dale Campbell, Tim Culligan, Bob Essex, Erik Halverson, Dave Henkemeyer, Jesse Inkpen, Larry Montoya, Craig Sarkinen, Mike Willardson, Ken Wolf Sponsor Industry: Electrical and Mechanical Engineering Dep’t of PSU. Project year: June, 1996 Title of the project: Facility Plan Project description: The project was to redesign an existing factory layout at Sequent Computer Systems, Inc. Focused on the subset of the overall factory layout and closely followed established methodology used in facilities planning at Sequent, the project reaches viable solutions for two large problems related to Production Floor Layout and Job Shop Layout. The solution meets the customer requirements for the new manufacturing system production and product logistics. Team members: Christian Vega, John Peterkort, James Chen, Vinesh Lal Sponsor Industry: Sequent Computer Systems, Inc. Project year: June, 1993

Title of the project: Curb-Climbing Wheelchair Redesign Project description: The project is the continuation of a senior electrical- mechanical joint project that began in 1996. The design was never operational though the substantial progress was made in the basic concept of the chair. Based on the previous design, the project was to redesign and build a prototype curb-climbing wheelchair that is safe and functional to both ascends and descends curbs automatically. The project spotted the problems from the previous design thus, setup new requirements and constraints, and proposed solutions so that the new prototype would be operational. Team members: Robert Deline, Clint Hutzenbilier, H. Mac Kuokka, Kent Nielson, Valentine Powers Sponsor Industry: Electrical and Mechanical Engineering Dep’t of PSU. Project year: June, 1997

Title of the project: Curb-Climbing Wheelchair Redesign Project description: The project targeted the existing problems of Single Roll Tissue (SRT) O-thane Belt Transport System that introduces product defects and resulting downstream machinery malfunction issues in the tissue processing. The project was to design a new SRT Transport System that eliminates snagging of SRT tails while meeting the needs of the existing system. Using QFD (quality function deployment) techniques, the project achieved a Retracting Table Top Chain SRT Transport System Design leading to reducing associated costs thus increasing productivity. Team members: Jeanne Lewis, Kellie Reid Sponsor Industry: James River Corporation. Project year: June, 1997 Title of the project: Design Project – James River Corp. (JRC) Wauna Mill Project description: The project utilizes the design methodology so called “Five Diamond Methodology”, developed by Migliore and Goulding of Portland State University, a design development process from initial conception to final implementation. The report details the methodology as it was used to solve problem associated with the work order requested at James River Corporation. The work order selected was a request for a closed loop liquid/liquid heat exchanger to cool the air compressor. Under the constraints of no change to the compressor and compressor operation, less than $100,000 budget, and keeping the water process chemistry acceptable, the project provides alternative approaches that are more cost effective than the corrosion inhibitors previously used at JRC to dealing with the corrosion problem of the air compressor leading to premature failure. Team members: Bob DeWitt, Geoff Ford, Martin Mance, Allen Zandonatti. Sponsor Industry: Wauna Paper Mill, James River Corporation. Project year: June, 1995

Title of the project: Freightliner Hood Tilt Assist Project Project description: The project was to redesign the hood tilt assist mechanism for more ergonomic reasons for Freightliner’s commercial trucks. Requiring less effort to open and close, the new proposed design offered a new hood tilt assist concept as an improvement upon Freightliner’s existing design. The final design for the hood locking mechanism utilized a linkage that mounts to the side of the radiator and also behind the front grill location. The design main advantage is its automation, meaning the driver needs only to open the hood in the conventional manner, and the locking mechanism automatically engages. The final design met Freightliner’s requirements of reducing the opening and closing forces to 35 and 40 pounts. Team members: Jaswant Sandhu, Ken Tran, Todd Wurster. Sponsor Industry: Freightliner Corporation. Project year: June, 1996 Title of the project: Evaluation and Redesign of a Bone Mill Project description: The project was about an evaluation and redesign of the bone mill for Acumed, Inc. Using functional decomposition techniques, the team performed an in- depth analysis on the previous design. Based on the knowledge and information gained during the preliminary assessment, the redesign generated the concept and prototype. Through a method of one-to-one comparison and using the criteria developed during the initial research, the team evaluated the redesign concepts and presented the most successful options of the redesign to Acumed so that Acumed could make the final decision on which prototype to pursue. The project presented a refined final prototype, a stainless steel, vertical cast body with integrated receiver bowl and inverting capability including drawings for manufacturing. The report also introduced new manufacturing processes including recommendations for fabrication and finishing processes into the design. Team members: Connie Drake, Shawn Gibbs, G. Vicky Jerome, Bruce Kell. Sponsor Industry: Acumed, Inc. Project year: June, 1994

