Government of West Bengal DIRECTORATE OF ANIMAL RESOURCES & ANIMAL HEALTH

Office of the Jt. Director of ARD, Institute of Animal Health & Veterinary Biologicals [(R&T), 37, Belgachia Road, Kolkata-700 037

Ref. No. 1977 /NIT-02/T-1 (B)/ 16-17 Date: 31/05/2016

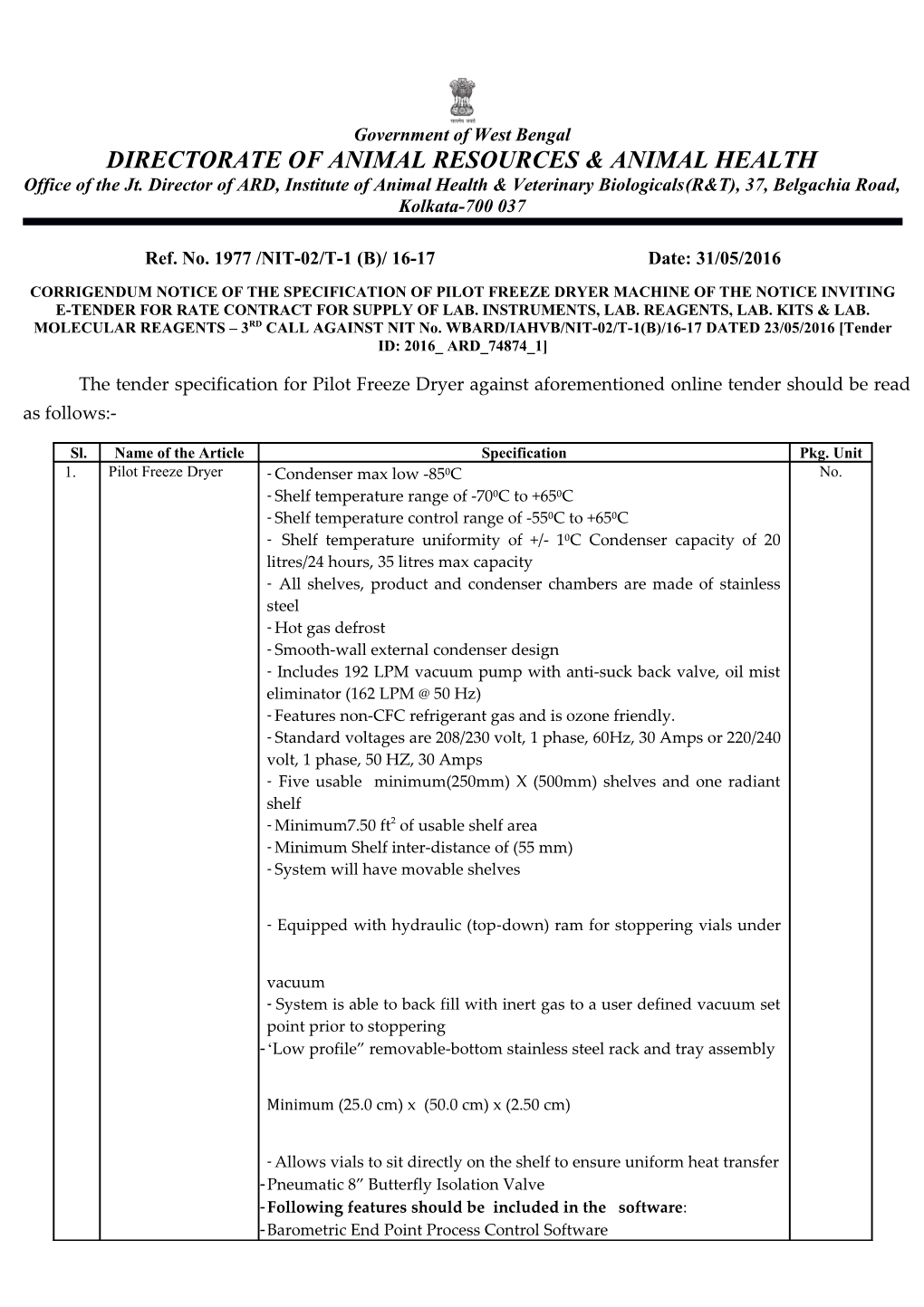

CORRIGENDUM NOTICE OF THE SPECIFICATION OF PILOT FREEZE DRYER MACHINE OF THE NOTICE INVITING E-TENDER FOR RATE CONTRACT FOR SUPPLY OF LAB. INSTRUMENTS, LAB. REAGENTS, LAB. KITS & LAB. MOLECULAR REAGENTS – 3RD CALL AGAINST NIT No. WBARD/IAHVB/NIT-02/T-1(B)/16-17 DATED 23/05/2016 [Tender ID: 2016_ ARD_74874_1]

