MAPICS XA VPI June 14, 2013

The purpose of this PTF is to communicate important information about the installation, fixes and new features of VPI “Visual Planner for System i” formally known as AVP.

PTF SH15085. This Golden Release will upgrade the VPI Engine to the latest level of code. SH15085 is applicable to both single and double byte systems. All current VPi documentation can be located in KB solution 1106232

To install the latest build of the VPI Engine, you must de-install the older version. Note: if running Windows7, right click and “Run with Administrator” when uninstalling, installing or any DBUtil maintenance or you might run into Microsoft errors

Traditional instructions to de-install the AVP Engine: 1. Go into the install path of AVP/VPi Engine (by default c:\MAPICSADVPLAN or c:\InforVPi) 2. Execute (double-click) UNWISE.exe program 3. Select Uninstall Method (recommend to take default - automatic) 4. Click 'Next' 5. Perform Uninstall - Click 'Finish'

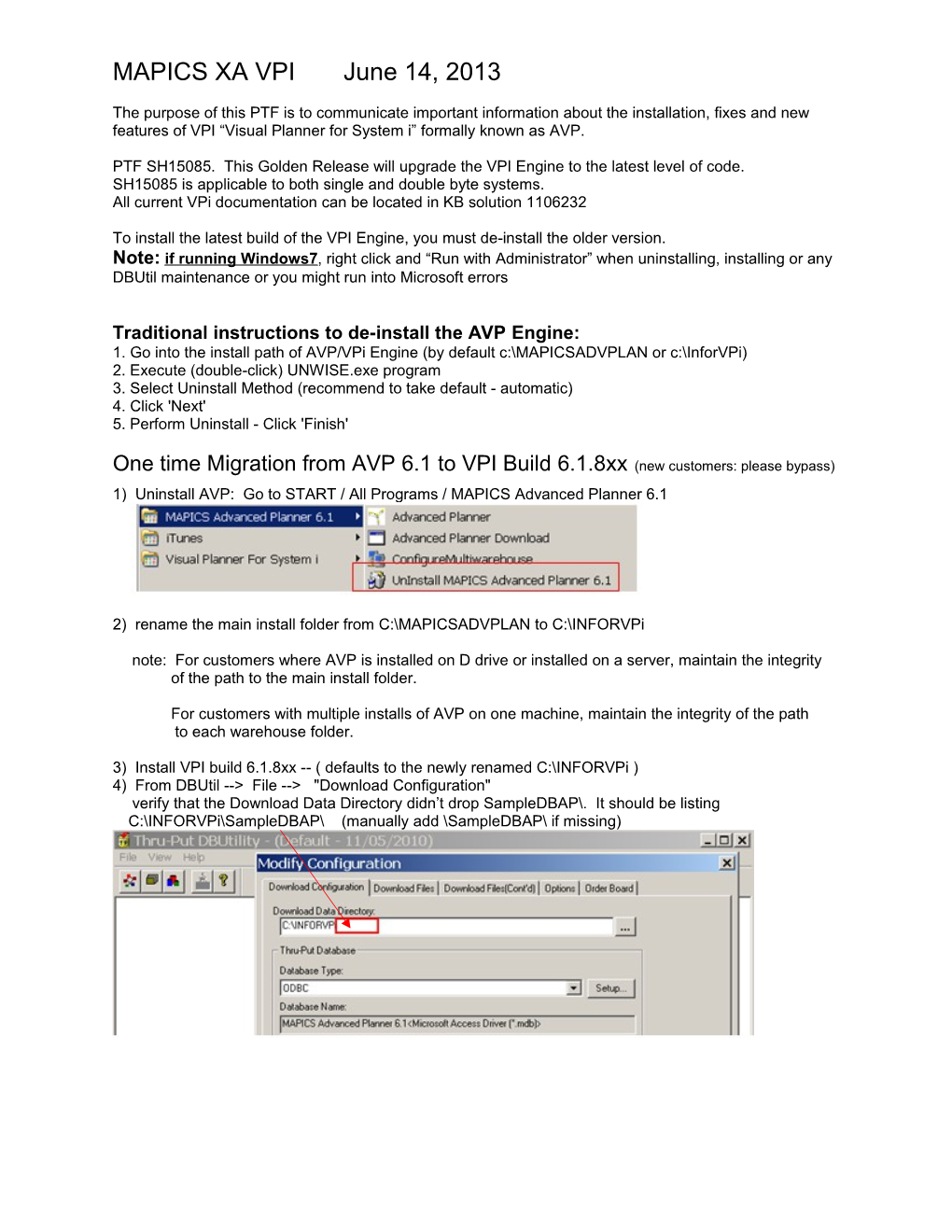

One time Migration from AVP 6.1 to VPI Build 6.1.8xx (new customers: please bypass) 1) Uninstall AVP: Go to START / All Programs / MAPICS Advanced Planner 6.1

2) rename the main install folder from C:\MAPICSADVPLAN to C:\INFORVPi

note: For customers where AVP is installed on D drive or installed on a server, maintain the integrity of the path to the main install folder.

For customers with multiple installs of AVP on one machine, maintain the integrity of the path to each warehouse folder.

