Last Name First Name Participant # Date Geometric Dimensioning and Tolerancing Second Midterm Examination

Answer all questions in accordance with the ASME Y14.5M-1994 Standard.

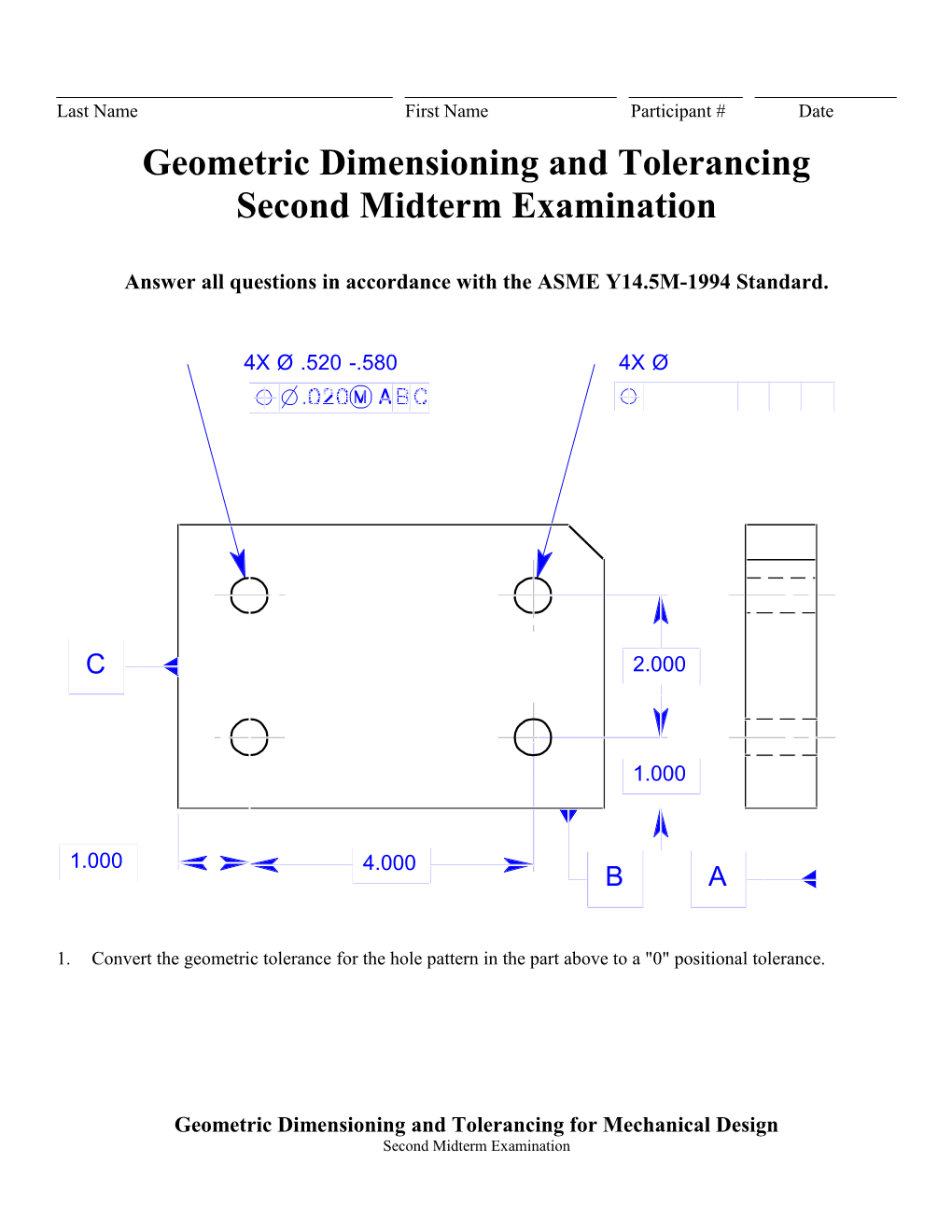

4X Ø .520 -.580 4X Ø

C 2.000

1.000

1.000 4.000 B A

1. Convert the geometric tolerance for the hole pattern in the part above to a "0" positional tolerance.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 2X Ø .275-.290

2. The two parts above are assembled with two 1/4–20 UNC hex head machine bolts. Using the hole size indicated, specify, in a feature control frame, the positional tolerance for the hole pattern located to datums A, B, and C. Perform all calculations, starting with the formula. 2X Ø ______- .230

2X (10) .190-24 UNC-2B

3. The two parts above are assembled with two 10-24 fasteners. Specify the positional tolerance and the clearance hole diameter at MMC. Use "0" positional tolerancing where appropriate. Perform all calculations, starting with a formula.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 2 2X .500-20 UNF-2B

C

2.00 1.000 B

6.00

Mating Part 2.00

A .50

1.000 4.000

.XX = ± .03 .XXX = ± .010 ANGLES = ± 1°

4. Specify the location tolerance of the threaded hole pattern to datums A, B, and C with a tolerance of .040 at MMC.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 3 2X 1.00

