Karen Pierce / Metalsmith THE PROCESS OF MAKING A DOUBLE-WALLED BOWL:

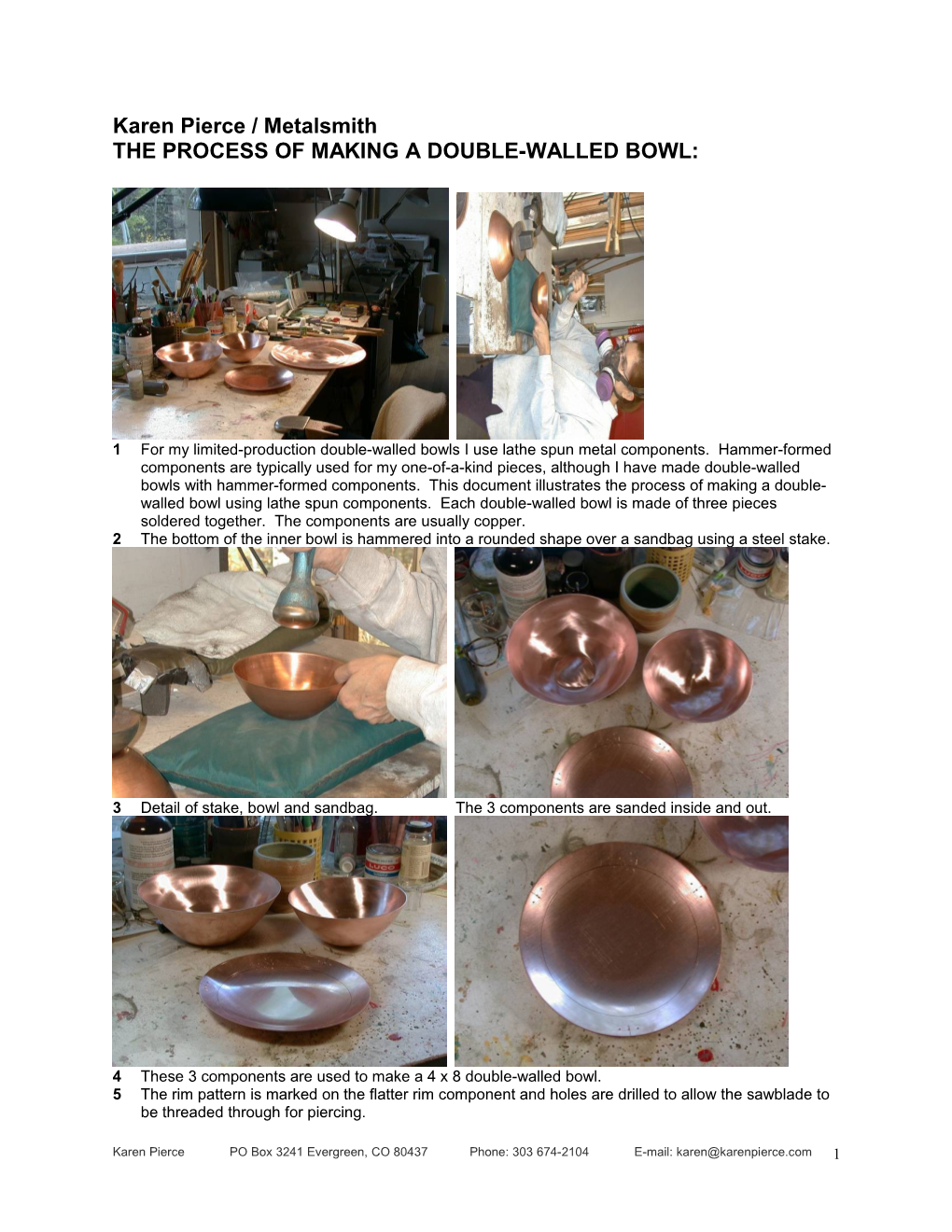

1 For my limited-production double-walled bowls I use lathe spun metal components. Hammer-formed components are typically used for my one-of-a-kind pieces, although I have made double-walled bowls with hammer-formed components. This document illustrates the process of making a double- walled bowl using lathe spun components. Each double-walled bowl is made of three pieces soldered together. The components are usually copper. 2 The bottom of the inner bowl is hammered into a rounded shape over a sandbag using a steel stake.

3 Detail of stake, bowl and sandbag. The 3 components are sanded inside and out.

4 These 3 components are used to make a 4 x 8 double-walled bowl. 5 The rim pattern is marked on the flatter rim component and holes are drilled to allow the sawblade to be threaded through for piercing.

Karen Pierce PO Box 3241 Evergreen, CO 80437 Phone: 303 674-2104 E-mail: [email protected] 1

6 An interior disk is cut away and the pattern is pierced using a jewelers saw. 7 The pierced pattern is then filed using small needle files.

8 The rim is then soldered to the inner bowl. 9 An overlap is necessary for soldering—this overlap is then removed by grinding it away with a grinding wheel.

10 The metal gets hot during grinding and polishing steps—gloves required! 11 If the bowl is to be plated either 24K gold or silver, the surface area that is not to be plated receives 2 coats of a rubber-like masking paint. It is then shipped away for electroplating.

Karen Pierce PO Box 3241 Evergreen, CO 80437 Phone: 303 674-2104 E-mail: [email protected] 2

12 After the inner bowl and rim are soldered and cleaned (and plated) this unit is then soldered to the outer bowl. 13 The overlap allowed for soldering is trimmed away using a Beverly Shear.

14 The outside edge must then be ground smooth. 15 The outside of the bowl and the rim are polished.

16 The interior of the bowl is then prepared for beadblasting (a type of sandblasting using fine glass beads) by masking the rim with tape so that is does not get beadblasted. 17 Beadblasting is done inside a blasting cabinet using compressed air and glass beads.

Karen Pierce PO Box 3241 Evergreen, CO 80437 Phone: 303 674-2104 E-mail: [email protected] 3

18 The piece is then ready to be patinated. If the inside of the bowl is silver it must be masked off, as the chemical used to color the copper a dark color will also color silver a dark color. Gold is unaffected. 19 The patination solution is sulfur based and is dissolved in water. It is rubbed onto the bowl surface using a soft brass brush.

20 After the copper is colored, it is sprayed with a coat of matte finish to protect it. 21 Finally, it is waxed with paste wax.

22 Bowls that are plated have a small area of “overplate” that creeps under the masking. This must be removed by grinding and polishing before this unit is soldered to the outer bowl. The plated area is protected from the grinding/polishing compounds by being covered with plastic and taped along the edge. Soldering, grinding and patination then proceed as above. 23 Single wall bowls that are plated also have this “overplate” which must be removed before patination.

Karen Pierce PO Box 3241 Evergreen, CO 80437 Phone: 303 674-2104 E-mail: [email protected] 4