The tender specification for Pilot Freeze Dryer against aforementioned online tender should be read as follows:-

Sl. Name of the Article Specification Pkg. Unit 1. Pilot Freeze Dryer ‐ Condenser max low ‐85⁰C No. ‐ Shelf temperature range of ‐70⁰C to +65⁰C ‐ Shelf temperature control range of ‐55⁰C to +65⁰C ‐ Shelf temperature uniformity of +/‐ 1⁰C Condenser capacity of 20 litres/24 hours, 35 litres max capacity ‐ All shelves, product and condenser chambers are made of stainless steel ‐ Hot gas defrost ‐ Smooth‐wall external condenser design ‐ Includes 192 LPM vacuum pump with anti‐suck back valve, oil mist eliminator (162 LPM @ 50 Hz) ‐ Features non‐CFC refrigerant gas and is ozone friendly. ‐ Standard voltages are 208/230 volt, 1 phase, 60Hz, 30 Amps or 220/240 volt, 1 phase, 50 HZ, 30 Amps ‐ Five usable minimum(250mm) X (500mm) shelves and one radiant shelf ‐ Minimum7.50 ft2 of usable shelf area ‐ Minimum Shelf inter‐distance of (55 mm) ‐ System will have movable shelves

‐ Equipped with hydraulic (top‐down) ram for stoppering vials under

vacuum ‐ System is able to back fill with inert gas to a user defined vacuum set point prior to stoppering -‘Low profile” removable‐bottom stainless steel rack and tray assembly

Minimum (25.0 cm) x (50.0 cm) x (2.50 cm)

‐ Allows vials to sit directly on the shelf to ensure uniform heat transfer -Pneumatic 8” Butterfly Isolation Valve -Following features should be included in the software: -Barometric End Point Process Control Software ‐ Pressure Rise Test for product dryness ‐ Automatically closes/opens isolation valve ‐ Measures vapor pressure rise in product chamber ‐ Includes option to remain in current step until user defined pressure rise criteria is met -Automated Control System ‐ Micro Logic PLC utilizing 64 bit technology ‐ (12) Twelve thermal treatment (pre freeze) steps each with rate/hold capability ‐ (16) Sixteen primary drying steps each with rate/hold capability ‐ Secondary drying step ‐ Storage (hold) phase until cycle ended

‐ Built‐in, automated function and leak rate testing

Continued on Page-2

Page-2

‐ Extensive library of conditional and emergency alarms provided to protect product and equipment ‐ (8) eight type “T” product thermocouples ‐ (1) one condenser temperature probe ‐ (1) one shelf temperature probe ‐ Pirani vacuum transducer ‐ Computer workstation with Windows 7 and Microsoft Office ‐ 3 levels of login security (Guest, Operator, Supervisor) ‐ Historical trending with ability to create user customized trends ‐ Run data stored indefinitely. Alarms stored for 1 year. ‐ Ability to export run data to a spreadsheet ‐ 17 inch. flat panel display, printer and mouse - Automatic Backfill and Stoppering Software ‐ For systems with stoppering ‐ At the completion of the freeze drying run: ‐ Automatically backfills the product chamber to a user defined vacuum set point and then stopper the vials ‐ System then holds at the backfill vacuum set point and storage temperature until the operator ends the freeze drying cycle ‐ Includes a separate unique vacuum backfill valve so vacuum level control and backfill can be connected to an inert gas supply (such as Nitrogen) separate from the vacuum release supply. (Normally room air) Capacitance Manometer in addition to Pirani Vacuum Sensor ‐ Allows for visual/manual comparison of vacuum readings from the Pirani gauge and the Capacitance Manometer to determine completion of primary drying. Includes Pirani /Capacitance Manometer Differential Automated Process Control Software ‐ Compares the Pirani gauge and Capacitance Manometer pressure values to determine completion of drying ‐ Process will remain in the current step until the user defined pressure differential is met, then will automatically advance to the next step. Validation Port ‐ Enables the use of external validation devices

‐ 1 ½” tri‐clover connection

Additional four (4) Product temperature probes and interfacing ‐ For Controls systems only Standard vacuum pump oil. (1 gallon/3.78 liters) Latching Kit for 5 Shelf system ‐ 5 Shelf to 4, 3 and 2 Shelf ‐ Increases shelf clearance to accommodate taller vials

‐minimum Clearance of 70mm when latched to 4 shelves

‐ minimum Clearance of 90mm when latched to 3 shelves

‐minimum Clearance of 135mm when latched to 2 shelves

To be supplied with compatible online UPS inbuilt IT with SMF Batteries for 30 minutes backup including Battery Rack and Interconnecting Cables for freeze dryer and computer load. 2 (two) years Warranty

Other contents of the said online tender will however remain unchanged.

Sd/- (Dr. Rudradeb Mukherjea) Joint Director of ARD, IAH & VB, Kolkata