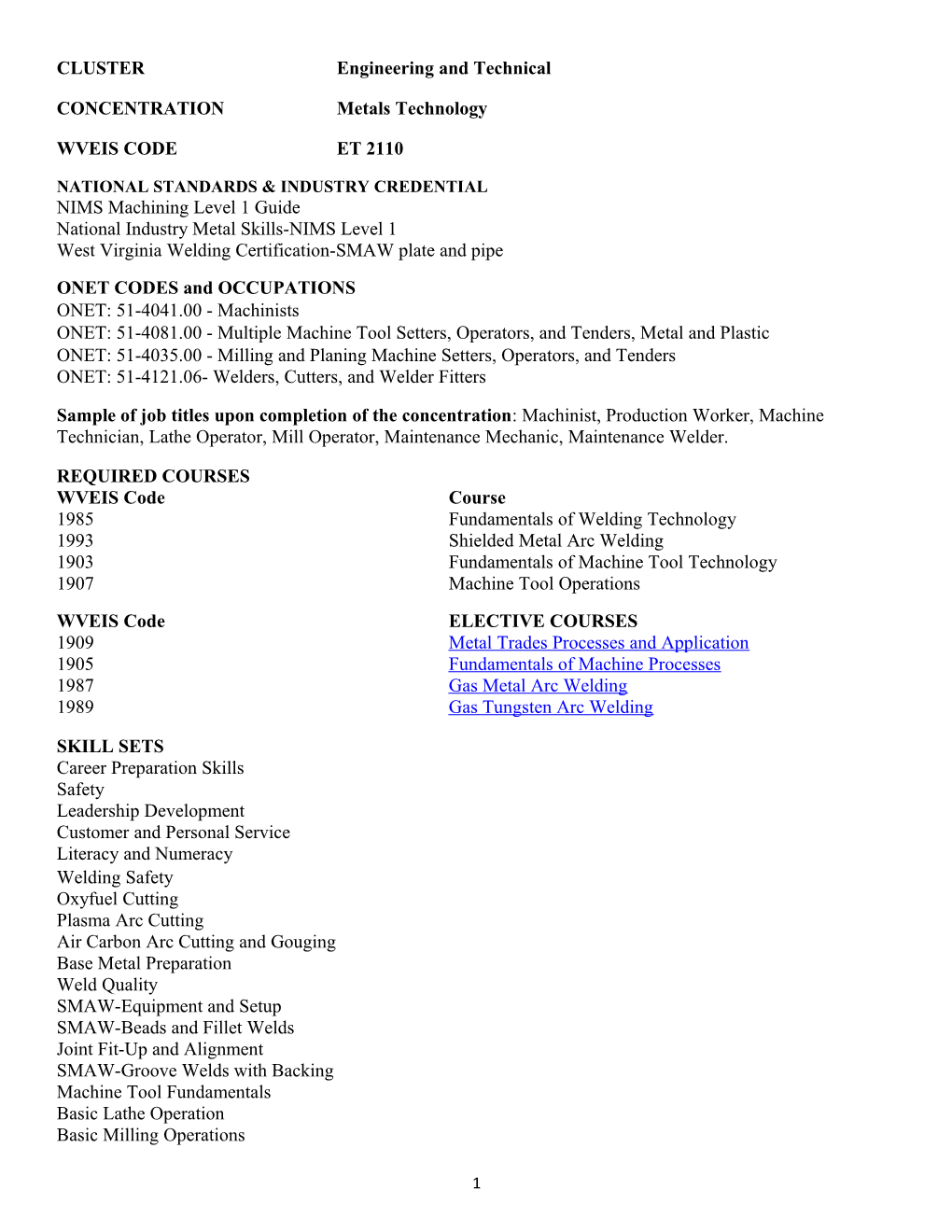

CLUSTER Engineering and Technical

CONCENTRATION Metals Technology

WVEIS CODE ET 2110

NATIONAL STANDARDS & INDUSTRY CREDENTIAL NIMS Machining Level 1 Guide National Industry Metal Skills-NIMS Level 1 West Virginia Welding Certification-SMAW plate and pipe

ONET CODES and OCCUPATIONS ONET: 51-4041.00 - Machinists ONET: 51-4081.00 - Multiple Machine Tool Setters, Operators, and Tenders, Metal and Plastic ONET: 51-4035.00 - Milling and Planing Machine Setters, Operators, and Tenders ONET: 51-4121.06- Welders, Cutters, and Welder Fitters

Sample of job titles upon completion of the concentration: Machinist, Production Worker, Machine Technician, Lathe Operator, Mill Operator, Maintenance Mechanic, Maintenance Welder.

