Engineering Policy Subcommittee: Tabled 11/14/02, Approved 11/22/02 Rev 02-0730E Engineering Policy Committee: Approved 2/24/03 Submitted by Construction & Materials Director’s of Operations & Project Dev.: Tabled 4/14/03, Approved 11/10/03 Team Leader: Pat McDaniel Chief Engineer: 12/11/03 11/10/03

Team Members Roger Baldwin, Hancor Dan Currence, ADS Dale McKay, Hancor Mark Shelton, MoDOT Dan Tschirgi, MoDOT Troy Clifford, Hancor Patrick Collings, ADS

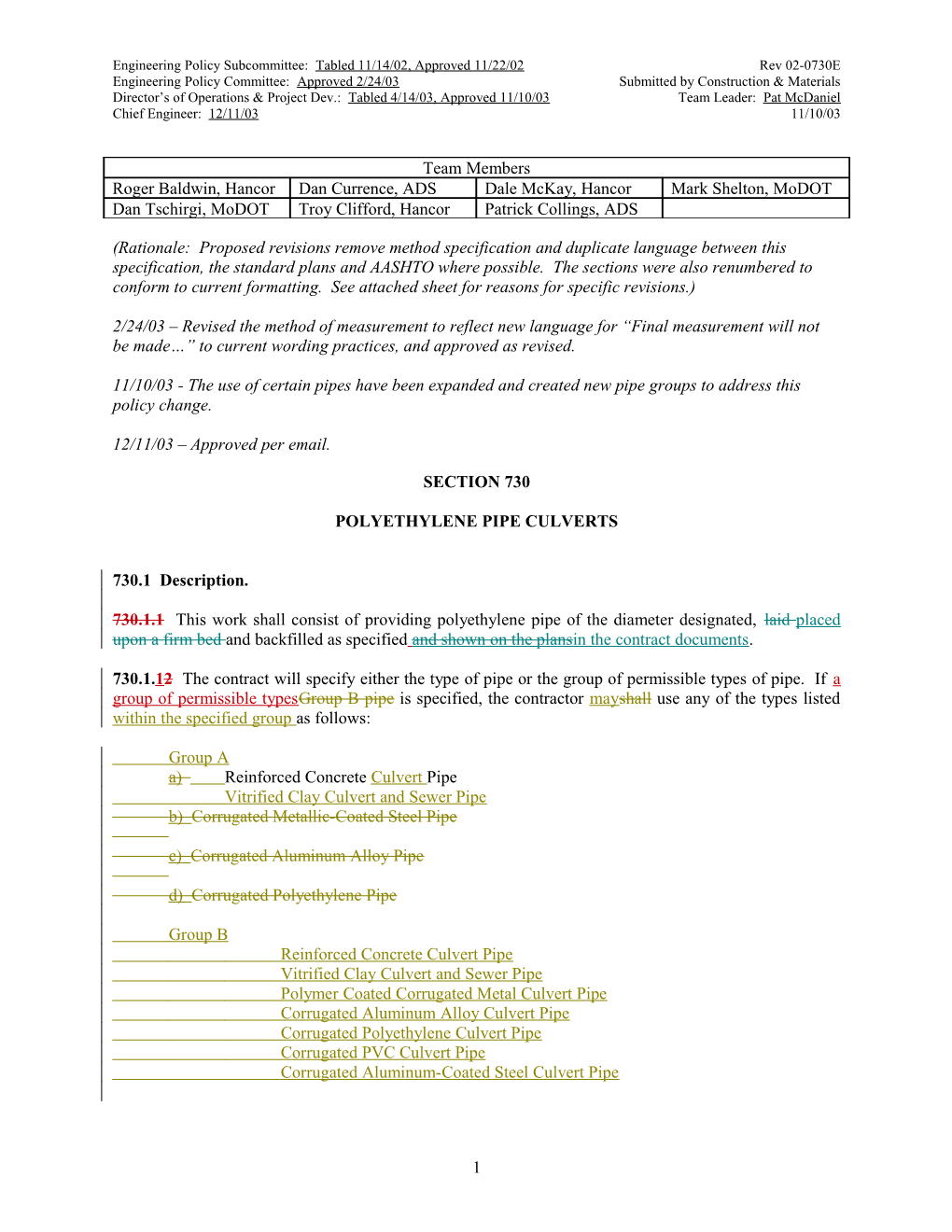

(Rationale: Proposed revisions remove method specification and duplicate language between this specification, the standard plans and AASHTO where possible. The sections were also renumbered to conform to current formatting. See attached sheet for reasons for specific revisions.)

