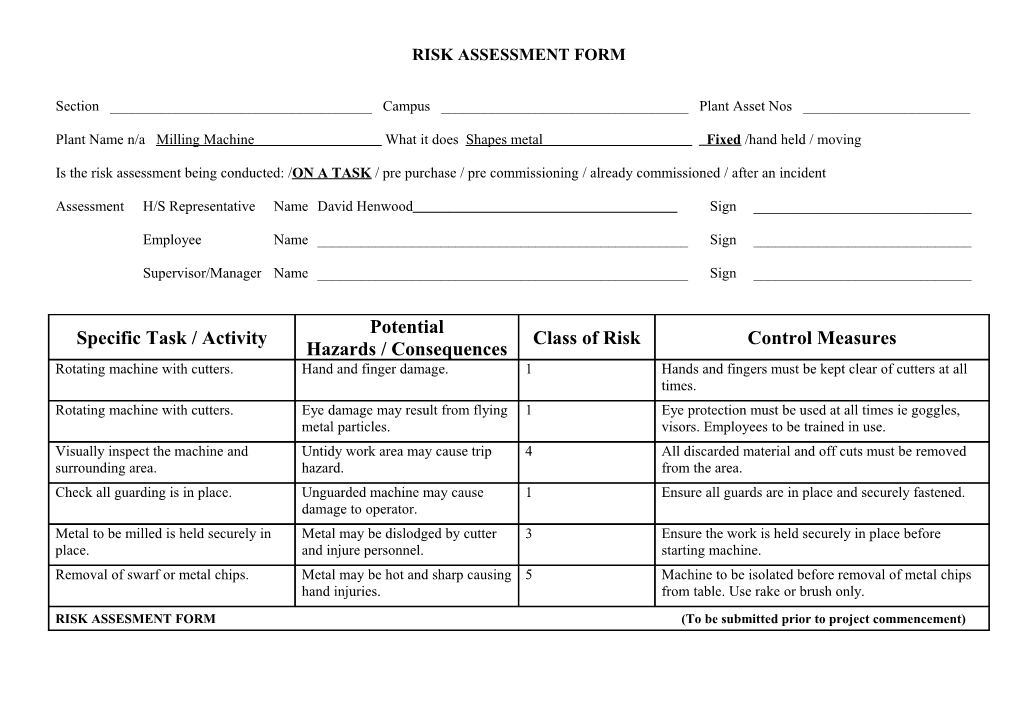

RISK ASSESSMENT FORM

Section ______Campus ______Plant Asset Nos ______

Plant Name n/a Milling Machine What it does Shapes metal Fixed /hand held / moving

Is the risk assessment being conducted: /ON A TASK / pre purchase / pre commissioning / already commissioned / after an incident

Assessment H/S Representative Name David Henwood Sign ______

Employee Name ______Sign ______

Supervisor/Manager Name ______Sign ______

Potential Specific Task / Activity Class of Risk Control Measures Hazards / Consequences Rotating machine with cutters. Hand and finger damage. 1 Hands and fingers must be kept clear of cutters at all times. Rotating machine with cutters. Eye damage may result from flying 1 Eye protection must be used at all times ie goggles, metal particles. visors. Employees to be trained in use. Visually inspect the machine and Untidy work area may cause trip 4 All discarded material and off cuts must be removed surrounding area. hazard. from the area. Check all guarding is in place. Unguarded machine may cause 1 Ensure all guards are in place and securely fastened. damage to operator. Metal to be milled is held securely in Metal may be dislodged by cutter 3 Ensure the work is held securely in place before place. and injure personnel. starting machine. Removal of swarf or metal chips. Metal may be hot and sharp causing 5 Machine to be isolated before removal of metal chips hand injuries. from table. Use rake or brush only.

RISK ASSESMENT FORM (To be submitted prior to project commencement) Potential Specific Task / Activity Class of Risk Control Measures Hazards / Consequences Manually operate the emergency stop Switch may not work in emergency 1 Ensure emergency cut out switch is operational. If not, switch. causing injury. tag machine out after isolating it. Changing cutters as required. Accidental start up may cause 1 The machine must be isolated at appropriate point injury to hand and fingers. prior to changing cutters or to cleaning swarf and chips. Switch on machine and allow bit to Bit may be damaged if speed is not 1 Alert other that machine is about to start. Allow bit to reach operational speed. operational. reach operational speed. Switch off machine on completion of Removing work while machine is 1 Ensure machine is switched off and cutter has stopped work. running may cause injury to before removing completed work. operation. Isolate the machine. Accidental start up / unauthorised 1 Isolate machine at appropriate isolation point. use. Clear machine and area after Untidy area is trip and fall hazard. 3 Ensure that machine and area is left clean and tidy. operation’s completed. Remove off cuts.

Date Conducted ______Date for Review ______

Procedure: Risk Assessment Revision: Effective Date Sept 01

Privacy Notice: The personal information collected by Charles Sturt University on this document will be used, stored and disposed of in accordance with the Privacy and Personal Information Act 1998. personal information will not be used for a purpose other than for which it was collected.

You may only provide personal information about yourself. If you are under 16 personal information must be provided by a parent or guardian. You may access this information, or make changes to this information by contacting Charles Sturt University.