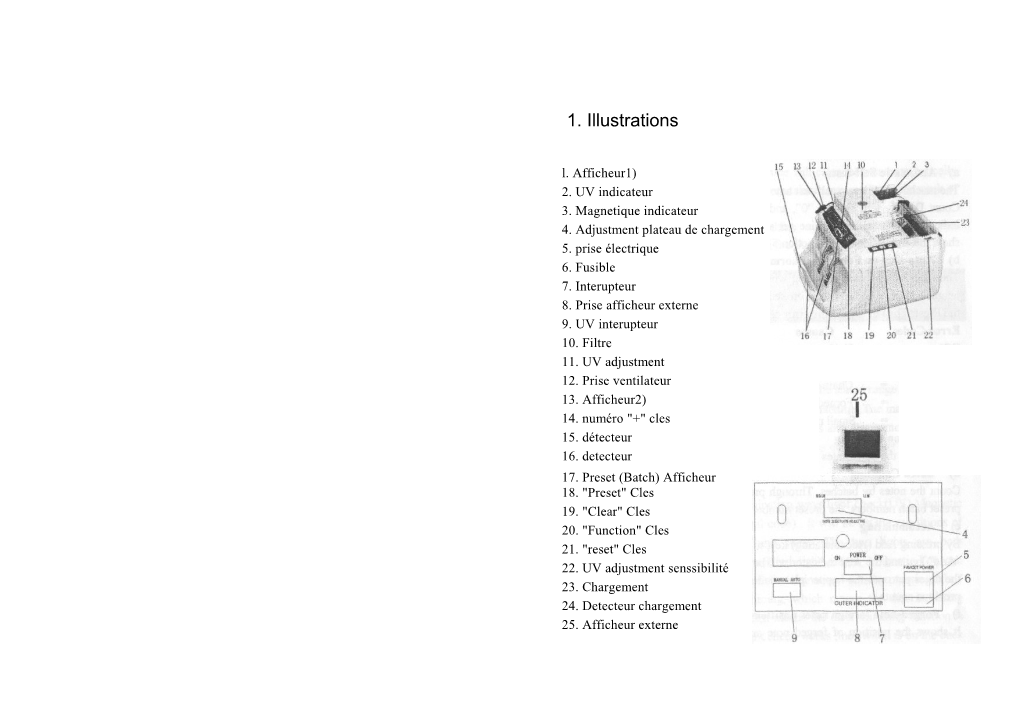

1. Illustrations l. Afficheur1) 2. UV indicateur 3. Magnetique indicateur 4. Adjustment plateau de chargement 5. prise électrique 6. Fusible 7. Interupteur 8. Prise afficheur externe 9. UV interupteur 10. Filtre 11. UV adjustment 12. Prise ventilateur 13. Afficheur2) 14. numéro "+" cles 15. détecteur 16. detecteur 17. Preset (Batch) Afficheur 18. "Preset" Cles 19. "Clear" Cles 20. "Function" Cles 21. "reset" Cles 22. UV adjustment senssibilité 23. Chargement 24. Detecteur chargement 25. Afficheur externe g) Auto-start: 2. Features: The machine will start working automatically when the notes were put onto the Hopper Plate. h) Auto-reset: a) Automatic Self-test: i. Under full range of counting, the machine will clear the sum automatically after the counted notes on the Stacker were taken away, The machine will begin self-test automatically when it was switched on. and another stack of notes were put into the Hopper Plate, The Count Display will show a "0", and the Preset Display shows ii. Under batch counting mode, the machine will clear the sum and reset nothing. UV indicator lights. If the machine got anything wrong, the automatically after the counted notes on the Stacker were taken away. Preset Display will show the error codes (Ref. Section 5). b) Auto-stop on Foreign (abnormal) Notes: The machine will stop counting when it finds forged notes, foreign notes, jammed notes, doubled notes, broken notes, etc. The buzzer will alarm. 3. Operations And the Preset Display shows the error codes. Error Codes Causes EC1 = Half notes. 1) Preparation for operation EC2 = Double notes EC3 = Chain notes i The three cable power socket connected with the machine must be in EC4 = Forged notes good grounding, and Voltage should be with in the stated range. EC5 = Small notes ii .Turn on the power supply and switch on the machine The machine c) Common Counting begin self-test to working conditions for every sensors and electrometer. To count all the bank notes which were put on the Hopper If there were anything wrong, it will show the error codes on the Preset Plate. d) Batch Counting Count the notes by batches. Through preset key and the opposite "+"key Display (As 1-1-2). to preset batch numbers, the preset number is between 1 and 999. e) Accumulating 2) Choice of discriminating ways

By pressing Add (Accumulating) key, to select accumulating function This machine have two discriminating ways: light check(UV),Magnetic (Press "Add" key and the Add Indicator will be on), then the machine (discriminate by magnetic and digital code) . It will be on the conditions of two discrimmating. when the machine starts. The two lights are both will count all the notes put onto the hopper plate and accumulate the shining, green light means light check, red light means Magnetic. You total numbers to the previous counts. can select the combination of two kind of discriminating ways by f) Forged-note foreign notes position pressing "fun" key. The corresponding light is shining, which means the discriminating functions do work, if the light is off it means the It shows the position of forged note and alarm according to condition of discriminating function is closed. When the UV light is on ,light check dividing notes. works the switch is on the back of the machine. Attention: Under the magnetic function, class discrimination means it can Every time the batch numbers were changed, the batch memory will be find small notes from large notes. renewed. 2) Forged (abnormal) notes display: iii. Accumulating

If there are forged, abnormal notes, thered digitron will show. Attention: The panel keys shall be operated when the machine is not counting notes, pressing any keys Press the ADD key, the ADD Indicator will be on. The machine is then when the machine is on working may cause jamming or disorder outing problems. undver accumulating mode, and to accumulate the quantity counted each time. 4) Counting methods Cautions: The panel keys shall be operated when the machine is not counting i. Full notes. Pressing any keys when the machine is on working may cause jamming or Press the Preset key to clear the Preset Display, so as to set the machine at common counting mode. disorder outing problems, Put the notes onto the Hopper Plate, and the machine will start working

