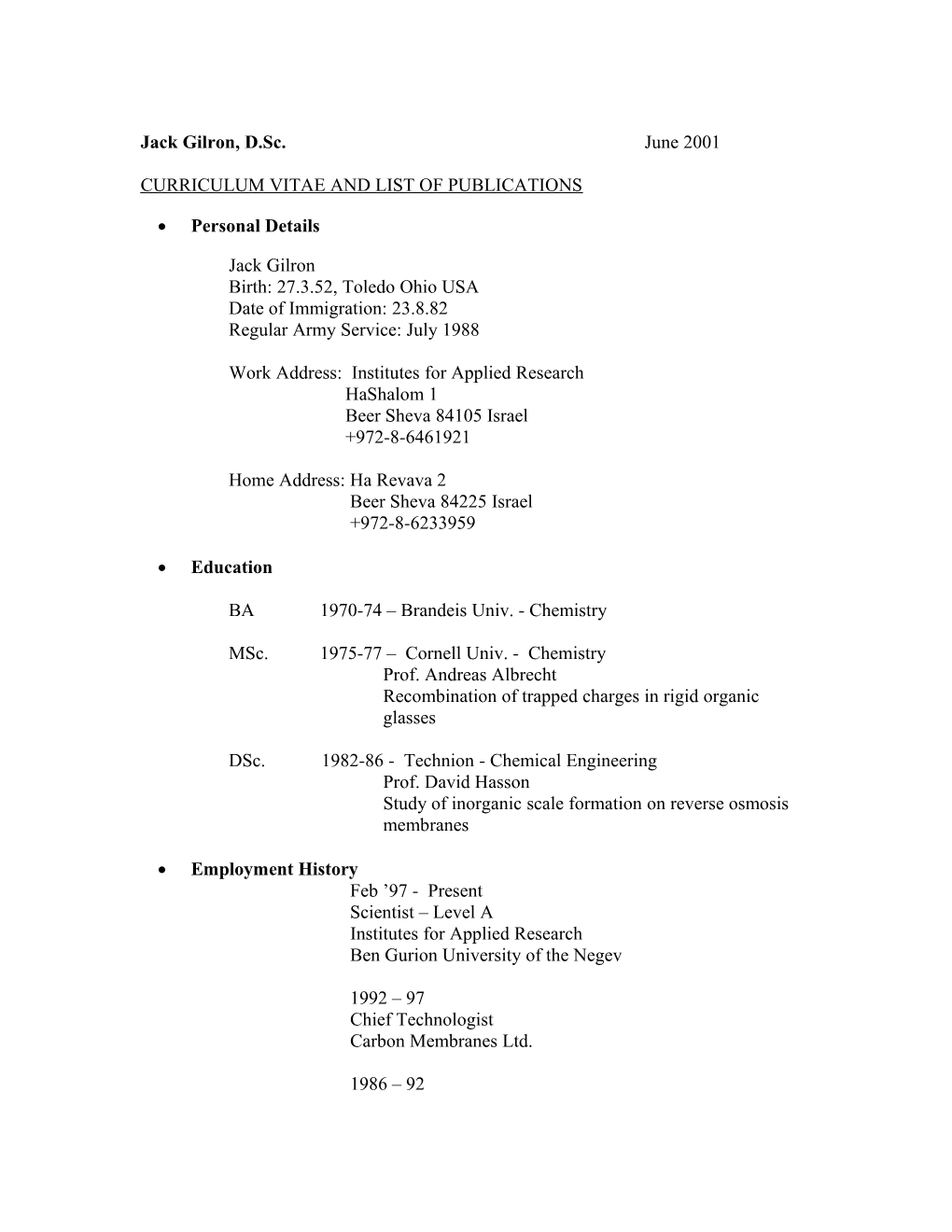

Jack Gilron, D.Sc. June 2001

CURRICULUM VITAE AND LIST OF PUBLICATIONS

Personal Details

Jack Gilron Birth: 27.3.52, Toledo Ohio USA Date of Immigration: 23.8.82 Regular Army Service: July 1988