3) Install VPI build 6.1.8xx -- ( defaults to the newly renamed C:\INFORVPi ) 4) From DBUtil --> File --> "Download Configuration" verify that the Download Data Directory didn’t drop SampleDBAP\. It should be listing C:\INFORVPi\SampleDBAP\ (manually add \SampleDBAP\ if missing) 5) On this same screen (DBUtil / Modify Configuration) click Setup as your first action, then click on ODBC Setup

Select the System DSN folder, highlight MAPICS Advanced Planner 6.1 and click Configure

Click on Select to change from C:\MAPICSADVPLAN\DB\ADVPlan.mdb to C:\InforVPi\DB\ADVPLAN.mdb

Then click the OK buttons to back out of the windows and exit DBUtil

Don’t miss the new features that have been added at Version 6.1.802, 6.1.818 and 6.1.857. Please review the details below starting on page 8. Post install instructions if going from the original AVP 6.0 to VPi VPI has replaced APDataLink.ini with IseriesIntegration.ini Linking VPi to the iSeries ERP environment Navigate to the INFORVPI folder on the drive on which you installed Visual Planner. Edit the IseriesIntegration.ini file in that folder to identify the data source, the user ID and password, the environment, and the warehouse. See the following for additional definitions.

[ODBC] ISeriesDataSourceName=AP60 VPI definition below ISeriesUserId=SCM VPI definition below ISeriesPassword=837602CDB869159D VPI definition below ISeriesEnv=66 VPI definition below ISeriesWarehouse=TP6 VPI definition below ISeriesUnencryptedPassword= APSI only [Download] APSActive=2 APSI only DownLoadMode=0 VPI definition below LoadItemProcess=0 VPI definition below PrintAuditReport=1 VPI definition below LongOperMinHours=0000040 VPI definition below OrderBoardMatch=1 APSI only IfNoMatchSendRequest=0 APSI only [System] AVPActive=0 VPI definition below [CTP] SCMCheckPurchaseMaterials=1 APSI only SCMPlantName=Default APSI only SCMDaysToExpire=5 APSI only SCMCharacterSetID=*CALC APSI only SCMUserId=SCM APSI only SCMPassword=SCM APSI only SCMDownloadFolder=661 APSI only SCMOverTime=s APSI only SCMAggressiveBuffer=s APSI only SCMEncryptedPassword= APSI only SCMIPAddress=10.70.04.203 APSI only SCMDaysFrozenForQuote=0 APSI only [Upload] UpdateOpenWorkOrders=1 APSI only UpdateOpenWOStart=1 VPI definition below UpdateCOMCOPromiseDate=0 VPI definition below UpdateCOMCODueDate=0 VPI definition below UpdateUserCODates=0 APSI only AutoCreateWorkOrders=0 APSI only AutoCreateWOShopPacket=0 APSI only AutoCreatePurchaseOrders=0 APSI only AutoCreateIntersiteOrders=0 APSI only AdjustOpStartForCurrentDate=1 APSI only AdjustOpStartForPrevOpStart=0 APSI only AdjustOpComplForPrevOpCompl=0 APSI only DemandsToTrack=20 APSI only RecordsForBatchUpload=500 APSI only APSMFGRTGOut=0 VPI definition below [Debug] UploadToXA=0 Diagnostics only ISeriesDataSourceName The DSN you gave the Client Access ODBC data source. ISeriesUserID A valid user ID in the MAPICS environment ISeriesPassword The "encrypted" password for the MAPICS user ID ISeriesEnv (Environment) The two-character MAPICS environment ID ISeriesWarehouse The three-character warehouse ID ISeriesEnv Type in your MAPICS environment ID. ISeriesWarehouse Type in the warehouse number of the warehouse to be planned. DownLoadMode One of the following: 0 Default. Test. You can run this while MRP (and, optionally, MPSP) is planning the warehouse in order to test the planning engine operation. This mode saves no data on the iSeries, and does not allow you to upload after planning. 1 Plan. You can run in planning mode only if VPI is active in the warehouse. You can save the plan and upload it after planning. This mode conflicts with the following MRP jobs from download until upload completion: • Maintain forecast • Maintain MLI requirements • Maintain horizon values • Maintain period intervals • Planning run execution options • Order review and approve • OBPM MRP recommendations. LoadItemProcess Applies only if EPDM is active. Specifies how many item processes, and the corresponding bills of material and routings, are downloaded for planning. With any option, only current and future processes are downloaded. One of the following: 0 Default. Only the curre nt primary process for an item. 1 All current and future primary processes for an item 2 All current and future processes for an item. PrintAuditReport One of the following: 0 Print no download audit reports 1 Default. Print errors only. 2 Show the detail of everything that is downloaded. LongOperMinHours Type in the minimum ho urs for a long-running operation. The default is 8. The maximum is 9999999. Only operations with either setup time or runtime per piece (or order, if the time basis code is C or H) greater than this value are considered long operations. In-progress information, with the remaining setup or run time, is downloaded for long operations that are in process. AVPActive One of the following, to activate or deactivate VPI in the warehouse in the next download: 0 (Default). VPI is not activated in the warehouse. 1 VPI is activated, if not already active, in that warehouse. 2 Deactivate VPI for the warehouse. UpdateOpenWOStart One of the following: 0 Ignore WO rescheduled and upload original dates 1 upload WO rescheduled dates UpdateCOMCOPromiseDate One of the following: 0 Do not update the promise date 1 Update the promise date only the first time it changes 2 Upload the promise date every time it changes UpdateCOMCODueDate One of the following: 0 Do not update the manufacturing due date 1 Update the CO manufacturing due date only the first time it changes 2 Upload the CO manufacturing due date every time it changes APSMFGRTGOut XAR7 & above One of the following: 0 Do not update the manufacturing operation Start and Completion Dates 1 VPI to control and update the manufacturing operation Start and Completion Dates DBUtil Maintenance: Some systems are not handling the conversion correctly. After installing VPI pull-up DBUtil and select File / Download Configuration. Make corrections to DBUtil if it does not show the following. 1) Download Data Directory should show C:\INFORVPI\SampleDBAP\ (see screen print #1 on the next page) 2) Database Name should show MAPICS Advanced Planner 6.1 (see screen print #1 on the next page) 3) Download files should show as follows: (see screen print #2 on the next page) Work Centers ppiwkc Part Master ppiprt Bill of Material ppibom Routings ppirtg Forecast ppifcs Sales ppicom Purchase ppipur Jobs in Progress ppijip Inventory ppiinv Work Order Header ppimom Work Order Routing ppimor Work Order Allocations ppimod

