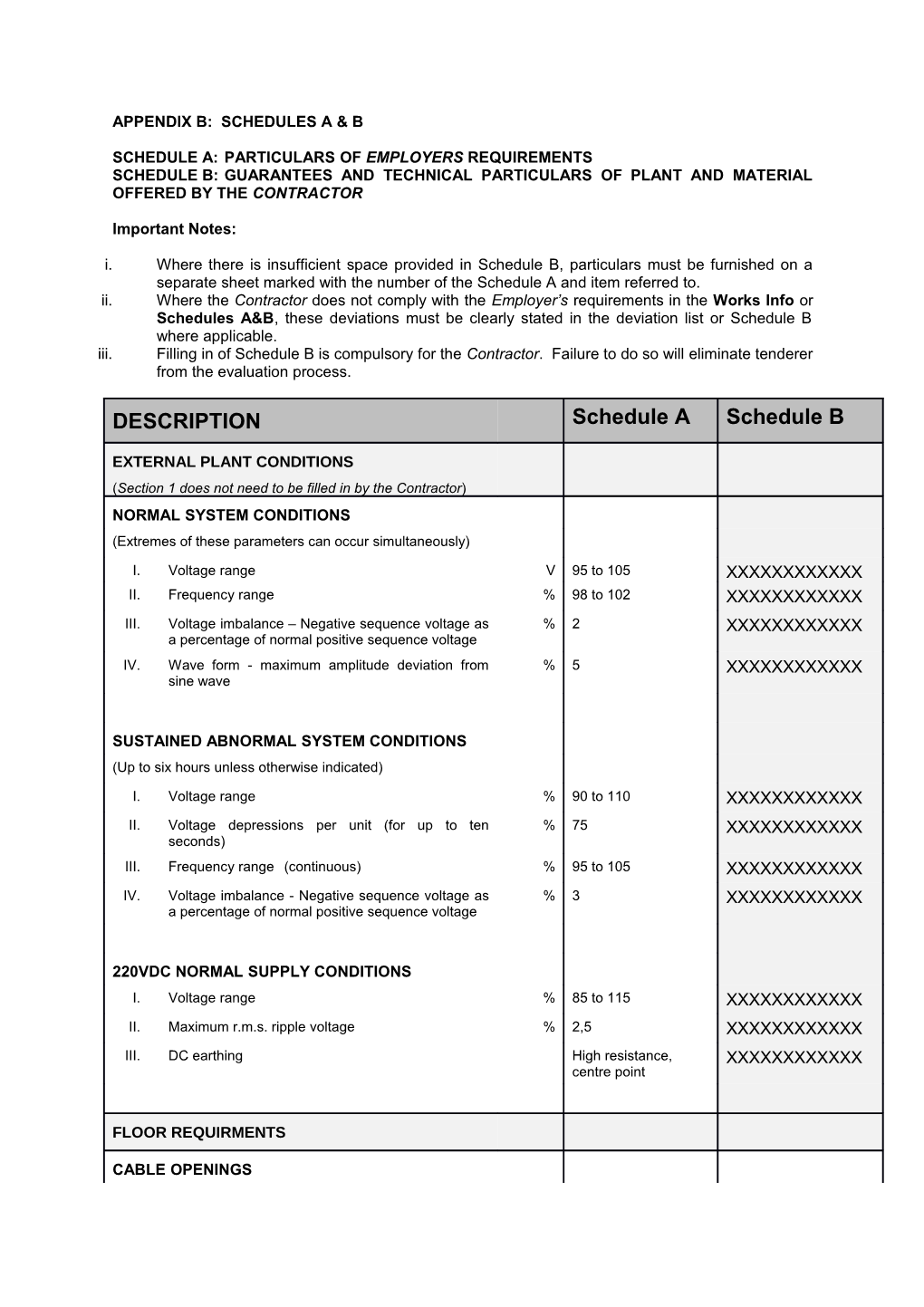

APPENDIX B: SCHEDULES A & B

SCHEDULE A: PARTICULARS OF EMPLOYERS REQUIREMENTS SCHEDULE B: GUARANTEES AND TECHNICAL PARTICULARS OF PLANT AND MATERIAL OFFERED BY THE CONTRACTOR

Important Notes: i. Where there is insufficient space provided in Schedule B, particulars must be furnished on a separate sheet marked with the number of the Schedule A and item referred to. ii. Where the Contractor does not comply with the Employer’s requirements in the Works Info or Schedules A&B, these deviations must be clearly stated in the deviation list or Schedule B where applicable. iii. Filling in of Schedule B is compulsory for the Contractor. Failure to do so will eliminate tenderer from the evaluation process.