Title of the project: Vehicle Diagnostics Project description: The project presents a study of the feasibility of monitoring the battery system of a Freightliner truck, and intends to measure the capacity of the battery by utilizing the data collected by Data Link of the truck. The goal is to predict when the battery is near the end of its life to start the truck. The Data Link of the truck previously gathered information about the trucks performance such as oil pressure, oil temperature, coolant temperature, ambient air temperature, and etc at 1-10 seconds. The project presents a test with the installation of additional analog sensors that measures the battery voltage, the current of the starter, and the battery temperature much faster. From the test data, a measurement of the capacity of the battery is calculated. From the calculated value, the characteristics of the start cycle, an estimation of the state of the battery is made. The information along with the start test is compared with the reference data from the start cycles performed on a new battery charged to specified percentages of its rate capacity. From the data, trends that indicate low battery capacity are identified. Team members: Jeff Lusardi, Wenyu Lin Sponsor Industry: Diameter-Benz Research and Technology Center, North America, Inc Project year: January, 1998 Title of the project: Proposal for Automated Molten Metal Delivery at Consolidated Metco Project description: Due to the request by Oregon Plant of Consolidated Metco, Inc for automation of a molten metal transportation and distribution system to reduce the cost and improve the die cast system, the project proposed a design of a semi-automatic system capable of delivering aluminum to an operator designated holding furnace without further human intervention. The project utilized concurrent engineering methods to research, evaluate, select, and design the system. Team members: Alan Hatfield, Tim long, Behnam Karandish, Qui Luu, Chris Stone Sponsor Industry: The Clackamas, Oregon Plant of Consolidated Metco, Inc Project year: June, 1998

Title of the project: Columbia Machine Palletizer Project description: The project proposed a replacement of the previous hydraulic system in Columbia Machine palletizer model FL200 with an alternate that performs as well as or better than the previous system, while eliminating environmental concerns, reducing noise, and maintaining consistent and reliable operation in a variety of climates. The project follows the design constraints such as non- hydraulic, same or better speed and control, environmentally safe, safe and smooth and quieter operation, reliable 24 hours / day operation, option of redesign the structure, and fall within budget. Team members: Antonio Edgar, Andrew McGuire, Robert Grossnickle, Jeff Wey Sponsor Industry: Columbia Machine, Inc. Project year: Jan, 1998 Title of the project: Warn Clutch System Project description: Requested by Warn Industries for their clutch system used in their 8-kip and 12-kip winches, the project presented a new design utilized a pull and twist motion to disengage the winch, and utilized a spring to allow the rotated lever to snap back to engage the winch. The new design offered the feature that when the motor is running, the operator cannot snap the lever into the engaged position. The project report identified and solved the problems of the previous clutch lever. The new design conforms Warn Industries constraints and the standards of SAE. Team members: James E. Smith, Bardia Razzaghi, Bill Sterling, Dan Seale Sponsor Industry: Warn Industries, Inc Project year: Jan, 1992

Title of the project: Strapbinder J-Series Hose Clamp Semi-automatic Hand Tool Project description: Requested by A.J. Gerrad LlC Company, the project was to design a hand held (less than 18 lbs) semi-automatic tool to install any J-series pre-formed hose clamps. Traditionally, the hose clamp installation tools were either manual versions or semi automatic bench mounted units. This portable tool would reduce the cost therefore reduce the price and gain the market. Powered by the compressed air (80 psi) and with less than 30 seconds, this installation tool tensions the clamp and reports the clamping force being applied to the hose, and then holds the tension force until the clamp is sealed and the excess banding material is cutoff. Team members: Michael V. Fenton, Dean C. Marleau Sponsor Industry: A. J. Gerrard LLC Company Project year: June, 1996 Title of the project: Weld improvement Project Project description: The paper dealt with the time required in the weld area when change their products at Custom Hoists department of Warn Industries. The project focused on the setup process and new fixturing that would allow faster change from product to product. The team analyzed and determined the problems, and provided solutions that would reduce the required time to change products for welding. Team members: Scott Lambing, Jon R. Stroud, Cory Williams Sponsor Industry: Warn Custom Hoists, Warn Industries, Inc Project year: January, 1995

