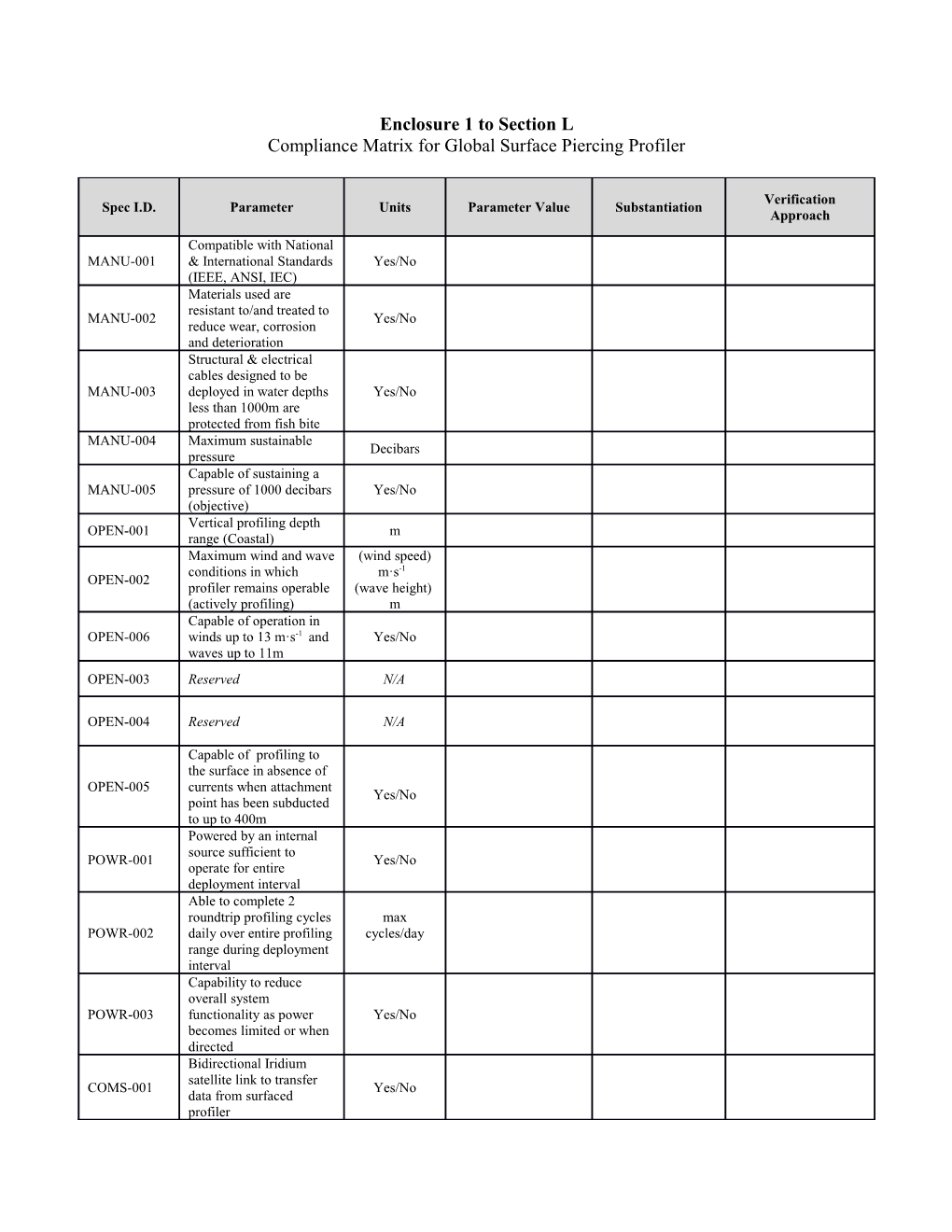

Enclosure 1 to Section L Compliance Matrix for Global Surface Piercing Profiler

Verification Spec I.D. Parameter Units Parameter Value Substantiation Approach

Compatible with National MANU-001 & International Standards Yes/No (IEEE, ANSI, IEC) Materials used are resistant to/and treated to MANU-002 Yes/No reduce wear, corrosion and deterioration Structural & electrical cables designed to be MANU-003 deployed in water depths Yes/No less than 1000m are protected from fish bite MANU-004 Maximum sustainable Decibars pressure Capable of sustaining a MANU-005 pressure of 1000 decibars Yes/No (objective) Vertical profiling depth OPEN-001 m range (Coastal) Maximum wind and wave (wind speed) conditions in which m·s-1 OPEN-002 profiler remains operable (wave height) (actively profiling) m Capable of operation in OPEN-006 winds up to 13 m·s-1 and Yes/No waves up to 11m OPEN-003 Reserved N/A

OPEN-004 Reserved N/A

Capable of profiling to the surface in absence of OPEN-005 currents when attachment Yes/No point has been subducted to up to 400m Powered by an internal source sufficient to POWR-001 Yes/No operate for entire deployment interval Able to complete 2 roundtrip profiling cycles max POWR-002 daily over entire profiling cycles/day range during deployment interval Capability to reduce overall system POWR-003 functionality as power Yes/No becomes limited or when directed Bidirectional Iridium satellite link to transfer COMS-001 Yes/No data from surfaced profiler Verification Spec I.D. Parameter Units Parameter Value Substantiation Approach

Able to send engineering COMS-002 data to shore station via Yes/No iridium satellite link Capability to receive commands from a shore COMS-003 Yes/No station via iridium satellite link Capability to control and COMS-004 monitor telemetry Yes/No subsystem Bidirectional inductive telemetry system to communicate data and COMS-005 Yes/No commands with instruments on the same mooring Sensors are an integral part of the profiler and SENS-001 are provided, installed Yes/No and integrated with each delivered unit Measures conductivity, SENS-002 Yes/No temperature and depth