Work Address: Institutes for Applied Research HaShalom 1 Beer Sheva 84105 Israel +972-8-6461921

Home Address: Ha Revava 2 Beer Sheva 84225 Israel +972-8-6233959

Education

BA 1970-74 – Brandeis Univ. - Chemistry

MSc. 1975-77 – Cornell Univ. - Chemistry Prof. Andreas Albrecht Recombination of trapped charges in rigid organic glasses

DSc. 1982-86 - Technion - Chemical Engineering Prof. David Hasson Study of inorganic scale formation on reverse osmosis membranes

Employment History Feb ’97 - Present Scientist – Level A Institutes for Applied Research Ben Gurion University of the Negev

1992 – 97 Chief Technologist Carbon Membranes Ltd.

1986 – 92 J. Gilron page 2

Research and Development Scientist Membrane Products Kiryat Weizmann (MPW) Ltd.

1978 – 82 Chemist, Mining Chemicals Group Nalco Chemical Company

Professional Activities (b) Professional Functions outside universities/institutions:

2000 Member - Scientific organizing committee for Euromembrane 2000

2000 Member - Scientific organizing committee for 2000 annual meeting of Israel Desalination Society, 2000

1999-present Member - Steering committee of Israel Desalination Society

1999 Co-Chair - Poster Sessions in New Membrane Developments, AIChE Fall Meeting.

1993, 1995-1996 Chair/co-chair - Sessions on membrane technology: IIChE annual meetings.

(c ) Consulting

1997-1999 – Carbon Membranes Ltd – patents related to carbon membrane gas separation technology

(f) Membership in Professional Societies: 1999-present – Israel Desalination Society 1994- present – European Membrane Society 1988 – present – Israel Institute of Chemical Engineers 1986-present – American Insitute of Chemical Engineers 1986-present – American Chemical Society

Educational Activities (a) Courses taught Introduction to Membrane Technology – Masters – Ben Gurion Membrane Technology II (design) – Masters – Ben Gurion University J. Gilron page 3

Desalination Lab – Masters – Ben Gurion University – 1998-2000 – jointly with Mr. Naphtali Daltrophe and Dr. E. Korngold

(b) Research Students Present – Evan Goldstein – M.Sc. student, joint supervision with Dr. Yoram Oren and Prof. E. Korin Present – Yaniv Soffer – serving on thesis advisory committee, Thesis Advisor – Prof. Avner Adin, Hebrew University 2000 – Naim Gara – M.Sc. - Ben Gurion Univ. – joint supervision with Prof. Ora Kedem 2000 – Norman Bischoffberger – predoctoral student – Freiberg Univ. – coop project with Carbon Membranes Ltd.

Awards, Honors, Fellowships (a) Honors, Citation Awards 1974 – Brandeis Univ. – Phi Beta Kappa, Summa Cum Laude, Snyder Chemistry Prize

(b) Fellowships 1981-1982 – Technion – Wolf Prize for doctoral student support 1975 – Cornell Univ. – Debye fellowship for graduate research in chemistry

Scientific Publications

(c ) Conference Proceedings

1. * Belfer, S., Gilron, J., and Kedem, O., (1999). Characterization of commercial and UF modified and fouled membranes by means of ATR/FTIR. Proceedings from European Conference on Desalination and Environment, Las Palmas-Gran Canary Islands, November 1999, Desalination, 124, pp 175-180.

2. * Belfer, S., J. Gilron, Y. Purinson, R. Fainshtain, N. Daltrophe, M. Priel, B. Tenzer and A. Toma, (2001). Effect of surface modification in preventing fouling of commercial SWRO membrane at Eilat seawater desalination plant. Proceedings from European Conference on Desalination and the Environment: Water Shortage, Limassol, Cyprus, May 2001, Desalination, 139, 169-176.

3. * Manttari, N. Daltrophe, Y. Oren, J. Gilron and M. Nystrom (2001) Treatment of Paper Mill Process Water with Lime Treatment, MF and NF. Engineering with Membranes, Granada, Spain. Proceedings, Vol I, pp 295-300.

