Dhiman et al. 2012

Supplementary Information

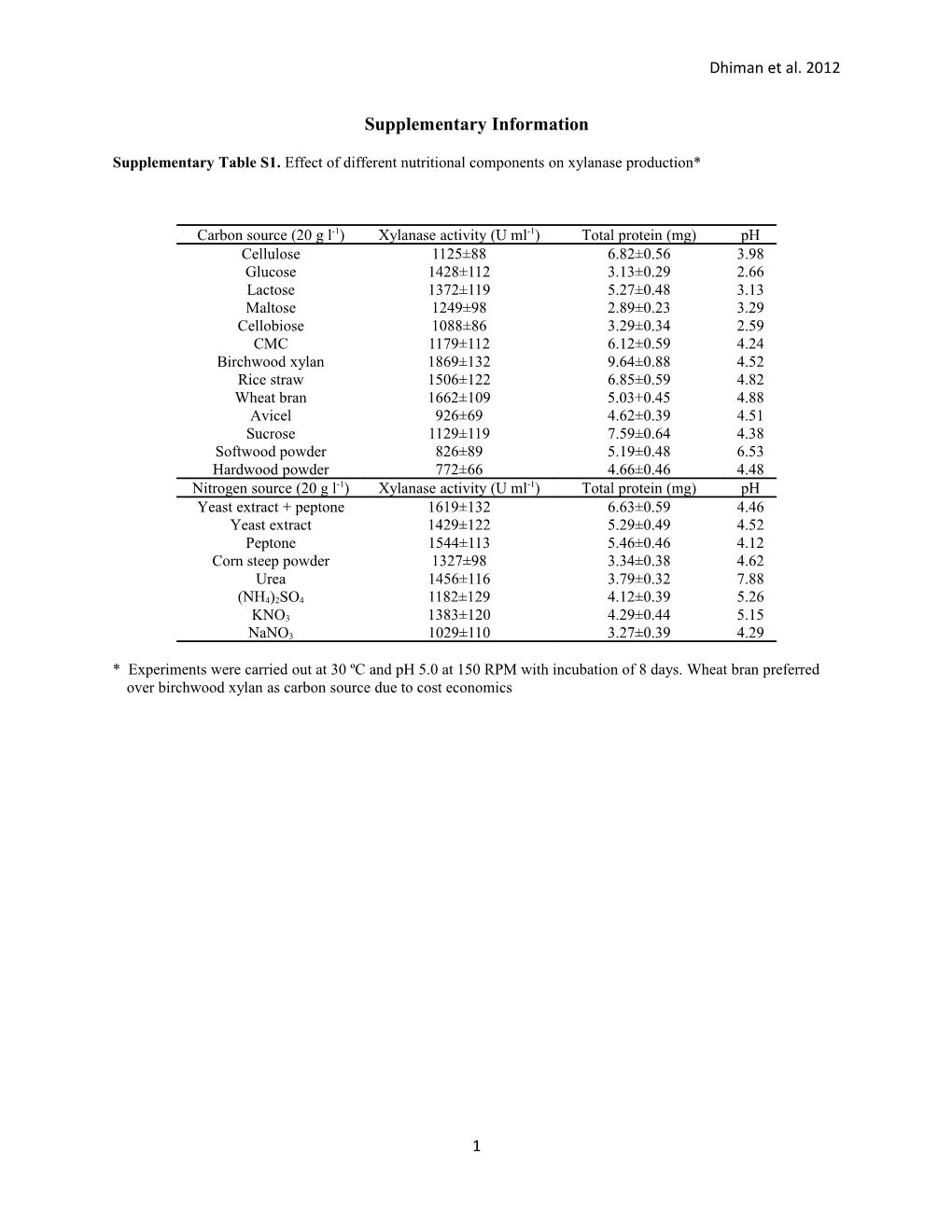

Supplementary Table S1. Effect of different nutritional components on xylanase production*

