Document Number: ECP 11-0512d

Version: 4.0

Date: 04/12/2015

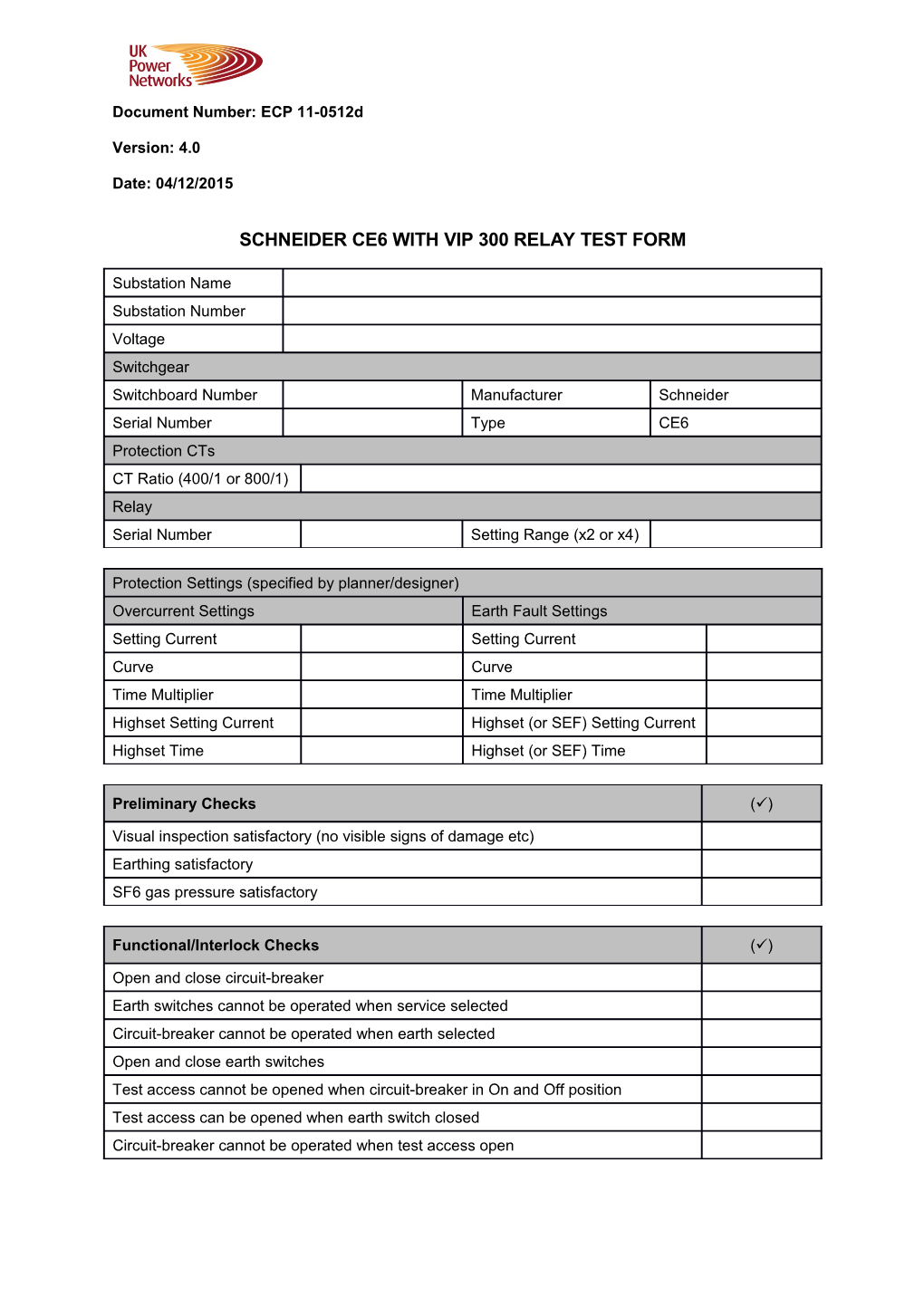

SCHNEIDER CE6 WITH VIP 300 RELAY TEST FORM

Substation Name Substation Number Voltage Switchgear Switchboard Number Manufacturer Schneider Serial Number Type CE6 Protection CTs CT Ratio (400/1 or 800/1) Relay Serial Number Setting Range (x2 or x4)