REQUIRED COURSES WVEIS Code Course 1985 Fundamentals of Welding Technology 1993 Shielded Metal Arc Welding 1903 Fundamentals of Machine Tool Technology 1907 Machine Tool Operations

WVEIS Code ELECTIVE COURSES 1909 Metal Trades Processes and Application 1905 Fundamentals of Machine Processes 1987 Gas Metal Arc Welding 1989 Gas Tungsten Arc Welding

SKILL SETS Career Preparation Skills Safety Leadership Development Customer and Personal Service Literacy and Numeracy Welding Safety Oxyfuel Cutting Plasma Arc Cutting Air Carbon Arc Cutting and Gouging Base Metal Preparation Weld Quality SMAW-Equipment and Setup SMAW-Beads and Fillet Welds Joint Fit-Up and Alignment SMAW-Groove Welds with Backing Machine Tool Fundamentals Basic Lathe Operation Basic Milling Operations

1 Career Preparation, Safety, Leadership Development, Customer Service and Literacy and Numeracy skill sets should be integrated throughout the concentration as remaining skill sets are delivered. Skill Set Career Preparation Skills Knowledge Objectives Students will demonstrate knowledge of ET.1 career paths. goal development and achievement. attitudes and work habits that support career retention and advancement. communication in varied contexts. Performance Objectives Students will ET.2 relate skills and abilities to possible career pathways. ET.3 explain methods of goal development. ET.4 discuss methods of time management and task coordination. ET.5 practice professionalism in punctuality, appropriate dress, task completion, etc. ET.6 investigate methods of supervision such as giving and receiving feedback and instruction. ET.7 develop and present a statement of their personal work ethic beliefs. ET.8 prepare an application, cover letter, resume and thank you letter. ET.9 create a personal portfolio for use when applying for employment. ET.10 practice simulated job interviews. Skill Set Safety Knowledge Objectives Students will demonstrate knowledge of ET.11 safety procedures. accident reporting agencies. Personal Protective Equipment (PPE). Performance Objectives Students will ET.12 recognize the main causes of accidents. ET.13 research agencies that are responsible for emergencies in the workplace. ET.14 develop a plan which outlines the procedures for handling an accident. ET.15 demonstrate operating instructions before using any equipment. ET.16 establish procedures for safe evacuation of the worksite in the event of an emergency. ET.17 follow safety and security procedures. ET.18 wear PPE as required for specified task. Skill Set Leadership Development Knowledge Objectives Students will demonstrate knowledge of ET.19 public speaking. parliamentary law. leadership concepts. characteristics of effective teams and organizations. Performance Objectives Students will ET.20 develop and deliver speeches. ET.21 participate in meetings using parliamentary procedure. ET.22 attend leadership conferences and training (local, state and/or national). ET.23 volunteer in community service opportunities. ET.24 participate in career development events. Skill Set Customer and Personal Service

2 Knowledge Objectives Students will demonstrate knowledge of

ET.25 customer needs assessment. quality standards for services. evaluation of customer satisfaction. Performance Objectives Students will

ET.26 confer with customers by telephone or in person to provide information about products or services, take or enter orders, cancel accounts, or obtain details of complaints. ET.27 keep records of customer interactions or transactions, recording details of inquiries, complaints, or comments, as well as actions taken. ET.28 check to ensure that appropriate changes were made to resolve customers' problems. ET.29 determine charges for services requested, collect deposits or payments, or arrange for billing. ET.30 refer unresolved customer grievances to designated departments for further investigation. Skill Set Literacy and Numeracy Knowledge Objectives Students will demonstrate knowledge of

ET.31 literacy and numeracy skills required to solve complex. real-world problems associated with their career/technical content area. improve their thinking and reasoning skills. Performance Objectives Students will

ET.32 utilize a variety of technical sources (e.g., Internet, manuals, journals, directions, reports, etc.) to complete career/technical assignments and projects. ET.33 demonstrate writing skills required to complete career/technical assignments and projects. ET.34 demonstrate accuracy in calculating and measuring graphical work required to complete career/technical assignments and projects. ET.35 analyze tables, charts, graphs and multiple data sources to complete career/technical assignments and projects.

