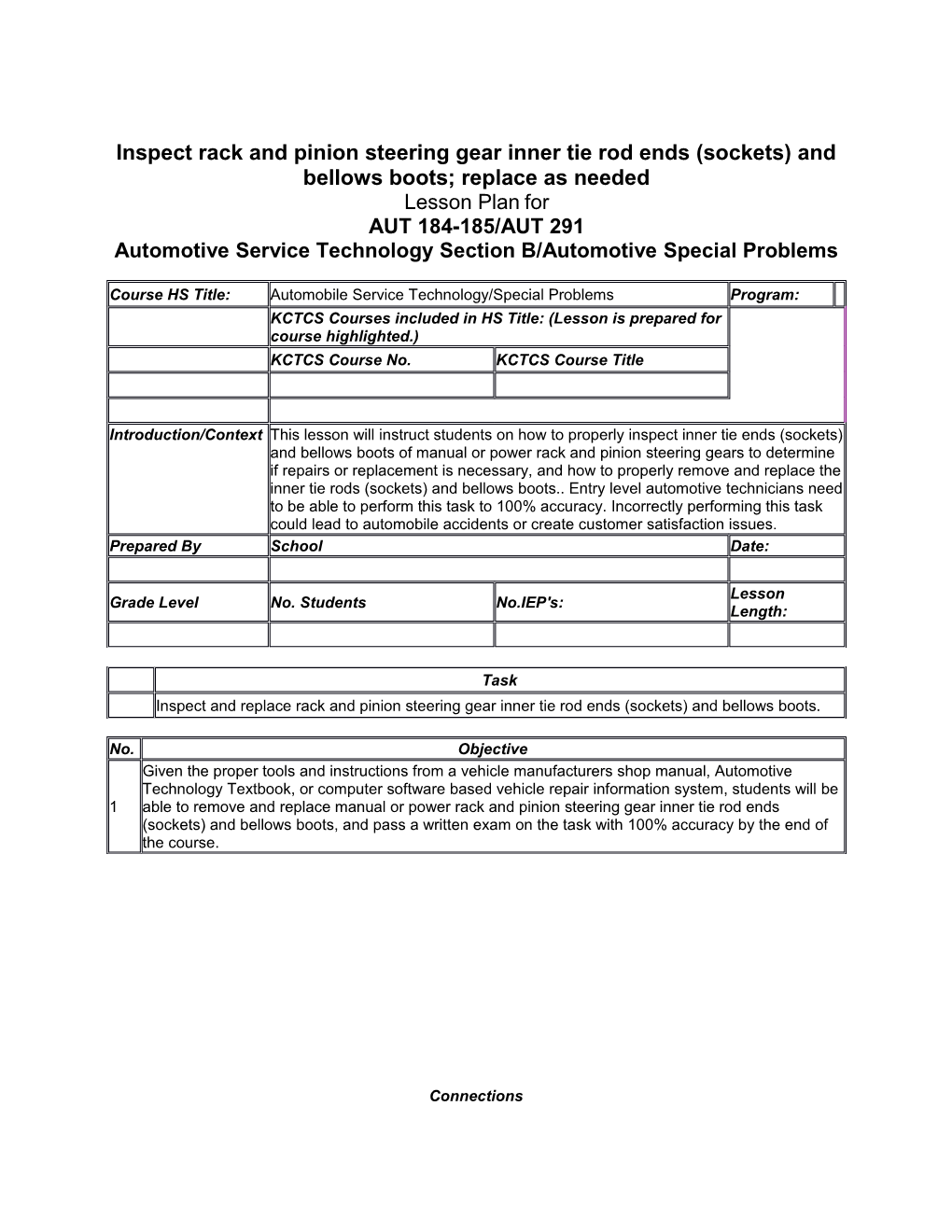

Inspect rack and pinion steering gear inner tie rod ends (sockets) and bellows boots; replace as needed Lesson Plan for AUT 184-185/AUT 291 Automotive Service Technology Section B/Automotive Special Problems

Course HS Title: Automobile Service Technology/Special Problems Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title

Introduction/Context This lesson will instruct students on how to properly inspect inner tie ends (sockets) and bellows boots of manual or power rack and pinion steering gears to determine if repairs or replacement is necessary, and how to properly remove and replace the inner tie rods (sockets) and bellows boots.. Entry level automotive technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task could lead to automobile accidents or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Inspect and replace rack and pinion steering gear inner tie rod ends (sockets) and bellows boots.