Download Files (cont'd) Part Process ppiprc Part Vendor ppispv <-- (introduced at Build 6.1.754) Screen Print #1

Screen Print #2 Cumulative Release Notes for the original AVP and the new VPi

Introduction

This document contains history of revisions done to the software after the launch of AVP and the new functionality added in VPI. These are changes that have not been captured in the User Guide.

Descriptions of modifications are provided for customer tracking and information purposes only and are not intended to serve as substitutes for any type of training or consulting.

In addition, statements in this document, which are attributed to new and enhanced functionality, are engineering claims and are not meant to serve the efforts of discussing or promoting such functionality in detail.

While fixes and enhancements are addressed in this document, certain known issues that are being actively addressed may disable some functionality and produce behavior, which could be viewed as undesirable by the user. All known issues are being addressed on the basis of their assigned priority and will become available in future releases.

Infor actively uses Infor365 Solutions for the purposes of tracking the issues that are reported with released products. Therefore, Infor365 problem-tracking call information can be found above each described fix – indicated by APAR number. Version: 6.1.865 VPi Date: 06/14/2013

Apar 52157: Released Orders not linked to Demand are not uploading back to XA has been fixed

New feature: Default Reschedule Code when firming a planned order In the earlier builds, all the plan supplies had a default Reschedule Code = 4, while firming up. If you did a drag and drop of planned work orders in Time Phased Load Profile Window, there was no way to set the Reschedule code to other than 4 unless you go to Modify Supply or Level Load Supply. With this build, you can set the default value of Reschedule code to be set automatically after firming up happens in drag and drop. You will see a new menu item under Display menu called ‘Select Default Reschedule Code’, which will bring up a dialog where you can pick the reschedule code 0 through 5. This value is stored in the RESPARA table with the field name DEFAULT_RESCHED_CODE. If there are no values set, it will use Reschedule Code of 1. But if you change it, new value will be the default for future VPi session (not only for current session). Note that this change will apply only to plan supplies being firmed up. All plan supplies will have reschedule code of 4 otherwise. Note again, in drag and drop this will automatically apply. In Modify Supply or Level Load command options, an explicit dialog pops up with Reschedule Code. Here for plan supplies, the reschedule code highlighted will be DEFAULT_RESCHED_CODE although user can change it any value case by case without affecting default.

New feature: Negative Qty Per in BOM, Byproduct, Reclaim New logic has been added where negative qty per will generate a firm planned supply order at the Due Date of the parent work order.

New feature: Min/Max logic replicating XA's Reorder Report See KB article 790868 for specific logic and setup details

New feature: LimitSupplierCapacity=-1 honor Make_Max_Lot for purchased parts needs to be manually added to [Schedule Outputs] section: As part of a Thruput enhancement, Development added a new config parameter named LimitSupplierCapacity under [Schedule Outputs] section which is used to control if planning needs to honor Make_Max_Lot for raw materials. If the value of this parameter is 0, then in memory, we overwrite Make_Max_Lot as 0 for both Buy parts and Consigned parts; else we go by Make_Max_Lot value in PART table for Buy parts and Consigned parts

Multi-sourcing received some fine-tuning adjustments 1. Showing allotted vendor in the orders Window 2. Incorrect splitting when three vendors are involved 3. Repeated splitting when allotted plan supply is firmed up for the Vendor.

This is a complicated issue and expected results could vary from situation to situation. Currently, we have partially solved this problem by adopting following design philosophy when a buy part has multi-sourcing rule: 1. If PO is split among different vendors based upon allocation percent, if one of these supplies is firmed up, then all the sister POs will also be firmed up to keep the target allocation percentage among all. If the Supply Qty was not modified using Modify Supply, then there will be not any change in the overall picture. In short no recalculation of vendor calculation happens and picture remains same. 2. If lot sizing and multiples are enabled for any vendor, it is possible that a single PO allocated to a vendor can satisfy multiple demands. If such PO is firmed up, then all the planned supplies that belong to these multiple demands will also be firmed up to maintain the same allocation picture. 3. If during a modify supply, if the quantity is changed and the quantity is increased for any supply, then remaining over allocation will remain so without readjustment. Based upon rule 1 & 2 above, all the PO supplies belonging to pegged demand(s) will be firmed up. 4. If during a modify supply, if the quantity is changed and the quantity is decreased for any supply and if the overall supplies is less than the requirement quantity, additional supply will be generated changing the picture of the allocation

Multi-warehouse planning received some fine-tuning adjustments providing the engine better material planning with the SC_Part_Xref when integrated with ISL/MISL/ML. New feature: Maintenance for the MACHINE table making it easier to maintain Variable Resource Units per Workcenter

You can move the cursor on them to see what they do. Here is the brief explanation of what each button does ( from left to right ): 1. Goto Last Row for adding a new row or search a record 2. Add a new Record 3. Delete a record 4. Search a record for an entry 5. Search Next

Variable Resource Units per Workcenter

Utilizing the MACHINE table, the fixed Units in WKCTR can be overridden for a span of time. WKCTR WORKCENTER_ID UNITS UTILIZATION CALENDAR_ID 18117 1 0.95 DEFAULT 18130 1 0.95 DEFAULT