(d) Refereed Articles J. Gilron page 4

1. Gilron, J. and D. Hasson (1986) Analysis of laminar flow precipitation fouling on reverse osmosis membranes. Desalination 60: 9-24.

2. Gilron, J. and D. Hasson (1987) Calcium sulfate fouling of reverse osmosis membranes: flux decline mechanism. Chem. Eng. Sci. 42: 2351-2360.

3. Borden, J., J. Gilron and D. Hasson (1987) Analysis of RO flux decline due to membrane surface blockage. Desalination, 66: 257-269

4. Treffry-Goatley, K.; Gilron, J (1993) Application of nanofiltration membranes to the treatment of industrial effluent and process streams. Filtration and Separation v 30 n 1 Jan-Feb 1993. p 63-66

5. * Gilron, J., D. Chaikin, and N. Daltrophe, (2000) Demonstration of CAPS pretreatment of surface water for RO Desalination, 127, p 271.

6. * Gilron, J., N. Gara, and O. Kedem, (2001) Experimental Analysis of negative salt rejection in NF membranes. Journal of Membrane Science, 185, pp. 223-236.

7. * Belfer, S., J. Gilron, P. Vaisanen, and M. Nystrom (2001) Modification of RO membranes for Antifouling resistance Accepted for publication in Desalination.

(g) Classified Articles and Reports

1. * Gilron, J. - 1998., Feasibility Study for treating process stream from Bromine Compounds Ltd. Dead Sea Bromine Compounds, Ltd.

2. * Gilron, J. and S. Belfer – 1998 Antifouling Strategies for RO membranes: Surface modification of RO membranes; report for June – August, 1998. Ben Gurion University for MEDRC.

3. * Gilron, J. and D. Chaikin - 1998. Research on water recovery; annual report, Nov. 1998 Ben Gurion University for Kunin-Rose Fund. J. Gilron page 5

4. * Gilron, J., and N. Daltrophe - 1998. Technology for the CAPS process. Silica removal from water Resources Ben Gurion University – Ministry of Trade and Industry.

5. * Gilron, J., Fainshtain, R., and S. Belfer - 1998. Membrane Modifications on RO Membranes. In: The Center for Water Science and Technology. Desalination Program – final summary report Wolfson Foundation. Ben Gurion University.

6. * Kedem, O. and J. Gilron, 1997. Silica Removal in the CAPS softening proceses; interim report. Ministry of Trade and Industry. Ben Gurion University.

7. * Kedem, O., Belfer, S., Daltrophe, N.C., Gilron, J.; Korngold, E; and R. Messalem, 1997. Desalination Program – interim report – Wolfson Foundation. Ben Gurion University.

8. * Kedem, O., Belfer, S. and J. Gilron, 1999. Functionalization of Synthetic Membrane Surfaces, Final Report., Ministry of Science.

9. * Gilron, J.; Belfer, S., Mantarri, M., Nystrom, M., Freger, V., Arnot, T., and J. Howell, 2000. Increased Water Recovery from Organic-Laden Process Streams (OLAPS) by combining NF and Selected Downstream Processes and Fouling Prevention, EC Contract BRPR-CT98-8001, 1st Annual Report – Nov 98- Oct 99. European Community.

10. * Gilron, J.; Belfer, S., Mantarri, M., Nystrom, M., Arnot, T., and J. Howell, 2000. Increased Water Recovery from Organic-Laden Process Streams (OLAPS) by combining NF and Selected Downstream Processes and Fouling Prevention, EC Contract BRPR-CT98-8001, 3rd Semester Scientific Report – Nov 99 – June 00. European Community.

11. * Gilron, J. , S. Belfer, and O. Kedem, 2000. Antifouling Strategies for RO membranes: Surface modification of RO membranes; Final Report. Middle East Desalination Research Center (MEDRC).