Fundamentals of Welding Technology WVEIS 1985 3 Skill Set Welding Safety Knowledge Objectives Students will demonstrate knowledge of

1985.1 safe welding practices. tool and equipment safety. the processes in relation to welding. the basic nomenclature and symbols for welding. Performance Objectives Students will

1985.2 review and practice general welding shop safety guidelines. 1985.3 describe the precautions to be taken when welding in confined areas. 1985.4 describe and discuss electrical safety precautions when using arc welding equipment. 1985.5 solve problems involving heat flow and temperature. 1985.6 review sample parts, blueprints, drawings, and engineering information to determine methods and sequences of operations needed to fabricate products. 1985.7 select the appropriate tools, machines, and materials to be used in preparation for welding. 1985.8 position and adjust work pieces. 1985.9 set up, adjust, and demonstrate the use of all of the basic welding tools and machines. Skill Set Thermal Welding and Cutting Processes Knowledge Objectives Students will demonstrate knowledge of

1985.10 welding processes. preparing base metal for welding. setting up oxy-fuel equipment. welding and cutting techniques using oxy-fuel equipment. Performance Objectives Students will

1985.11 perform safety inspections of equipment and accessories. 1985.12 explain how to transport oxy-fuel cylinders, assemble and set-up oxy-fuel welding and cutting equipment. 1985.13 connect and turn regulator valves to activate and adjust gas flow and pressure so that desired flames are obtained. 1985.14 explain and describe base metal preparation techniques for cutting and welding. 1985.15 prepare base metal for cutting and welding. 1985.16 select and install torches, torch tips, filler rods, and flux, according to welding chart specifications or types and thickness of metals. 1985.17 solve problems involving heat flow and temperature. 1985.18 perform oxy-fuel gas cutting, beveling, and piercing operations. 1985.19 perform shape cutting and bevel cutting on plain carbon steel. 1985.20 position and weld mild steel using oxy-fuel equipment. 1985.21 position and braze mild steel using oxy-fuel equipment. 1985.22 operate a motorized, portable oxy-fuel gas cutting machine. Skill Set Air Carbon Arc Cutting and Gouging Knowledge Objectives Students will demonstrate knowledge of

4 1985.23 air carbon arc equipment . air carbon arc cutting process. metal removal using the air carbon arc equipment. Performance Objectives Students will

1985.24 perform set-up procedures for manual air carbon arc gouging and cutting on mild steel. 1985.25 demonstrate using the air carbon arc the process of gouging. 1985.26 demonstrate using the air carbon arc the process of cutting. Skill Set Plasma Arc Cutting Knowledge Objectives Students will demonstrate knowledge of

1985.27 plasma arc equipment . plasma arc cutting process. Performance Objectives Students will

1985.28 perform set-up procedures for manual plasma arc cutting operations on plain carbon steel, aluminum, and stainless steel. demonstrate using the plasma arc the process for cutting. 1985.29 demonstrate using the plasma arc the process of shape cutting on plain carbon 1985.30 steel, aluminum, and stainless steel.

5 Shielded Metal Arc Welding WVEIS 1993 Skill Set Shielded Metal Arc Welding Equipment and Setup Knowledge Objectives Students will demonstrate knowledge of

1993.01 safe (SMAW) welding practices. tool and equipment safety. the processes in relation to welding. how to setup a machine for welding. Performance Objectives Students will

1993.01 review and practice general welding shop safety guidelines. 1993.02 describe the precautions to be taken when welding in confined areas. 1993.03 describe and discuss electrical safety precautions when using arc welding equipment. 1993.04 identify factors that affect electrode selection. 1993.05 select the appropriate tools, machines, and materials to be used in preparation for welding. 1993.06 explain joint design considerations based on a welding procedure specification. 1993.07 set up, adjust, and demonstrate the use of all of the basic welding tools and machines. 1993.08 position and adjust work pieces. 1993.09 identify and explain weld imperfections and their causes. Skill Set SMAW-Beads and Fillet Welds Knowledge Objectives Students will demonstrate knowledge of

1993.10 operate SMAW equipment properly striking and extinguish an arc. distortion and how it is controlled. explain grove welds and backing. Performance Objectives Students will

1993.11 perform safety inspections of equipment and accessories. 1993.12 determine required equipment and welding methods, applying knowledge of metallurgy, geometry, and welding techniques. 1993.13 weld stringer, weave and overlapping beads. 1993.14 weld components in flat, vertical and overhead position. 1993.15 check for joint misalignment or poor fit-up before and after welding. 1993.16 solve problems involving heat flow and temperature. 1993.17 monitor the fitting, burning, and welding processes to avoid over heating of parts or warping, shrinking, distortion, or expansion of material. 1993.18 chip or grind off excessive weld, slag, or spatter to finish metal surfaces.