MACHINE WORKCENTER_ID START_DATE END_DATE UNITS LOCATION_ID 18117 01-Feb-10 05-Feb-10 5 1 18130 01-Feb-10 05-Feb-10 5 1

Notice the Blue Capacity line reflects the increase to 5 units Feb 1 - Feb 5 and drops back to 1 unit beginning Feb 8. Version: 6.1.845 VPi Date: 10/29/2012

If you are migrating from 6.1.790 or older, please see Action Required under 6.1.818

If you are migrating from 6.1.802 or 6.1.818: Action required to update your VISUALPLAN.mdb to work with Build 6.1.845: Before the first Download, delete tables REP_TEMPLS, SC_CUSTOMER_MASTER and SC_PLANTS. This will allow DBUtil to rebuild the tables with the new fields required for this engine.

New feature: Job Step Start Date logic for the XA Upload can include Setup time Prior to this, interactive planning included Setup Time, but the operation start dates uploaded to XA did not include the setup time.

A new config parameter allows customers to determine whether setup time is included or not. Under the grouping of [Schedule Outputs] IncludeSetupInDDB=1 "yes" or 0 "no"

This new config parameter builds upon the logic in the following parameter: DDBEqualsStartTime 1 - typical buffer is excluded from the Job Step Start Date and puts the buffer between this job step and the preceding, upstream job step. If this is the 1st job step, both the job step & work order Start Date exclude the buffer. 0 - typical buffer is included in start time for the job step & work order (this can create out-of-sync operation dates between the engine and XA) Note1: Typical buffer is included in Component Required Date calculation for both config settings Note2: Setup Time is excluded for both config settings

New feature: Discard Negatives has been split into two separate parameters DiscardNegativeOnHand= 0 - allow negative on hand to be downloaded and included in the planning process 1 - discard negative on hand in the download process

DiscardNegativeBOM=0 0 - allow negative BOM "qty per" to be downloaded and included in the planning process 1 - discard negative BOM "qty per" in the download process

Improvements for DBCS With the install of VPI version 6.1.834 and higher the folder SampleDBAP2 will be created within the installation directory containing the DBCS format files and the iSeriesIntegration.ini belonging to these files. This iSeriesIntegration.ini needs to be copied into the main install folder (i.e.: C:\INFORVPi\). Make sure that the correct ODBC data source is added to this iSeriesIntegration.ini to connect to the iSeries and also the correct warehouse and environment. Furthermore the correct InputFileDir needs to be set in the iSeriesIntegration.ini and Config.ini. This download directory should be C:\INFORVPi\SampleDBAP2 in case you have installed VPI using the default install. Version: 6.1.818 VPi Date: 10/10/2011

If you are migrating from 6.1.790 or older Action required to update your ADVPLAN.mdb to work with Build 6.1.818: Before the first Download, delete tables BNSCHED, PART, PURCHASE, PURCHASE_PREV, REP_TEMPLS, ROUTE, SALES, SC_CUSTOMER_MASTER, SC_PLANTS, WOHEAD and WOROUTE. This will allow DBUtil to rebuild the tables with the new fields required for this engine.

New feature: Individual Routing Overlap This new enhancement has been added to handle Transfer size between operations. In ROUTE and WOROUTE a new field called Transfer_Size has been added. If this value is positive and is greater than or equal to Batch Size, then this number will be used in determining the overlap between the operations. Transfer_Size = 1 will be the greatest overlap. Note: back-to-back operations across a work center currently are designed to not allow overlap. It is assumed the first operation occupies the resource or resources in the work center until the entire quantity is completed.

TRANSFER_SIZE works in conjunction with Config parm TransferEntireBatch=0. TransferEntireBatch=1 ignores Transfer_Size.

XA does not have a specific field reserved for transfer size. One option: use RTGOPR field RTOOL & MOROUT field TOOLS “Tool Number” as the XA base field

DBUtil File Formatting PPIRTG.fmt Transfer_Size 25 257 6

PPIMOR.fmt Transfer_Size 25 269 6 New feature: Group Mode - Operation Delay Time

"Modify Operation Delay Time" will allow better scheduling between two critical workcenters. Rescheduling is done at the Order Level, so when you reschedule one jobstep, all jobsteps on the order are rescheduled. For example, jobsteps 40, 50, & 60 and the Due Date of the order are right on target but jobstep 30 is overloaded. You can easily expedite jobstep 30, three days earlier, but now that creates an overload on jobstep 50 by it being expedited three days. Currently, it can be cyclic chaos. This new feature will allow the user to insert three days buffer between jobsteps 30 and 40, thus pushing jobstep 30 three days earlier and jobsteps 40, 50 & 60 remain at the proper dates

"Modify Operation Delay Time" is only active for released mfg orders. And utilizes the same WOROUTE work files in the Upload as the Offload function to add the new value to XA's MOROUT field MOVTM. Enhanced feature: Shipping Buffer (in hours) creates a buffer for End Items only Use the same value in both Minimum & Typical to keep backward & forward scheduling in-sync. Demand Due Date less Shipping Buffer = Demand Required Date Location_ID is the planning warehouse

Global setting PLANT_CONFIG LOCATION_ID PARAMETER_NAME PARAMETER_VALUE 1 FLEX_SHIPPING_MINIMAL_BUFFER 12 1 FLEX_SHIPPING_TYPICAL_BUFFER 12

Shipping Buffer by Item PART PART_ID LOCATION_ID MINIMUM_SHIPPING_BUFFER TYPICAL_SHIPPING_BUFFER VPIFCSTPARENT 1 72 72

Ship Buffer = 0 hours

Ship Buffer = 72 hours New feature: Fixed Yield logic has been added to the engine

