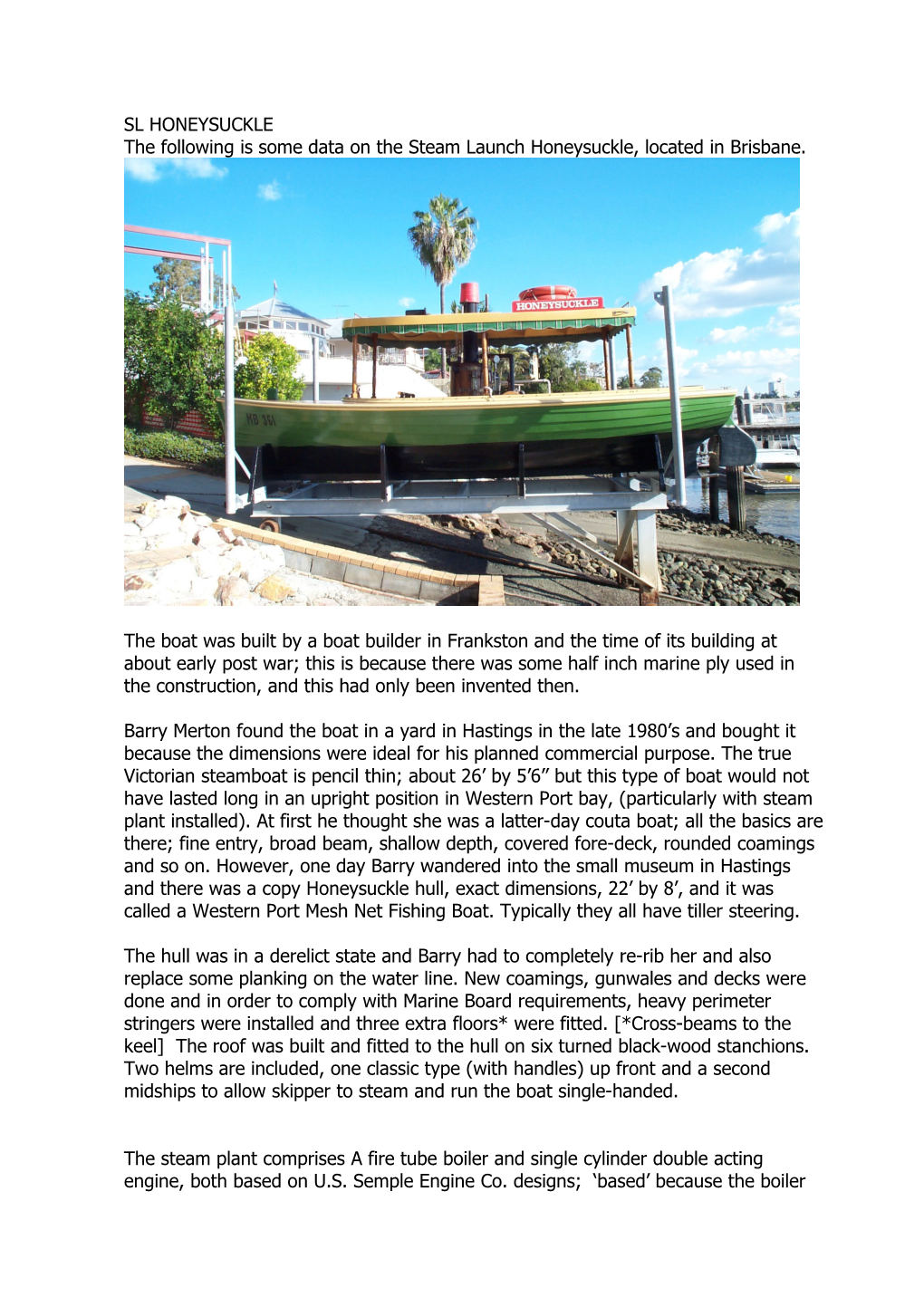

SL HONEYSUCKLE The following is some data on the Steam Launch Honeysuckle, located in Brisbane.

The boat was built by a boat builder in Frankston and the time of its building at about early post war; this is because there was some half inch marine ply used in the construction, and this had only been invented then.

Barry Merton found the boat in a yard in Hastings in the late 1980’s and bought it because the dimensions were ideal for his planned commercial purpose. The true Victorian steamboat is pencil thin; about 26’ by 5’6’’ but this type of boat would not have lasted long in an upright position in Western Port bay, (particularly with steam plant installed). At first he thought she was a latter-day couta boat; all the basics are there; fine entry, broad beam, shallow depth, covered fore-deck, rounded coamings and so on. However, one day Barry wandered into the small museum in Hastings and there was a copy Honeysuckle hull, exact dimensions, 22’ by 8’, and it was called a Western Port Mesh Net Fishing Boat. Typically they all have tiller steering.