12. * Gilron, J.; Belfer, S., Mantarri, M., Nystrom, M., Arnot, T., and J. Howell, 2000. Increased Water Recovery from Organic-Laden Process Streams (OLAPS) by combining NF and Selected Downstream Processes and Fouling Prevention, EC Contract BRPR-CT98-8001, 2nd Annual Scientific Report – Nov 99 – Oct 00. European Community.

13.* Gilron, J. and S. Belfer, 2001. Autopsy of BW30 elements from Migdal 15 pilot station. Mekorot Water Company. March 2001. J. Gilron page 6

Lectures and Presentations at Meetings and Invited Seminars not Followed by Published Proceedings:

(b) Presentations of papers/posters at conferences/meetings:

1. Gilron, J., N. Gara, and O. Kedem, (2000). Direct Experimental Evaluation of the effects of polyelectrolytes and convection on salt transport through membranes. Proceedings of Euromembrane 2000, Maale Hahamisha, 21-24 Sept 2000, p 232.

2. Gilron, J., Belfer, S., Fainshtain, R., Purinson, Y., Chaikin, D., Daltrophe, N. and O. Kedem, (1999). Anti-fouling Strategies in Pressure-Driven Processes, Proceedings of AIChE Annual Fall Meeting, Nov. 1999, Dallas.

3. Gilron, J., Chaikin, D. and N. Daltrophe (1999), A Novel Pretreatment Process, Proceedings of Fouling Mitigation in Membrane Processes, Israel Desalination Society, 26-28 Jan 1999, Haifa, p 13.

4. Belfer, S., Feinstein, R., Purinson, Y., Gara, N. and J. Gilron (1999), Antifouling modifications of RO membranes, Proceedings of Fouling Mitigation in Membrane Processes, Israel Desalination Society, 26-28 Jan 1999, Haifa, p 17.

5. Gilron, J., and A. Soffer, (1997). Membrane-Based Separations of linear from branched hydrocarbons, (1997). Proceedings of Euromembrane ’97, Univ. of Twente, June 23-27, 1997, p 44.

6. Gilron, J. (1993). “Gas separations using cryomembrane technology,” Katzir Conference, Weizmann Institute, Sept. 1993.

7. Gilron, J. (1985). “Laminar Precipitation Fouling of RO Membranes,“ 1985 Annual Meeting - American Institute of Chemical Engineers, Chicago. d) Seminar Presentations at Universities and Institutions 1999 – Dept. of Chem. Eng. – Rensselaer Polytechnic Institute – Salt transport in NF membranes. 1999 – Dept. of Chem. Eng. – Univ. of Colorado, Boulder – CAPS as membrane pretreatment process. 1997 – Dept. of Chemical Technology – Lappeenranta U. of Technology – Precipiation fouling of RO membranes 1997- GKSS, Geesthaacth Germany – High temperature transport in open carbon molecular sieve membranes 1996 – Dept of Chemical Engineering, Ben –Gurion Univ. – Use of membranes in hybrid processes with cryogenic gas separation. 1993-Dept. of Chemical Engineering, Technion – Carbon Membranes for gas separations. J. Gilron page 7

Patents: 1. 1999 – Soffer, Abraham; Gilron, Jack; Saguee, Shlomo; Hed-Ofek, Rafael; Cohen, Haim Process for the production of hollow carbon fiber membranes, US Patent 5,925,591,July 20, 1999

2. 1999 - Soffer, Abraham; Gilron, Jack; Cohen, Haim, Separation of linear from branched hydrocarbons using a carbon membrane , US Patent 5,914,434. June 22, 1999.

3. 1997 - Soffer; Abraham; Gilron; Jack; Hed-Ofek; Refael; Hassid; Moshe, Method for the separation of gases at low temperatures, US Patent 5,649,996. July 22, 1997.

4.1992 - Perry; Mordechai; Gilron; Jack; Ketraro; Reuven; Linder; Charles. Process and device for separating electrically charged macromolecular compounds by forced-flow membrane electrophoresis, US Patent 5,087,338. Feb. 11, 1992.