It is stored in the PART table’s YIELD column -- values .01 to 1.00 are reserved for Part Yield (XA Shrinkage) -- any whole value greater than 1 represents Fixed Yield

Examples of how different part yields would be interpreted. .95 0 fixed amount 95% percentage yield 1.00 0 fixed amount 100% percentage yield 1.85 1 fixed amount 85% percentage yield 2.00 1 fixed amount 100% percentage yield and so on

Example of Fixed Yield and Routing Yield Routing Yield = .90 PART table Yield = 6.00 100% Part Yield + 5 fixed yield (( post yield ) ((F.G. + fix yield) / rtg yield = pre-yield (( 90 + 5 ) / .90 = 105.56)

XA Where to store the value? Original design is for Shrinkage to be downloaded to the field YIELD in the PART table however, shrinkage only allows a value up to 1.000

One option is to store fixed yield in ITEMBL field UUCAIB XA download work file PPIPRT extracts from: ITEMBL field UUCAIB Alpha 5 start position 527 User field-code A

DBUtil’s format file must be mapped to the user field SampleDBAP\PPIPRT.fmt Yield 34 341 13 <<------change to Yield 34 377 5 Version: 6.1.802 VPi Date: 01/01/2011

Action required to update your ADVPLAN.mdb to work with Build 6.1.802: Before the first Download, delete tables BNSCHED, PART, PURCHASE, PURCHASE_PREV, ROUTE, SALES, SC_CUSTOMER_MASTER, WOHEAD & WOROUTE. This will allow DBUtil to rebuild the tables with the new fields required for this engine.

New feature -- a powerful tool for quickly identifying material shortages This new option was added to Waterfall - Feeding Supplies. Show Material Shortages allows the planner to quickly check for material shortages as an order is being rescheduled.

New feature: Replenishment Parts - Mfg & Purchased Items (Lean Manufacturing - Red, Yellow, Green tags) The concept of the replenishment planned items is a sophisticated 3 tier reorder point system not requiring either customer orders or forecast demand. The replenishment logic can be used to maintain an inventory level without independent demand driving the planning. Any customer order or forecast demand is decoupled and is ignored.

The MRP Current Date is used to establish the Required Date for the Red tag demand. Safety Stock Lead Time is extracted as the Planning Fence. Yellow is MRP Current Date plus 1x Planning Fence Green is MRP Current Date plus 2x Planning Fence Facility Enhancement Variable Resource Units per Workcenter Utilizing the MACHINE table, the fixed Units in WKCTR can be overridden for a span of time.

The global fixed units spanning the time of the workcenter calendar resides in WKCTR. The MACHINE table allows for individual dates or a range of dates being overridden.

New Planning Logic sets a Planned Order Time Fence

Horizon Start Date + MinMRPLeadTime (from the PART table) establishes a date where VPi will not generate planned orders within this fence for both purchased and manufactured items. This time fence logic will also be used so VPI will push all planned orders out to the farthest Released or Firmed Orders with a Reschedule Code = 1. Applies for both mfg and purchased items. Version: 6.1.790 Date: 06/15/2010

Action required to update your ADVPLAN.mdb to work with Build 6.1.790: Before the first Download, delete tables BNSCHED, PART, PURCHASE, PURCHASE_PREV, ROUTE, REP_TEMPLS, SALES, SC_CUSTOMER_MASTER, WOHEAD & WOROUTE. This will allow DBUtil to rebuild the tables with the new fields required for this engine.

Follow-up to Facility Enhancement Previously we introduced the New Config setting: SplitQtyAcrossUnitsForNonDrums=1 allowing a work order to spread over multiple units in a work center.

SplitQtyAcrossUnitsForNonDrums= -1 drops the global setting and becomes work center dependent using WRKCTR / ATTRIBUTE5 with one of the following values: 0 - entire task will be placed on unit while computing the lead-time 1 - the work orders quantities will be equally divided over number of units available (whole numbers) 3 units & qty 4 splits 1,1,2 2 - the work orders quantities will be equally divided over number of units available (fractional) 3 units & qty 4 splits 1.33, 1.33, 1.33. It does not split a qty of 1.

New feature: allows individual item forecast demand time fence ForecastFenceByPart= New parameter added to config.ini under [Order board Options] section ForecastFenceByPart=1 the value of PABZoneDays will be read from PART table, instead of reading the global value from DBUtil Order Board / Forecasting Method / Forecast Fence. PART table PLANNING_FENCE value will serve as Forecast Fence Days part by part. There is no mix of logic, it’s either global or by individual part.

New feature: Engine logic changed to handle By-Product (negative qty per in BOM) Config.ini parameter: DiscardNegFGI=0

New feature: Work Center Utilization has been added to AVP as protective capacity On the L:C window, it will be displayed as Protective Capacity. If the sum of the maximum capacities for the three shifts is not greater than zero: .95; otherwise, if the sum of the desired capacities divided by the sum of the maximum capacities is not greater than 1: the result; otherwise, 1. Version: 6.1.754 Date: 05/15/2009

Action required to update your ADVPLAN.mdb to work with Build 6.1.754: Before the first Download, delete tables BNSCHED, PART, PURCHASE, PURCHASE_PREV, ROUTE, SALES, SC_CUSTOMER_MASTER, WOHEAD & WOROUTE. This will allow DBUtil to rebuild the tables with the new fields required for this engine.