2/24/03 – Revised the method of measurement to reflect new language for “Final measurement will not be made…” to current wording practices, and approved as revised.

11/10/03 - The use of certain pipes have been expanded and created new pipe groups to address this policy change.

12/11/03 – Approved per email.

SECTION 730

POLYETHYLENE PIPE CULVERTS

730.1 Description.

730.1.1 This work shall consist of providing polyethylene pipe of the diameter designated, laid placed upon a firm bed and backfilled as specified and shown on the plansin the contract documents.

730.1.12 The contract will specify either the type of pipe or the group of permissible types of pipe. If a group of permissible typesGroup B pipe is specified, the contractor mayshall use any of the types listed within the specified group as follows:

Group A a) Reinforced Concrete Culvert Pipe Vitrified Clay Culvert and Sewer Pipe b) Corrugated Metallic-Coated Steel Pipe

c) Corrugated Aluminum Alloy Pipe

d) Corrugated Polyethylene Pipe

Group B Reinforced Concrete Culvert Pipe Vitrified Clay Culvert and Sewer Pipe Polymer Coated Corrugated Metal Culvert Pipe Corrugated Aluminum Alloy Culvert Pipe Corrugated Polyethylene Culvert Pipe Corrugated PVC Culvert Pipe Corrugated Aluminum-Coated Steel Culvert Pipe

1 Group C Reinforced Concrete Culvert Pipe Vitrified Clay Culvert and Sewer Pipe Polymer Coated Corrugated Metal Culvert Pipe Corrugated Aluminum Alloy Culvert Pipe Corrugated Polyethylene Culvert Pipe Corrugated PVC Culvert Pipe Bituminous Coated Corrugated Metal Culvert Pipe Corrugated Aluminum-Coated Steel Culvert Pipe Corrugated Zinc-Coated Steel Culvert Pipe

730.1.23 If the contract specifies corrugated polyethylene pipe, or if the contract specifies pipe culverts by group and the contractor elects to furnish corrugated polyethylene pipe, the allowable overfill height shall be in accordance with the plans, unless otherwise specified. Minimum cover will be measured as shown on the plansfrom the top of the pipe to the bottom of the pavement.

730.1.34 If the contract specifies pipe culverts by group and the contractor elects to furnish metal pipe, the culvert shall be constructed in accordance with Sec 725. If the contractor elects to furnish concrete or vitrified clay pipe, the pipe culvert shall be constructed in accordance with Sec 726. If the contractor elects to furnish corrugated PVC pipe, the pipe culvert shall be constructed in accordance with Sec 728.

730.1.5 The size and shape of the corrugation and thickness of wall shall not be changed throughout the length of any individual pipe culvert.

730.1.46 The type of pipe permitted in extending an existing pipe shall be equivalent to the existing pipe, and if different from the existing pipe, shall be approved by the engineerthe same type as used in place, except as otherwise specified in the contract, or unless prohibited by any of the requirements set out herein.

730.1.4 Pipe used for storm sewers may be any of the pipe listed under Group B pipe, with the following exceptions. All corrugated metal culvert pipes shall be Type IA or Type IR. Sewer pipe placed beneath the paved portion of roadways with average daily traffic greater than 3500 vehicles per day shall be either reinforced concrete pipe or vitrified clay sewer pipe. No other substitutions will be allowed, regardless of what type or group of pipe is specified for storm sewers outside of the paved portion for these roadways.

730.2 Material.

730.2.1 All material shall conform tobe in accordance with Division 1000, Materials Details, and specifically as follows:

Item Section Metallic-Coated Steel End Sections 1020 Precast Concrete Flared End Sections 1032 Corrugated Polyethylene Pipe 1047

730.3 Construction Requirements.

730.3.1 Handling. All pipe shall be unloaded and handled with reasonable care to avoid damage. The pipe shall not be dropped or dragged. Tie down straps or bands shall not be removed until the pipe has been secured to prevent rolling or dropping the pipe. Pipe shall be stockpiled on level ground, and if stacked, blocking shall be provided to prevent rolling. Stacked pipe shall be placed with bells alternated

2 on successive layers, and the bells shall overhang the layer to prevent deforming the bell. The protective wrap on the gaskets of the spigot end shall be left on the pipe until it is ready for installation. Damaged pipe, unless repaired to the satisfaction of the engineer, will be rejected at the site and shall be repaired or replaced to the satisfaction of the engineer at the contractor’s expense.