DESCRIPTION Schedule A Schedule B

EXTERNAL PLANT CONDITIONS (Section 1 does not need to be filled in by the Contractor) NORMAL SYSTEM CONDITIONS (Extremes of these parameters can occur simultaneously) I. Voltage range V 95 to 105 XXXXXXXXXXXX II. Frequency range % 98 to 102 XXXXXXXXXXXX III. Voltage imbalance – Negative sequence voltage as % 2 XXXXXXXXXXXX a percentage of normal positive sequence voltage IV. Wave form - maximum amplitude deviation from % 5 XXXXXXXXXXXX sine wave

SUSTAINED ABNORMAL SYSTEM CONDITIONS (Up to six hours unless otherwise indicated) I. Voltage range % 90 to 110 XXXXXXXXXXXX II. Voltage depressions per unit (for up to ten % 75 XXXXXXXXXXXX seconds) III. Frequency range (continuous) % 95 to 105 XXXXXXXXXXXX IV. Voltage imbalance - Negative sequence voltage as % 3 XXXXXXXXXXXX a percentage of normal positive sequence voltage

220VDC NORMAL SUPPLY CONDITIONS I. Voltage range % 85 to 115 XXXXXXXXXXXX II. Maximum r.m.s. ripple voltage % 2,5 XXXXXXXXXXXX III. DC earthing High resistance, XXXXXXXXXXXX centre point

FLOOR REQUIRMENTS

CABLE OPENINGS DESCRIPTION Schedule A Schedule B

a) Dimensions of cable openings required for mm excitation panels b) Number of cable openings required

FLOOR LOADING a) Mass of completed excitation panels kg

b) Mass of completed excitation transformer assembly kg

PANEL DESIGN AND CONSTRUCTION

GENERAL a) Manufacturer of panels

SIZE OF EXCITATION PANELS a) Length mm

b) Width mm

c) Height (including base frame) mm

SIZE OF EXCITATION TRANSFORMER CUBICLE/ASSEMBLY d) Length mm

e) Width mm

f) Height (including base frame) mm

SPACE ALLOCATED FOR PLACING EXCITATION PANELS a) Length mm 4700

b) Width mm 850

SPACE ALLOCATED FOR PLACING THE EXCITATION TRANSFORMER ASSEMBLY c) Length mm 3600

d) Width mm 1300

MINIMUM MATERIAL THICKNESS a) Base plates mm 5

b) Gland plates mm 5 DESCRIPTION Schedule A Schedule B

c) Supporting structures mm 2.5

d) Cover plates mm 2.5

e) Removable covers mm 2.5

f) Doors mm 2.5

g) Equipment mounting panels (Chassis plate) mm 2.5

PANEL ACCESS a) Front panel access Yes, doors

b) Rear panel access Yes, doors and bolt on panels c) Excitation panels cable entry Bottom

d) Excitation transformer cubicles cable entry Top

COMPARTMENT SEPARATION a) Separate switching devices compartment Yes

b) Separate control electronics compartment Yes

c) Excitation transformer phase separation Yes

d) Access restriction to live parts when doors are open Transparent polycarbon barriers

PANEL DOORS a) Door locking mechanism Pad-lockable lever

a) Minimum latching points (Doors >800mm) 4

b) Minimum hinges 4

c) Door over-swing protection Yes

d) Door reinforcement required Yes

CORROSION PROTECTION & FINISHING a) External colour RAL1015 or RAL7035

b) Surface finish Epoxy powder coated, textured c) Internal mounting plates/chassis plates colour White, high gloss

d) Surface finish Epoxy powder coated

e) Framework/support structures Galvanised or alloy cold rolled zinc steel f) Gland plates Corrosion resistant & unpainted

MINUMUM DEGREE OF ENCLOSURE PROTECTION (TO IEC 60529) a) Excitation cubicles IP54CH DESCRIPTION Schedule A Schedule B

b) Excitation transformer cubicles IP24

EARTHING

PANEL MAIN PE CONDUCTOR a) Connections Bolted

b) Earth conductor position Rear of panel

c) Earth conductor material Solid Copper

d) Min earth conductor size mm² 150

e) Earth conductor rated short-time fault withstand s 3 time

METAL COMPONENTS/FRAMES a) Connections Lugged, Non-daisy chained b) Material Stranded copper

c) Colour coding Green & Yellow

d) Min material thickness mm² 2.5

DOORS a) Connections Stud/bolted connections b) Material Braided copper straps

EXCITATION CONTROL SYSTEM

GENERAL a) Manufacturer

b) Model number

a) Type Digital

b) Configuration Fully redundant dual channel. (AVR, ARPR and field current control per channel) c) Test mode Open loop, user selectable

