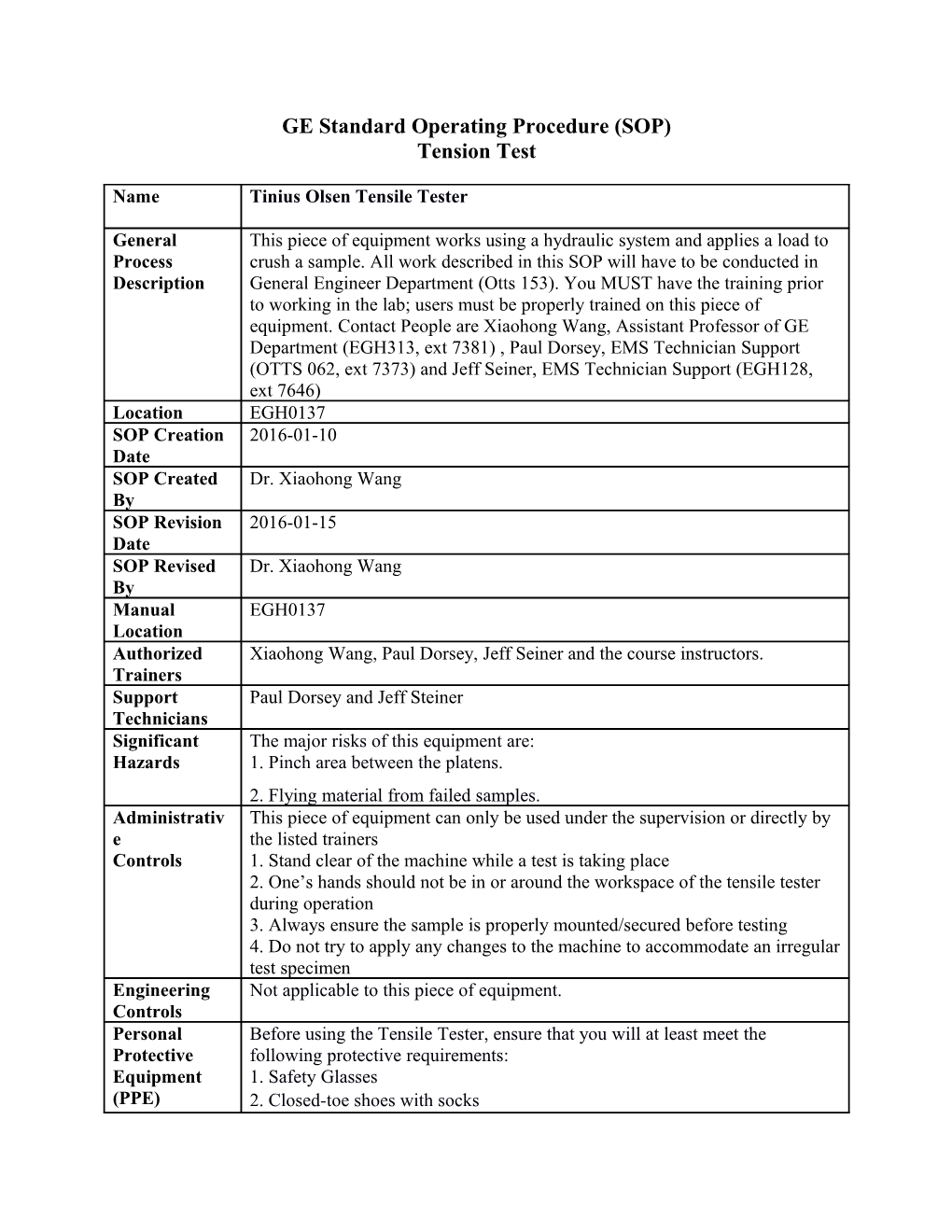

GE Standard Operating Procedure (SOP) Tension Test

Name Tinius Olsen Tensile Tester

General This piece of equipment works using a hydraulic system and applies a load to Process crush a sample. All work described in this SOP will have to be conducted in Description General Engineer Department (Otts 153). You MUST have the training prior to working in the lab; users must be properly trained on this piece of equipment. Contact People are Xiaohong Wang, Assistant Professor of GE Department (EGH313, ext 7381) , Paul Dorsey, EMS Technician Support (OTTS 062, ext 7373) and Jeff Seiner, EMS Technician Support (EGH128, ext 7646) Location EGH0137 SOP Creation 2016-01-10 Date SOP Created Dr. Xiaohong Wang By SOP Revision 2016-01-15 Date SOP Revised Dr. Xiaohong Wang By Manual EGH0137 Location Authorized Xiaohong Wang, Paul Dorsey, Jeff Seiner and the course instructors. Trainers Support Paul Dorsey and Jeff Steiner Technicians Significant The major risks of this equipment are: Hazards 1. Pinch area between the platens. 2. Flying material from failed samples. Administrativ This piece of equipment can only be used under the supervision or directly by e the listed trainers Controls 1. Stand clear of the machine while a test is taking place 2. One’s hands should not be in or around the workspace of the tensile tester during operation 3. Always ensure the sample is properly mounted/secured before testing 4. Do not try to apply any changes to the machine to accommodate an irregular test specimen Engineering Not applicable to this piece of equipment. Controls Personal Before using the Tensile Tester, ensure that you will at least meet the Protective following protective requirements: Equipment 1. Safety Glasses (PPE) 2. Closed-toe shoes with socks 3. Long pants (no shorts!) 4. Safety Shield (optional) Although not required having a second person working with you would be better if an injury was to occur. Before proceeding you must have read and are familiar with the safe operations of the Tensile Tester. Special When placing the sample in between the platens MAKE sure that the valve for Handling the Load is completely closed. If possible use a push bar or some other type to Procedures place the sample in between the platens. Make sure that there are no apparent and Storage leaks from the hydraulic system. Requirements Accident If you are injured; depending on the severity of the injury either go to the Procedures Technical staff for first aid and fill out a incident report or if the injury is severe call (need to check) and receive medical attention immediately. If an injury does occurs, make sure the Tensile Tester is shut off (and locked down), do not clean the area if an accident occurs, the emergency response team must assess the accident scene to assess what occurred, leave the room and call immediately, and Laboratory Manager (this part needs to check) Emergency Switch off the power button on the back of the machine Shutdown Procedure Waste Not Applicable Disposal Training Prior to entering and working in the laboratory, you must have completed the requirements training. Any person