COATINGS FEBRUARY 2014 CONFIRMED MINUTES

CONFIRMED MINUTES FEBRUARY 24-27, 2014 LONDON, UNITED KINGDOM

These minutes are not final until confirmed by the Task Group in writing or by vote at a subsequent meeting. Information herein does not constitute a communication or recommendation from the Task Group and shall not be considered as such by any agency.

MONDAY, FEBRUARY 24 TO THURSDAY, FEBRUARY 27, 2014

1.0 OPENING COMMENTS

1.1 Call to Order / Quorum Check

The Coatings Task Group (CTTG) was called to order at 9:00 a.m., 24-Feb-2014.

It was verified that only SUBSCRIBER MEMBERS were in attendance during the closed portion of the meeting.

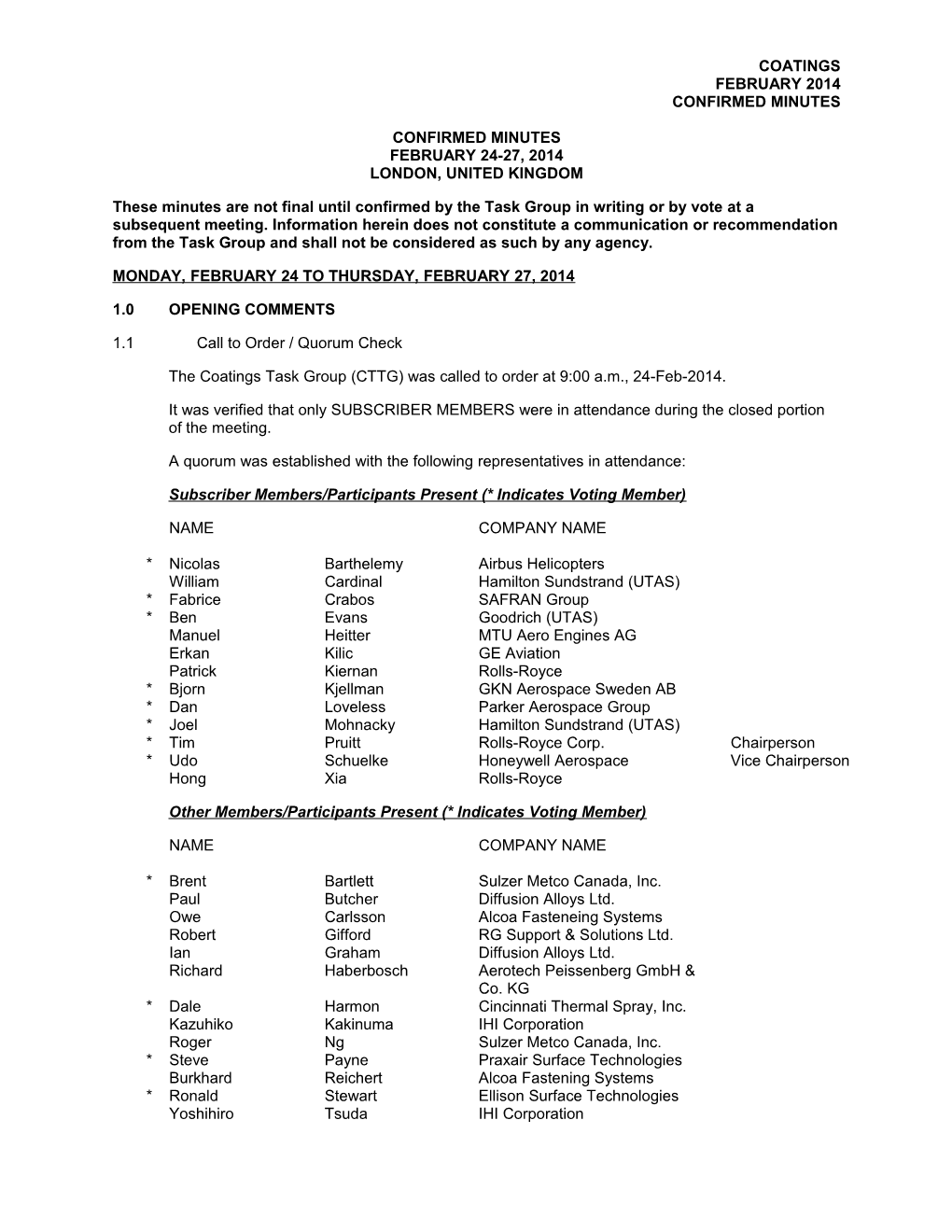

A quorum was established with the following representatives in attendance:

Subscriber Members/Participants Present (* Indicates Voting Member)

NAME COMPANY NAME

* Nicolas Barthelemy Airbus Helicopters William Cardinal Hamilton Sundstrand (UTAS) * Fabrice Crabos SAFRAN Group * Ben Evans Goodrich (UTAS) Manuel Heitter MTU Aero Engines AG Erkan Kilic GE Aviation Patrick Kiernan Rolls-Royce * Bjorn Kjellman GKN Aerospace Sweden AB * Dan Loveless Parker Aerospace Group * Joel Mohnacky Hamilton Sundstrand (UTAS) * Tim Pruitt Rolls-Royce Corp. Chairperson * Udo Schuelke Honeywell Aerospace Vice Chairperson Hong Xia Rolls-Royce

Other Members/Participants Present (* Indicates Voting Member)

NAME COMPANY NAME

* Brent Bartlett Sulzer Metco Canada, Inc. Paul Butcher Diffusion Alloys Ltd. Owe Carlsson Alcoa Fasteneing Systems Robert Gifford RG Support & Solutions Ltd. Ian Graham Diffusion Alloys Ltd. Richard Haberbosch Aerotech Peissenberg GmbH & Co. KG * Dale Harmon Cincinnati Thermal Spray, Inc. Kazuhiko Kakinuma IHI Corporation Roger Ng Sulzer Metco Canada, Inc. * Steve Payne Praxair Surface Technologies Burkhard Reichert Alcoa Fastening Systems * Ronald Stewart Ellison Surface Technologies Yoshihiro Tsuda IHI Corporation PRI Staff Present

Bob Lizewski

1.2 Task Group Tutorial – OPEN

Bob Lizewski presented a tutorial explaining the functions of Nadcap and the CTTG, and showed a video, narrated by Joe Pinto, on Antitrust to participants.

1.3 Review Agenda – OPEN

The agenda for the meeting was reviewed. No changes were proposed or made.

1.4 Expectations – OPEN

Attendees were given the opportunity to identify expectations to be addressed during the week of meetings. A list was started in the closed meeting and reviewed again in the open meeting. Expectations beyond agenda items: Maintaining tools/training/ etc. current/relevant and up to date; identify NCR categories for improved classification/analysis.

1.5 Approval of Previous Meeting Minutes – OPEN

Motion made by Ben Evans and seconded by Dan Loveless to approve the minutes for the October 2013 meeting held in Pittsburgh, Pennsylvania, U.S.A. without change. Motion passed.

2.0 METRICS

2.1 Review of Delegation Oversight – CLOSED

Data was reviewed for CTTG Subscriber concurrence with audit report reviewer decisions. The delegated audit report reviewers (Jim Lewis and Bob Lizewski) met the criteria of over 10% audits reviewed and greater than 90% concurrence. Delegation is maintained.

2.3. Review Auditor Consistency – OPEN

Aggregate data for auditor evaluations and NMC standard data metrics were reviewed in the open meeting.

Auditor Evaluation Score - average for the quarter was 5.83 versus 5.87 for previous period; this is considered to be a very good score. The 3-year trend of overall score was reviewed and was above 5.8 for all periods except for October 2012 (5.64).

The average increase of NCRs with the next auditor chart was not included in the review during this meeting.

Actions and suggestions taken as a result of reviewing auditor consistency data: consider separating auditors that only perform 2-3 audits per year and review multiple years of data to facilitate comparison with ‘core’ auditors and include their primary Task Group data; for Supplier Feedback Q15 analysis request that the NMC consider expanding the criteria for obtaining green metric (currently at 100%) and change the question rating from Yes/No to a scale 0-6; suggest to NMC to consider removing initial audits from the standard data set as initials are not a good indicator for auditor consistency (too many other variables) .

