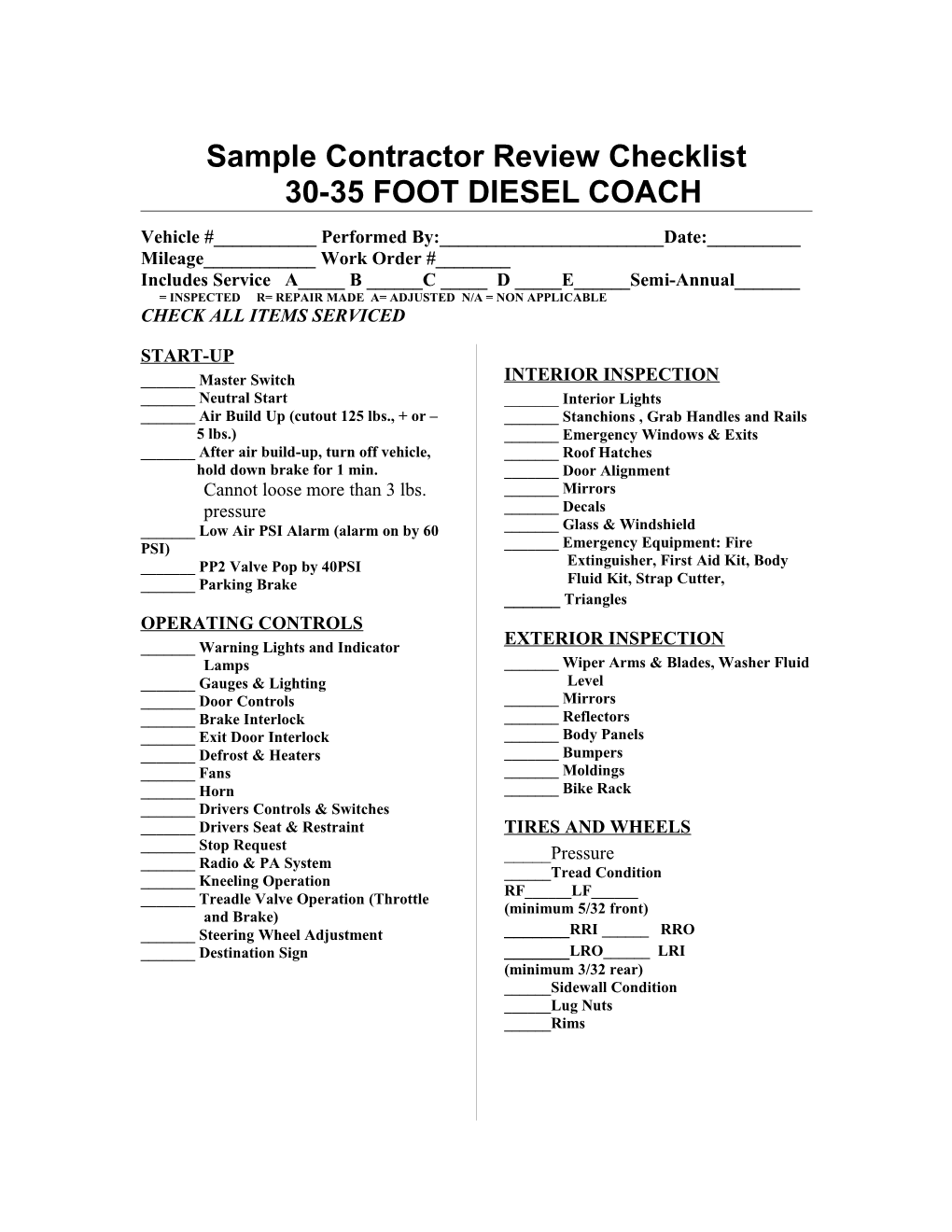

Sample Contractor Review Checklist 30-35 FOOT DIESEL COACH

Vehicle #______Performed By:______Date:______Mileage______Work Order #______Includes Service A_____ B ______C _____ D _____E______Semi-Annual______= INSPECTED R= REPAIR MADE A= ADJUSTED N/A = NON APPLICABLE CHECK ALL ITEMS SERVICED

