Case study SA-ERWAT

DIFFUSED-AIR INJECTION

(Mechanical and FLOATING fine-bubble aeration in “PASVEER” activated sludge system)

As a result of continuing severe increases in the price of electricity and high maintenance cost of the Brush aerators, ERWAT has investigated new energy efficient Floating Fine-bubble Aeration systems. ERWAT has selected their Carl Grundlingh wastewater treatment plant in Nigel. This plant is currently operating at an average of 3 MGL/day over the last four years and uses primarily brush aerators. However, maintenance problems with the brush aerators has required the installation of two surface aerators to supplement the oxygen demand. Carl Grundlingh WWTW treats both industrial and residential waste water, resulting in a high raw water COD level. The COD averaged 958 mg/l over the past 4 years. Due to the high COD of the raw water and aeration limitations, this plant would benefit from improved aeration efficiency. The most important factor in selecting aeration equipment for a specific application is the oxygen transfer rate. Other factors that are equally important are reliability, serviceability, capital cost, altitude above sea level and cost of operation and maintenance. Although there are many systems designed to aerate and mix the waste water, they vary in effectiveness of providing uniform oxygen absorption into the sewage water.

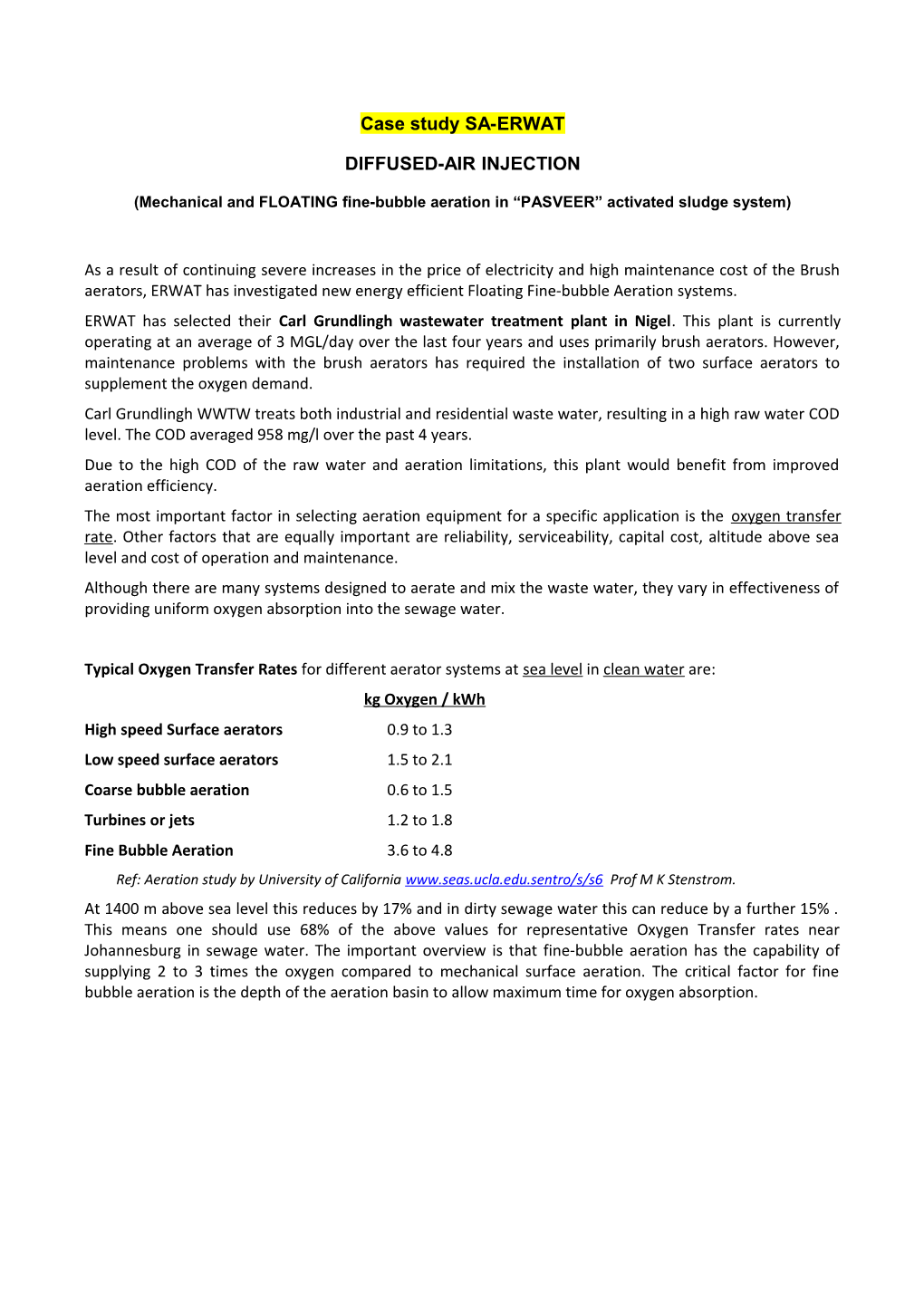

Typical Oxygen Transfer Rates for different aerator systems at sea level in clean water are: kg Oxygen / kWh High speed Surface aerators 0.9 to 1.3 Low speed surface aerators 1.5 to 2.1 Coarse bubble aeration 0.6 to 1.5 Turbines or jets 1.2 to 1.8 Fine Bubble Aeration 3.6 to 4.8 Ref: Aeration study by University of California www.seas.ucla.edu.sentro/s/s6 Prof M K Stenstrom. At 1400 m above sea level this reduces by 17% and in dirty sewage water this can reduce by a further 15% . This means one should use 68% of the above values for representative Oxygen Transfer rates near Johannesburg in sewage water. The important overview is that fine-bubble aeration has the capability of supplying 2 to 3 times the oxygen compared to mechanical surface aeration. The critical factor for fine bubble aeration is the depth of the aeration basin to allow maximum time for oxygen absorption.

DIFFUSED-AIR INJECTION

(Mechanical and FLOATING fine-bubble aeration in “PASVEER” activated sludge system)

Description of Current Aeration Process: ERWAT’s Carl Grundlingh wastewater treatment plant uses a “Pasveer” ditch 1.6m deep as the aeration basin. Four brush-aerators are installed in the first linear section of the ditch. One of these aerators is out- of-service, a 2nd has one of the 3 brushes removed. To supplement the oxygen demand a surface aerator has been installed at the inlet to the aeration ditch. A 2nd surface aerator has been installed at the start of the next linear section of the ditch. The average Raw and Final water analysis over the period January 2008 to December 2011 is as follows:

