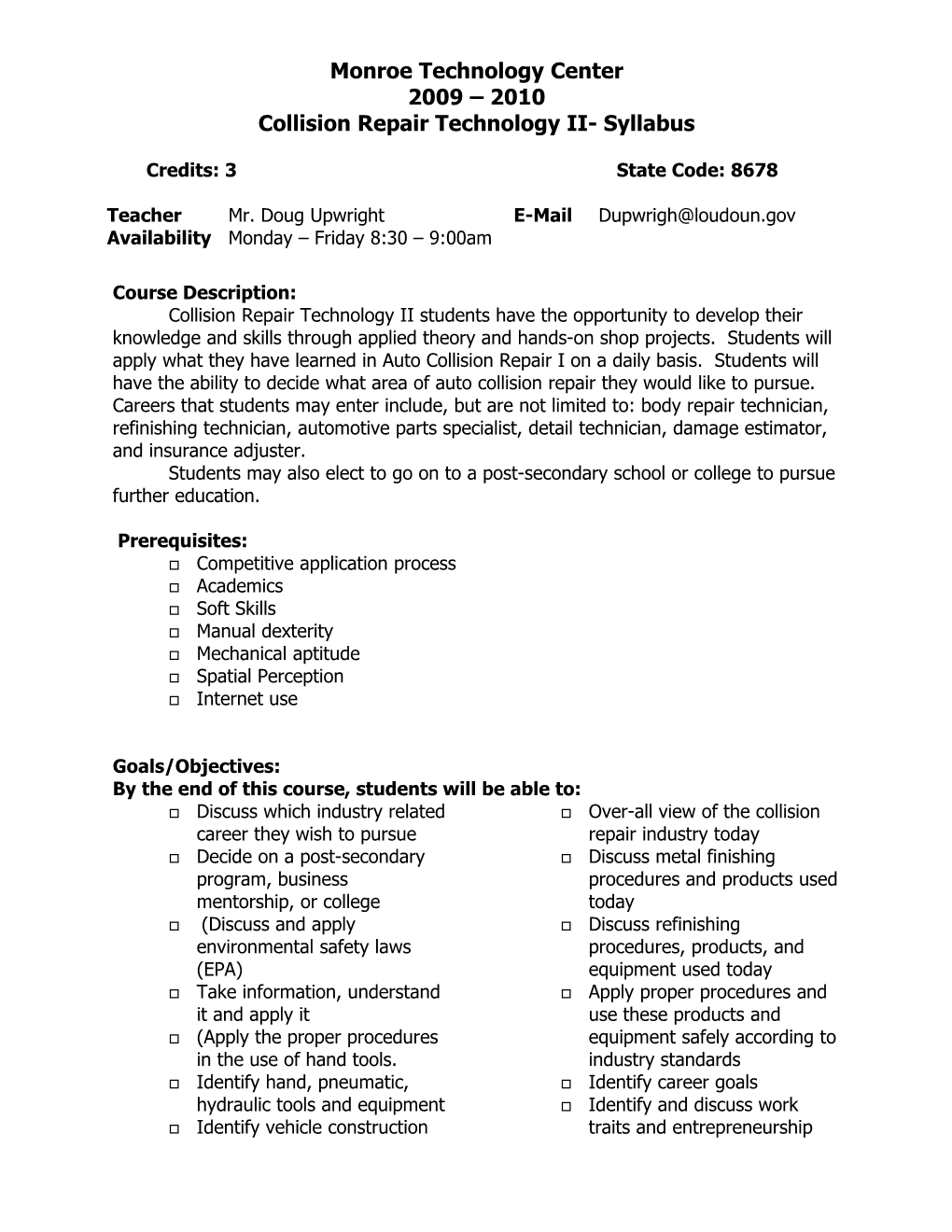

Monroe Technology Center 2009 – 2010 Collision Repair Technology II- Syllabus

Credits: 3 State Code: 8678

Teacher Mr. Doug Upwright E-Mail [email protected] Availability Monday – Friday 8:30 – 9:00am

Course Description: Collision Repair Technology II students have the opportunity to develop their knowledge and skills through applied theory and hands-on shop projects. Students will apply what they have learned in Auto Collision Repair I on a daily basis. Students will have the ability to decide what area of auto collision repair they would like to pursue. Careers that students may enter include, but are not limited to: body repair technician, refinishing technician, automotive parts specialist, detail technician, damage estimator, and insurance adjuster. Students may also elect to go on to a post-secondary school or college to pursue further education.

