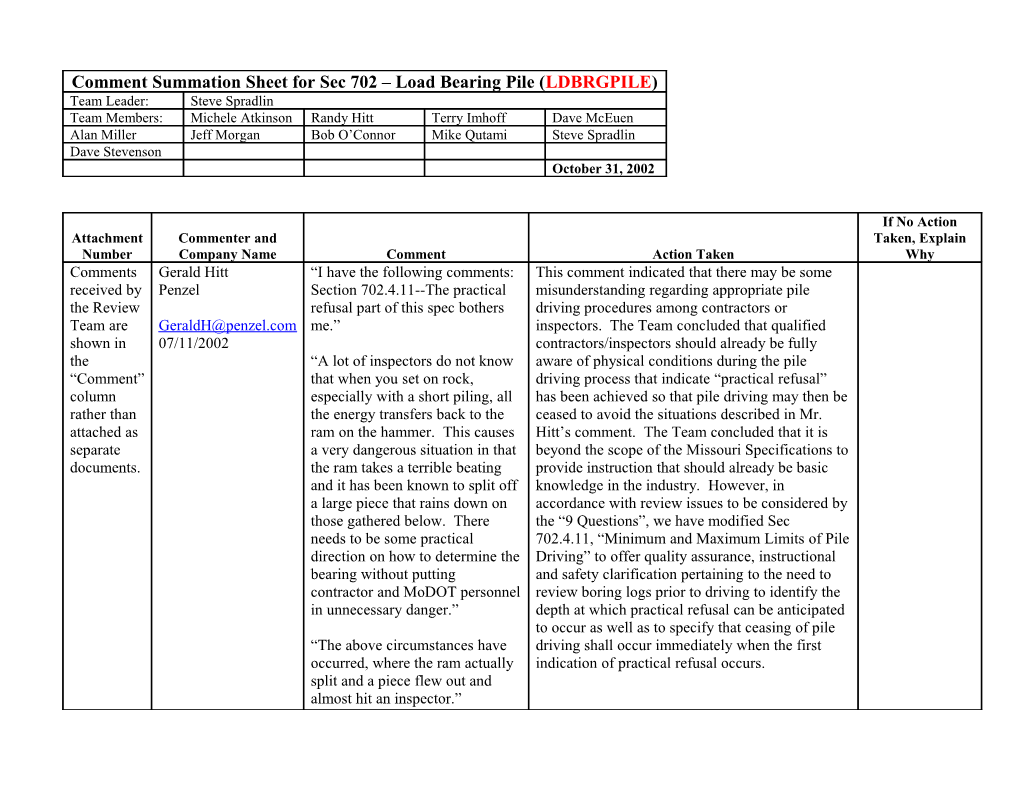

Comment Summation Sheet for Sec 702 – Load Bearing Pile (LDBRGPILE) Team Leader: Steve Spradlin Team Members: Michele Atkinson Randy Hitt Terry Imhoff Dave McEuen Alan Miller Jeff Morgan Bob O’Connor Mike Qutami Steve Spradlin Dave Stevenson October 31, 2002

If No Action Attachment Commenter and Taken, Explain Number Company Name Comment Action Taken Why Comments Gerald Hitt “I have the following comments: This comment indicated that there may be some received by Penzel Section 702.4.11--The practical misunderstanding regarding appropriate pile the Review refusal part of this spec bothers driving procedures among contractors or Team are [email protected] me.” inspectors. The Team concluded that qualified shown in 07/11/2002 contractors/inspectors should already be fully the “A lot of inspectors do not know aware of physical conditions during the pile “Comment” that when you set on rock, driving process that indicate “practical refusal” column especially with a short piling, all has been achieved so that pile driving may then be rather than the energy transfers back to the ceased to avoid the situations described in Mr. attached as ram on the hammer. This causes Hitt’s comment. The Team concluded that it is separate a very dangerous situation in that beyond the scope of the Missouri Specifications to documents. the ram takes a terrible beating provide instruction that should already be basic and it has been known to split off knowledge in the industry. However, in a large piece that rains down on accordance with review issues to be considered by those gathered below. There the “9 Questions”, we have modified Sec needs to be some practical 702.4.11, “Minimum and Maximum Limits of Pile direction on how to determine the Driving” to offer quality assurance, instructional bearing without putting and safety clarification pertaining to the need to contractor and MoDOT personnel review boring logs prior to driving to identify the in unnecessary danger.” depth at which practical refusal can be anticipated to occur as well as to specify that ceasing of pile “The above circumstances have driving shall occur immediately when the first occurred, where the ram actually indication of practical refusal occurs. split and a piece flew out and almost hit an inspector.” Gerald Hitt (Cont’d) “General: The references to This comment was in regard to first draft reference Penzel dynamic testing are understood. to “other methods of testing” that currently are However, it is not clear when the considered to be more modern and reliable. extra testing is absolutely However, the Team subsequently concluded that it required or if it is paid as a bid would be best at this time to eliminate within item or is supposed to be Section 702 specific references to other, more included as incidental.” modern, means of testing. It was determined that if “other methods” are deemed appropriate by the “Either way, the trigger is not design, specific requirements can then be defined so that a bidding identified by means of Job Special Provisions. In contractor would know when to addition, changes in this Section to identify add the extra cost, or which requirements for more modern methods of testing method of extra testing would enter an area of specification development (dynamic or static) is required that is beyond the primary intent of this under what circumstances.” assignment - to review for potential revisions that allow performance-based requirements. Instead, Gerald W. Hitt, P.E. we now indicate in the “rationale” that future MoDOT investigation regarding other methods of testing may be desired.

James Carney “Please check with Harold or Sec 702.4.8, “Protective Coatings” has now been MoDOT Kent since I seemed to have modified to eliminate reference to System G paint 07/11/2002 misplaced my notes on protective and instead, provide reference to calcium sulfonate coatings for H pile. Paragraph coating procedures in accordance with current 702.4.8 refers to using system G practice. and I believe most of the current projects are probably using the calcium sulfonate paint since the system G is more expensive and requires abrasive blasting.” Bernie Mares Steve Spradlin received phone The Team agreed that this was not clearly stated in Versa Steel call requesting clarification of the existing Section 702 and confirmed that the (800) 678-0814 MoDOT existing Section 702 minimum thickness of the pile point’s web or 08/22/2002 requirements for minimum flange is to be measured at the “open end” of the casting thickness of pile point pile point where it attaches to the pile. This reinforcement. The specific clarification has been added to the renumbered question was “where on the pile 702.4.5, “Pile Point Reinforcement” as is currently point for structural steel piles is proposed. the minimum thickness determined?“

(B. Mares had noted that for cast points, the thickness varies from that at the open end to that at the point tip)

Kirsten Munck Various recommended changes to All recommended changes have been made to the MoDOT conform to standard MoDOT document. 07/30/2002 specification formatting.

Also commented on the “System See “Action Taken” discussion above regarding G” protective coating wording in Jim Carney’s similar comment. Sec 702.4.8

Ron Temme A construction-stage question As Paul Kelly has advised Steve Spradlin on MoDOT arose regarding interpretation of 10/30/02, the Review Team is to leave the 10/25/2002 the equation for safe bearing information in this subsection as currently shown value of a battered pile (as shown and submit our final draft of Section 702 when in what is now the renumbered ready. Any needed changes or clarifications to Sec 702.4.10.2) this subsection will be made if determined to be appropriate after further investigation by the Bridge Unit.