Carbon source (20 g l-1) Xylanase activity (U ml-1) Total protein (mg) pH Cellulose 1125±88 6.82±0.56 3.98 Glucose 1428±112 3.13±0.29 2.66 Lactose 1372±119 5.27±0.48 3.13 Maltose 1249±98 2.89±0.23 3.29 Cellobiose 1088±86 3.29±0.34 2.59 CMC 1179±112 6.12±0.59 4.24 Birchwood xylan 1869±132 9.64±0.88 4.52 Rice straw 1506±122 6.85±0.59 4.82 Wheat bran 1662±109 5.03+0.45 4.88 Avicel 926±69 4.62±0.39 4.51 Sucrose 1129±119 7.59±0.64 4.38 Softwood powder 826±89 5.19±0.48 6.53 Hardwood powder 772±66 4.66±0.46 4.48 Nitrogen source (20 g l-1) Xylanase activity (U ml-1) Total protein (mg) pH Yeast extract + peptone 1619±132 6.63±0.59 4.46 Yeast extract 1429±122 5.29±0.49 4.52 Peptone 1544±113 5.46±0.46 4.12 Corn steep powder 1327±98 3.34±0.38 4.62 Urea 1456±116 3.79±0.32 7.88 (NH4)2SO4 1182±129 4.12±0.39 5.26 KNO3 1383±120 4.29±0.44 5.15 NaNO3 1029±110 3.27±0.39 4.29

* Experiments were carried out at 30 ºC and pH 5.0 at 150 RPM with incubation of 8 days. Wheat bran preferred over birchwood xylan as carbon source due to cost economics

1 Dhiman et al. 2012

Supplementary Table S2. Different levels of independent variables

Levels Parameter Independent Variable –α –1 0 +1 + α for xylanase production Temperature (°C) A 20 25 30 35 40 pH B 4.0 4.5 5.5 6.5 8.0 RPM C 150 200 250 300 350 for crude xylanase immobilization Temperature (°C) D 20 25 30 35 40 pH E 3.0 4.0 5.0 6.0 7.0 RPM F 35 75 115 150 190 Incubation time (h) G 6 12 30 48 60

2 Dhiman et al. 2012

Supplementary Table S3. Regression equation analysis for xylanase production from Pholiota adiposa using 7 liter jar fermenter

Sum of Degree of p-value Source squares freedom Mean Square F-value Prob. > F Model 4819049 9 535449.9 10.47956 0.0005 significant A-Temp 199395.9 1 199395.9 3.902475 0.0064 B-pH 29183.49 1 29183.49 0.571165 0.0162 C-RPM 293617.9 1 293617.9 5.746541 0.0037 AB 30184.25 1 30184.25ta 0.590751 0.4599 AC 98879.05 1 98879.05 1.935211 0.1944 BC 87236.65 1 87236.65 1.707351 0.2206 A2 2501142 1 2501142 48.95108 < 0.0001 B2 1909887 1 1909887 37.37935 0.0001 C2 268637.5 1 268637.5 5.257638 0.0448 Residual 510947.2 10 51094.72 Lack of Fit 510947.2 5 102189.4 Pure Error 0.0001 5 0.0001 Cor Total 5329997 19

3 Dhiman et al. 2012

Supplementary Table S4. Effect of different combinations of reaction parameters (un-coded value) on xylanase production in 7-liter jar fermenters. P. adiposa cultures were incubated for 8 days*

Run Temp. (°C) pH RPM Xylanase activity (U/ ml) Actual Predicted 1 30 5.5 250 1237±88 1245±54 2 30 5.5 250 1237±88 1245±54 3 25 6.5 200 350±23 339±21 4 30 5.5 250 1237±88 1245±54 5 30 8 250 665±41 638±44 6 35 6.5 300 868±51 826±56 7 30 5.5 250 1237±88 1245±54 8 25 4.5 200 526±43 584±45 9 40 5.5 250 368±29 270±19 10 30 5.5 350 1680±48 1662±77 11 30 5.5 250 1237±88 1245±54 12 30 5.5 150 652±52 613±40 13 25 6.5 300 377±34 340±24 14 35 6.5 200 380±33 402±29 15 35 4.5 200 227±19 280±27 16 22 5.5 250 371±31 335±24 17 30 5.5 250 1237±88 1245±54 18 30 4 250 672±57 293±19 19 35 4.5 300 281±22 587±47 20 25 4.5 300 452±33 446±39

*Composition of production medium (g/l) peptone (5.0), yeast extract (5.0), KH2PO4 (5.0), K2HPO4 (5.0),

. MgSO4 7H2O (3.0), thiamin-HCl (0.02), KNO3 (2.0), and wheat bran (20)

4 Dhiman et al. 2012

Supplementary Table S5. Substrate specificities of purified xylanase from Pholiota adiposa