The hull was in a derelict state and Barry had to completely re-rib her and also replace some planking on the water line. New coamings, gunwales and decks were done and in order to comply with Marine Board requirements, heavy perimeter stringers were installed and three extra floors* were fitted. [*Cross-beams to the keel] The roof was built and fitted to the hull on six turned black-wood stanchions. Two helms are included, one classic type (with handles) up front and a second midships to allow skipper to steam and run the boat single-handed.

The steam plant comprises A fire tube boiler and single cylinder double acting engine, both based on U.S. Semple Engine Co. designs; ‘based’ because the boiler design in particular required considerable modification to comply with Australian class ‘1’ design codes. These included using ½ inch tube plates instead of 3/8ths, heavier tubes and two each of the gauge glasses and safety valves. There are 73 *1” tubes and 40 feet of heating surface. Originally the fire tubes were offcuts from the Dandenong “Puffing Billy” loco boiler, but they have recently been replaced by the current owner with copper tubes for faster steaming. The boiler is ‘wet backed’ and in all, it is a very lively boiler rated to 150 Psi It is a non-condensing “puffer” design. The single cylinder engine uses eccentric fwd/reverse cam gear and all bearings are roller race. The engine was built in Melbourne by a retired ship’s engineer and rebuilt with some improvements by another engineer by the name of Ray Roberts.

The vessel was finally brought up to survey with the Marine Board of Victoria and since Barry Merton wanted to run her commercially, he had to study for and obtain a Masters ‘5’ Inland Waters ticket. Subsequently, Barry and his wife ran the boat as a passenger launch on the Yarra River for three and a half years.

Barry Merton has since said that this adventure was one of the happiest times in their lives, so it is a happy boat.

So it has been for the current owner, Arthur Nommensen, too, who had bought Honeysuckle about 10 years ago from Barry.

A steam launch trip always proves to be a major attraction to adults, children, and even dogs, and always gives a lovely and interesting day out on the water.

As age gangs up on all of us, however, and other interests intrude on time, Arthur has not used Honeysuckle for two years now. The boat is on a dry-foot slipway rail at his home. (see photo 2).

Arthur notices with regret that the Brisbane climate has allowed some dry-rot to enter (a) the gunwale rails, and (b) some small area of deck ply and part of a top row ply planking strake. (c) some internal wooden seats need renewing. (d) all needs loving paint and varnish.

After contemplating a rejuvenation job himself, and noting that things mechanical are good on Honeywind, and that he (Arthur) is good at them too, but he is NOT good at carpentry. Arthur has now therefore decided to offer the boat for sale as a renewal project, should there be an interested party.

ANY AND ALL OFFERS, for as-is-where-is purchase, will therefore now be considered so that this lovely and historic craft can regain its former glory and steam happily again with new people to delight.

Arthur Nommensen Email: [email protected] Phone: 07 3217 9690 Address: 16 Wendell Street, Norman Park, Brisbane, Queensland 4170

HONEYSUCKLE CARE AND OPERATIONAL ADVICE

Boiler treatment. Take the whistle connection off the boiler fitting, insert funnel provided and put about in twelve Bottle-caps of boiler water (tannin etc) treatment each time, before you fill the boiler to show water 2/3 up in the sight glasses. The water in the glasses should be the colour of black tea. A more scientific method is to use litmus paper. (There is some in a jar.) Drain the gauge glasses and let them refill to see the true colour of the water.

Filling the boiler. A filler pipe is in place ready for filling with a hose. The stop cap is also in place below the injector. You will see how to restore the fittings after filling. Fill to about two-thirds up the gauge glasses. Don’t forget to leave a valve open (suggest the whistle-blower valve) to allow air to escape as the water fills in.

Blowing down the boiler: There are two schools of thoughts about this. Some say it’s OK to leave the boiler full (with treated water) and some say you should blow it out, particularly if you will not be using the boat again for a while. Blowing down is done by turning the square lug on the valve near the floor deck on the starboard side of the boiler a quarter turn. Don’t forget to turn it back again otherwise, next time you fill the boiler the water will start running out taking all your freshly inserted treatment with it.

To blow down the boiler you must wait until the boiler pressure is down to 35 PSI, otherwise you run the risk of blowing the back of the boat off! In reducing the pressure you can hurry things along a bit by holding a safety valve open.