730.3.24 Laying.

730.3.24.1 Flexible pipe shall be carefully laid true to lines and gradesas shown on the plans, with bell ends upstream and with the spigot end entered the full length into the adjacent section of pipe. If the pipe is to be laid below the ground line, a trench shall be excavated to the required section and depth to permit required compaction of the backfill under the haunches and around the pipe. Any pipe which is not in true alignment or which shows any undue settlement after laying, but before the fill is placed, shall be taken up and relaid at the contractor's expense. If shown on the plans or directed by the engineer, camber shall be built into the pipe structure to allow for settlement from fill loads.

730.3.24.2 Joints shall be soiltight unless otherwise specified. Joints shalland shall be installed so such that the connection of pipe sections will form a continuous line free from appreciable irregularities in the flow line. Suitable fField joints can may be obtained with the following types of connections: corrugated bands, double bell couplings, bell and spigot pipe ends with rubber o-ring gasket meeting ASTM F 477 or an alternative connection approved by the engineerdouble bell couplings.

730.3.35 Bedding & Backfill Material.

730.3.35.1 Backfill material for polyethylene pipe shall consist of gravel, sand, or sandy silt soil as shown on the plans. Backfill shall be free of organic material, stones larger than 1.5 inches (38 mm) in greatest dimension, or frozen clumps.

730.3.35.1.1 Gravel and sand shall consist of a well-graded mixture of stone fragments, gravel and sand and shall meet the requirements ofbe in accordance with AASHTO M 145, classification Al or A3.

730.3.35.1.2 Sandy silt soil shall consist of non-plastic granular material with silt content higher than that of gravel or sand and shall meet the requirements ofbe in accordance with AASHTO M 145, classification A2-4 or A2-5.

730.3.35.2 Bedding material (material between the bottom of the trench and the bottom of the pipe) shall have a maximum particle size of 1.25 inches (30 mm). Backfill shall be free of organic material, stones larger than 1.5 inches (38 mm) in greatest dimension, or frozen clumps.

730.3.46 Installation.

730.3.46.1 Trench Requirements. The pPipe shall be installed in a trench whether installed below grade or in an embankment. The construction sequence shall be as shown on the plans. When pipe is installed in an embankment, the embankment shall be placed and compacted to the required density to a minimum elevation of one foot (300 mm) above the top of pipe before a subtrench is excavated. The bedding backfill shall be placed to the required thickness and grade taking care to avoid compaction of the bedding backfill under the middle one third of the pipe. The beddingbackfill outside the middle one third of the pipe shall be compacted to the required density shown on the plans before placing the pipe. The pipe shall be installed to grade according to Sec 730.4. Special care shall be taken to properly compact theCompaction of backfill material under the haunches of the pipe shall be accomplished without disturbing the pipe alignment.

3 730.3.46.2 Bedding in Unsuitable Material. If rock is encountered, the bedding depth shall be increased to 6 inches (150 mm) below the bottom of the pipe. If soft, spongy or unstable material is encountered, ithe material shall be removed and excavated to a minimum depth of 6 10 inches (1250 mm) below the bottom of the pipe and replaced with a suitable granular material. Payment for removal of unsuitable material and for backfilling will be made in accordance with Sec 206.6.3, unless the unsuitable material is a result of the contractor's operations, in which case the removing and backfilling shall be at the contractor's expense.

730.3.46.3 Backfilling. Backfilling shall be completed as soon as possiblepractical. Suitable backfill material free from large lumps, clods or rocks, shall be placed alongside the pipe and compacted as shown on the plans. in loose layers not exceeding 8 inches (200 mm) thick. Each 8-inch (200 mm) layer shall be thoroughly compacted to the same density required for the adjacent embankment or to a minimum of 90 percent standard density. Backfill material may be moistened to facilitate compaction. The placement of the remainder of the backfill shall be conducted in a manner to prevent misalignment of the pipe and in accordance with Sec 203.to at least 1 foot (300 mm) above the top of the pipe shall be brought up evenly on both sides of the pipe by working backfill operations from side to side. The side to side backfill differential shall not exceed 24 inches (0.6 m) or 1/3 of the size of the pipe, whichever is less. Additional backfill shall be provided as necessary. Backfill shall be compacted to a minimum of 90 percent standard maximum density or otherwise specified embankment density.

