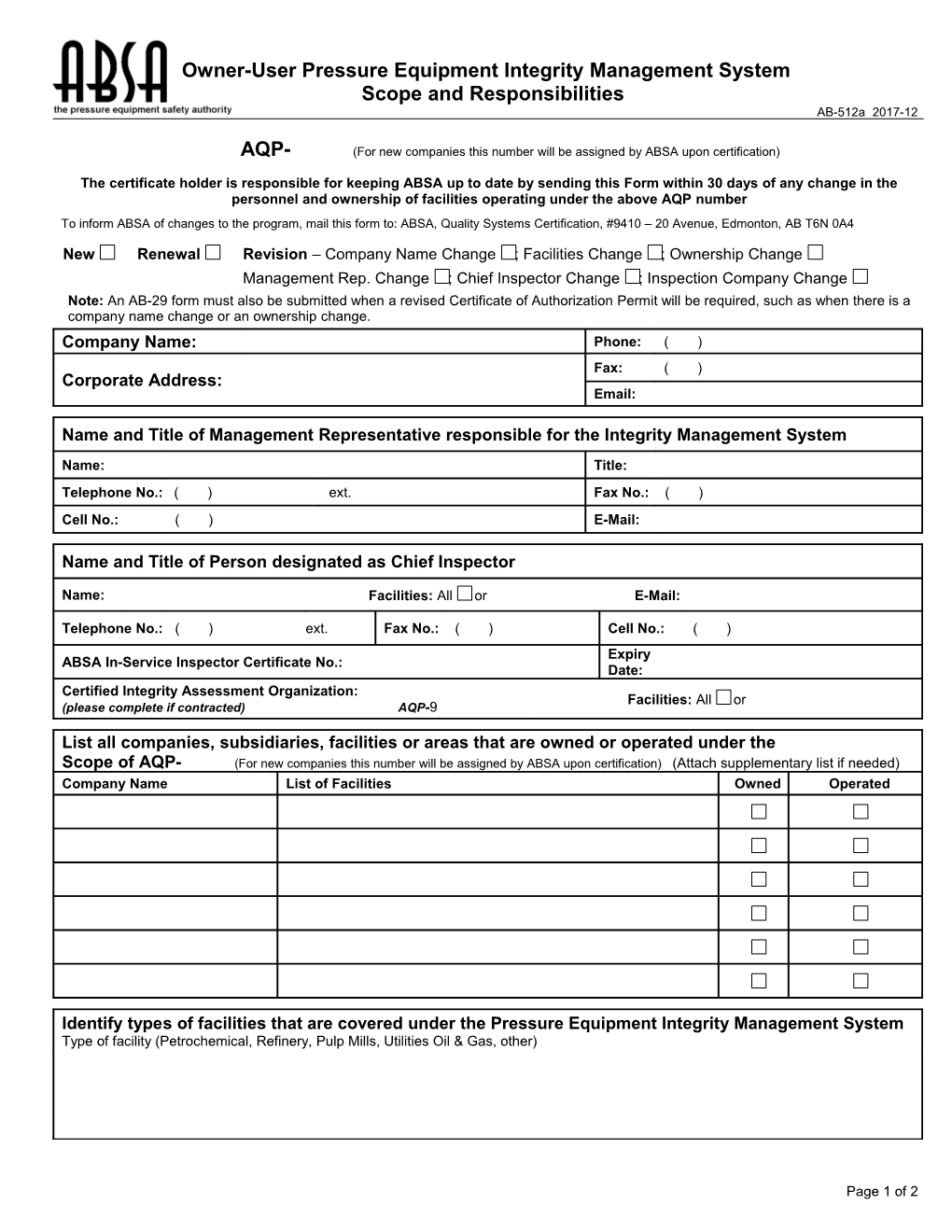

Owner-User Pressure Equipment Integrity Management System Scope and Responsibilities AB-512a 2017-12

AQP- (For new companies this number will be assigned by ABSA upon certification)

The certificate holder is responsible for keeping ABSA up to date by sending this Form within 30 days of any change in the personnel and ownership of facilities operating under the above AQP number To inform ABSA of changes to the program, mail this form to: ABSA, Quality Systems Certification, #9410 – 20 Avenue, Edmonton, AB T6N 0A4

New Renewal Revision – Company Name Change ; Facilities Change ; Ownership Change Management Rep. Change ; Chief Inspector Change ; Inspection Company Change Note: An AB-29 form must also be submitted when a revised Certificate of Authorization Permit will be required, such as when there is a company name change or an ownership change. Company Name: Phone: ( ) Fax: ( ) Corporate Address: Email:

Name and Title of Management Representative responsible for the Integrity Management System

Name: Title: Telephone No.: ( ) ext. Fax No.: ( ) Cell No.: ( ) E-Mail:

Name and Title of Person designated as Chief Inspector

Name: Facilities: All or E-Mail:

Telephone No.: ( ) ext. Fax No.: ( ) Cell No.: ( ) Expiry ABSA In-Service Inspector Certificate No.: Date: Certified Integrity Assessment Organization: Facilities: All or (please complete if contracted) AQP-9

List all companies, subsidiaries, facilities or areas that are owned or operated under the Scope of AQP- (For new companies this number will be assigned by ABSA upon certification) (Attach supplementary list if needed) Company Name List of Facilities Owned Operated

Identify types of facilities that are covered under the Pressure Equipment Integrity Management System Type of facility (Petrochemical, Refinery, Pulp Mills, Utilities Oil & Gas, other)

Page 1 of 2 Owner-User Pressure Equipment Integrity Management System Scope and Responsibilities AB-512a 2017-12

Type of Work: Performed by (indicate ABSA Quality System registration number if covered under a separate certificate) In-House Contracted Engineering Functions Process Design Mechanical Design Technical Engineering Services (materials, corrosion, etc.)

Construction, Repair and Alteration of Pressure Piping Systems (piping, valves, fittings) (In accordance with AB-518 Requirements): - Welded piping, valves, fittings - Mechanically Assembled piping, valves, fittings

Pressure Welder Testing and Pressure Welder PQ Card Issuance Construction of Boilers and/or Pressure Vessels Boiler and/or Pressure Vessel Repairs and Alterations - Performance of Work Pressure Relief Valve Servicing

Replacement in Kind of Mechanically Assembled Pressure Piping Components Yes No (In accordance with the AB-523 Guideline) Alternative Test Methods for Pressure Piping Procedure (In accordance with AB-519 Requirements) Yes No Note: Owner-user inspectors who certify boilers must hold an Alberta in-service Boiler Boiler Certification & Pressure Vessel Inspector Certificate of Competency Owner-User ABSA Formal ABSA accepted RBI program used? Yes No Note: The program must have been audited by ABSA and accepted to meet the requirements of AB-505 A Documented Risk Analysis Process complying with AB-506 Appendix B is implemented? Yes No Inspection intervals for Upstream (E&P Pressure Vessels per API-510) may be assigned based upon AB-506 Appendix B and API 510 Section 9 requirements.

Scope of boiler, pressure vessel, fired-heater pressure coil, indirect fired heater coil, thermal fluid heater and boiler external piping repairs that are inspected and certified by the owner-user (per AB-513). List the types of repairs that are to be inspected and certified by the owner-user and reference the applicable manual section or referred procedures where these are described. Indicate “None” if all repairs are to be certified by ABSA. (Attach supplementary list if needed)

Name of Management Representative or Designate : Please Print

Signature: Date : Signature of Management Rep. or Designate

Page 2 of 2