automatically. The counting result will be shown on the Count display. Take 4. FUNCTION OF DISCRIMINATION away the notes from the Stacker, and put another stack of notes onto the Hopper Plate, the Count Displayer will reset "0", and the machine will count from "0". i . Fluorescence test If the counted notes were still there on the Stacker, the machine will never Discriminating all the notes. After turning it on heat addition for 3-5 reset and start working, ii. Batch Counting minutes, It is the best discriminating. When discriminating forged-notes, if fluorescence sensitivity is very low. Please adjust the adjust the adjustor of Press Preset key and make the Preset Display to show "000", through sensitivity. opposite key of preset "+"key to preset the batch numbers between 1 and 999. ii. Magnetism and digital test After then, the machine has already been under batch counting function. Put the Discriminating notes with oil throughout magnetism and digital. No notes onto the Hopper Plate, the machine will start counting automatically, When disturbed by man. it comes to the batch number preset beforehand , it will stop automatically. iii. It can test out the money in different width and denomination. Take away the counted notes from the Stacker, the machine will reset and Attention: Take out the following notes avoid appearing error. be ready for a next batching counting. (1) glue notes with white paper (2) notes throught washing If the actual quantity of the notes on the Hopper Plate is less than the batch (3)dirty notes seriously (4) torn notes number as preset, it is necessary to put more notes onto the Hopper Plate, and let the machine finish the counting. 6. 8.Troublesv .Falseness-discriminationNotice Shooting of maintain: and alarm iii.vi, Driving Error partcodes of self-test after turning 5. AdjustmentsTrouble condition on theReason Hopper of trouble Plate Removing method Trouble condition ReasonForeword Removing method HopperError Signals Plate system.:Meaning Solutions Meeting false note alarms Motor control the circuit Check whether the power plate ERO Left CountingToo Sensor much dustdusted; on theCleanClean the orCounting replace Sensor, Cautionbut not :close It must . be turnedgoes wrong,off the machine isand bad andtake repaired out orthe replace Power the automatic note-dropping note-dropping electric brokenor itReplaoe with new one Cablei . The from machine the plug must before be in goodchecking. grounding, Topower make place, the count display electric eye or damaged eye i . a)Note-entering Adjustment part: on the Plate System -- TheER1 chiefWelcome electrical toRight machine, select Counting our Note-goingcomputer Sensor electricalcontrol intelligentCleanCheck the Countingeverydiscriminating- circuit Sensor, from and body. The rated of fuse in the mainframe is "1 A" not be high. brokendusted; or machine connection cut.itReplace withpower new to one electrical Alarm for true note when 1. Fluorescence for true note Reduce ultraviolet sensitivity. TroubleTo adjust condition the HopperReason Adjuster of trouble Screws (As IllustrationRemoving method 2, No. 19). machine, and connect the iifluorescence . After working takereflects off toopower high. socket, clean the machine with a fakeER2 banknote counterHopper series,Sensor which covered are with latest Cleanhigh-tech the Hopperproduct, Sensor, The series dust; or Replacebroken it position b)brush, Adjustment then take the ResistanceTheon frictiondust cap.between Rubber If rubber have -- tyre troubleAdjust theto adjustment ask for screw repairman to to havenote-going many electrical features:broken machine disvriminatingThe capacitor by computer of the with control,full- Replacenew one new capacitor falseness-discrimination . 2. True note with white paper Remove this kind of notes. and ressamce rubber is not add to friction. don'tER3 run Slacker Sensorelectric covered motor with is brokenClean(help the to startSlacker by hand Sensor; to Whenrepair. ever If the Resistancecountenough display hasRubber fluorescentis bad gets then reflection. worn, it out it to is send necessary the factory to screw back, off the automatic,easy to operate,accurate and stable and soprove on. the it iscapacitor one of is the iii. Take on and off is more than 3 second to avoid dispturbing for display. not positioneddust; well; or or it; replaceReposition it with new one HopperCount inexactly Plate screwsCusp and of the rubber Hopper type is wornSpring, Replacereplace new it rubberwith tyrethe spare rubber broken or the electric Dust on the surface detector Clean dust with soft brush.r most.advancedER4 (UV UVbrokenand Sensor efficient covered banknote with counters. dust Cleanmotor the isUV burned Sensor; out attached in the Resistance andrubber external