New functionality: VPI _PCC integration In conjunction with Build 6.1.754, XA78 Enhancement SH85276 modified the VPI planning process so VPI has the ability to upload the operation scheduled start & scheduled complete dates in MOROUT. Prior to this enhancement, VPI was an infinite scheduler, it was positioned as a Planner (vs a Scheduler), and uploaded only work order due dates (MOMAST) expecting that users could use one of the 4 PCC scheduling options to execute the plan, as they do with MRP. As users learned to use VPI, they found that it has scheduling capabilities that PCC does not (e.g., ability to use different calendars for different work centers, option to split the WO quantity across the units in a work center, option to schedule the following operation to start after the first item is complete at the prior operation), and utilize them while interacting with VPI to develop executable plans ‘manually’. They found that when the plan results were uploaded to the “System I”, where PCC did not have those capabilities, users could not execute the plan, as the (operation) schedule produced by PCC did not match the schedule in the VPI plan. Thus the requirement to provide an option for VPI to upload its planning results at the operation level.

Actions required on the client side: 1) IseriesIntegraton under [Upload], set APSMFGRTGOut=1 This triggers VPI to upload route records to PPRTGW.out. Then XA translates to work file PPMORT, which in turn updates MOROUT. If you do not want VPI to upload routing dates, set APSMfgRtgOut=0.

2) Writeschedule Pass MUST be run before selecting the Save Plan. Writeschedule Pass builds the records in the T_To_Make table, which is used to build the routing records.

When VPI updates the operation Start & Complete Dates, it also updates: - MOMAST / MPROR = “*” and GAPS = “1” - MOROUT / MPROR = “*” These field values flag PCC rescheduling to ignore these orders.

New functionality: Multi-sourcing simulating the logic in MRP In conjunction with Build 6.1.754, XA78 Enhancement SH85276 modified the VPI download process to utilize a new XA work file PPISPV to extract the information from the XA multi-source vendor files VENQTY & VENSPL. The download also extracts Item Warehouse multi-sourcing code of “R” rotate or “S” split and passes this code to VPI as the PART Primary_Vendor.

Actions required on the client side: 1) Config.ini set SCPartVendorOverride=1 2) DBUtil / Modify Configuration / Download Files (continued) and set: Part Vendor = PPISPV

DBUtil file formatting: SC Part Vendor PPISPV.fmt Start Length "" Part_ID 1 0 25 Location_ID 2 25 3 Vendor_ID 3 28 15 Ytd_Received_Qty 7 68 13 Start_Date 13 143 8 End_Date 14 151 8 Allocation_Percent 15 159 5 Min_Lot 20 216 13 Multiple_Of 21 229 13 Processing open work orders by their Progress

SortOpenWOByWorkProgress= 1 -- In the current version, when there are multiple open work orders for a given part, the work order with earliest release date was chosen first to work on. If the release dates of the work order were same, then work order id in the ascending order was chosen. In some customer scenario, this was not practical. Because of the huge volume of work orders being open and those work orders being processed in different routes/departments/vendors, some orders were progressing faster than other work orders and there was neither any particular work order sequence nor release date sequence. In such cases, user would like to process first the work order with most completed route operations. Now, this is facilitated by a config.ini parameter in the config.ini. Thus, if you set SortOpenWOByProgress=1, then work orders will be chosen based upon the work order progress index which varies between 0 and 1. Further, if you set AllocQOHToOpenWOFirst, then even the on hand will be allocated to open work orders with higher completion index first. This will help to optimally close the open work orders quicker.

2 -- In the earlier version, while picking the work order based upon progress, progress determined by how much has been completed after all the component have arrived. Progress Index was computed beyond the last assembly operation only. Now, a new value of 2 introduced to this parameter, which will compute the progress until the first job step, instead of stopping at assembly node. Stopping at assembly node is still activated with value 1.

Auto-Run Commands for Download, Upload and Writeschedule Pass Download command: C:\INFORVPI\APDATALINK -C:D -T:1 Upload command: C:\INFORVPI\Resonance -rap -s Writeschedule Pass & Upload command: C:\INFORVPI\Resonance -rap -sw Version: 6.1.718 Date: 08/15/2008

New feature added to the Export Option to allow user the ability to select columns and rows

Added option 2 to Config parameter SplitQtyAcrossUnitsForNonDrums= On a non-drum work center, the work orders quantities will be equally divided over number of units available. If the quantity is cannot be divided equally, the quantity will be rounded off to next integer or the batch size. This generally leads to uniform distribution of load across the units on a non drum workcenters. Before this enhancement, VPI's planning logic was "One Order spread over only one Resource Unit per day" 0 -- entire task will be placed on unit while computing the lead-time 1 -- the work orders quantities will be equally divided over number of units available (whole numbers) 3 units & qty 4 splits 1,1,2 2 -- the work orders quantities will be equally divided over number of units available (fractional) 3 units & qty 4 splits 1.33, 1.33, 1.33. It does not split a qty of 1

New Interceding Time Calculations calculate more accurate Jobstep Start and Completion Dates NewIntTimeCalc=1 The new calculations are triggered by a new config parameter residing in the [System] section. Note: due to the backward and forward calculations, it is important to keep the minimum and typical buffers in-sync.

1) Shipping Buffer (in hours) creates a buffer for End Items only. Use the same value in both Minimum & Typical to keep backward & forward scheduling in-sync. Demand Due Date less Shipping Buffer = Demand Required Date PLANT_CONFIG LOCATION_ID PARAMETER_NAME PARAMETER_VALUE 1 FLEX_SHIPPING_MINIMAL_BUFFER 12 1 FLEX_SHIPPING_TYPICAL_BUFFER 12

2) Workcenter Minimum & Typical buffer for each workcenter are downloaded from XA's Facility Standard Queue Time. VPI Mapped Field Definition in DBUtil for PPIWKC: Field Description Start Length Min_Buffer_Time 0015 094 0016 Typical_Buffer_Time 0016 094 0016

Waterfall - Feeding Supplies now displays Setup Time if config setting IncludeSetup=Yes. With config setting IncludeSetup=Yes, Load Time will be displayed on L:C, Timephased and Waterfall - Feeding Supplies.