6 Fundamentals of Machine Tool Technology WVEIS 1903 Skill Set Machine Tool Fundamentals Knowledge Objectives Students will demonstrate knowledge of 1903.1 the types of steel used in general fabrication work. the basic forms of steel from the supplier. materials and processes in relation to machining. the basic nomenclature and symbols for blueprint reading. Performance Objectives Students will

1903.2 identify the types of steel and their differing characteristics and attributes. 1903.3 solve problems involving heat flow and temperature. 1903.4 study sample parts, blueprints, drawings, and engineering information to determine methods and sequences of operations needed to fabricate products, and determine product dimensions and tolerances. 1903.5 measure, examine, or test completed units to check for defects and ensure conformance to specifications, using precision instruments, such as micrometers. 1903.6 calculate dimensions and tolerances using knowledge of mathematics and instruments such as micrometers and vernier calipers. 1903.7 lay out, measure, and mark metal stock to display placement of cuts. 1903.8 measure and mark reference points and cutting lines on workpieces, using traced templates, compasses, and rules. 1903.9 select the appropriate tools, machines, and materials to be used in preparation of machining work. 1903.10 align and secure holding fixtures, cutting tools, attachments, accessories, or materials onto machines. 1903.11 position and fasten work pieces. 1903.12 set up, adjust, and operate all of the basic machine tools and specialized or 1903.13 advanced variation tools to perform precision machining operations. measure and mark reference points and cutting lines on workpieces, using 1903.14 traced templates, compasses, and rules. set up or operate metalworking, brazing, heat-treating, welding, or cutting 1903.15 equipment. shrink-fit bushings, sleeves, rings, liners, gears, and wheels to specifications, using portable gas heating equipment.

7 Machine Tool Operations WVEIS 1907

Skill Set Basic Lathe Operation Knowledge Objectives Students will demonstrate knowledge of specific safety rules applicable to the machine lathe. 1907.1 setting up the metal lathe in a shop setting. the sequence of operations for a part requiring facing or turning. Performance Objectives Students will

1907.2 identify the basic parts of a lathe. 1907.3 identify and use the controls that are used to start and stop the spindle. 1907.4 identify and use the carriage hand wheel and the cross slide hand wheel. 1907.5 demonstrate how to change the speed of the chuck. 1907.6 practice moving the hand slide. 1907.7 read blueprints or job orders to determine product specifications and tooling instructions and to plan operational sequences 1907.8 confer with instructor before turning on machine. 1907.9 calculate machine speed and feed ratios and the size and position of cuts. 1907.10 start lath or turning machines and observe operations to ensure that specifications are met. 1907.11 operate engine lathe to grind, file, and turn, taper, and thread machine parts to dimensional specifications. 1907.12 monitor the feed and speed of machines during the machining process. 1907.13 adjust machine controls and change tool settings in order to keep dimensions within specified tolerances. 1907.14 set machine stops or guides to specified lengths as indicated by scales, rules, or templates. 1907.15 program computers or electronic instruments, such as numerically controlled machine tools. 1907.16 remove and sharpen dull cutting tools. 1907.17 inspect sample work pieces to verify conformance with specifications, using instruments such as gauges, micrometers, and dial indicators.

Skill Set Basic Milling Operations Knowledge Objectives Students will demonstrate knowledge of

8 1907.18 specific safety rules applicable to the milling machine. the sequence of operations for a part requiring milling. Performance Objectives Students will

1907.19 interpret scaled machine tool and materials forming prints to produce parts or finished products. 1907.20 select cutting tools and tooling instructions, according to written specifications or knowledge of metal properties and shop mathematics. 1907.21 select and use appropriate inspection devices. 1907.22 align the vise to be parallel with the table. 1907.23 position and fasten work pieces. 1907.24 lay out, measure, and mark metal stock to display placement of cuts. 1907.25 set controls to regulate machining: keyway, boring head, angular indexing, simple indexing, and direct indexing. 1907.26 select the proper coolants and lubricants and start their flow. 1907.27 stop machines to remove finished work pieces or to change tooling, setup, or work piece placement, according to required machining sequences. 1907.28 clean machines, tooling, or parts, using solvents or solutions and rags.

9