5. 1984 - Gilron, Jack Mixtures of organic phosphonates and anionic polymers to improve acid extraction of uranium US Patent 4,431,611

RESEARCH GRANTS: 1. 1998-2002 – European Community – J. Gilron (PI), S. Belfer and O. Kedem NF treatment of Organic-laden process streams using fouling prevention technologies JG serving as coordinator for the project including 8 partners from Finland, England, Germany and Israel. Nov 98- May 02: $79,000/year; $277,000 total

2. 1996-1997 - Rose-Kunin Canada Research Fund; O. Kedem (PI) $12,800 Canadian,

3. 1998 – Middle East Desalination Research Center (MEDRC) – J. Gilron (PI), S. Belfer and O. Kedem. Antifouling Strategies for RO membranes, May 98 – Sept 00: $12,400/year; $31,000 total

4. 1997 – Ministry of Science, O. Kedem (PI), S. Belfer Functionalization of polymer surfaces 1997-1998; 94,000 NIS total J. Gilron page 8

5. 1999 – Ministry of Trade and Industry, Y. Oren (PI), Charles Linder, J. Gilron, R. Messalem Use of CAPS and ED for treating domestic wastewater. 2000 $115,000/yr same total.

6. 2000 – Ministry of Science; J. Gilron (PI), Y. Oren and A. Abeliovitch Infrastructure grant for developing methods of treating domestic and industrial wastewater Nominal July 00 – June 03; $41,000/yr; $164,000 total

7. 2000-2003 European Community – S. Belfer (PI) and J. Gilron Development of solvent and acid and base-stable NF membranes. Participating in a consortium involving industries and academic institutions in Israel, Italy, Finland and Germany. Mar 01 – Feb 03; $48,000/yr; $144,300 total

Synopsis of Research

In the last three decades membrane processes have become increasingly important as unit operations used by process engineers for separation and purification of products and to treat water resources and wastestreams for both resource recovery and environmental protection. However the use of membranes is still not as widespread as it could be. This is due in part to the lack of exposure to membrane technology still found among many practicing engineers, and to the problems of membrane fouling often encountered in the use of membranes. My professional activity has been associated with finding new opportunities for introducing membrane technology in industry and in understanding and solving fouling problems that can sometimes complicate their use.

One of the most important developments in expanding the use of membranes in industry is the combination of different membrane processes or combining membrane processes. This has taken new impetus with the rapid expansion of integrated membrane systems in the water treatment industry including UF/MF with RO. Such processes that I have worked on in the past include working on separation of proteins by membrane aided free- flow electrophoresis (Patent 4) and developed a method combining superimposed flow fields and electric fields that allowed purifying proteins from impurities whose pI’s differed from it by as little as 0.1 units. In the food processing industries I have worked on combined membrane processes (UF,NF,RO) for isolating valuable byproducts. In gas separations I worked on molecular sieve carbon membranes formed from hollow fibers (Pat. 1) and studied their application to low temperature separation where O2/Ar selectivities could be increased from 4 to 50 (Patent 3) and on separations of linear from branched hydrocarbons ( Patent 2 ) and recovery of perfluoronated hydrocarbons (patent pending). The first two of these membrane gas separation processes would most likely be coupled to distillation processes and all would likely involve coupling to cryogenic separation. J. Gilron page 9

Another of the challenges facing the use of membranes in industry is improving their stability to extremes in pH and aggressive solvents. In this area I have been involved in feasibility testing for use of special acid stable membranes for the textile industry, especially using nanofiltration.

The fouling of membranes is another challenge that must be met in applying membranes. In membrane fouling my first area of research was on precipitation fouling of RO membranes [see D.Sc. thesis, (d) 1-3]. We found that the mechanism by which inorganic precipitate fouls RO membranes is by blocking the surface and the extent of flux decline is directly proportional to the amount of membrane area covered. A special shadowgraph technique was developed [(d) –2] that allowed the amount of area covered by the deposit to be quantified.

