Shop Safety Vertical Band Saw Operation and Safety

The primary use of the bandsaw is to make curved shapes. It is not, however, limited to curves but can be used for a variety of other types of cuts. Many bandsaws come equipped with a rip fence and a miter gauge. These cuts are usually best performed on other machines if they are available. The size of a bandsaw is determined by the diameter of the wheels that turn the blade.

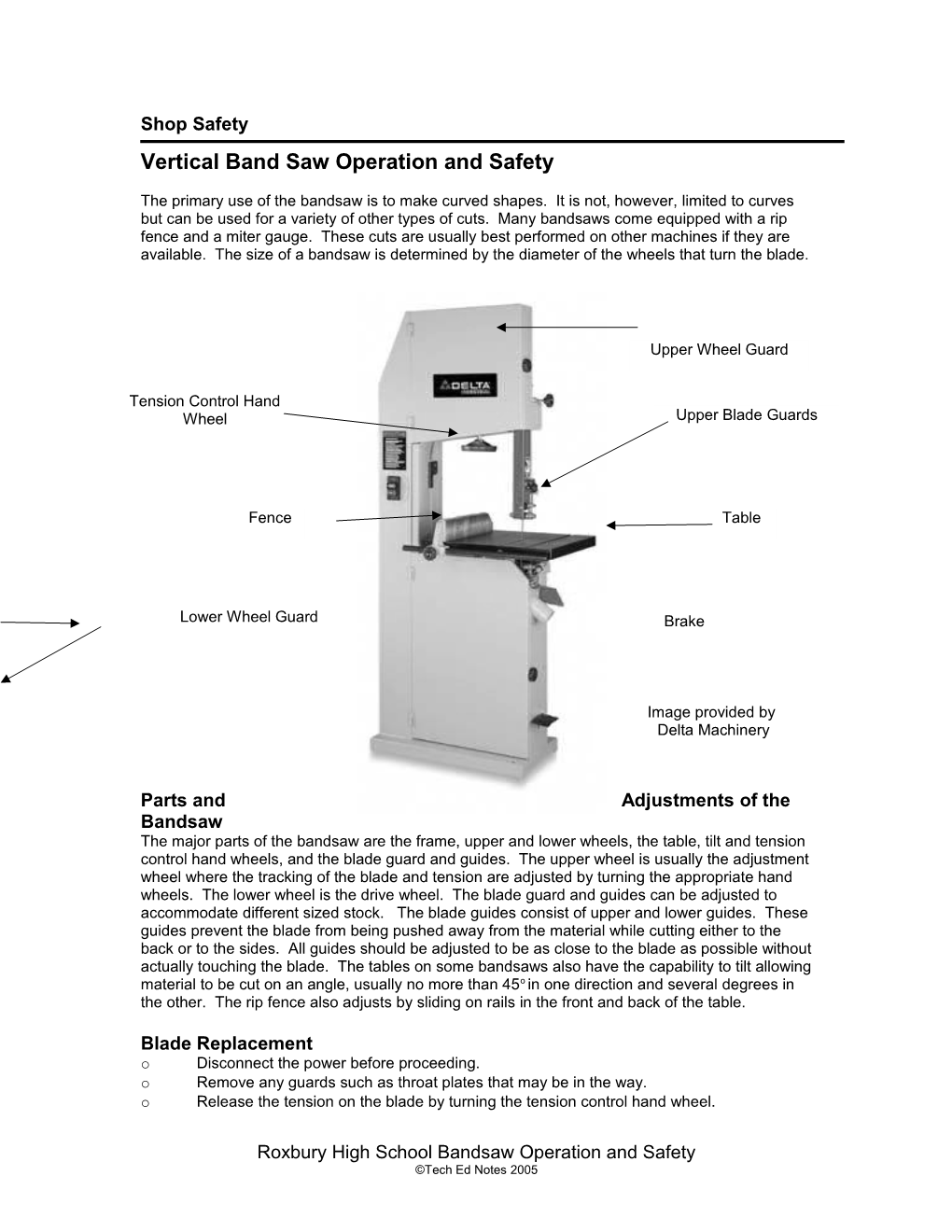

Upper Wheel Guard

Tension Control Hand Wheel Upper Blade Guards

Fence Table

Lower Wheel Guard Brake

Image provided by Delta Machinery

Parts and Adjustments of the Bandsaw The major parts of the bandsaw are the frame, upper and lower wheels, the table, tilt and tension control hand wheels, and the blade guard and guides. The upper wheel is usually the adjustment wheel where the tracking of the blade and tension are adjusted by turning the appropriate hand wheels. The lower wheel is the drive wheel. The blade guard and guides can be adjusted to accommodate different sized stock. The blade guides consist of upper and lower guides. These guides prevent the blade from being pushed away from the material while cutting either to the back or to the sides. All guides should be adjusted to be as close to the blade as possible without actually touching the blade. The tables on some bandsaws also have the capability to tilt allowing material to be cut on an angle, usually no more than 45o in one direction and several degrees in the other. The rip fence also adjusts by sliding on rails in the front and back of the table.

Blade Replacement o Disconnect the power before proceeding. o Remove any guards such as throat plates that may be in the way. o Release the tension on the blade by turning the tension control hand wheel.

Roxbury High School Bandsaw Operation and Safety ©Tech Ed Notes 2005 o Once tension is slackened enough, remove the blade and guide it out of the table through the provided slot. o Select an appropriate blade for the required operation. Guide the blade through the table and place the blade over the upper and lower guide wheels making sure that the teeth face forward and down. o Using the tension control hand wheel, tighten the tension until there is correct tension on the blade. o Replace any guards that were removed. o Turn the upper wheel completely to check the tracking of the blade. Adjust as necessary. The blade should rest in the center of the upper wheel. o After adjusting the tracking, check the tension and adjust as necessary. There should be a firm, but not rigid pressure. o Remember that the blade guides should be as near as possible to the blade but not touching.