730.3.46.4 Construction Loading. Before heavy construction equipment is operated over the pipe, the contractor shall provide an adequate depth and width of compacted backfill or other cover to protect itthe pipe from damage or displacement as shown on the plans. Any damage or displacement shall be repaired or corrected at the contractor's expense.

730.3.46.5 Pipe Plugs. The ends of all pipe stubs for future connections at inlet and manhole structures and of all pipe installed as a portion of future sewers shall be sealed with suitable plugs. The plugs shall be installed in a manner preventing infiltration of dirt into the pipe. No direct payment will be made for furnishing and installing plugs.

730.3.4.6 Skewed Ends. A pipe end may be cut to a The maximum angle of 10 degrees a pipe end may be cut to provide a skewed end shall be 10 degrees.

730.73.5 Inspection. The internal diameter of the barrel shall not be reduced by more than 5% percent of itsthe pipe’s base specified inside diameter when measured not less than 30 days following completion of installation. After the roadway has been completed and before final acceptance of the project, Tthe engineer will select no less than 10 percent of the installed pipe for deflection inspection for proper installation. A more extensive inspection will be conducted if pipe is found to be improperly installed. If deflections greater than 5 percent are found, a more extensive inspection will be conducted. Any section of pipe with deflections greater than 5 percentfound to be improperly installed shall be replaced or repaired by the contractor at the contactor’s expense and to the satisfaction of the engineer. Repaired or replaced pipe will be retested as deemed necessary by the engineer. The contractor shall provide equipment and assistance as deemed necessary by the engineer to perform the deflectionany testing. Pipe deflections will be determined by the engineer by having the contractor pushing or pulling a mandrel through the pipe. Mandrels used for deflection testing may have either fixed or adjustable arms, but shall be approved by the engineer prior to use. The following will constitute improper installation:

(a) If alignment is in excess of 15 percent, will restrict flow or will cause excessive ponding within the pipe.

(b) Any section of pipe with deflections greater than 5 percent.

4 (c) If settlement is greater than one inch (25 mm) at five percent or more joints.

(d) If the pipe shows evidence of being crushed at any location.

(e) If the pipe shows evidence of joint separation.

730.48 Method of Measurement.

730.730.4.18.1 Measurement of flexible pipe, complete in place, will be made to the nearest foot (0.5 m) along the geometrical center of the pipe. Final measurement will not be made except for authorized changes during construction, or where appreciable errors are found in the contract quantity. The revision or correction will be computed and added to or deducted from the contract quantity. Where required, measurement of flexible pipe, complete in place, will be made to the nearest foot (0.5 m) along the geometrical center of the pipe.

730.4.28.2 Excavation for placing pipe, pipe-arches, corrugated metal drop inlets and metal curtain walls will not be measured, except when excavation of the installation is shown on the plans. Excavation for placing pipe, pipe-arches, corrugated metal drop inlets and metal curtain walls will be measured and paid for as Class 3 Excavation in accordance with Sec 206.

730.59 Basis of Payment.

730.59.1 The accepted quantities of pipe, complete in place, including all necessary tees, bends, wyes, cutting and joining new pipe to existing pipe unless otherwise specified, will be paid for at the contract unit price for each pay item included in the contract. The accepted quantities of pipe by groups will be paid for in accordance with the item numbers, pay items and pay units listed.

730.59.2 Unless specified otherwise, N no direct payment will be made for the following:

(a) mMaterial or work required for placing couplings on exposed ends of the pipe.

(b)730.9.3 No direct payment will be made for anyRequired bBackfilling, required except as specified in Sec 206.6.3.

(c)730.9.4 No direct payment will be made for the cConstruction of bedding or for bedding material. (d) Work or equipment to perform deflection testing.Trench excavation and backfilling, except when Class 3 Excavation is shown on the plans for a given pipe location. When shown on the plans, payment for Class3 Excavation will made in accordance with Sec 206.

5