Ref: “Carl Grundlingh Operational Data” Excel Spread-Sheet provided by Dr. Z. Godongwana, R & D Manager Erwat 16 March 2012 The literature oxygen efficiency for brush aerators is 1.8 Kg O2/ kWh. This will reduce to 1.22 Kg O2/ kWh when adjusted for altitude and sewage water. With all four brush aerators, each with 18.5 kW motors, the maximum oxygen supply from 74 kW total is 90 Kg O2/ kWh At current conditions with one brush aerator out of service and another operating at 66% capacity, the brush aerators can deliver a maximum of 49.2 kW of power and supply 60 Kg of Oxygen per hour to the water. The two surface aerators have a combined power rating of 60 kW, drawing approximately 54 kW with the capability of delivering 1.8 Kg O2/ kWh at sea level in clean water. Adjusted for altitude and sewage water this would drop to 1.22 Kg O2/ kWh. This would add approximately 65.9 Kg Oxygen to the water per hour. The Total Power consumption for aeration is estimated at 103.2 kW (49.2 + 54) which can supply a maximum of 129.5 kg per hour (60 + 65.9) ERWAT wish to evaluate the feasibility of using Floating Fine-Bubble Aerators to increase the oxygen availability and increase energy efficiency.

Case study SA-ERWAT DIFFUSED-AIR INJECTION

(Mechanical and FLOATING fine-bubble aeration in “PASVEER” activated sludge system)

Ref Case study SA-ERWAT Response information, description and remarks 1 Location: ERWAT is Based north of Johannesburg with their Carl Grundelingh Sewage plant near to the small town of Nigel, 20km east of OR Tambo Airport. Nigel is a small mining and farming town with an industrial area and light density suburban areas. 2 Sector: Sewage – mixed liquid phase treating residential and industrial waste water 3 Works Owner or Operator: The plant is owned by the ERWAT (Water Services Authority) and operated and maintained by ERWAT. Department of Water Affairs is the Regulator and ERWAT need to comply with the water use license specific to each of its WWT plants.

4 Size: The Nigel sewage plant has an average load of 3 million litres per day of water to be treated from 40 000 residents and the industrial area

5 Energy Provider: Power is in form of electricity, provider by the national electricity agency, ESKOM. Electricity tariffs are made up of 74.4 cents/kWh

6 Process: Operation consists of oxygen transfer through Brush aerators and Surface aerators to the mixed liquid in the activated sludge basins. As result of this physical intervention, both biological and chemical reactions are facilitated.