conducting work in EGH0137 using this SOP must receive specific training on the contents of this SOP. Approval All faculty, teaching staff and students must be trained prior to starting work Required with the Tensile Tester. If working after hours you have to ask for approval from your Supervisor and the Person In-charge, Laboratory Manager Ed McCaffery. Start-up Make sure before entering that you are wearing all PPE Procedure 1. Using a gage punch and a hammer, make notches (which are 2 inches away from each other) on a specimen. 2. Measure the gage length (already marked by notches) and the diameter of the specimen using a caliper. 3. Prepare machinist scales in 0.05 inch increment using a caliper 4. Set up the data acquisition system. Switch on main electrical outlet by pulling lever up (located on the back of the machine) Switch on power strip for computer Inspect the equipment for any defects or leaks Make sure the (LOAD) valve is completely closed. Press the (START) button to turn on the Hydraulics Move the upper Platen either up or down (“RAISE or LOWER” push buttons) to allow the user to place the sample onto the lower platen without being in danger of pinching their hands. Push the upper pin hold. Rotate and grip the top head of the specimen till one or two threads can be seen. Screw the tail end of the specimen at the lower grip. Be careful not to over tighten the specimen so that there is no overloading. Attach the extensometer on the specimen to measure elongation

Operating Run the tensile test machine Procedure Choose the appropriate load range with the “SELECTORANGE”. Slowly open the (LOAD) valve to apply pressure. Once the specimen reaches its proportional limit, tensile machine stops and asks to remove the extensometer. After extensometer is removed, monitor the elongation of specimen. When the gage length reaches the preset machinist scale values, read and record the live load from the computer until the fracture occurs. Once the sample has failed close the (LOAD) valve and open the (RELEASE) valve to release the load. Once the load has been removed close the (RELEASE) valve Remove the specimen (two pieces) from tensile testing machine. Try to fit two pieces of specimen to measure final gage length and smallest diameter (at the necking region). Shutdown When all of the testing is complete turn off the hydraulics (OFF button). Procedure After testing is finished, save data and close the material testing software. Shutdown computer stationed beside the tensile tester. Pull the main breaker down on the back of the computer. Clean-up Remove all materials from in and around the tensile tester and they will be moved to waste recycle process. Wipe down area when finished, if there is a hydraulic leak (depending on the amount) use the absorbent pads and dispose the pads in a garbage bag and label the garbage bag with the waste disposal sheets and drop the garbage bag off to (need to check) lockout Follow the regular shutdown procedure listed above Maintenance Refer to the manual for repair or service operations. This machine is a product and Repair of Instron, Norwood MA (Tel: 1-800- 461-9123 or 905-333-9123