START-UP ______Master Switch INTERIOR INSPECTION ______Neutral Start ______Interior Lights ______Air Build Up (cutout 125 lbs., + or – ______Stanchions , Grab Handles and Rails 5 lbs.) ______Emergency Windows & Exits ______After air build-up, turn off vehicle, ______Roof Hatches hold down brake for 1 min. ______Door Alignment Cannot loose more than 3 lbs. ______Mirrors pressure ______Decals ______Low Air PSI Alarm (alarm on by 60 ______Glass & Windshield PSI) ______Emergency Equipment: Fire ______PP2 Valve Pop by 40PSI Extinguisher, First Aid Kit, Body ______Parking Brake Fluid Kit, Strap Cutter, ______Triangles OPERATING CONTROLS ______Warning Lights and Indicator EXTERIOR INSPECTION Lamps ______Wiper Arms & Blades, Washer Fluid ______Gauges & Lighting Level ______Door Controls ______Mirrors ______Brake Interlock ______Reflectors ______Exit Door Interlock ______Body Panels ______Defrost & Heaters ______Bumpers ______Fans ______Moldings ______Horn ______Bike Rack ______Drivers Controls & Switches ______Drivers Seat & Restraint TIRES AND WHEELS ______Stop Request _____Pressure ______Radio & PA System ______Tread Condition ______Kneeling Operation RF______LF______Treadle Valve Operation (Throttle (minimum 5/32 front) and Brake) ______Steering Wheel Adjustment ______RRI ______RRO ______Destination Sign ______LRO______LRI (minimum 3/32 rear) ______Sidewall Condition ______Lug Nuts ______Rims WHEELCHAIR LIFT ______Lift Operation BATTERIES ______Warning Light and Alarm or Override ______Terminals & Cables ______W/C Restraints ______Fluid Level ______Clean Tie-down Pocket ______Hold Downs ______Lift Extension Belt (Ricon Lifts Only) ______Door Hinge Stability

ROAD TEST UNDERCARRIAGE ______Acceleration ______Steering Box and Joints ______Engine Performance ______Tie Rod Ends and Drag Links (replace ______Transmission Performance if 1/8” movement) ______Steering Performance ______King Pin Play (max is ¼” at top of tire) ______Braking Performance (Use VC3000 @ ______Shock Absorbers 20MPH) Record G______Suspension: Air Suspension, Radius & Must be 0.5000 or higher to pass Torque Rods, Air Bags brake test. ______Brake Chambers ______Retarder Operation ______Brake Lines ______Brake Diaphragms ______Brake Lining Thickness Ft. ______R ______B Inspection (add the following to the ______Wheel Seals list) ______Check Brake Relay Valve ______Slack Adjusters _____Oil ______Wheel Bearings _____Filter ______Fluid Leaks ______Air Leaks C Inspection (add the following to the ______Fuel Tank: Condition, Mounting, list) Lines & Vents _____Fuel Filter ______Check Air Dryer for Leaks _____Clean Heater Core ______Axles, Differential Oil & Vent (Thomas ONLY) ______Underbody: Mud Flaps, Spray Guards _____Rotate Tires ______Frame Cracks, Loose Crossmembers D Inspection (add the following to the EXHAUST SYSTEM list) ______Hangers ______Mufflers _____Transmission Fluid & Filter ______Pipes _____Replace Air Filter _____Radiator Condition ENGINE COMPARTMENT E Inspection (add the following to the ______Turbo, intercooler piping, clamps and list) hoses ______Hydraulic Fluid _____Inspect Differential Oil ______Coolant Level ______Hoses & Clamps ______Check Belt Tension ______Air Intake (Check trap in duct.) ______Starter Cables ______Run Selenoid Sample Contractor Review Checklist CUTAWAYS

Vehicle #______Performed By:______Date:______Mileage______Work Order#______Includes Service A____B ____C ____ D ____ E____ Semi-Annual______