7 Component: This case study refers to the activated sludge and mixed suspended solids phase only.

8 Motivation for the case study: The cost of electricity is set to double over 5 years starting 2012 in South Africa. With most cities and large towns employing aeration of the mixed liquor suspended solids in the activated sludge processes, the energy efficiency of different aeration types are becoming a key consideration as part of the overall life cycle cost.

9 Process/Plant changes: Comparison of energy efficiency, fine bubble aeration system, using mechanical aeration as the benchmark.

10 Civil/Physical Changes: Selecting the energy efficient and cost effective aeration equipment for wastewater treatment plants.

11 Operational Changes: Minimising power consumption and maximising performance in aeration systems, by controlling oxygen concentration in aerated liquid within 1 – 2 mg/l, provide minimum required aeration intensity, and monitor and service and performance for uninterrupted operation. Good operator knowledge is required.

12 Risks and Dependencies: Risk is in considering only energy efficiency as criteria when making technology decisions. Decisions need to be based on multiple criteria to include aeration efficiency, energy efficiency, meeting legal specification, and life cycle costs. 13 Implementation: Due to the current aeration limitations at Carl Grundlingh WWTW Erwat are evaluating potential solutions to the operational and energy efficiency issues at this plant.

14 Mechanical surface aeration: Energy Efficiency gains: 129.5 kg O2/h demand from 103.2 kW = 1.26 kg O2/kWh

Floating Fine bubble aeration: (design basis)

15 Cost / Benefit analysis: International experience with Floating Fine-bubble aeration reduces energy usage by 50 to 70 % compared to mechanical surface aeration.

Erwat wish to evaluate this technology.

Section 14 above shows a 52.5% energy saving for the design of the Floating Fine Bubble system to deliver the same amount of Oxygen.

16 Project review With floating fine-bubble aeration, the aeration equipment levels itself from the water surface and can be installed and maintained with the aeration basin in operation. The air column above the fine bubble diffusers creates a very effective “air-lift” which provides excellent vertical and radial mixing to suspend sludge and keep the dissolved oxygen levels uniform 17 Confidence grade: Medium – this document forms the design basis of the case study which requires to be validated in practice based on material and data analysed during the trials. Further work is continuing. International experience with similar “Pasveer” type plants has shown over 50% energy saving.

The cost of electricity is a significant component of the overall cost of wastewater treatment. The aeration of the mixed liquor suspended solids in the activated sludge process constitutes a major portion of the electricity consumption on a plant. The majority of plants in South Africa use mechanical surface aerators for aeration, with some variations in bubble diffused aerations systems. As results of sharp increases in the price of electricity and the need to conserve energy, Erwat wishes to investigate various fine bubble aeration systems and their performance and potential cost savings against the existing surface aeration systems.

Description of Process

The performance of existing aeration systems based on existing influent sewage and treated effluent characteristic and historic energy consumption of the aeration systems has been evaluated. The following site with the design parameters below has been selected for evaluation: The average Raw and Final water quality over the period January 2008 to December 2011 is as follows:

Ref: “Carl Grundlingh Operational Data” Excel Spread-Sheet provided by Dr. Z. Godongwana, R & D Manager Erwat 16 March 2012

Process Description: To convert the Carl Grundelingh Plant to Floating Fine Bubble aeration the plant will not need to be stopped or emptied. The Floating Fine Bubble aeration units would be assembled and lowered into the “Pasveer” channel using a truck mounted crane. Road access is available around 60% of the aeration basin, which is adequate for installation of the required Floating fine bubble units. Below is a typical conversion similar to the Carl Grundelingh Plant

Efficient air blowers will be required to supply air at 0.2 bar. Individual air supply pipes are fitted to each floating unit. This makes installation and maintenance very easy without changing the plant operation. Flow-makers will be used to ensure that the water flows around the channel at the correct rate. All the fine bubble diffusers to be used are tubular in shape and are fitted with membranes that do not scale easily. These diffusers have been in service for 10 years without loss of energy efficiency.

References:

i) Aeration by Prof. M. K. Stenstrom and D. Rosso University of California – Los Angeles 2010 www.seas.ucla.edu/stenstro/s/s6

ii) MAPAL Case Study: Ramat Hasharon Sewage Works Upgrade from Brush Aerators to Floating Fine Bubble aerators