Since precipitation of sparingly soluble salts is one of the main factors limiting higher water recovery, the use of a precipitation process prior to the RO or ED unit to remove sparingly soluble species can be an effective pretreatment. This is often done by lime softening. CAPS which is a compact version of lime softening incorporating microfiltration and adsorption as well, can be used for this purpose. We have demonstrated that CAPS drastically reduced RO fouling by highly contaminated surface water from fish ponds in Nahal Tanninim [ (d)-5] and allowed 90% recovery. In other experiments using backwashable filters, CAPS was shown to reduce silica levels by 90% [Res. Grant 2, (g)- 4] and to reduce heavy metals and organics in a paper mill effluent [Res. Grant 1, (g)- 9]. As a result the flux obtainable in nanofiltration was considerably higher than without pretreatment. Based on these results, the research group at BGU designed a pilot unit that was assembled by Nitron Ltd and shipped to Lappeenranta Technical Univ in Finland where it was tested on fresh paper mill effluent where it gave similar results [(c) – 3]. The pilot unit is now on-site at the paper mill in Lappeenranta.

Another strategy for preventing fouling is to modify the membrane surface. In general more hydrophilic surfaces are less susceptible to fouling by adsorption of organic molecules. In studies carried out with Dr. Belfer’s group, we showed that modified membranes have lower contact angles and adsorb less organic material than unmodified membranes [ (c ) – 1, (d)-7, (g)-8, (g)-11, Res. Grant 4]. This was shown for RO membranes (Res. Grant 3) and for NF membranes on paper effluent [Res. Grant 1, (g)- 9-10]. Membranes that are smoother tend to be less susceptible to colloidal fouling. AFM studies of modified polyamide RO membranes showed that they had surface roughnesses of <30 nm where unmodified membranes had roughness > 100 nm [Res. Grant 4, (g)-8]. Further work on effects of membrane modification is ongoing (see below).

My efforts to improve the exposure of practicing engineers to membrane technology have included: chairing several sessions on membrane separations at the IIChE annual convention, teaching an introductory course to M.Sc. students in environmental engineering for the past three years , and providing an introductory seminar inhouse to engineers at Dead Sea Bromine group. J. Gilron page 10

Some of the work on membrane applications has led to transport and characterization studies to better understand how they work and how best to use them. On gas separation methods, we have shown that the selectivities of relatively open carbon molecular sieve membranes can be explained by a two pore in series model assuming that Knudsen diffusion dominates in the large pore and activated diffusion dominates in the smaller diameter pore (Lecture GKSS, manuscript submitted to JMS). In liquid separations we showed in nanofiltration experiments that negative rejections of monovalent salts in the presence of polyelectrolytes could be correctly predicted by measuring the Donnan equilibrium independently in a separate system using dialysis measurements. [(c)-6]. Further we showed that a significant portion of the salt flux in an NF membrane can be attributed to convection and measured this salt flux in independent experiments. At the same time we estimate that a significantly large fraction of the salt flux is still due to diffusion even at relatively high flux rates. [ Res. Grant 1, presentation 1.].

Using fluorescently labelling, RO polyamide membranes have been shown to have significant amounts of unreacted and terminal amines when received as flat sheet samples and that these amines are oxidized by chlorates [Res. Grant 3, (g)- 11]. Most spiral elements are already much lower in primary amine density leading to the likely conclusion that they have already been treated to oxidize unreacted amines. There are indications that the free amine density is much greater below the membrane surface than on the membrane surface since crosslinking is greatest at the surface during the interfacial condensation by which the membrane is formed.

Present Academic Activities

My continuing research efforts are to be focussed on ways to increase the use of membrane technology in industrial processing and water treatment industries. One area which will now begin is looking at the expanded use of ultrafiltration for processing and wastetreatment. An effort was recently begun under the EC OLAPS Project [Res. Grant 1] using micellar enhanced ultrafiltration to remove halogenated phenols from saline wastewater. This effort will continue with piloting tests with an Israeli industry in the coming year. One of the problems encountered in this work was the instability of the standard UF membranes to aggressive solvents. In the new EU project recently awarded [Res. Grant 7], I will be seeking out industrially relevant applications for solvent stable UF membranes being developed by the group at GKSS with pore size tailoring being carried out by Dr. Belfer’s group at IAR-BGU. As part of this work I will carry out pore size distribution measurements of the obtained membranes in solvent systems using model solutes whose hydrodynamic radii are known or can be measured for that solvent system.

