Monthly report- February 2010

Status of the project: Experiments for lignin weight chemistry, Nitrobenzene oxidation, 2D -NMR (Nuclear Magnetic resonance spectroscopy), TG (Thermogravetometric analysis) and conducted to evaluate the chemical structural changes in the heterogeneous mixture.

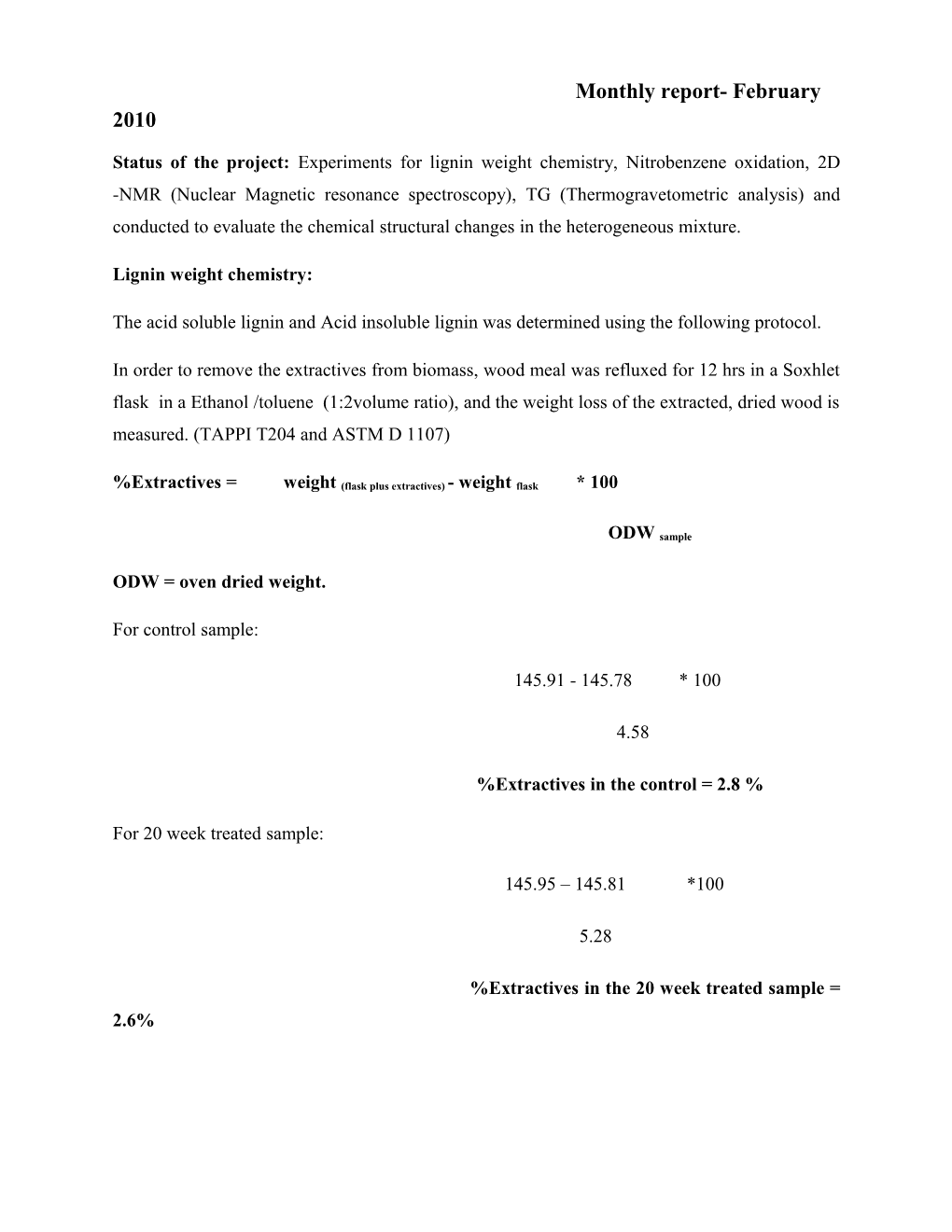

Lignin weight chemistry:

The acid soluble lignin and Acid insoluble lignin was determined using the following protocol.

In order to remove the extractives from biomass, wood meal was refluxed for 12 hrs in a Soxhlet flask in a Ethanol /toluene (1:2volume ratio), and the weight loss of the extracted, dried wood is measured. (TAPPI T204 and ASTM D 1107)

%Extractives = weight (flask plus extractives) - weight flask * 100

ODW sample

ODW = oven dried weight.

For control sample:

145.91 - 145.78 * 100

4.58

%Extractives in the control = 2.8 %

For 20 week treated sample:

145.95 – 145.81 *100

5.28

%Extractives in the 20 week treated sample = 2.6% The sugars were removed from extractive free biomass by two step hydrolysis. Later the acid soluble lignin was analyzed at 205nm.

The data for the sugars and lignin are as follows. Inference from this result: The lignin in control sample is contributed by biomass, where as the acid insoluble lignin was increased with the time scale as biomass is mixed with soil, no reaction is observed after 4 weeks but as the time period increases, there is a reaction between the monomeric lignin units and soil organic matter. As a result the lignin content increased further as the SOM was reacting with lignin.

For the 2-D NMR analysis, pure lignin has to be extracted. Pure lignin has been isolated by using the following protocol:

In order to remove the extractives from biomass, wood meal was refluxed for 12 hrs in a Soxhlet flask in a Ethanol /toluene (1:2volume ratio), and the weight loss of the extracted, dried wood is measured. (TAPPI T204 and ASTM D 1107)The extractive free biomass was autoclaved in 100ml of water after which it was filtered and dried at 570C for overnight. The filtrate was diluted to 20 times and was analyzed for IC. The over dried samples were grinded into fine powder using cryomill. After the Sugar removal by using cellulase enzyme, the precipitate was mixed with doxane and water (96:4) and kept at 370C for two days in shaker. The liquid was centrifuge at 5000k rpm for 10 mins and the supernatant was collected after filtration. The filtrate was sent for freeze dry.

Nitrobenzene oxidation was tried several times, its basically done in order to understand the monomeric units of lignin structure.

But the method requires OIL BATH at constant 1700c and Bombtubes.

TG (Thermogravetometric analysis)

▸ Determine changes in weight in relation to change in temperature.

▸ Analysis is carried out by raising the temperature gradually and plotting weight against temperature. The temperature in many testing methods routinely reaches 650°C or greater

The TG data is analysed by comaparing all the five batch samples in relation to the three phases where in the change in the percentage was calculated. The experiments are conducted for replicates of three for each sample under three different heating rates; 20, 40 and 60. .Results for TG, 2-D NMR are to be analyzed this week.