Substrate (1%) Specific activity (U/mg-protein) Relative activity (%) Birchwood xylan 418 ± 27 100 Oat spelt xylan 401 ± 32 95.8 Avicel 29.7 ± 1.2 7.10 Carboxymethyl cellulose 1.2 ± 0.3 0.28 p-Nitrophenyl xylopyranoside 0.6 ± 0.1 0.14 p-Nitrophenyl glucopyranoside ND* ND* p-Nitrophenyl cellobioside ND* ND*

*ND: Not Detectable

5 Dhiman et al. 2012

Supplementary Table S6. CCD-RSM design of different independent variables (un-coded) affecting the immobilization of crude xylanase from Pholiota adiposa on gluteraldehyde-activated SiO2 nanoparticles

Efficiency (%) Run Temp. (°C) pH RPM IT (h) Yield (%) Actual Predicted 1 35 4 75 12 77.2±6.6 102±8.5 94.7±7.5 2 25 4 150 12 80.2±7.4 88.8±4.7 69.6±3.8 3 25 4 75 12 84.0±6.8 75.4±6.4 80.1±4.5 4 25 6 150 12 61.7±5.2 85.8±5.6 82.7±6.6 5 20 5 115 30 70.4±6.4 79.7±6.5 90.5±8.4 6 35 6 75 48 66.7±5.9 109±10.6 127±10.2 7 35 4 75 48 72.8±6.8 105±3.8 104±6.9 8 30 5 35 30 66.0±5.6 144±9.8 134±9.3 9 25 4 75 48 47.5±3.4 89.4±7.3 90.9±5.7 10 30 5 115 30 75.9±5.9 122±10.6 123±9.8 11 30 5 115 30 75.9±5.7 122±11.6 123±9.8 12 25 6 150 48 59.9±6.1 118±11.4 125±10.9 13 30 3 115 30 49.4±3.9 65.5±5.5 79.2±6.2 14 35 4 150 48 65.4±4.2 128±11.3 122±9.8 15 25 4 150 48 66.7±6.2 110±11.2 99.6±5.8 16 35 4 150 12 64.8±3.8 87.0±4.5 93.4±6.3 17 30 5 115 30 75.9±3.4 122±10.9 123±10.5 18 25 6 75 48 79.0±3.6 122±10.2 120±9.9 19 30 5 115 30 75.9±5.4 122±9.8 123±9.8 20 35 6 75 12 61.1±5.4 98.7±7.9 105±10.4 21 35 6 150 12 65.4±5.4 102±9.8 99.7±7.2 22 30 7 115 30 69.8±5.6 123±5.9 115±10.6 23 30 5 115 6 66.0±2.9 45.9±2.4 49.0±3.9 24 30 5 115 30 75.9±5.2 122±5.9 123±9.7 25 35 6 150 48 64.8±2.8 149±6.8 141±9.4 26 25 6 75 12 52.5±3.4 92.9±5.9 97.5±6.9 27 40 5 115 30 76.5±5.6 126±9.6 121±9.8 28 30 5 190 30 69.1±3.9 121±9.7 137±10.4 29 30 5 115 66 67.3±4.2 99.2±6.8 101±10.2 30 30 5 115 30 75.9±4.6 122±9.8 123±10.2

6 Dhiman et al. 2012

Supplementary Table S7. Regression equation analysis for immobilization of crude xylanase on gluteraldehyde activated SiO2 nanoparticle

Sum of Degree of p-value Source squares freedom Mean Square F-value Prob. > F Model 13667.57 14 976.2551 7.316471 0.0002 significant A-Temp 1404.54 1 1404.54 10.52622 0.0054 B-pH 1958.427 1 1958.427 14.67728 0.0016 C-RPM 15.68167 1 15.68167 0.117525 0.7365 D-IT 4118.64 1 4118.64 30.86684 < 0.0001 AB 47.61 1 47.61 0.35681 0.5592 AC 85.5625 1 85.5625 0.641242 0.4358 AD 0.81 1 0.81 0.00607 0.9389 BC 18.0625 1 18.0625 0.135368 0.7181 BD 156.25 1 156.25 1.171004 0.2963 CD 370.5625 1 370.5625 2.777153 0.1164 A2 477.1433 1 477.1433 3.575915 0.0781 B2 1095.852 1 1095.852 8.212781 0.0118 C2 294.9376 1 294.9376 2.210388 0.1578 D2 3832.652 1 3832.652 28.72353 < 0.0001 Residual 2001.488 15 133.4325 Lack of Fit 2001.488 10 200.1488 Pure Error 0.001 5 0.001 Cor Total 15669.06 29