Measures dissolved SENS-003 Yes/No oxygen Measures Chlorophyll a SENS-004 Fluorescence, and Optical Yes/No Backscatter? Measures Partial Pressure SENS-005 of Carbon Dioxide in Yes/No water Measures multispectral SENS-006 optical attenuation and Yes/No absorption Measures Spectral SENS-007 Yes/No Irradiance SENS-008 Measures Nitrate Yes/No Samples all sensors at SENS-009 least once in every 25 cm Yes/No of vertical travel Capability to monitor SENS-10 orientation (heading, Yes/No attitude) Capability to turn off sensors or instruments DATA-001 Yes/No that malfunction or when commanded from shore Contains a GPS receiver capable of acquiring a fix Yes/No with a minimum of 3 & DATA-002 satellites within 5 minutes Time of surfacing 90% of the (minutes) time Verification Spec I.D. Parameter Units Parameter Value Substantiation Approach

Contains a real time clock that can be synchronized Yes/No DATA-003 to UTC with +/- 1 sec Time(seconds) using GPS receiver Ability to stamp all data with time of acquisition DATA-004 Yes/No obtained from the real time clock Ability to time-stamp all DATA-005 data from sensors in non- Yes/No volatile memory Data storage capacity to store all engineering and DATA-006 sensor data collected Yes/No during the maintenance interval Data and command communication protocol DATA-007 employs an error Yes/No detection/correction protocol Profiler assesses the surface wave conditions by measuring pressure fluctuations, tension, acceleration of the OPSM-001 Yes/No profiler (or other means) and avoids surfacing the sensor package in conditions deemed hazardous to the profiler Profiler responds to commands from a remote shore station via Iridium satellite to change Yes/No OPSM-002 operation of the profiler, sensor package, sensors and telemetry system Capability to control and OSPM-003 monitor vertical velocity Yes/No of sensor package Capability to control and monitor the range of Yes/No OSPM-004 vertical motion of sensor package Capability to control and monitor the data Yes/No OSPM-005 acquisition and storage of sensor data Monitors the health of subsystems and record the time-stamped Yes/No OSPM-006 engineering data in non- volatile memory Verification Spec I.D. Parameter Units Parameter Value Substantiation Approach