COMMUNICATIONS PROTOCOL TO EMPLOYER’S SCADA a) Protocol: First option (Most preferred) IEC 60870-5-104 DESCRIPTION Schedule A Schedule B

b) Protocol: Second option IEC 61850

c) Protocol: Third option OPC

d) Time synchronisation NTP/SNTP

e) Time synchronisation method External GPS clock (Provided by Employer)

PERFORMANCE INDEX a) Transient gain pu 20

b) Nominal response s-1 2

c) Voltage over shoot (@10% step) % 30 of step size

d) Rise time (From 10%Ugn to 90%Ugn) ms < 300

e) Maximum voltage reached after disconnection from % 120 of Ugn grid at rated field current. f) Minimum stator voltage at which rated excitation % 50 Ugn field current can be maintained

o g) Positive ceiling voltage (α=15 , Ugen=80%) pu 1.6 Ufn (Gen Mode)

h) Channel changeover steady state deviation % 0.5 Ugn

i) Voltage control accuracy (AVR Mode) % Within 0.5 of Ugn

j) Open loop regulator accuracy (FCR mode) % Within 1 of Ifn

VOLTAGE CONTROL LIMITS a) Upper limit % Ugn +10

b) Lower limit % Ugn – 10

FIELD CURRENT CONTROL LIMITS a) Upper limit % 110 of Ifn

b) Lower limit % 0 of Ifn

STEP FUNCTION a) Amplitude (adjustable) % 0.05 to 30 of Ugn or Ifn b) Resolution % 0.1 of Ugn or Ifn

FREQUENCY SWEEP FUNCTION a) Amplitude (adjustable) % 0.05 to 30 Ugn

b) Resolution % 0.1 of Ugn DESCRIPTION Schedule A Schedule B

c) Frequency range Hz 0.1 to 4

d) Frequency resolution Hz 0.01

OVER EXCITATION LIMITER a) Operating mode Fixed time or I2t curve - User selectable b) Max ceiling value adjustable pu 0.85 to 2.2 of Ifn

c) Thermal value adjustable pu 0.85 to 1.1 of Ifn

STATOR CURRENT LIMITER a) Operating mode pu I2t curve

b) Operating in capacitive or inductive region Selectable (either or both)

FLUX LIMITER a) Operating value pu 1 to 1.25

b) Time to operate s 0 to 30

c) Operating mode Fixed time or I2t curve - User selectable

UNDER EXCITATION LIMITER a) Reactive power offset range pu 0 to –1 Sn

b) Limiting incline deg 20 to 90

c) Resolution deg 1

d) External reactance pu 0 to 1 in steps of 0.01

e) Resolution of Q setting when limiter is Q(P) pu 0.01

f) If the UEL is a Q(P) limiter then at least 4 points be pu |P|: 0 to 1 available for setting the characteristic in both import Q: -1 to 0 and export quadrants and must operate in both gen and pump modes.

MINIMUM FIELD CURRENT LIMITER a) Settable range pu 0 to 0.5 of Ifn

b) Time to operate Instantaneous

SOFT START FUNCTION a) Time to reach pre-set s 0 to 60

b) Resolution s 0.1 DESCRIPTION Schedule A Schedule B

EXCITER FIELD WINDING OVER VOLTAGE PROTECTION a) Positive bar Yes

b) Negative bar Yes

DC SHORT CIRCUIT PROTECTION a) Range pu 0 to 5 Ifn

b) Resolution pu 0.01

POWER SYSTEM STABILISER (PSS) a) Damping ratio local mode >0.1

b) Frequency operating range Hz 0.2 to 4

c) Active power switch-on level pu 0 to 1.0 Sn

d) Active power switch-on time delay s 0 to 10

e) Timer resolution s 0.1

f) Active power switch-off level pu 0 to 1.0 Sn

g) Active power switch-off time delay s 0 to 10

h) Stator voltage switch off (low level) % 100 to 85 of Ugn

i) Stator voltage switch off (upper level) % 100 to 110 of Ugn

j) PSS switch-off time delay due to PSS output out of s 0 to 10 bounds k) PSS switch-on time delay due to PSS output s 0 to 10 recovery l) PSS output Low limit % 0 to 10 of Ugn