Title of the project: Drum Weld Fixture Project description: The paper presented a welding fixture that deals with welds between flanges and tubing on the winch drum at Custom Hoists department of Warn Industries. The existing fixtures did not work well and took too much time to setup. The project presented modifications on the existing fixtures to solve the problems the existing fixtures have. As a redesign, the modifications focused on the fixture holding the spool flanges firmly against the headstock and tailstock while allowing the flanges of the spool to rotate, and expanding outward against the flanges when activated. Team members: Scott Lambing, Jon R. Stroud, Cory Williams Sponsor Industry: Warn Custom Hoists, Warn Industries, Inc Project year: June, 1995

Title of the project: Palletizer Push Bar Design Proposal Project description: This proposal outlines a strategy for increasing the speed of a palletizer HL90 manufactured by Columbia Machine. With minimal additional cost, the goal of the project is to increase the processing speed by eliminating a product backup at the pusher section of the palletizer. Team members: Marvin Joanis, Arnold Top, Ralf Busby, Scott Witt Sponsor Industry: Columbia Machine, Inc. Project year: January, 1994 Title of the project: Human Powered Vehicle Project description: The project was to design and build a high performance vehicle to compete in the 1996 ASME sponsored human- powered vehicle competition. The PSU human-powered vehicle is a semi-recumbent bicycle fully enclosed in a carbon fiber/Kevlar faring. Continued from the last year’s competition, this project focused on the fairing and additional seat design offered the improvements that allow a greater degree of reliability and rider comfort. Team members: Basem Abdallah, Shawn Murphy, Jason Wilson Sponsor Industry: ASME Project year: June, 1996

Title of the project: Veterinary Hospital Animal Cage Heater Project description: This report presents the design of a simple device that provides uniform heat to all parts of the animal, allows for bodily fluid drainage, easy to clean, and operates quietly without hazardous to animals during and after the animal surgery. The device does not interfere with the cage door motion and veterinarian’s view of the animal inside the cage. The design utilized a combination of existing devices which added to its flexibility. The device consists of a lightweight plastic slab that fits inside of a medium sized animal cage and two fans that attached to the slab allowing heated air to flow under the animal and out of the cage. Team members: Martia Jenkins, Hung Dang, Patrick Sandow, Jamie White Sponsor Industry: East Mill Plain Animal Hospital Project year: June, 1995

Title of the project: Electrical Resistance Space Heater Project description: The design presented a quiet, compact, smoothly warm, and inexpensive space heater that would compensate heat due to the heat loss varied from ventilation performance, and satisfy 10% occupants who always feel cold on their feet in the heating climate of the building. Cadet Manufacturing made heaters but not satisfactory to the 10% unsatisfied building occupants. The design offered features of the heater capable of floor, wall, or desk knee- hole mounting, one hour running and automatically shutoff, hand, or toe, or knee activation with push button, maximum 500W power, and noise level is below 40 dBA. Team members: Wayde Hager, David L. Hall, Steve Waitman Sponsor Industry: Cadet Manufacturing, Vancouver, Washington Project year: June, 1992 Title of the project: Precision Chain Grinder Project description: This project concerns the design of a precision saw chain grinder to be used in the test laboratory of Oregon Cutting Systems Division (O.C.S.D). The task of the project was to design a fully adjustable, partially automated, precision saw chain grinder that would be able to meet the requirements such as sharpening a standard 20 in loop of saw chain in 20 min. or less, sustaining cutter to cutter repeatability of +/- 2 degrees of accuracy for all three angles of concern, allowing fabrication of the design at the O.C.S.D to use existing components, and keeping the total cost of the design below $15,000. Team members: Tim Vonderohe, Kelly Jackman, Taylan Caglar, Vince Tejeda Sponsor Industry: Oregon Cutting Systems Division (O.C.S.D) Project year: June, 1991

