Problem 3-Page 403:

By: Mr. Sukhum Rattanasereekiat Parisay’s comments are in red: Please pay attention to my general guidelines.

Solve Problem 3 on page 403 of your textbook, using WinQSB. Print the solution. Perform only one sensitivity analysis of your choice. Explain your motivation for selecting that sensitivity analysis. Write a report for a manager and explain important findings.

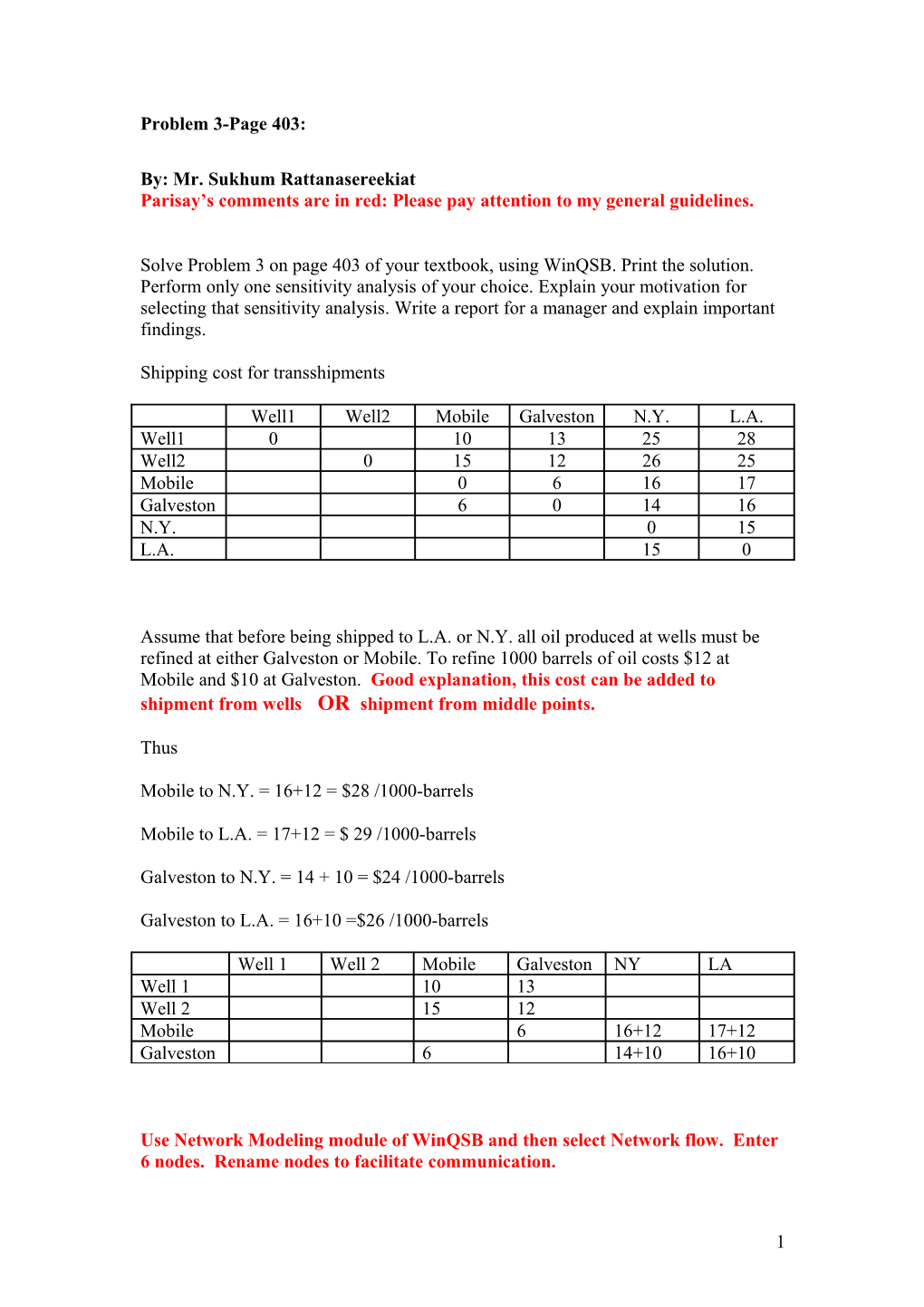

Shipping cost for transshipments

Well1 Well2 Mobile Galveston N.Y. L.A. Well1 0 10 13 25 28 Well2 0 15 12 26 25 Mobile 0 6 16 17 Galveston 6 0 14 16 N.Y. 0 15 L.A. 15 0

Assume that before being shipped to L.A. or N.Y. all oil produced at wells must be refined at either Galveston or Mobile. To refine 1000 barrels of oil costs $12 at Mobile and $10 at Galveston. Good explanation, this cost can be added to shipment from wells OR shipment from middle points.