Packaging of profiler contains emergency position locator to allow Yes/No OSPM-007 location and recovery if detached from main body Profiler is recoverable and reusable following Yes/No OSPM-008 refurbishment and refueling Science sensors on profilers are user- replaceable in the field Yes/No OSPM-009 with identical spares without requiring opening of pressure housing Science sensor replacement (with identical spares) requires Yes/No OSPM-010 no modification to profiler hardware or software Maximum deployment period before maintenance is necessary Months OSPM-011 (max achievable maintenance interval) Vendor supplies operation manual(s) detailing operation, Yes/No OSPM-012 maintenance, handling, shipping Profiler is deployable by Yes/No OSPM-013 UNOLS ships Vendor provides mission planning tool to provide estimate of energy usage Yes/No OSPM-014 as a function of sensor payload, and sampling interval Mission planning tools available to estimate energy usage as a function of profiling Yes/No OSPM-015 speed, vertical profiling speed, current speed and in situ water density Mission planning tool provides estimate of data storage needs as function Yes/No OSPM-016 of sensor payload and sampling interval Mission planning tool monitors power usage of deployed profiler and OSPM-017 Yes/No provides estimates of capacity remaining Verification Spec I.D. Parameter Units Parameter Value Substantiation Approach

Mission planning tool monitors data storage usage of deployed Yes/No OSPM-018 profiler and provides estimates of capacity remaining Mission planning tool provides estimates if telemetry bandwidth requirements as function OPSM-019 Yes/No of sensor payload, sampling interval, data decimation options Vendor provided modeling tool to predict Yes/No influence of ocean Drag currents on profiling coefficients, range of profiler. May OPSM-020 wetted areas, assume uniform, other unidirectional currents. assumptions Tabulation or datasheet is acceptable Yes/No Profiler manufactured in Records of accordance with QA tests shall QUAL-001 manufacturer’s best be available practices for review Certificate of Compliance provided containing: Factory Acceptance Test and calibration records, Yes/No QUAL-002 following each sensor’s integration with the profiler ISO-9001:2008 certified QUAL-003 quality management Yes/No system (objective) Profiler can be provided with a custom, indelible Yes/No IDNT-001 mark on exterior surface Transportation cases provided and include Yes/No IDNT-002 external labels specifying safe handling precautions Storage temperature (w ithout damage or Yes/No SHIP-001 degradation to profiler) °F, days between 0°F and 120°F for up to 1 year Transportation cases survives shipping conditions in ASTM Yes/No SHIP-002 D4169 truck Assurance Level 1 Transportation cases reusable via commercial Yes/No SHIP-003 carriers specified in contract or purchase order Enclosure 2 to Section L (will become Section J, Attachment #7 of the Contract) (See L-8.2, Volume I – A. Technical Approach for details)

Proposed Instrument Models

Contractor Instrument Make and Model Number or Instrument Type Specification Designation CTD Version 2-00 Document Control Number 1331-00001 2011-03-10 DO Version 2-00 Document Control Number 1331-00002 2011-03-04 Multiple Version 2-00Document Wavelength Control Number 1331- Fluorometer/Optica 00003 2011-02-15 l Backscatter Partial Pressure of In water, Version 1-00 Carbon Dioxide Document Control pCO2 Number 1331-00012 2011-04-16 Optical Attenuation Version 1-00 Document and Absorption Control Number 1331- 00007 2010-11-16 Spectral Irradiance Version 1-00 Document Control Number 1331- 00006 2010-12-10 Nitrate Version 1-00 Document Control Number 1331- 00014 2011-03-02