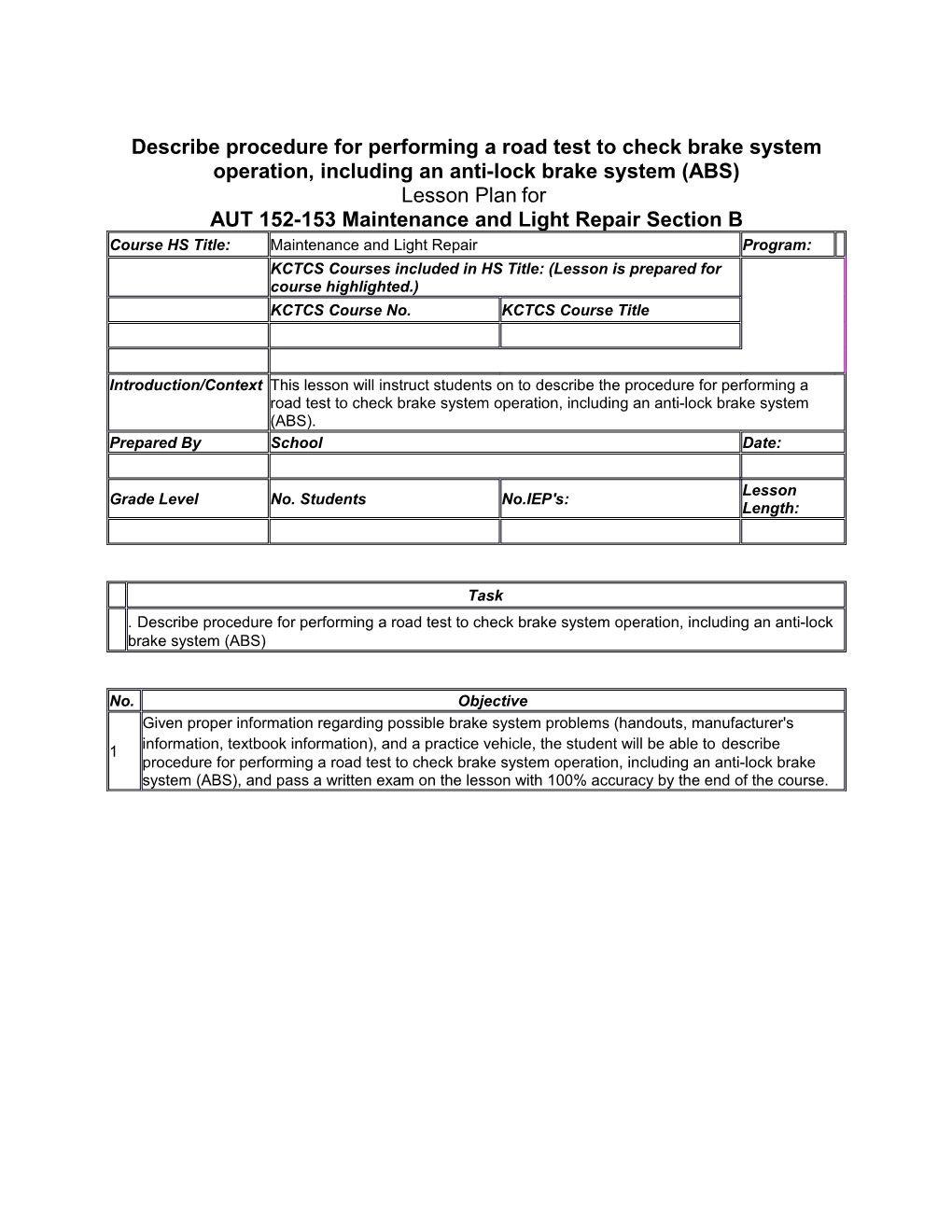

Describe procedure for performing a road test to check brake system operation, including an anti-lock brake system (ABS) Lesson Plan for AUT 152-153 Maintenance and Light Repair Section B Course HS Title: Maintenance and Light Repair Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title

Introduction/Context This lesson will instruct students on to describe the procedure for performing a road test to check brake system operation, including an anti-lock brake system (ABS). Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task . Describe procedure for performing a road test to check brake system operation, including an anti-lock brake system (ABS)

No. Objective Given proper information regarding possible brake system problems (handouts, manufacturer's information, textbook information), and a practice vehicle, the student will be able to describe 1 procedure for performing a road test to check brake system operation, including an anti-lock brake system (ABS), and pass a written exam on the lesson with 100% accuracy by the end of the course. Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-OPS.2 TD-SYS.2 New Common Core State Standards: RST 11-12 3 RST 11-12 2 N-Q-3 N-Q-1 New Generation Science Standards: HS-PS2-1. HS-PS3-3.

INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts Handout/chart listing procedure for road testing, symptoms, and causes for the brake system problems listed in the content/procedure section. Instructor can use the Content/Procedure section to create this handout, or find one in a manufacturer's shop manual

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Automotive Brake Systems (Today's Technician) 2nd Delmar Edition Automotive Excellence,Vol. 1 Glencoe Duffy Modern Automotive Technology Goodheart, Wilcox VanGelder Fundamentals of Automotive Technology 2013 Jones/Bartlett 1071

Equipment Quantity Item Source Content/Presentation/Demonstration Outline

Instruct students that diagnosis usually starts with understanding the customer’s concern. Tell them that communicating directly with the customer is the best way to do that, but also that the customer is not always available. Explain that an experienced service advisor will gather the required information, so they should read the service advisor’s notes on the repair order carefully or speak with them directly. Inform students that once you understand the customer's concern, a test-drive is usually needed to verify the accuracy of the concern. Let them know that this is a good opportunity to test the brakes under a variety of conditions. Tell them replicating the customer concern is important in order to address the situation. Inform students that during the test-drive they should find a safe place to operate the brakes at a variety of speeds with a variety of brake pedal pressures, and try to mimic the conditions the customer described. Explain that it is may be necessary to go on a test drive with the customer driving, allowing them to operate the vehicle in the way that makes the problem evident and point out the particular situation they experiencing. Also, let them know that it is good to have the customer along in case the problem does not occur, that way they won't think you don’t believe them or are ignoring the issue. Instruct students that if there is a concern related to the anti-lock brake system (ABS) that requires a road test, they should use extreme caution. Let them know that ABS only operates under extreme braking or bad traction conditions, they should test the vehicle away from all other traffic, since applying the brakes with enough force to activate the ABS System could result in an accident or the car being rear-ended. Instruct students on some of the brake system concerns they may experience, along with the causes. 1. Brake Vibration: Shows up as chatter, vibration or shake in the brake pedal or steering wheel. Is present only when the brake pedal is applied. Usually, caused by a warped disc/rotor, or an out of round brake drum. Hard spots on the rotor or drum can also cause this problem. Replace or turn rotors or drums to eliminate problem. 2. Grabbing Brakes: Brakes that apply to quickly. Usually caused by brake fluid or grease on the linings, a faulty metering valve, a mechanical problem, or worn brake linings. Replace or repair defective parts. 3. Hard Pedal: A noticeable increase in the amount of pressure needed to apply the brakes. Can be caused by a frozen wheel cylinder or caliper piston, a clogged brake line, a disconnected/clogged brake booster vacuum line or defective booster, and contaminated linings or bad master cylinder. 4. Hard Pedal: A noticeable increase in the amount of pressure needed to apply the brakes. Can be caused by a frozen wheel cylinder or caliper piston, a clogged brake line, a disconnected/clogged brake booster vacuum line or defective booster, and contaminated linings or bad master cylinder. 5. Spongy Brake Pedal: Pedal feels like it is connected to a rubber band or spring. Pedal does not feel solid, but the brakes do apply. Pedal travel will also be further than normal. This is usually caused by air in the brake system. It can also be caused by maladjusted rear brakes and faulty residual pressure check valves. 6. Dropping Brake Pedal: Pedal moves all the way down to the floor when steady pressure is applied to it. Pedal can start out feeling normal, but then may drop. Usually caused by a leak in the master cylinder. Brake fluid is slowly leaking by the piston cups in the unit. Fluid level does not drop. 7. Low Brake Pedal: Pedal travels to far towards the floor before the brakes are applied. Brakes work normally once they are applied. Can be caused by inoperative brake adjusters, maladjusted master cylinder push rod, or a mechanical problem in the wheel brake assemblies. 8. Dragging Brakes: Brakes remain partially applied after the pedal is released. Brakes can overheat if driven too far. Can be caused by frozen wheel cylinder pistons, over-adjusted parking brake, weak return springs, over-adjusted master cylinder push rod, brake fluid contamination, clogged hose or line, stop-lamp switch not adjusted properly, or a problem in the master cylinder such as the cap not venting. 9. No Brake Pedal: No braking action at all. Most likely caused by a leak or driver neglect. (Complete loss of braking is unlikely because of dual master cylinders.) 10. Brake Light On: Indicates an internal leak in the master cylinder, an external leak in the system, unequal pressure in the hydraulic system or the master cylinder. 11. Brake Noise: Some noise is normal, as when the brakes are first actuated in the morning when you first start out. Noises other than normal include grinding sounds that can be caused by metal-to-metal contact due to worn brake linings. The shoe or pad is rubbing on the rotor or drum. Squeaking noises may be caused by glazed (hardened) brake linings, unlubricated brake drum backing plate, foreign material embedded in the linings, or a wear indicator rubbing on the rotor. A rattle may be caused by a missing anti- rattle clip or spring in the brakes. Loose or disconnected parts in the drum brake assembly can also cause a rattle. 12. Instruct students that there may be other causes for many of these problems, but those indicated above are causes directly relating to the brake system.

Applications/Practice Students can practice this task by practicing on shop vehicles when applicable. Instructor can duplicate 1 many of these problems by installing these symptoms into a vehicle and allowing the students to get a “feel” for the problem.

Evaluation and feedback Prior to Testing or Lab Work 1 Objective 1/ Formative assessment / Instructor will observe students as they practice the procedure to assure correct methods and safety practices are being followed. A checklist should be utilized to chart student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1/ Summative assessment / written test questions on stated objective / adaptation and / or accommodations for special needs students will be added if required.

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)