Prerequisites: Competitive application process Academics Soft Skills Manual dexterity Mechanical aptitude Spatial Perception Internet use

Goals/Objectives: By the end of this course, students will be able to: Discuss which industry related Over-all view of the collision career they wish to pursue repair industry today Decide on a post-secondary Discuss metal finishing program, business procedures and products used mentorship, or college today (Discuss and apply Discuss refinishing environmental safety laws procedures, products, and (EPA) equipment used today Take information, understand Apply proper procedures and it and apply it use these products and (Apply the proper procedures equipment safely according to in the use of hand tools. industry standards Identify hand, pneumatic, Identify career goals hydraulic tools and equipment Identify and discuss work Identify vehicle construction traits and entrepreneurship Identify and discuss industry related certification programs Text(s): Autobody Repair Technology, 4th Edition: James E. Duffy, Thompson Delmar Learning 2004

Autobody Technicians Manual, Thompson Delmar Learning, 2005

Student Module References: Auto Collision Technology-University of Missouri- Columbia Columbia, MO Grading: Grading will follow the policy of Loudoun County Public Schools.

Grade Scale A+ 98-100 C+ 77-79 A 93-97 C 73-76 A- 90-92 C- 70-72 B+ 87-89 D+ 67-69 B 83-86 D 63-66 B- 80-82 D- 60-62 F 0-59

Evaluations: Daily lab and classroom participation Practical lab projects Oral and written tests Home assignments

Requirements: Lab Safety Test Collision Repair Technology Competencies Dress Code

Format and Expectations: Students in the Collision Repair Technology program are being trained to be professionals in the collision repair industry. All students are expected to be in class on time everyday, dressed appropriately with the necessary books, paper, and writing utensils. Respect for other students, staff, and guests is mandatory. The class will be conducted in many formats. The textbook will be used for reading and writing assignments. Readings, discussions, projects, and lab assignments will accompany each unit as necessary. Students are expected to work hard and communicate in an appropriate fashion on a regular basis.

Helpful Hints: Soft skills and manners are a must. Follow all school, lab, and classroom procedures, participate, ask questions, and give feedback. Remember, if you are going to be a professional, you must talk, act, and dress like one. Course Outline: Collision Repair II

Week of: Topics/ Major Concepts Readings to be Major Assignments, Covered Discussed Projects, Activities Estimating and Repair Chapter 10 Lab application Costs

August 29 Estimating and Repair Chapter 10 Lab application Costs

September 5 Estimating and Repair Chapter 10 Lab application Costs

September 12 Estimating and Repair Chapter 10 Lab application Costs Writing a damage Report

September 19 Estimating and Repair Chapter 10 Lab application Costs Writing a damage Report

September 26 Estimating and Repair Chapter 10 Lab application Costs Writing a damage Report

October 3 Painting and refinishing/ Chapter 24 Lab projects Equipment and procedures

October 10 Painting and refinishing Chapter 24 Lab projects Equipment and procedures

October 24 Painting and refinishing/ Chapter 24 Lab projects Equipment and procedures

October 31

Week of: Topics/Major Concepts Readings to be Major Assignments, Covered Discussed Projects, Activities Painting and refinishing/ Chapter 24 Lab projects Equipment and procedures

November 7 Painting and refinishing Chapter 24 Lab projects Equipment and procedures

November 14 Refinishing Chapter 24 Lab projects

November 21 Refinishing Chapter 24 Lab projects

November 28 Refinishing Chapter 24 Lab projects

December 5 Frame and Unibody Chapter 24 Lab projects Construction and Repair

December 12 Vehicle Structural Chapter 24 Lab projects Repair

December 19 Vehicle Structural Chapter 24 Lab projects Repair

January 16 Month of: Topics/Major Concepts Readings to be Major Assignments, Covered Discussed Projects, Activities Hood, Bumper, Chapter 14 Lab Application Lid and Trim Service

January

Door, roof and Chapter 15 Lab Application Glass service

February Passenger Chapter 16 Lab Application Compartment Service March

Reinforcing Chapter 20 Lab Application Corrosion Protection

April

Refinishing Fenders or Lab Application Project Other

May

June