become ultraviolet thin Use the other side or replace one model or The wire circle of motorReplaceReplace it with new electrical pipe. only) broken new one c package The hopper plate spring is too dust the hopper plate sprung to It is suitable for finance,burnedPost, or cut offcommercemachine and Department etc. c fore fit postion TheER5 chief electricalBesmirch machine or eyewinkerDriving belt onis too the old Cleanor Replace the besmirch new driving and belt surface eyewinker c The friction between rubber tyre Adjust the adjustment screw to Pleaseruns, but read note-going the ofinstruction electricalmagnetic carefully head,burned out. before operation so that you can take 9.No wearing alarm for false parts: note when Low ultraviolet sensitivity Adjust the sensitivity a bit c)Please Adjustmentfluorescence pay attention on theand to Plateresistomce the positionSpring rubber -- isof too the Platereduce Springhigher. the friction and the Resistance machine doesn't run, much too tight theIf reins there performance is quality problem best. that you can't solve,please contact our Rubber. The Plate Spring should be 8mm -10mm after the Resistance There is noise from the The driving wheel isn't Let the driving wheel) Note-enteringfalseness-discrimination. is not Cusp of rubberFluorescent type is reflectionworn isReplace newZncrease rubber sensitivitytype of branch office or agents in time, we’ll serve you sincerely. expedite. driving wheels. close to by axletree, so close to axletree, and Rubber.lseness-discrimination. If the distanceResistanceweak is rubber too for falsemuch is worn note short, becomingUse the the fluorescencenotes other sidecan't or replaceremovebe separated onetorn note as to let the axletree tighten the fixed screw resistance rubber black.one smoothly, and if the distance is too much long, then the notes can't go down move left and right. rubber tyre The hopper platesix spring is too just the hopper plate spring to Driving axletree is aged hind fit scion Replace new axletree easily.big driving belt one or worn The notes disorder when e left andUltraviolet right frictions lamp ages or itdurstReplace the two-side lamp positionpipe (ow) of . countingAftersmall above driving mentioned betweenbelt doesn'tresistance adjustments,one light rubber fully. and switchresistance on resistance the machine, rubber a gainuse one iv. Count display part rubber tyre is the above wearing parts are with accessories together.there are Counting Speed >= 900 PCs. piece of note to test the system.different With one end in your hand, let the other Trouble condition Reason of trouble Removing method Abnormal for magneticThe test hopperTom plate notes doesn't and washed tight the andTightenClear the fixedtorn notes screw Banknotes Sizes 115 X 50 ~ 173 X 85 mm alsoend fittings,please go vertically tolookfixed the screwat Feed dutythe packingRollers. list.You will feel a balanced tension on Banknotes1. Hopper Thickness Plate Dust on photosensitized 0.0756. ~pipeHopper 0.015 Clean mmSensor the dust or replace both sides of the Rollers. The gap between the Hopper Plate and the Feed or damaged.. the photosensitized pipe. Face of magnetic head Is bad Washing with water and acky or Hopper2. Plate Capacity Spring old7. 130 Bottom pcs. news Plate 150pcs. Rollersii . Control can note be partadjusted bydirt the and Hopper abrasion Adjust Screws.replace Turn clockwise, will DisplayEnvironmental "0" but not TemperatureIncorrect alignment 0~40Cof Adjust relative position count. photosensitized pipe. between the two counting Trouble condition Reason of trouble Removing method 3. Resistance Rubber 8. 5x5 Pin become tighten, and anti-clockwise, will become loosen. Moisture 40~90% detector, make their light Light spectum test Count magin eye os dirty or Clear or put it right 4. Adjusters 9. Feed Roller keam focusing is not right Power Source AC I 10V(1 ±align 10%), and down.60 Hz(1 ±5%) Note going out is There is worn and rolled Eliminate then count NotPower display Consumption "0" when power line cut away <80W or safety (In operation),Replace power line or note in the counted notes. again. 5. Adjusters Spring 10. Feed Roller Core Netstarting Weight, and motor Gross Weightpipe burned. 7 kg, 7.5 kg same specification safety doesn't run. pipe. Noise 1. adjust the hopper < 60dB(A) plate 1. adjust the hopper plate The note is untidy when Tidy up the notes then Short of crowded. Banknotes driving ways:improperly. rolling placing. place notes 2. there is dust on light counting 2. clean the dust. sensitive tube.