.50 1.000

2X.50 3.00

1.000

4X R 1.500 A 4.00

C B

5. Supply the appropriate geometric tolerancing necessary to locate the elongated holes in the drawing above. The location tolerances are .060 in the horizontal (length) direction and .010 in the vertical (width) direction. Use MMC wherever possible. Complete the drawing.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 4 2X Ø.500-.580 2X Ø 1.000-1.045

Ø 2.500

.50

C

B A

6. The two hole patterns in the drawing above are to be considered one composite pattern. Provide the feature control frames necessary to control these patterns to each other and to the datums specified. The tolerance for the Ø .500 hole pattern is .000; the tolerance for the Ø 1.000 hole pattern is .005. Use MMC wherever possible. 4X Ø .250-.335

.50

3.00 1.000

1.000

1.000 2.000

4.00

7. The pattern of clearance holes in the part above is to be located within a cylindrical tolerance zone of . 060 at MMC to the datums. The plate is designed to be assembled to the mating part with Ø .250 bolts as floating fasteners. Tolerance the hole pattern with both tolerances.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 5 Ø1.500-1.515 Ø1.490-1.500

4X .250 – 20 UNC-2B 4X Ø — .305

.XX = ± .03 .XXX = ± .005 ANGLES = ± 1°

8. Tolerance the parts above. Specify flatness controls of .004 on the primary datums. Specify the appropriate orientation control to control the relationships between the primary and secondary datums. Finally, complete the location tolerances for the hole patterns using "0" positional tolerance and MMC wherever possible.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 6 Ø .995-1.000 Ø 1.010-1.025

C Y X

1.000 B

1.500 3.000

6.00

A

.XX = ± .01 .XXX = ± .005 ANGLES = ± 1° 9. Calculate the Virtual Condition of the PIN. Calculate the Virtual Condition of the HOLE.

V.C.P= V.C.P/2= V.C.H= V.C.H/2=

10. Calculate the Resultant Condition of the PIN. Calculate the Resultant Condition of the HOLE.

R.C.P= R.C.P/2= R.C.H= R.C.H/2=

Calculate the maximum and minimum distances indicated on the drawing above:

11. Maximum X =

12. Minimum X =

13. Maximum Y =

14. Minimum Y =

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 7 Ø 2.500 - 2.515 A

Ø 4.500-4.520

15. On the drawing above, specify the coaxiality control that locates the Ø 2.500 within zero tolerance at MMC to datum A. Use MMC wherever possible.

Ø .995-1.000 Ø 1.005-1.015

Ø 1.120-1.125 Ø 1.125-1.135

A A

16. Calculate the coaxial tolerance for the socket. Draw the appropriate feature control frame to specify coaxiality between the two features. Use MMC wherever possible.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 8 4X Ø .750-.760

2.500

1.500 A B

17. Draw the appropriate feature control frame that will locate the four holes within a tolerance of .020 to datums A and B and control the coaxiality of the holes within a tolerance of .000 at MMC. Use MMC wherever possible.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 9 Ø 2.500-2.540 Ø 2.000-2.010

B

Ø 4.00

A

.XX = ± .01 .XXX = ± .005 ANGLES = ± 1° 18. In the drawing above, specify a .010 tolerance at LMC to the datums indicated for the 2.000-inch inside diameter. Use LMC (circle L) wherever possible. 19. Calculate the worst-case wall thickness between datum B and the 2.000 inside diameter in the drawing above.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 10 3X Ø .400-.425

3X 120°

A

12° 1.260

Ø 3.000

A

Ø 1.125-1.135

Section A-A .250-.280

.XX = ± .01 .XXX = ± .005 ANGLES = ± 1°

20. On the drawing above, orient the keyseat perpendicular to datum A and locate it to the Ø 1.125 hole with a tolerance that will allow it to accept a quarter-inch key. Orient the hole-pattern perpendicular to datum A, locate it to the Ø 1.125 hole, and clock it to the keyway with a tolerance of zero at MMC. Orient the counterbore pattern perpendicular to datum A, locate it to the Ø 1.125 hole, and clock it to the keyway with a tolerance of .010. The counterbores are a diameter of .615-.640, .375-.390 deep. Use MMC wherever possible.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 11 4.000-4.020 1.000-1.010

A

4.00 2.00

.XX = ± .01 .XXX = ± .005 ANGLES = ± 1° 21. Tolerance the one-inch slot perpendicular to datum A and symmetrical with the four-inch feature within . 010 at MMC. Use MMC wherever possible. 22. What is the worst-case distance between the upper surface of the slot and the top surface of the part.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 12 .250-.265 1.250 A

4X Ø .500-.510 A A Ø 1.000-1.015

B Section A-A

23. On the drawing above, orient the keyseat perpendicular to datum A and locate it to the Ø 1.000-inch hole with a tolerance that will allow it to accept a quarter-inch key. Use MMC wherever possible. 24. On the drawing above, orient the four-hole pattern parallel to datum A, locate it to the Ø 1.000-inch hole, and clock it to the keyseat all within a tolerance of .030. Refine the feature-to-feature relationship between the four holes and orient the four-hole pattern parallel to datum A, perpendicular to the axis of the Ø 1.000- inch hole, and clock to the center plane of the keyseat all within a tolerance of .010. Use MMC wherever possible.

Geometric Dimensioning and Tolerancing for Mechanical Design Second Midterm Examination 13