With config setting IncludeSetup=No, Setup is dropped and Run Time will be displayed on L:C, Timephased and Waterfall - Feeding Supplies. Version: 6.1.668 Date: 01/20/2008

New Functionality Auto-Offload based on batch size.

Suppose there are three alternate routes with batch sizes 50, 100 and 150. And a new work order is required for 75. Then the work order will be placed on route 2. If there is another demand for 125, it will go to route 3. Another order with 45 will go to route 1. Please note: the logic does not apply to open work orders.

Setup for Auto-Offload

Changes required in the VPI database:

WKCTR table: 1. Set ATTRIBUTE3 to ALTERNATE - Not supported in XA 2. WORKCENTER_FAMILY should be set to common family for all the workcenters belonging to a group. XA Field WKGRP "Work Center Group ID" in WRKCTR/PDM or FACMST/EPDM downloads this data.

ROUTE table: 1. Each route needs to be separately defined with unique Route ID 2. Route Priority should be set to 0 3. Even if only operation is different, you still need to copy all the job steps in a route (with different RtgID) 4. The batch size should be distinct for different alternate workcenters. Since the purpose of the algorithm is to reduce the batches, first preference will go to the workcenter with lowest batch size.

XA SH82319 provides complete integration with XA EPDM environments allowing multiple route records with distinct batch sizes to be downloaded to VPI.

JSBOM table: If each route has different BOM, then you need to download separate BOM with PARENT_ROUTE_ID mapped (Used for alternate BOM). If all routes have same BOM, set the parent route ID = "_ALL_".

Version: 6.1.633 Date: 09/12/2007

Enhancements included in the 6.1 Engine

New Functionality

Users are now provided three new options to select and work with requirements to be pushed out. These new windows will list the orders affected by level loading on a facility

Background In VPI, we have the option to level load a facility by rescheduling work orders. Net effect is that the customer (sales) orders also need to be delivered later. Since, some Customer orders are very important and their promise dates need to be honored, users need visibility of the orders affected by scheduling on a facility.

Traditionally, users either go to the Supply Demand detail screen to see the pegged customer order or using Waterfall View of Pegged Orders. There is need to show the summary list in a tabular format so that user can reschedule the customer orders of choice.

The new commands “Which Orders to Push Out” & "Which Customer Orders to Push Out" show the potential order list that will be delayed based upon the current schedule. Notice Customer Name is also included. The Customer Name comes from a cross reference table SC_CUSTOMER_MASTER, which needs to be manually populated.

The following are some of the actions when you select DISPLAY

Records Generated from within the Facility

Global Records not limited to within Facility

Which Orders to Push Out is the same function as Re-Schedule Requirement Push All Orders Out is the same function as Re-Schedule All Requirements Explanation of the difference between "Which Orders..." & "Which Customer Orders..." using the Supply Demand window as the foundation. This example has No Shipping Buffer in PLANT_CONFIG table & No Typical Buffer in Facility APS1 -- the results will be different when buffer penetration is involved.

The window above "Which Orders..." works with the current Facility and lists Supply Orders where "Supply Due Date" > "Supply Suggested Date" (records shown in red in Supply Demand window).

The window below "Which Customer Orders..." is global and lists only Customer Orders where Demand Suggested Date > Demand Due Date.

Customer Orders pushed out will be displayed from the option: "List of Customer Orders Pushed Out" New Functionality

Users are now given an option to select multiple orders for an Alternate Routing in the Orders Window. Please hold the “Ctr” key, while clicking on multiple orders to execute this functionality. After needed orders have been selected, please proceed to right click on the screen and pick “Alternate Route”. At this time you will be able to change all orders to the same "Alternate Route" at the same time. Please make sure to select “OK” at the end when you have finished changing "Alternate Route" in order to commit these changes into memory.

New Functionality

Users are now given the option to select "Alternate Route" from the Time Phased window.

New Functionality

Users are now given the ability to save a planning session back to the ACCESS database with the option Write-schedule Pass. The traditional SCM write-schedule pass was duplicated for VPI; but, SCM does not handle firm-planned orders so at the end of write-schedule pass, when you click the OK button, that's when the additional VPI function saves the firm-planned orders to WOHEAD utilizing the new queries "ADD_FIRMWO" & "V_TO_MAKE_ROUTES" and the new OutPutCustom.sql that resides in the main install folder.

As a bonus, the Write-schedule pass creates the full functioning waterfall chart used by APSI.

Material Planning Enhancement

AllocQOHToOpenWOFirst The VPI engine recorgnizes this Config setting. AVP 6.0 allocated quantity on hand based on Required Date. This setting allocates on hand to open work orders, ignoring planned orders with an earlier requirement date.

New Functionality

Work order jobsteps has been added to Waterfall - Feeding Supplies New Functionality Timephased Labor Load Summary

This option is listed on the Display drop down list. Please select Table option before trying this option. Use this window to see the Plant's labor load per facility. This window utilizes the Telescopic Bucket option to define planning buckets as Days, Weeks or Months. This can be a great tool for next year's budget by loading the forecast for the new year, working in monthly buckets and then exporting to an Excel spreadsheet.