2.4. NMC Metrics – OPEN

The NMC metrics were presented by Bob Lizewski and reviewed by the Task Group.

Audit Capacity Goal 130%: Green – 212% capacity projected through July 2014 On-Time Certifications Goal 98% on-time: Green – no lapsed certs through Jan 2014 Supplier Merit Goal 80%: Yellow – 78% on merit as of Jan 2014 COATINGS FEBRUARY 2014 CONFIRMED MINUTES

Cycle Time (Initial) Oct13-Jan14, 2 audits Total Goal 52 days: Nov13 audit – RED 65 days, Jan14 audit - Green 26 days Staff Goal 14 days: Nov13 audit – RED 16 days, Jan14 audit - Green 3 days Supplier Goal 30 days: Nov13 audit – RED 41 days, Jan14 audit - Green 13 days Cycle Time (Reaccreditation) Oct13-Jan14, 32 audits Total Goal 52 days: Green 43 days Jan14 Staff Goal 14 days: Green 3 days Jan14 Supplier Goal 30 days: Green 29 days Jan14

3.0 TASK GROUP RESOLUTION ITEMS – CLOSED

An audit in Pakistan has yet to be scheduled. Auditors have refused to travel to Pakistan to conduct the audit. The previous audit was conducted in October 2011. The certification was scheduled to expire 31-Jan-2014, but the Task Group extended the certification 6 months to 31- July-2014. Other Task Groups are experiencing difficulty scheduling audits in certain regions of the world. The topic is being discussed at the NMC level. At some point a process will be formalized in procedures. The current thinking is that the Task Group may employ various means to extend an accreditation up to a limit of perhaps 2 years. If an official audit performed by an approved CT auditor cannot be conducted within the defined limit, then the certification will lapse.

ACTION ITEM: Bob Lizewski to add discussion of the Pakistan audit to the June Agenda as action will be required given the certificate expiry date is July 31, 2014. (Due Date: 14-Mar-2014)

Tim Pruitt reviewed the process of Allegation Handling and Resolution (NOP-001 13.0) with the Task Group. An allegation was made in October 2013 and resolved per NOP-001. As this situation occurs infrequently, Tim wanted to take the opportunity to remind the Task Group that there is a process for handling allegations made against accredited Suppliers.

4.0 AUDITOR CONSISTENCY – CLOSED

The 2014 audit observation plan was reviewed. 3 observations identified in January were not completed. 2 Observations are scheduled in March. The audit list for audits scheduled in June through August was reviewed for additional observation opportunities. The updated list was posted to the work area.

Auditor consistency data was reviewed. The review included individual auditor evaluations and supplier feedback for all audits conducted between 1-Sep-2013 and 31-Dec-2013, peer comparison of average number of NCRs written per audit day; influence of failure criteria on written NCRs per audit. Supplier feedback comments were excellent. There were no negative comments or suggestions for improvement. One new observation was performed in December and overall three observations were performed in 2013; which met the plan. Feedback was positive and no actions were identified based upon the observation report review.

Actions and suggestions taken as a result of reviewing auditor consistency data are detailed in section 2.3 above.

The NOP-012 requirement for providing feedback to each auditor was discussed. The CT Auditor Consistency Work Instruction currently does not address this requirement. The Task Group suggested providing one on one feedback in the event of negative data trends or feedback. During the subsequent NOP-012 roundtable, the NMC indicated that positive as well as negative feedback is to be given. Therefore, the topic will need to be reviewed again at the June meeting to develop a one on one feedback mechanism for all auditors.

The group went over the CTTG milestone plan that was presented at the NOP-012 Roundtable. 5.0 MEMBERSHIP REVIEW – OPEN

The voting records and meeting attendance for CTTG Voting Members (Subscriber and Supplier) were reviewed for compliance to the requirements for maintaining membership. The requirements state that to maintain membership a member must not be absent without approved alternate representation from three consecutive regular Nadcap Task Group meetings and the member, or approved alternate representation, shall not miss a vote on more than 2 consecutive letter ballots. The Task Group Chairperson is allowed to waive these requirements if other circumstances warrant retention. All current Voting Members are meeting requirements with the exception of Nicolas Barthelemy who missed votes on 2 consecutive letter ballots. Based upon Nicolas’ long standing participation in the Task Group, the Task Group Chair, Tim Pruitt, maintained his Subscriber Voting Member privileges.