Title of the project: Mining Vehicle Tilt Table Design Project description: The project was to design a 15x 40 ft tilt table that tips in one plane along 40 ft edge using a two-way hydraulic cylinder and journal bearings. Using structured design methodology, the team evaluated the concepts, and selected the concept. The team completed a detailed analysis of the hinge and pin connections and has provided detailed drawings for the components. Using FEA and maximum deflection technique, the project presented the platform design, calculated the required section properties, and determined the configuration of the structural members. Team members: Robert W. Cowling, Casey Dotson, Minh Nguyen, Hai Vu Sponsor Industry: Atlas Copco Wagner Project year: June, 1996

Title of the project: Design of A Telephone Answering Machine Project description: The project was to design a telephone answering machine for those individuals who are intimidated by electronic devices. The project was requested for the senior people, in age from 50 to 75, who are not yet familiar with using answering machine. The project examined the design of a telephone answering machine from lust to dust. The fact that many people dislike missing phone calls was a major factor in the project selection. Therefore, a design methodology was formulated to attack the problem. The project included problem recognition and definition, defining customer restraints, gathering and analysis of information, generating alternative solutions, and evaluating and implementing solutions. The end result is a design that is compact and user friendly. Team members: Kellie Reid Sponsor Industry: Unknown Project year: March, 1996

Title of the project: Prime Mover, Human Powered Vehicle Project description: The report is a one man project in addition to Portland State University’s 1996 HPV entry. The author designed and built his own fairing using his connections with the experts in composites and laying up fiberglass and carbon cloth. Continued from 1995’s work that provided the frame design and prototype, the project focused on the fairing design report, prototype, and the testing that was required. Team members: Trent Warwick Sponsor Industry: ASME Project year: June, 1996

Title of the project: Prime Mover, Human Powered Vehicle Project description: The report is a one man project in addition to Portland State University’s 1996 HPV entry. The author designed and built his own fairing using his connections with the experts in composites and laying up fiberglass and carbon cloth. Continued from 1995’s work that provided the frame design and prototype, the project focused on the fairing design report, prototype, and the testing that was required. Team members: Trent Warwick Sponsor Industry: ASME Project year: June, 1996

Title of the project: Design Submittal for Energy Resource Center for HVAC Laboratory Project description: The project proposed to build a HVAC laboratory that is not available in Portland area for educational and research purpose by students, professionals, and others who with an interest in HVAC. Used a cause and effect and affinity diagrams, the project conducted a survey of the potential customers, and compiled their needs. Using Quality Function Development (QFD) procedure, the project ranked the needs of the potential customers, and developed measurable engineering goals for the design. Using Paul’s decision matrix, the project developed concepts based on the needs of the potential customers. The final design incorporated a Variable Air Volume (VAV) Air Handler Unit (AHU) supplying a test chamber and an additional HVAC zone equipped with false heating and cooling loads. An extensive and comprehensive array of instrumentation and controls is included for analysis of psychometric relationships and energy usage. Team members: Roger Sorrentino, Dennis Conser, Dennis Vega Sponsor Industry: The Energy Resource Center (ERC) Project year: June, 1996

Title of the project: Log Boss Group Project description: The Project report describes the conceptual development of an active-sensor bandmill strain system. The system has two objectives: first, to reduce the response time of the strain system, and second, to maintain a dynamically controlled strain on the bandsaw blade during operation. The project includes study of the straining process development and evaluation of possible strain configurations, ANSYS analysis of response time, and recommendation of a strain system with integration into a commercial bandmill. The project predicted future work that would entail the building of a bandmill prototype using an active-sensor straining system, testing and performance evaluation, further modification if necessary, and finally, production of a commercial bandmill. Team members: Tim Golik, James Knope, Dan Smith, Allen Williams Sponsor Industry: Log Boss, Inc Project year: June, 1998