Users are now provided the Export function in the Timephase Labor Load Summary - table format.

For exporting the data in the 'Display time phased labor summary' report, user needs to select the required columns or all columns in the report and right click and select Export option to export the data.

Or user can click on the icon in the first row of the first column in the report; this will highlight all the rows to be exported. Then, user has to right click on the first row and select the 'Export' option

Timephased Facility Load Summary

This option is listed on the Display drop down list. Please select Table option before trying this option. When you click this on this menu, user can see the time phased load profile on all facilities (work centers) in a single tabular display. Each row will represent one work center while each bucket will represent the column. If load exceeds capacity in any buckets, the color will be shown in red. User can export this table to Microsoft Excel and take hard copy of the screen. New Functionality

Users are now provided the Export function in the Timephase Labor Load Summary - table format.

For exporting the data in the 'Display time phased labor summary' report, user needs to select the required columns or all columns in the report and right click and select Export option to export the data.

Or user can click on the icon in the first row of the first column in the report; this will highlight all the rows to be exported. Then, user has to right click on the first row and select the 'Export' option

Forecast Enhancement

Customer ID# has been added to the FCST Consumption Window. This gives VPI Planners visibility if they are forecasting at the customer level rather than utilizing the traditional global forecast.

Forecast Enhancement II

There were originally three ways to consume forecast: 1) Individual Item 2) Component Forecast consumed by Parent Customer Order Demand 3) Planning Bill Family Forecasted at the Parent Planning Bill Item and forecast is pushed down to the "shippable" items (percentages based on qty per in Planning Bill)

VPI introduces a fourth: Product Family, which doesn't utilize a Planning Bill. The "Base" Item is forecasted. Customer Order Demand for items within the Product Family consume the "Base" Item's forecast

On the XA side: Product Family requires the "Base" Item to include the family ID in file PPITEM for fields IPFMID "Family ID" and IPPRTF "Forecast family ID". The "Shippable" Items require the family ID in file PPITEM for field IPPRTF "Forecast family ID". Both "Base" Item and "Shippable" Items will have PPITEM field IPPLNB "Planning bill item" = 0.

In the VPI database: - the FORECAST table will contain records for the "Base" Item and Part_Family_ID will list the family ID - the PART table will list family ID in FC_Family_ID for both the "Base Item and "Shippable" Items

TimePhased Window Enhancement

Made firm-planned orders a unique color to make them readily identifiable from planned orders GREEN: Planned Orders PINK: Firm Planned Orders BLUE: Planned Orders with Alternate Routings YELLOW: Released Orders & REP planned schedules that can be offloaded ORANGE: Released Orders that cannot be offloaded

New Functionality

Functionality has been added to allow VPI to work with an SQL Server database Facility Enhancement

New Config setting: SplitQtyAcrossUnitsForNonDrums=1 Before this enhancement, VPI's planning logic was "One Order spread over only one Unit per day"

The following is an extreme example displaying one order spread over multiple units. Facility VAT3 with 5 units (days) associated to a calendar set for 1 work day per week: 23.9hr * 5 days = 119.5hrs New Functionality "Modify Operation Delay Time"

This requires companion XA APAR SH81522

"Modify Operation Delay Time" will allow better scheduling between two critical workcenters. Rescheduling is done at the Order Level, so when you reschedule one jobstep, all jobsteps on the order are rescheduled. For example, jobsteps 40, 50, & 60 and the Due Date of the order are right on target but jobstep 30 is overloaded. You can easily expedite jobstep 30, three days earlier, but now that creates an overload on jobstep 50 by it being expedited three days. Currently, it can be cyclic chaos. This new feature will allow the user to insert three days buffer between jobsteps 30 and 40, thus pushing jobstep 30 three days earlier and jobsteps 40, 50 & 60 remain at the proper dates

"Modify Operation Delay Time" is only active for released mfg orders. And utilizes the same WOROUTE work files in the Upload as the Offload function to add the new value to XA's MOROUT file.

This change in XA APAR 81522 provides the ability to add a much needed new feature on the engine to change the buffer between two critical work centers.

Benefits of making these changes: 1) one field (Move Time) recognized by both XA & VPI 2) Move Time is maintainable in PDM Routing maintenance -- Buffer Out is not. For PDM you must use DFU to maintain Buffer Out. 3) Move Time is maintainable in a released mfg order 4) PCC will also recognize the Move Time and will reschedule accordingly 5) provides scheduling flexibility order by order within VPI

New Functionality Auto-Offload based on Batch Qty

Setup for Auto-Offload

Changes required in the input tables are:

WKCTR table: Set ATTRIBUTE3 to ALTERNATE - Not supported in XA WORKCENTER_FAMILY should be set to common family for all the workcenters belonging to a group. Field WKGRP "Work Center Group ID" in WRKCTR/PDM or FACMST/EPDM downloads this data.

ROUTE table: 1. Each route needs to be separately defined with unique Route ID 2. Route Priority should be set to 0 3. Even if only operation is different, you still need to copy all the job steps in a route (with different route ID) 4. The batch size should be distinct for different alternate workcenters. Since the purpose of the algorithm is to reduce the batches, first preference will go to the workcenter with lowest batch size.

JSBOM table: If each route has different BOM, then you need to download separate BOM with PARENT_ROUTE_ID mapped (Used for alternate BOM). If all routes have same BOM, set the parent route ID = "_ALL_".

Suppose there are three alternate routes with batch sizes 50, 100 and 150. And a new work order is required for 75. Then the work order will be placed on route 2. If there is another demand for 125, it will go to route 3. Another order with 45 will go to route 1. Please note: the logic does not apply to open work orders.