Thus

Mobile to N.Y. = 16+12 = $28 /1000-barrels

Mobile to L.A. = 17+12 = $ 29 /1000-barrels

Galveston to N.Y. = 14 + 10 = $24 /1000-barrels

Galveston to L.A. = 16+10 =$26 /1000-barrels

Well 1 Well 2 Mobile Galveston NY LA Well 1 10 13 Well 2 15 12 Mobile 6 16+12 17+12 Galveston 6 14+10 16+10

Use Network Modeling module of WinQSB and then select Network flow. Enter 6 nodes. Rename nodes to facilitate communication.

1 Table1: Input Transshipment problem using Win QSB

Table2: Solution by using WinQSB

And its graphical presentation:

Dear Manager,

Based on solution information, total minimum cost is $11,220 and below is our shipment strategy: (First part covers info on Z and Xij.)

2 Well 1 will only produce 100,000 barrels and then ship them to Mobile. After refining at this facility, all 100,000 barrels will be transported to LA. Well 2 will produce 200,000 barrels and then ship them to Galveston and then Galveston will refine all 200,000 barrels, then 60,000 barrels will be shipped to LA to complete its demand of 160,000. The rest of 140,000 barrels will be shipped to NY to meet its demand of 140,000.

(Second part covers info on Si and Dj, extra capacity and unmet demand, unused warehouses, capacity needed at each warehouse for incoming and outgoing items)

All demands are met. We have extra capacity at Well 1 as much as 50,000 barrels. This means either we should not produce that much at Well 1 or try to increase demand. We need a refinery capacity of 100,000 barrels at Mobil and 200,000 barrels at Galveston.

(Third part covers info on “what if”, that is sensitivity analysis, indicate your motivation for sensitivity analysis)

You can perform sensitivity analysis using WinQSB as below:

After solving the problem, select Result in top menu, select “Range of Optimality”. The following table provides information on coefficients of Xij. This is the same as LP and you can apply the same types of analysis here (use my transparency on this topic). For example Galveston to LA has a solution of Xij=60 and its coefficient is Cij=26. The reduce cost is 0, which means it is BV. The allowable range is 13 to 27. You can manually draw a line segment for sensitivity analysis in this range. The slope of this line will be Xij=60 and one point is {Z=11220 and Cij=26}.

You can also use “Perform Parametric analysis” from Result in menu to perform sensitivity analysis. This will provide a wider range of sensitivity analysis, as much as you want. Below I selected the coefficient (cost) of Galveston to LA and

3 the range is -20 below the solution to +30 above the solution with steps of 2. Notice that you can perform Parametric analysis on Arc (coefficient of OF, cost of shipment) or on Node (RHS, capacity of demand or supply point).

4 The result can be presented as table, as below, if selecting “Show parametric analysis- table”.

5 The result can be presented as graph, as below, if selecting “Show parametric analysis- graphic”.

After solving the problem, select Result in top menu, select “Range of Feasibility”. The following table provides information on RHS (capacity of demand and supply points). This is the same as LP and you can apply the same types of analysis here (use my transparency on this topic). For example Shadow Price of Well 1’s capacity is zero which indicates it is a nonbinding constraint (we have not used all the capacity of Well 1). Shadow Price of Well 2 is -1 which indicates that this capacity is a binding constraint (we have used all the capacity of Well 2). Capacity of Well 2 is 200 now and the allowable range is 200-300. You can manually draw a line segment for sensitivity analysis in this range. The slope of this line will be SP=-1 and one point is {Z=11220 and RHS=200}.

Table 3 is the same input data as table 1; however we reduced the cost of shipping from well 1 to Mobile by one dollar. (What is your motivation?)

6 Table 3: input data into WinQSB

Table 4: summary of sensitivity analysis

Report to manager (This report can be improved using the guideline above.)

Dear manager,

Based on costing information, total minimization cost is $11,120 and here is our business strategy when we reduced the cost of shipping from well 1 to Mobile by one dollar. Well 1 will need to produce 150,000 barrels and then ship them to Mobile. After refining at this facility, all 150,000 barrels will transport to LA. Well 2 needs to produce 150,000 barrels and then ship them to Galveston and then Galveston will refine all 150,000 barrels. 10,000 barrels will transport to LA to complete its demand of 160,000. Other 140,000 barrels will ship to NY to meet its demand 140,000. If production at well 2 has a current production level 200,000, there will be extra 50,000 barrels. It means we don’t have to produce all capacity at well2 or we have to look for new demand.

You can see if we reduced the cost of shipping from well 1 to Mobile by one dollar, we need to change transshipment. We increase to ship oil from well1 to Mobile (from 100,000 barrels to 150,000 barrels. Also, we reduce to ship oil from well 2 to Galveston (from 200,000 barrels to 150,000 barrels) and other routes and units of shipment change following the above data. Moreover, Mobile needs a capacity of 150,000 barrels instead of 100,000 barrels and Galveston needs a capacity of 150,000 barrels instead of 200,000 barrels. Total minimization cost will change from $11,220 to $11,120

7