6.0 FIRST TIME SUPPLIER FEEDBACK – OPEN

No first time Suppliers in attendance.

7.0 NUCAP SCOPE EXCEPTIONS – OPEN

No NUCAP resolution items.

8.0 RAIL (ROLLING ACTION ITEM LIST) – OPEN

The Rolling Action Item List (RAIL) was reviewed.

For specific details on all RAIL items, please see the current Coatings Rolling Action Item List posted at www.eAuditNet.com, under Public Documents.

9.0 GRINDING OF COATING – OPEN

Subscribers were surveyed to determine if any critical parts would mandate grinding of coating. GKN Aerospace identified a single critical part that will fall under the grinding mandate. Ben Evans from Goodrich stated that no action has been taken to mandate grinding of coating for critical parts. The topic will be added to the June agenda to identify any changes.

ACTION ITEM: Ben Evans to review presentation given by Goodrich at the Feb 2014 Conventional Machining as a Special Process Task Group meeting, and if there is value, present at the June CTTG meeting. (Due Date: 30-May-2014)

10.0 INDUSTRY STANDARD CHAMPION REPORT – OPEN

The Coatings Industry Standard watch list was reviewed. ASTM C 633 was revised in December 2013 and now stands at revision 13. Dan Loveless briefed the Task Group on the changes. No changes impact the audit criteria.

NSCL Z 540 was discussed. Dan pointed out that AC7109 5.3.1 calls out NCSL Z 540-1 and the current document is NCSL Z 540-3. After discussion, the Task Group decided to raise the issue with the AQS Task Group to determine if AC7109 5.3.1 is an appropriate question. Also, it was decided not to issue an auditor advisory. NCRs have not been written against this question and an advisory would serve to confuse rather than clarify the issue.

Dan also asked if there are any timeframe requirements for implementing specification revisions.

Joel Mohnacky raised both questions with AQS during the Nadcap meeting and the AQS responses are recorded in the AQS report out section 17.0.

ACTION ITEM: Bob Lizewski to post the CTTG Industry Standard Watch List on eAuditNet CT Public Documents. (Due Date: 14-Mar-2014)

11.0 NOP-011 – OPEN

Proposed NOP-011 Mode B Failure Criteria for initial and reaccreditation audits were reviewed to establish the criteria for 2014. Criteria were calculated using 2 years of data (2012 and 2103) and COATINGS FEBRUARY 2014 CONFIRMED MINUTES

a failure threshold of 96.5%. For initials, the calculated criteria are nearly identical to the existing criteria that have remained unchanged since 2011. For reaccreditations, the calculated criteria are 1 NCR less, for both Majors and Total per audit day, than the existing 2011 criteria.

Motion made by Dan Loveless and seconded by Udo Schuelke to not change the existing NOP- 011 Mode B failure criteria. Motion passed.

The new Risk Mitigation process, that is effective on or after 18-May-2014, was reviewed with the Task Group.

ACTION ITEM: Bob Lizewski to post the Risk Mitigation Summary presentation on eAuditNet CT Public Documents. (Due Date: 14-Mar-2014)

12.0 AUDIT CRITERIA (CHECKLIST) REVISION – OPEN

Comments on the AC7109/7 Rev D Task Group Draft 1 letter ballot were resolved.

AC7109/3 Rev E was completed. Changes include aligning the criteria with AC7109/7 Rev D, adding equivalent Maintenance Repair and Overhaul (MRO) terminology in the job audit and delineating in-process and completed job audits. AC7019/3 Rev E and AC7109/7 Rev D will be issued with the same effective date. Definitions for OEM (Original Equipment Manufacturing) and MRO, along with other MRO terminology, will be added to the CT Audit Handbook.

Revisions to AC7109/5 Rev F were started and will continue at the June meeting.

The Task Group resolved that AC7109/5 Rev E 6.0 Quality of Test Results does not apply to residual stress testing.