Protection Settings (specified by planner/designer) Overcurrent Settings Earth Fault Settings Setting Current Setting Current Curve Curve Time Multiplier Time Multiplier Highset Setting Current Highset (or SEF) Setting Current Highset Time Highset (or SEF) Time

Preliminary Checks ()

Visual inspection satisfactory (no visible signs of damage etc) Earthing satisfactory SF6 gas pressure satisfactory

Functional/Interlock Checks ()

Open and close circuit-breaker Earth switches cannot be operated when service selected Circuit-breaker cannot be operated when earth selected Open and close earth switches Test access cannot be opened when circuit-breaker in On and Off position Test access can be opened when earth switch closed Circuit-breaker cannot be operated when test access open Switchgear Continuity Test

Circuit- Circuit- Terminals Under Test Continuity Terminals Under Test Continuity breaker breaker Closed L1 - L1 Earthed L1 - E L2 - L2 L2 - E L3 - L3 L3 - E

HV Insulation Tests using Test Voltage from using Test Voltage from ECS 11-0006

Circuit-breaker Terminals Voltage Duration IR (M) (kV) (min) Under Test Earthed Closed L1 L2, L3 Closed L2 L1, L3 Closed L3 L1, L2 Open L1, L2, L3 L1, L2, L3

Protection CTs Insulation Resistance using 1kV Test Voltage

Disconnect CT wiring from relay C11, C31, C51, C71 () Remove CT wiring earth link C70 - C90 () Measure the insulation resistance C70 - Earth M Replace CT wiring earth link C70 - C90 ()

Protection CTs Loop Continuity (from CT wiring terminal block)

Measure L1 CT continuity C11 - C70 Measure L3 CT continuity C31 - C70 Measure L3 CT continuity C51 - C70

Dual Ratio Protection CTs

For switchgear with dual ratio protection CTs select the appropriate ratio (see appendix () Dual Ratio CT Connections) to give the required protection settings and record CT ratio on the front of the form CT Ratio Terminal Block Connections C112 - 2 400/1 C132 - 6 () C152 - 10 C112 - 3 800/1 C132 - 7 () C152 - 11 300 Relay Test Form Document Number: ECP 11-0512d

Version: 4.0

Date: 04/12/2015

Relay CT Connections

Reconnect the CT wiring to the relay - use the x2 range unless the required setting current is greater than that available within the range (Appendix Relay CT Connections) and record the range on the front of the form Range Relay Connections 200/1 CTs 400/1 CTs 800/1 CTs C11 - 8 C31 - 6 x2 20-100A 40-200A 80-400A () C51 - 4 C71 - 2&9 C11 - 7 C31 - 5 x4 40-200A 80-400A 160A-800A () C51 - 3 C71 - 1&9 Ensure the reversible scale label matches the CT ratio and selected range () Measure the earth resistance between the relay case and the switchgear earth

© UK Power Networks 2015 All rights reserved 3 of 6 Test Protection Settings

Apply the following temporary settings to the relay (refer to – Vip 300 for guidance) () Overcurrent Settings Earth Fault Settings Is 72A or 80A* Ios 60A or 64A* I> curve SI Io> curve SI DT only 3 DT only 3 t> 0.6 x10 to> 0.6 x10 I>> off Io>> off t>> 0.03 to>> 0.03 * Available setting will depend on the CT ratio and the range being used. Note: It is not possible to carryout the pickup test below for 800/1 CTs on the x4 range.

Relay Operation - Primary Injection Test

Increase current until the LED starts to flash and record the current value. Reset the relay and, if necessary, close the circuit breaker before each test

Overcurrent Pickup Test

CB Conductors Short Is Setting Calculated Pickup Actual Pickup Under Test Conductors Current (Is + 20%) Current Closed L1 - L2 L1, L2, L3 72/80A 87/96A A Closed L2 - L3 L1, L2, L3 72/80A 87/96A A

Earth Fault Pickup Test

CB Conductors Under Test Ios Setting Calculated Pickup Actual Pickup Current (Ios + 20%) Current Closed L1 - L1 60/64A 72/77A A Closed L2 - L2 60/64A 72/77A A Closed L3 - L3 60/64A 72/77A A

