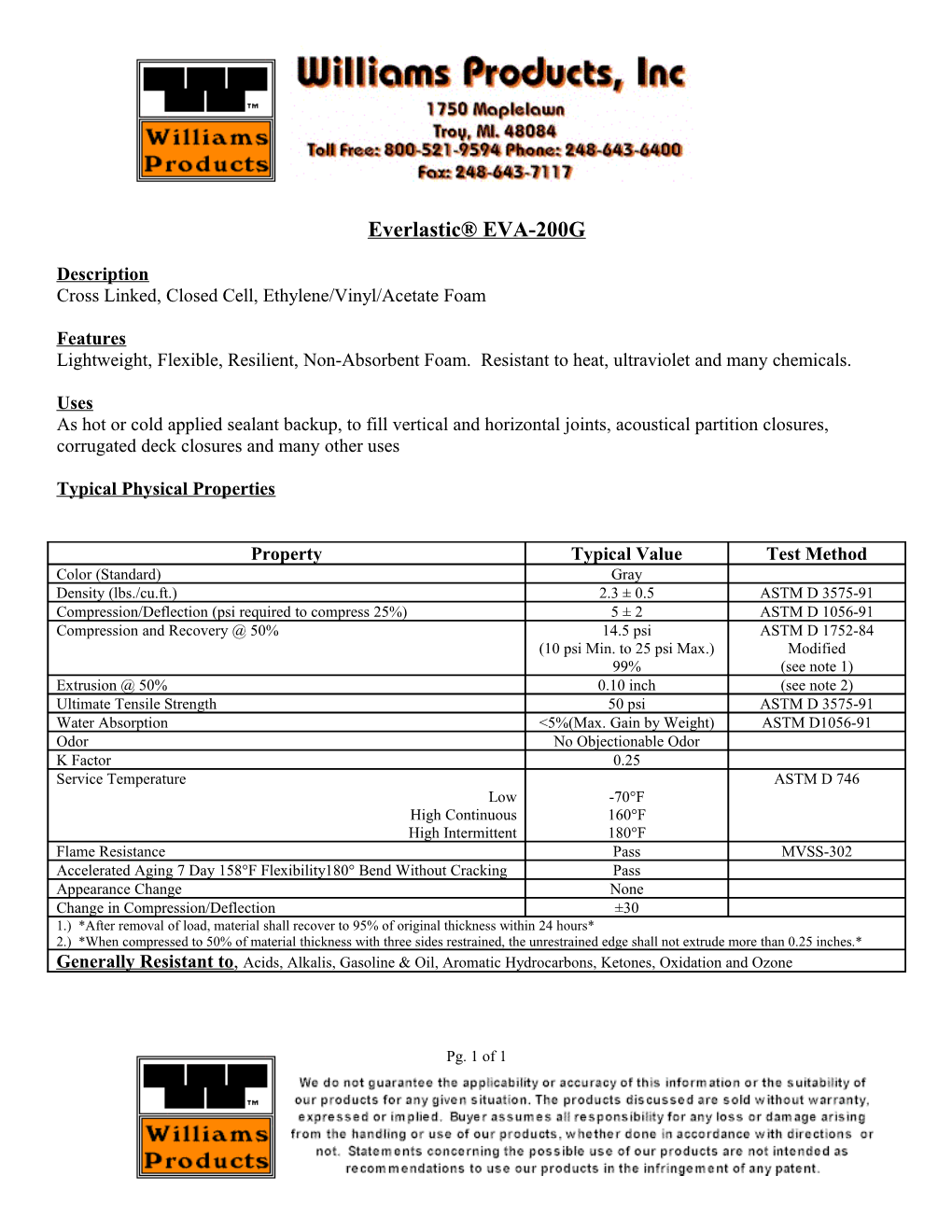

Everlastic® EVA-200G

Description Cross Linked, Closed Cell, Ethylene/Vinyl/Acetate Foam

Features Lightweight, Flexible, Resilient, Non-Absorbent Foam. Resistant to heat, ultraviolet and many chemicals.

Uses As hot or cold applied sealant backup, to fill vertical and horizontal joints, acoustical partition closures, corrugated deck closures and many other uses

Typical Physical Properties

Property Typical Value Test Method Color (Standard) Gray Density (lbs./cu.ft.) 2.3 ± 0.5 ASTM D 3575-91 Compression/Deflection (psi required to compress 25%) 5 ± 2 ASTM D 1056-91 Compression and Recovery @ 50% 14.5 psi ASTM D 1752-84 (10 psi Min. to 25 psi Max.) Modified 99% (see note 1) Extrusion @ 50% 0.10 inch (see note 2) Ultimate Tensile Strength 50 psi ASTM D 3575-91 Water Absorption <5%(Max. Gain by Weight) ASTM D1056-91 Odor No Objectionable Odor K Factor 0.25 Service Temperature ASTM D 746 Low -70°F High Continuous 160°F High Intermittent 180°F Flame Resistance Pass MVSS-302 Accelerated Aging 7 Day 158°F Flexibility180° Bend Without Cracking Pass Appearance Change None Change in Compression/Deflection ±30 1.) *After removal of load, material shall recover to 95% of original thickness within 24 hours* 2.) *When compressed to 50% of material thickness with three sides restrained, the unrestrained edge shall not extrude more than 0.25 inches.* Generally Resistant to, Acids, Alkalis, Gasoline & Oil, Aromatic Hydrocarbons, Ketones, Oxidation and Ozone

Pg. 1 of 1