Biofouling is one of the major fouling problems involving membranes in desalination and other forms of drinking and wastewater treatment. Together with Prof. Aharon Abeliovich and Dr. Yoram Oren we will look at the extent to which CAPS can reduce biofouling by reducing the level of organic nutrients available for bacteria attached to the membrane [Res. Grant 6]. In this respect I will work closely with Prof. Abeliovich to J. Gilron page 11 introduce standard fluorescent tagging techniques into quantification of bacterial populations on membrane surfaces as part of our standard practice in analyzing for membrane biofouling. I will also continue to work with Dr. Belfer on evaluating the extent to which membrane modifications reduce the amount of biofouling on desalination membranes which we propose to do in cooperation with Mekorot Water Company [(g) – 13]. Dr. Belfer and I are also collaborating on developing an membrane element autopsy service for membrane users.

Disposal of the brine left over from desalination processes can add significantly to the costs of inland desalination (5-33%), mainly due to the costs of brine evaporation pond construction. Also there is a need to reduce the risks and size of impoundment ponds in many other industries including agriculture (irrigation drainage), power industry (cooling tower blowdown), hazardous wastetreatment and mining and energy (tailings ponds and oil pits). Prof. Ora Kedem, Mr. Avraham Kedem and Mr. Yigal Folkman and I have come up with a method to increase the evaporation rate from holdings ponds without the concomitant risk of drop dispersal associated with spray enhanced evaporation. It involves setting up an array of wetable surfaces exposed to the wind in an isotropic manner. These surfaces are then wetted by pumping the pond water over them and leading the excess water back to the pond (Isr. Patent Application 140158 ). Lesico, a large Israeli industrial infrastructure company, has acquired rights to the project and together with us is working on the development of the process. Mekorot has agreed to participate with Lesico in a small scale demonstration of the process as a step towards introducing it into a large inland desalination project that Mekorot is developing in the Negev.

Articles Submitted for publication: J. Gilron and A. Soffer, Knudsen diffusion in microporous carbon membranes with molecular sieving character, submitted to Journal of Membrane Science.

Patents Pending: 2001. Agam, Giora; Dagan, Gil; Gilron, Jack; Krakov, Vitaly; Tsesin, Natalia. Carbon hollow-fiber membranes for separation of alkenes and alkanes with identical carbon number. PCT WO 0117664.

2000. Kedem, A., Gilron, J., and O. Kedem, Evaporation Device, PCT WO 0075078- A1..

1998. Soffer, A., Agam, G., Bar-Nes, G., Boxer, D., Dagan, G., Gilron, J., Kleiner, L, and Krakov, V., Recovery of perfluorinated compounds and hydrofluorocarbon gases from process gases using molecular sieve membranes, PCT WO 9832521.

Additional Information: Educational and related service activities

Israeli industry is not as aware and involved in the of the use of membrane technology in its processes as are many of its counterparts abroad. Many of the industries do not have the resources or inclinations to set up their own efforts at screening membranes for J. Gilron page 12 applications and the vendors will usually only provided limited feasibility testing services. What’s more, the industry may sometimes suspect the impartiality of answers to feasibility testing that it receives from vendors.

I would propose that the membrane group at the Institutes for Applied Research move in a concerted way to spearhead expanded introduction of membrane processes into Israeli industry. In doing so we could operate on a model similar to the government organization of CSIR Enviromintek of South Africa and similar to other government sponsored membrane groups in other parts of the world which serve the water treatment industries of their area. This effort would involve two activities: feasibility studies undertaken for industry, and continuing education of practicing engineers both in formal courses offered at the University and in short 1-2 day seminars offered for industry.