m) PSS output Upper limit % 0 to 10 of Ugn

CONVERTOR OPTIONS a) Model number

b) Type 6 pulse, full wave, thyristor controlled c) Redundancy 1+1 or N-1

d) Continuous rating of one converter at ambient of A 35oC

DC FIELD BREAKER

a) Number of main poles 1 or 2

b) Coil nominal operating voltage (DC) V 220 DESCRIPTION Schedule A Schedule B

c) Coil operating voltage min range (trip and close) % 80 of Un

d) Normally open auxiliary contacts for use other than 4 potential free by the ECS e) Normally closed auxiliary contacts for use other 4 potential free than by the ECS f) Number of mechanical operations ≥10000

g) Operating counter Mechanical 5 digit non resettable h) Trip coils 2

i) Time to block breaker operation switch from s 5-30 opening to closing

FIELD FLASHING

AC FIELD FLASHING SUPPLY a) Nominal voltage V 400

b) Voltage range % ±5

c) Supply VA requirement VA

DC FIELD FLASHING SUPPLY a) Nominal voltage V 220

b) Supply VA requirement VA

FIELD SUPPRESSION

a) Overlapping time ms 2-15

b) Nominal voltage V 400

RECORDING DEVICES

EVENT RECORDER a) Minimum number of stored events 255

b) Sampling rate minimum cycle time of processing system (3ms typically) c) Type of event display All internal signals causing a trip, channel change over or any alarm state

TRANSIENT RECORDER a) Minimum digital quantities 16 DESCRIPTION Schedule A Schedule B

b) Contact voltage 24V to 250 VDC or potential free on at least 8 inputs for external signals c) Minimum analogue quantities 6

d) Sampling rate for non-instantaneous signals (i.e. ms 5 voltage converted to DC value) e) Minimum recording time window s 10

f) Triggering criteria Binary or analogue

g) Pre-trigger s 2

h) Digital trigger Positive and/or negative edges i) Analog trigger Exceeding limit values and gradients j) Export file types Comtrade

k) Minimum number of records stored in memory 10

TRANSFORMERS

EXCITATION TRANSFORMERS a) Type Three individual dry type single phase units b) HV side nominal voltage kV 11

c) LV side nominal voltage V

d) Size (electrical) VA

e) Impedance %

f) Vector group Ydx

g) Maximum winding operating temperature at rated oC power @ ambient of 40oC h) Maximum core operating temperature at rated oC power @ ambient of 40oC i) Maximum cubicle surface temperature at rated oC power @ ambient of 40oC j) Excitation transformer sizing calculations required Yes

CURRENT TRANSFORMERS FOR EXCITATION OVER CURRENT PROTECTION a) CT ratio

b) VA rating VA

c) CT class 5P10

PROTECTION IED’S a) Manufacturer DESCRIPTION Schedule A Schedule B

b) Type Digital

c) Connection 3 phase

d) Nominal current (In) A 1

e) Current setting range 0.05 to 2.5 In

f) Time multiplier 0.05 to 1.00

g) Error of settings % < 7.5

h) Overload capability 100 In for one second

i) Curve/characteristic IEC very inverse & extremely inverse selectable j) High set 1.0 to 30.0 In

k) High set time s 0.04 to 5.00

l) Number of IDMT curves simultaneously active 1 or 2

m) Logic functionality to add sustained fault timer Yes

n) Sustained fault timer range s 0.00 to 10.00

o) Setting resolution ms 10

AUXILLIARY ELECTRICAL & MISCELLANEOUS COMPONENTS

INTERNAL POWER SUPPLY UNITS a) Manufacturer

b) Input voltage range to maintain nominal output % 85 to 120 voltage c) Maintain rated output voltage in case of supply loss ms 500

d) Overload indication and protection Yes

MCB’S FOR CONTROL CIRCUITS a) Manufacturer

b) Rated breaking current kA 5

c) Rated voltage VAC/VDC

d) Curve selections

FUSES POWER ELECTRONICS a) Manufacturer

b) Type industrial HRC for power electronics

CONTROL CIRCUIT FUSES a) Manufacturer DESCRIPTION Schedule A Schedule B

b) Type BS88 or Cylindrical

c) Rated voltage V

d) Rated breaking current kA

SIGNAL LAMPS OR LIQUID DISPLAY a) Manufacturer

b) Type LED

c) Supply voltage V

LABELS a) Language English

b) Colour (General Labels) White background, black lettering c) Colour (Warning Labels) White background, red lettering d) Letter print: Internal labels Laser printed or engraved e) Letter print: External labels Engraved