In-service Protection Settings

Apply the in-service protection settings as specified by the planner/designer to the relay () and record them below – refer to – Vip 300 for guidance Overcurrent Settings Earth Fault Settings Is Ios I> curve Io> curve DT only DT only t> Select from to> Select from table x10 / x1 table on relay x10 / x1 on relay I>> (Highset Current ÷Is) Io>> (Highset Current ÷Is) t>> to>>

Table A - Calculate Injection Currents Overcurrent Setting Earth Fault Setting

CT Ratio Primary Setting Current (Is) (Ios) 300 Relay Test Form Document Number: ECP 11-0512d

Version: 4.0

Date: 04/12/2015

Secondary Setting Current (Primary Setting Current ÷ CT Ratio) 2 x Secondary Setting Current 5 x Secondary Setting Current I>> or Io>> x Secondary Setting Current (highset)* DT x Secondary Setting Current (SEF)*

Table B - Calculate Operating Times Overcurrent Setting Earth Fault Setting

Curve (I>) (Io>) Time Setting on relay (t>) (to>) (if x10 is selected multiply t> or to> setting by 10) (t>>) (to>>) Tripping time at 2 x secondary current Curve SI (t> or to> x 3.38) +0.09s s s Curve VI (t> or to> x 9) + 0.09s s s Curve EI (t> or to> x 33) + 0.09s s s Tripping time at 5 x secondary current Curve SI (t> or to> x 1.44) + 0.09s s s Curve VI (t> or to> x 2.25) + 0.09s s s Curve EI (t> or to> x 4.1) + 0.09s s s Tripping time at I>> or Io>> or DT x Secondary Setting Current Highset/Instantaneous t>> or to>> + 0.09s s s SEF* to> + 0.09s s * Only calculate highset, instantaneous or SEF settings if used.

Relay Operation - Secondary Injection Test

Connect timer circuit to auxiliary contacts 64 and 65 (contact closed when CB open) ()

Overcurrent Test

Calculated Calculated Actual Operating Times Setting Injection Current Operating Time (from table A) (from table B) C11 - C31 C31 - C51 C51 - C11 2x A s s s s 5x A s s s s Instantaneous A s s s s

Earth Fault Test

Calculated Calculated Actual Operating Times Setting Injection Current Operating Time (from table A) (from table B) C11 - C70 C31 - C70 C51 - C70 2x A s s s s

© UK Power Networks 2015 All rights reserved 5 of 6 5x A s s s s Instantaneous A s s s s SEF* A s s s s * The trip current may have to be increased to operate the circuit breaker if the current is below the minimum operating current. 300 Relay Test Form Document Number: ECP 11-0512d

Version: 4.0

Date: 04/12/2015

Final Checks ()

Check correct CT and interposing CT ratios selected Check correct ratio labels have been fitted Check correct protection settings applied Check relay reset Reconnect umbilical cable to RTU (if fitted) Asset data form completed

Test Equipment

Make/Type Serial Number Calibration Date

Certification ()

All tests have been completed satisfactorily Comments

Commissioning Signature Date Engineer

The completed test form shall be left on-site in a plastic wallet and in secure location. A copy of the completed test shall be sent to the relevant ART mailbox.

© UK Power Networks 2015 All rights reserved 7 of 6 300 Relay Test Form Document Number: ECP 11-0512d

Version: 4.0

Date: 04/12/2015

Appendix 1.1.1.1.1.A – Vip 300 A.1 Introduction

The Vip 300 is a self-powered three phase overcurrent and earth fault protection relay. Protection settings are displayed on the relay front panel (see section Front Panel) along with manual reset and trip flags.

The CTs are connected to one of two sets of inputs to the relay, to give two different setting current ranges. It is important to ensure that the correct scale label (see section Scale Labels) is in place (either x4 or x2) depending on the inputs and the CT ratio used.

Settings are applied by adjusting the dial selectors to the correct location using a screwdriver. Care should be taken when applying the time settings as the Vip 300 does not use the time multiplier as the time input for IDMT curves (t> or to>). Instead the table on the top right of the front panel should be used to convert the required time multiplier to the Vip 300 setting depending on the IDMT characteristic being applied. For definite time settings (DT, I>>, Io>>) the dials give the relay operating time.