ACTION ITEM: Jennifer Kornrumpf to issue 14 day Task Group affirmation ballot for changes to AC7109/7 Rev D Draft 2. (Due Date: 31-Mar-2014)

ACTION ITEM: Jennifer Kornrumpf to issue 45 day Task Group letter ballot for changes to AC7109/3 Rev E Draft 1. (Due Date: 31-Mar-2014)

ACTION ITEM: Bob Lizewski to determine if other Task Groups define MRO. (Due Date: 31-Mar- 2014)

ACTION ITEM: Bob Lizewski to issue an auditor advisory stating that AC7109/5 Rev E 6.0 Quality of Test Results does not apply to residual stress testing. (Due Date: 14-Mar-2014)

ACTION ITEM: Bob Lizewski to post AC7109/5 Rev F working Draft 1 to eAuditNet. (Due Date: 14- Mar-2014)

ACTION ITEM: Bob Lizewski to add an agenda item to the June meeting to review the tests included in AC7109/5 Rev F. In addition a matrix will be created to facilitate review. Matrix to include the tests in the current scope, where the test is performed (lab vs. shop floor), who performs the test (lab technician or operator), whether the test must be included in the tracker, and if the test must be included in the Quality of Test Results section. (Due Date: 14-Mar-2014)

13.0 NCR PARAGRAPGH REFERENCE DATA ANALYSIS – OPEN

At the October 2013 meeting, NCR paragraph citations by auditor for AC7109, AC7109/1, and AC7109/5 were reviewed. The Task Group identified two areas, profilometry and process parameters in AC7109/1, that were cited often by all auditors and the number of citations increased from the period 2011/12 to 2012/13. The Task Group requested an analysis of the specific citations to determine if there are any opportunities for improvement – question clarity, training material, advisories etc. The profilometry data showed that verification of standards, setting of measurement parameters, and the stylus tip radius were not defined in an internal procedure. The stylus tip radius was cited 16 times compared to 10 times for measurement parameters and 8 times for verification against standards. There were multiple sources of non-compliance for verification against standards: not defined in procedure (8); compliance with defined requirement (4); acceptance criteria not defined (3); and no record of verification (1).

The process parameter data included a single chart listing each of the cited Appendix A parameters and the source of non-compliance [not defined, compliance with defined requirement and parameter not calibrated]. In total 20 different parameters were cited. Robot type was the most frequently undefined parameter (13) followed by part cooling pressure (7), console type (7), and powder port type/position (6). Compliance issues occurred on 10 parameters; however no parameter was cited more than once. Only 2 parameters were not calibrated; however part cooling pressure was cited 3 times.

The Task Group concluded that there were no opportunities for improvement with the checklist questions, so the analysis was viewed as a training/educational opportunity.

ACTION ITEM: Bob Lizewski to post NCR Paragraph Reference Data Analysis to eAuditNet and to incorporate it into the AC7109/1 eQuaLearn Audit Preparation course. (Due Date: 14-Mar-2014)

14.0 CONTINUOUS IMPROVEMENT INITIATIVE – OPEN

The CTTG Subteam (Dale Harmon, Vern Talmadge, Jim Dunn, and Fabrice Crabos) reported out on activities supporting the Continuous Improvement Project: Informational Pack for CT Audits. The Subteam proposed a simple communication that points to the Supplier Tools spreadsheet. The Supplier Tools spreadsheet was updated and renamed Coatings Audit Tool Resource. Notification will be provided through periodic mass emails, attendee’s guide, Nadcap meeting Introduction Tutorial and the PRI Website.

The Task Group accepted the proposal without change.

ACTION ITEM: Bob Lizewski to coordinate implementation of the Informational Pack for CT Audits per the Subteam proposal. (Due Date: 31-Mar-2014)

The next Continuous Improvement Project was selected (Checklist Question Guidelines) and the project charter completed. A Subteam was formed to work on the project and report out in June.

ACTION ITEM: Subteam (Dale Harmon, Steve Payne, Dan Loveless, Tim Pruitt, Nicolas Barthelemy, Joel Mohnacky) to develop guidelines for checklist question creation/revision and report out at the June meeting. (Due Date: 06-Jun-2014)

Brent Bartlett raised a new Continuous Improvement Project idea on NCR categorization and described some work he has done to date. The intent is to build on the existing Nadcap NCR categories to better identify industry wide issues. The project was added to the Continuous Project list for future consideration.