FERRULE NUMBERING a) Manufacturer Grafoplast or Equivalent b) Material

c) Size mm 15x4

d) Type Sleeve type

e) Font Arial, bold

f) Colour White background, black lettering

CABLE NUMBERING a) Manufacturer Grafoplast or Equivalent b) Material PVC, UV resistant

c) Size mm 70x10

d) Type Sleeve type

e) Font Arial, bold

f) Colour Yellow background, black lettering g) Placement Above gland plate and before panel entry (top/bottom)

TRANSDUCERS DESCRIPTION Schedule A Schedule B

a) Manufacturer

b) Type mA 4-20

c) Accuracy Class 1

d) Power supply Vdc 24/220

CT TEST BLOCKS a) Manufacturer IST / GE

b) Type PK2 (4 or 6way)

c) Mounting Panel/surface

d) Supply test handles Yes

VT TEST BLOCKS a) Manufacturer IST / GE

b) Type PK2 (4 way)

c) Mounting Panel/surface

d) Supply test handles Yes

INDICATING INSTRUMENTS a) Manufacturer

b) Type mA 4-20

c) Size mm 72x72

d) Full scale deflection angle deg 240

e) Accuracy Class 1

f) Mounting Flush

g) Generator stator voltage range kV 0 to 15

h) Generator stator current range kA 0 to 20

i) Generator active power range MW -300 to 300

j) Generator reactive power range MVAr -300 to 300

k) Generator field current range A 0 to 2200

l) Generator field voltage range V 0 to 500

EXCITATION TRANSFORMER CUBICLE SAFETY SWITCHES a) Type Roller lever or plunger b) Roller lever: Minimum pre travel deg 10 DESCRIPTION Schedule A Schedule B

c) Roller lever: Minimum over travel deg 20

d) Roller lever: Minimum total travel deg 50

e) Plunger: Minimum pre travel mm 2

f) Plunger: Minimum total travel mm 10

g) Material Die cast (Zinc or Aluminium) h) IP rating IP65

i) Contact rating at 220VDC (IEC 60947-5-1), Trip coil DC-13 with no economising resistor j) Contact rating at 220VDC (IEC 60947-5-1), Trip coil DC-14 with economising resistor k) Number of contacts Two N/C

l) Contact action Snap

CABLING

PROCESS CONTROL AND INSTRUMENTATION CABLING (<1 AMP SIGNALS) a) Manufacturer

b) Code UVG_ _ _CM

c) Type Low halogen

d) Core identification Colour coded with stripes per core e) Minimum voltage rating V 300/500

LV POWER & CONTROL CABLING a) Manufacturer

b) Code BVV_ _ _ CM

c) Type Low halogen

d) Core identification (2-4 cores) Colour coded

e) Core identification (>4 cores) Individual core numbering f) Minimum voltage rating V 600/1000

ROTOR CABLING a) Manufacturer

b) Code

c) Type Low halogen

d) Minimum voltage rating V 600/1000 DESCRIPTION Schedule A Schedule B

EXCITATION TRANSFORMER HV CABLING a) Manufacturer

b) Code

c) Type Low halogen

d) Core identification Heatshrink to colour code e) Minimum voltage rating kV 22

EXCITATION TRANSFORMER LV CABLING a) Manufacturer

b) Code

c) Type Low halogen

d) Core identification Heatshrink to colour code e) Minimum voltage rating V 600/1000

HV INSULATION

A) Tests on power plant and material IEC 60036-1

b) Tests on electronic plant and material IEC 60255 Class II

SUB-CONTRACTORS a) Subcontractor engaged in delivery of assembly

b) Subcontractor engaged in erection of assembly

c) Subcontractor engaged in commissioning of assembly d) Other subcontractors

MANUALS & SOFTWARE

OPERATING AND MAINTENANCE MANUALS a) Number of copies of all instruction/O&M manuals 5 required b) Electronic submission required Yes – CD/DVD

c) Format At least searchable pdf

SPECIAL TOOLS a) Number of each special tool set required for 2 maintenance b) Software packages Windows compatibility Windows 7 upwards DESCRIPTION Schedule A Schedule B

TRAINING

NUMBER OF STAFF TO BE TRAINED a) Engineering/Commissioning staff 8

b) Maintenance personnel 12

c) Operating personnel 15

LOCATION a) Engineering /Commissioning staff

b) Maintenance personnel Drakensberg Power Station c) Operating personnel Drakensberg Power Station