For example, to apply the following typical settings to a Vip 300 relay with 400/1 CTs:

OC 200A VI 0.1TM

SEF 32A DT 3s

Looking at the range cards for 400/1 CTs it can be seen that the x2 range provides the option for a phase overcurrent setting (Is) of 200A and an earth fault setting current (Ios) of 32A, the x2 range inputs should be used.

Applying the overcurrent setting:

1. Is should be set to 200.

2. I> curve selection should be set to VI.

3. t> should be set to 0.3 with a multiplier of x1 (from the table provided this corresponds to a time multiplier of 0.1).

4. As no high set overcurrent is required, I>> should be set to OFF.

5. As no high set overcurrent is required, t>> should be set to 0.03.

Applying the earth fault setting:

1. Ios should be set to 32.

2. Ios> curve selection should be set to DT.

3. DT should be set to 1.

4. t> should be set to 0.3 with a multiplier of x10

5. As no high set earth fault is required, Io>> should be set to OFF.

© UK Power Networks 2015 All rights reserved 8 300 Relay Test Form Document Number: ECP 11-0512d

Version: 4.0

Date: 04/12/2015

6. As no high set earth fault is required, to>> should be set to 0.03.

A.2 Front Panel

phase I> DT only I>> VIP 300 overcurrent VI EI 1.8 2.1 9 12 sensors: SI VIP300 Equivalent Time 800/1 4509169A0 1.5 2.4 6 15 EI,VI,SI Settings Multiplier I> VIP 300LH range: x2 RI off 1.2 2.7 4 20 t>, to> DT SI VI EI DT 1 3 3 off 0.05 x1 0.02 0.03 0.06 curve selection ( x Is) ( x Is) 0.07 x1 0.02 0.05 0.09 0.1 x1 0.03 0.07 0.12 0.15 x1 0.05 0.1 0.19 192 Warning 168 224 trip 0.15 0.2 0.4 0.2RI x1 0.07 0.13 0.25 144 256 0.2 0.1 0.3 0.1 0.6 0.3 x1 0.1 0.2 0.37 120 288 0.07 0.4 x 10 not time 0.05 0.9 0.4 x1 0.13 0.27 0.5 96 320 0.05 0.6 multiplier 0.03 1.5 80 360 x 1 0.05 x10 0.17 0.33 0.62 400 (s) (s) 0.6 x1 0.2 0.4 0.74 (A) Is see table 0.07 x10 0.24 0.47 0.87 t > t >> 0.1 x10 0.34 0.67 1.24 reset 0.15 x10 0.5 1 1.86 minimum operating 0.2 x10 0.67 1.33 2.48 phase current: 80A Io> DT only Io>> 0.3 x10 1.01 2 3.71 VI EI 1.8 2.1 9 12 0.4 x10 1.35 2.67 4.95 SI 1.5 2.4 6 15 0.6 x10 2.02 4 7.43 RI off 1.2 2.7 4 20 3 trip DT 1 3 off curve selection ( x Ios) ( x Ios)

Warning 64 96 128 0.15 0.2 0.4 48 160 0.2 0.1 0.3 0.1 0.6 Io> 32 200 0.07 0.4 x 10 not time 0.05 0.9 16 240 0.05 0.6 multiplier 0.03 1.5 8 280 x 1 320 (s) (s) (A) earth fault Ios to > see table to >> VAP6 test plug

A.3 Scale Labels

Reversible scale label for Reversible scale label for Reversible scale label for Ringmaster fitted with Ringmaster fitted with Ringmaster fitted with 200/1CTs 400/1CTs 800/1CTs

© UK Power Networks 2015 All rights reserved 9 300 Relay Test Form Document Number: ECP 11-0512d

Version: 4.0

Date: 04/12/2015

A.4 Dual Ratio CT Connections

Note: The orientation of the connections may vary depending on the vintage of the switchgear.

A.5 Relay CT Connections

© UK Power Networks 2015 All rights reserved 10 300 Relay Test Form Document Number: ECP 11-0512d

Version: 4.0

Date: 04/12/2015

This page is intentionally left blank.

© UK Power Networks 2015 All rights reserved 11 300 Relay Test FormDocument Number: ECP 11-0512d

Version: 4.0

Date: 04/12/2015

Appendix 1.1.1.1.1.B – Schematic Diagram

© UK Power Networks 2015 All rights reserved 12