The two safety valves: The one nearest the engine driver is a percussion valve; it lets off steam in short bursts and is set just below 150 PSI. The second safety valve is set a little higher and blows off if the first valve is not able to control the boiler pressure. The second one blasts away continuously until it almost halves the pressure in the boiler and there is no way you can talk it out if it!

Cleaning the tubes: Owners need a 3/4” bronze pipe brush with a long wire handle. The tubes don’t need much attention since the hearty exhaust draft tends to blow the ash out if you use clean-burning ironbark wood fuel. However, if the boiler seems to be getting sluggish at some stage, you will need to do it. Remove the funnel assembly then prize off the smoke box cover with a screwdriver. Vacuum off the ash from the top of the tube plate and then go to work with the brush. A couple of passes for each tube is enough. An even better plan is to use the steam-lance (on the end of the flexi pressure-hose provided) at the end of each days steaming, and blow steam up through the firebox into the tubes while the pressure is still up in the boiler.

Checking and cleaning the boiler internals: I have left a large wrench in the boat as you need something like this to remove the inspection lugs. You only need to do this if you want to satisfy yourself that the boiler treatment is working and keeping the boiler rust free but you should also clean the mud ring every year or so. You know that the fire box has a water jacket around it (wet backed) and mud and scale can sometimes build up around the base ring. The theory is that if excessive material builds up on the mud ring the steel becomes insulated from the water and this can lead to failure. You have to poke a hose in and try to dislodge any muck with high- pressure water.

The injector. This usually works well but it does not function below about 70 PSI. Also it needs to be cool. If problems arise, first tip cold water over it and try again. Always ease the lever down, listening for the cistern sound. It also tends to start struggling if the water level is too low in the tanks By the way, the two-way whistle valve on the roof is a great little gadget; built for me by a friend, but it is starting to leak steam and may need looking at. I have been turning off the main whistle valve and only opening it when I want to sound the whistle.

Filling the water tanks: There are three water tanks, each holding 57 litres of water. One tank is in the stern and the other two up under the foredeck. The filler pipe for the front tanks is up in front of the helm (should have a cork in it) and the rear filler is covered with a brass cap in the stern deck.

The valve under the little black cover on the floor is a three-way unit. The fill the forward tanks, push the handle to the front. This opens the tanks to the boiler inlet and isolates the rear tank. Fill the front tanks watching the plastic pipe gauge as you go. When full, simply put the hose to the stern tank and fill it also.

It’s best to leave the three-way valve in the forward position for the time being since with the front tanks full the vessel tends to be a little down by the bow, so it’s a good idea to use up the front tanks first. You can counteract the initial weight distribution problem by placing most of your passengers aft until some of the water level drops.

You will know when the water level is getting low because the injector will start fooling around, sending blasts of steam out the overflow pipe on the starboard side. So at this stage it’s best to put the three-way valve in the central position which opens up the whole system. This way the stern tank comes on stream but you will still use up any water left in the front tanks.

Caution. It you fill the front tanks without pushing the floor valve lever forward, the water will start flowing through to the stern tank. Because the front tanks are higher than the stern tanks the water level will tend to equalise and it will soon start running out the overflow pipe in the stern and emptying down into the bilges.

The lubricator. Use only steam cylinder oil (some supplied). You can see the oil level in the longer glass tube as the water pushes the oil up. When it needs refilling, remove the big (angled) wing nut to break the air lock then loosen off the nut right underneath until water starts to trickle out. When all the water has drained, tighten the nut and then refill the unit from the top. The smaller wing nuts, which protrude at right angles from the top and bottom of the unit control those little bubbles of oil that lubricate the cylinder and valve gear.

You need to lubricate the reversing gear, the eccentric and the chain from an oil can and there are three grease nipples. One is down on the shaft near the stern transom, the other you can see is on the bearing above the chain and a third one I have just installed is meant to lubricate the thrust bearing on the front of the prop shaft. The thrust bearing is not pre-packed. The old one lasted seven years but if you can find the nipple and use it, the bearing should last for ever. Keep the crosshead oilers filled but and try and reduce the drip rate to a minimum.

In general: Do tell people not to touch anything around the boiler when moving about the boat, except the white safety rails. Be careful yourself, when operating the injector valve, not to burn your forearm on the lubricator loop. Unfortunately, the loop must not be covered in any way; otherwise the lubricator won’t work. The Marine Board advised, when loading passengers, to go aboard first and stand on the opposite side to the jetty in order to balance the boat, then help each person on while directing them to a seat.