= INSPECTED R= REPAIR MADE A= ADJUSTED N/A = NON APPLICABLE

CHECK ALL ITEMS SERVICED

OPERATING CONTROLS ______Ignition Switch EXTERIOR INSPECTION ______Neutral Start ______Wiper Arms & Blades, Washer Fluid ______Warning Lights and Indicator Level Lamps ______Mirrors ______Gauges & Lighting ______Reflectors ______Parking Brake ______Body Panels ______Door Controls ______Bumpers ______Brake Interlock ______Moldings ______Exit Door Interlock ______Bike Rack ______Defrost & Heaters ______Curb Feelers ______Fans ______Horn TIRES AND WHEELS ______Drivers Controls & Switches ______Drivers Seat & Restraint ______Pressure ______Stop Request ______Tread Condition RF______LF______Radio (minimum 5/32 front) ______Steering Wheel Adjustment RRI______RRO ______Destination Sign, if applicable LRO______LRI______(minimum 3/32 rear) INTERIOR INSPECTION ______Sidewall Condition ______Lug Nuts ______Interior Lights ______Rims ______Stanchions, Grab Handles and Rails ______Emergency Windows & Exits WHEELCHAIR LIFT ______Roof Hatches ______Door Alignment ______Lift Operation ______Mirrors ______Warning Light and Alarm or Override ______Decals ______W/C Restraints ______Glass & Windshield ______Clean Tie-down Pocket ______Emergency Equipment: Fire ______Lift Extension Belt (Ricon Lifts Only) Extinguisher, First Aid Kit, Body Fluid Kit, Strap Cutter, Triangles UNDERCARRIAGE B Inspection (add the following to the ______Steering Box and Joints list) ______Tie Rod Ends and Drag Links (replace _____Oil if 1/8” movement) _____Filter ______Ball Joints ______Shock Absorbers C Inspection (add the following to the ______Suspension: Air Suspension, Radius & Torque Rods, Air Bags list) ______Brake Lines _____Rotate Tires ______Brake Lining Thickness Ft. ______R ______D Inspection (add the following to the ______Wheel Seals list) ______Wheel Bearings ______Fluid Leaks _____ Replace Air Filter ______Air Leaks _____ Transmission Fluid & Filter ______Fuel Tank: Condition, Mounting, _____ Wheel Bearings Lines & Vents _____ Inspect Differential Oil, change if needed ______Axles, Differential Oil & Vent _____ Fuel Filter ______Underbody: Mud Flaps, Spray Guards ______Frame Cracks, Loose Crossmembers

EXHAUST SYSTEM ______Hangers ______Mufflers ______Pipes

ENGINE COMPARTMENT ______Power Steering Fluid ______Coolant Level ______Brake Fluid ______Hoses & Clamps ______Check Belt Tension ______Starter Cables ______Radiator & Fan Shroud ______Fan

BATTERIES ______Terminals & Cables ______Fluid Level ______Hold Downs

ROAD TEST ______Acceleration ______Engine Performance ______Transmission Performance ______Steering Performance ______Braking Performance (Use VC3000 @ 20MPH) Record G______Must be 0.5000 or higher to pass brake test. Sample Contractor Review Checklist For Agencies with No Maintenance Staff

Physical Inspection 1) Under the hood F. Fire Extinguisher secure and tag A. Belts, frayed not expired. B. Hoses, cracked G. Dash lights all operative, check C. Engine block, clean of oil, all switches for operation, wiper coolant etc. Hood light operative. blades in good condition, washer D. Check all fluid levels oil, coolant, fluid full, horn, backup alarm in power steering fluid. reverse. 2) Exterior Walk-around 4) Wheelchair lift operation A. Fluid leaks under coach. A. Lift clean B. Suspension, coach sagging any B. Check override on lift belt, is direction, check front end bounce up light operating? and down to check shocks on smaller C. Smoothness of operation on lift coaches. Should go down and up outboard barrier. only 1 x. Visual on leaf springs- D. Check override that lift will not nothing hanging that shouldn't be. work without vehicle being in Park C. Obvious cleanliness of coach with Emergency Brake on and W/C D. All exterior lamps working, switch activated at driver seat. clearance, license plate light, tail,turn and 4-ways. Documentation E. Unreported body For each vehicle maintained by the damage/scratches. service contractor: 1) What are the required maintenance 3) Interior Check intervals for the vehicle(s)? A. All interior lights working, including dimmer switch. B. Check all wheelchair tiedowns for cleanliness, proper # of and order of 2) Do the contractor’s records reflect tiedowns. that they are performing preventative C. Seat condition, clean, no cuts or maintenance in a timely manner? stains in vinyl or upholstery. D. Check seats that raise for wheelchair stations for smoothness Comments: of operation. E. First Aid Kit - full, strap cutter, Body Fluid Cleanup - full, triangles neatly folded and secured with proper number needed.