7 Dhiman et al. 2012

Supplementary Table S8. Comparison of immobilization yield and immobilization efficiency for different supporting matrix

Resin Type Immobilization Yield (%) Immobilization Efficiency (%) Amberlite XAD-16 14.8±1.6 17.5±1.9 XAD-4 22.2±1.8 19.7±1.8 Amberlite IRA-400 14.2±1.1 29.0±2.5 XAD-2 17.2±1.4 18.3±1.6 XAD-7HP 19.7±1.6 14.6±1.3 DUO-A7 27.1±2.1 37.4±2.9

8 Dhiman et al. 2012

Supplementary Figure S1. The phylogenetic dendrogram for P. adiposa and related strains based on the IT rDNA sequence. Numbers following the names of the strains are accession numbers of published sequences.

9 Dhiman et al. 2012

100

90

80 ) % ( 70 y t i v i

t 60 c A 50 e v i t

a 40 l e

R 30

20

10

0 30 35 40 45 50 55 60 65 70 75 80

Temperature (oC)

1 2 3 4 5 6 7 8 9 pH

Supplementary Figure S2. Effect of different temperature and pH values on xylanase activity. Xylanase activity was determined at various temperature () and pH () values to indentify the optimal conditions for purified

PaXyl

10 Dhiman et al. 2012

Supplementary Figure S3. Effect of birchwood xylan concentration on the activity of xylanase. Xylanase activity was measured in the presence of the indicated concentrations of birchwood xylan at pH 5.0. The inset shows the

Lineweaver-Burk plot of initial velocity versus various fixed substrate concentrations. Each value represents the mean of triplicate measurements and varied from the mean by not more than 10%.

11 Dhiman et al. 2012

100

90

80 ) % (

70 y t i v

i 60 t c A

50 e v i t 40 a l e

R 30

20

10

0 0 10 20 30 40 50

Temperature (oC)

Supplementary Figure S4. Thermal stability profile of purified xylanase from Pholiota adiposa. Relative xylanase activity (%) at 4°C (); at 25°C (); at 40°C (); at 50°C (△); at 60°C (); at 70°C (); at 80°C ()

12 Dhiman et al. 2012

100

90

80 ) % ( 70 y t i v i

t 60 c A 50 e v i t

a 40 l e

R 30

20

10

0 40 45 50 55 60 65 70

Temperature (oC)

3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 pH

Supplementary Figure S5. Effect of immobilization on temperature and pH stability of crude xylanase from

Pholiota adiposa. Relative activity (%) of free () and immobilized (△) crude xylanase at different temperatures; relative activity (%) of free () and immobilized () crude xylanase at different pHs

13 Dhiman et al. 2012

100

90

80 ) % ( 70 y t i v i

t 60 c A 50 e v i t

a 40 l e

R 30

20

10

0 40 45 50 55 60 65 70

Temperature (oC)

3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 pH

Supplementary Figure S6. Effect of unoptimized (low protein loading) and optimized (high protein loading) enzyme dose on the relative activity of immobilized PaXyl at different temperature and pH values. Relative activity

(%) of the immobilized crude xylanase with low enzyme dose () and high enzyme dose (△) at different temperatures; relative activity (%) of the immobilized crude xylanase with low enzyme dose () and high enzyme dose () at different pHs

14 Dhiman et al. 2012

100

90

80 ) % ( 70 y t i v i 60 t c A 50 e v i t

a 40 l e

R 30

20

10

0 0 10 20 30 40 50 60 70 80 90 100 110 120 130 Incubation (h)

Supplementary Figure S7. Thermal stability profile of crude un-immobilized and immobilized PaXyl. Relative xylanase activity (%) at 50°C; un-immobilized enzyme (); immobilized enzyme ()

15 Dhiman et al. 2012

100

90

80 ) % ( 70 y t i v i

t 60 c A 50 e v i t

a 40 l e

R 30

20

10

0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 Reusability Cycle

Supplementary Figure S8. Reusability of immobilized crude PaXyl for XOS synthesis. One cycle is defined as the time taken to hydrolyze all of the substrates present in the reaction mixture under the standard assay condition.

16 Dhiman et al. 2012

a.

b.

Supplementary Figure S9. High-pressure liquid chromatography (HPLC) chromatogram showing synthesis of xylooligosaccharide (XOS). a. by crude unimmobilized xylanase; b. by crude immobilized xylanase

17