Operation of the Bandsaw As mentioned, the most common use of the bandsaw is to cut curved shapes in material. Plan your cuts completely before beginning as it is important that you do not back out of curved cuts if you get stuck. It is acceptable to back out of a straight cut when necessary but never a curve.

Stand to one side of the blade when cutting. It is important to always have both hands on the material you are cutting. Use one hand to guide and the other to hold. Make sure that your hands are out of the cut line and feed the stock in a firm, steady manner. Do not feed the material rapidly into the blade.

When cutting curves, know the minimum radius that the blade is capable of cutting before you start your cut. When necessary, make relief cuts in the material before you start your cut. This will provide you with additional clearance as you make your cut. When cutting a right angle, you can also pre-drill clearance holes to give yourself room to turn the blade.

Safety Rules o Follow all safety rules found in General Laboratory Safety, General Machine Safety, as well as all oral instructions and demonstrations provided by your instructor. o Have your instructor’s permission before beginning operation on the bandsaw. o If you have any questions or concerns, do not use the bandsaw until you discuss them with your instructor. o Always wear safety glasses. o You should never allow anyone to stand on the right side of the table. If the blade breaks, it may hit the table and feed out to the right side of the operator. o While machine is in operation, your hands will never be any closer than 4 inches from the blade. Use push sticks if you are cutting narrow material. o Disconnect power whenever making adjustments to the saw or changing the blade. o Use the correct blade for your operation. o Never rush your work. Allow the machine to cut the material at a comfortable pace.

Roxbury High School Bandsaw Operation and Safety ©Tech Ed Notes 2005 o The blade guard should never be more than 1/8 inch above the material to be processed. Keep the guard as close as possible to minimize blade deflection. o Do not stand directly behind the work. Stand to one side or the other. o Always use all safety guards. o Make sure all doors and covers are closed before beginning your operation. o Always ask for help when cutting large or bulky material. o Never reach in close to the blade to remove scraps. Turn the saw off, wait until it comes to a complete stop, and then remove the scraps. o Always check the blade for proper tensioning and tracking. o You should never back out of long or curved cuts. o Use relief cuts whenever necessary. o Do not place your fingers in the cut line of the saw. o When cutting cylindrical stock, use a v-block or clamp to keep the stock from spinning. o Never cut material that cannot be safely held.

Roxbury High School Bandsaw Operation and Safety ©Tech Ed Notes 2005