No. Objective Given the proper tools and instructions from a vehicle manufacturers shop manual, Automotive Technology Textbook, or computer software based vehicle repair information system, students will be 1 able to remove and replace manual or power rack and pinion steering gear inner tie rod ends (sockets) and bellows boots, and pass a written exam on the task with 100% accuracy by the end of the course.

Connections Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-SYS-2 New Common Core Standards: RST 11-12.2 RST 11-12 3 New Generation Science Standards: HS-PS2-1. HS-PS3-3.

INSTRUCTIONAL MATERIALS/TECHNOLOGY

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Chappell, Dodge, Hat, Delft, Automotive Excellence Vol 1 Volume 1 Glencoe 436 Grekowicz, Wicker Technical Applications Volume 1 Automotive Steering, Suspension, Second James D. Halderman Prentice Hall 172-178 and Alignment ISBN 0-13-799719-1 Edition Automotive Technology A System's 2nd Erjavec/Scharff Delmar 986-987 Approach Edition Today's Technician Automotive Thomson Delmar Don Knowles 3rd Edition 361-363 Suspension and Steering Systems Learning

Supplies Quantity Item Source As Needed Inner tie rod bellows Various As Needed Roll Pin assortment Various As Needed Power steering fluid Various

Equipment Quantity Item Source As Needed Floor Jacks Various As Needed Four Post Lift (12,000 lb minimum) Various As Needed Tie Rod End Tools Various

Content/Presentation/Demonstration Outline Instruct students that safety rules concerning proper use of tools, vehicle lifting equipment, and jack stands, as well as safety procedures concerning supplemental restraint systems (air bags) must be understood and adhered to. Instruct students that the inner tie rod ends (sockets) of a steering rack assembly (manual or power) may become worn and loose over time and use, and the bellows boots may become dry rotted, oil soaked, heat compromised, or otherwise damaged, allowing dirt, moisture and road debris access to the inner tie rod ends. This dirt and moisture rapidly accelerates normal wear which may result in loose erratic steering, wandering or vehicle pull caused by slack in the steering rack assembly. Instruct students that they must locate and follow vehicle specific instructions for removing and installing manual or power steering rack assemblies inner tie rod ends (sockets), and bellows boots, however make sure they understand these basic steps: Instruct students to secure SIR system components (disconnect air bag, tape steering wheel to protect clockspring, etc. as applies to vehicle) Inspect and eliminate all other suspension system components for cause of looseness. Inspect other manual or power steering rack components for loose components (outer tie rods, pinion gear shaft) or mounting issues. Inform students how to raise vehicle and safely support it (properly placed jack stands or shop lift). Remove front wheels. Inform students of the different means of “staking” the inner tie rod or socket to steering gear rack (manufacturer specific, roll pin, rivet, set screw, staked socket, etc.). Disconnect outer tie rods. Remove inner tie rod end bellows clamp and slide bellows down tie rod toward outer tie rod Instruct students how to identify staking procedure used, and demonstrate un-staking inner tie rod. Remove inner tie rod assembly from end of the steering rack. Remove inner tie rod bellows. Instruct students that they will need to reverse procedure to install a new inner tie rod and bellows boot assembly. Instruct students that removal of any steering or suspension component will require vehicle alignment

Applications/Practice 1 Refer to content.

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required.

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.) REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)