The Continuous Improvement project list was updated and posted to eAuditNet.

15.0 MERIT SYMPOSIUM – OPEN

Bob Lizewski previewed the Achieving Merit CTTG Supplier Symposia that will be offered as a webinar through eQuaLearn.

16.0 SSC REPORT – OPEN

Dale Harmon (Cincinnati Thermal Spray), Coatings representative to the Supplier Support Committee (SSC), presented an overview of the SSC and items of interest from the SSC meeting held the previous afternoon. For complete details, see published minutes of the SSC posted on www.p-r-i.org. COATINGS FEBRUARY 2014 CONFIRMED MINUTES

17.0 NMC, AQS AND PLANNING & OPS REPORT – OPEN

Chairperson Tim Pruitt updated the CTTG on items of interest from the Nadcap Management Council (NMC) meeting earlier in the day. For complete details, see published minutes of the NMC posted on www.p-r-i.org.

Joel Mohnacky reported out on the Aerospace Quality Systems (AQS) meeting. The AQS response to the CTTG inquiry concerning the calibration question AC7109 5.3.1 is that the question should be revised because it tests for existence of quality system elements rather than validating compliance.

AQS also reported that gauges need only be labelled for calibration if the gauge controls the output of the process. There is no quality system requirement to label all gauges as being calibrated or for reference only. In surveying all Task Group questions, AQS found that less than 10% of calibration questions probe calibration labelling.

AQS stated that there are no industry standard requirements for implementing specification revisions. The Supplier must define specification revision implementation in their system along with meeting any customer specific requirements.

ACTION ITEM: Bob Lizewski to add AC7109 5.3.1 Rev E question to the checklist revision list. (Due Date: 31-Mar-2014)

ACTION ITEM: Bob Lizewski to obtain guidelines from AQS on acceptable questions that validate compliance rather than probe existence of quality system elements. (Due Date: 31-Mar-2014)

ACTION ITEM: Bob Lizewski to add guidance of specification implementation to the CT Audit Handbook and review with the CTTG in June. (Due Date: 31-Mar-2014)

Chairperson Tim Pruitt and Staff Engineer Bob Lizewski briefed the CTTG on items of interest from the Planning and Ops meeting. Major discussion topics were NOP-012, New Task Groups progress (Measurement and Inspection [M&I] and Metallic Materials Manufacturing [MMM]), Task Group Chair and Vice Chair training at the June meeting, and Task Group report outs.

18.0 NEW BUSINESS – OPEN

No new business.

19.0 MEETING CONCLUSION – OPEN

19.1 Review Expectations

All expressed expectations for this meeting were met.

19.2 Agenda Items for Next Meeting

Next meeting will be June 23-26, 2014 in Dublin, Ireland. Proposed agenda items beyond the standard items include: AC7109/5 rev F and, specifically, evaluation of tests that are in the scope, and sample preparation concerns expressed by MTU representative; AC7109/1 revision; CI Project report out [Guidelines for creating/revising checklist questions]; Auditor Conference agenda and form team to develop technical brief for Coating Composition by EDS/WDS; CT Audit Handbook review and update (review definitions in CT audit handbook [OEM, MRO, etc.], specification revision implementation guidance); framework for compliance to NOP-011 Risk Mitigation.

19.3 New Action Items

New action items were documented by Task Group Secretary Dale Harmon. For details see the Coatings Action Item List (RAIL) posted at www.eAuditNet.com. 19.4 Meeting Feedback

Meeting feedback was positive.

ADJOURNMENT – 27-FEB-2014 – Motion made by Udo Schuelke and seconded by Steve Payne to adjourn the meeting at 12:45 p.m. Motion passed.

Minutes Prepared by: Dale Harmon, [email protected] Bob Lizewski, b [email protected]

RAIL: See eAuditNet/Public Documents/Coatings

***** For PRI Staff use only: ******

Are procedural/form changes required based on changes/actions approved during this meeting? (select one) YES* ☐ NO ☒

*If yes, the following information is required: Documents requiring revision: Who is responsible: Due date: