Computer Integrated Manufacturing WVEIS 2465

Computer Integrated Manufacturing is a component of the Project Lead the Way (PLTW) pre-engineering curriculum. This course will introduce students to principles of robotics and automation and CAD design. The course builds on computer solid modeling skills developed in Computer Integrated Manufacturing, and Design and Drawing for Production. Students use CNC equipment to produce actual models of their three-dimensional designs. Fundamental concepts of robotics used in automated manufacturing and design analysis are included. Students will utilize problem-solving techniques and participate in laboratory activities to develop an understanding of course concepts. Safety instruction is integrated into all activities. Students are encouraged to become active members of TSA, the national youth organization for those enrolled in technology education. TSA is an integral component of the program and provides curricular opportunities that enhance student achievement. The West Virginia Standards for 21 st Century Learning include the following components: 21st Century Content Standards and 21st Century Learning Skills and Technology Tools. All West Virginia teachers are responsible for classroom instruction that integrates learning skills, technology tools and content standards and objectives.

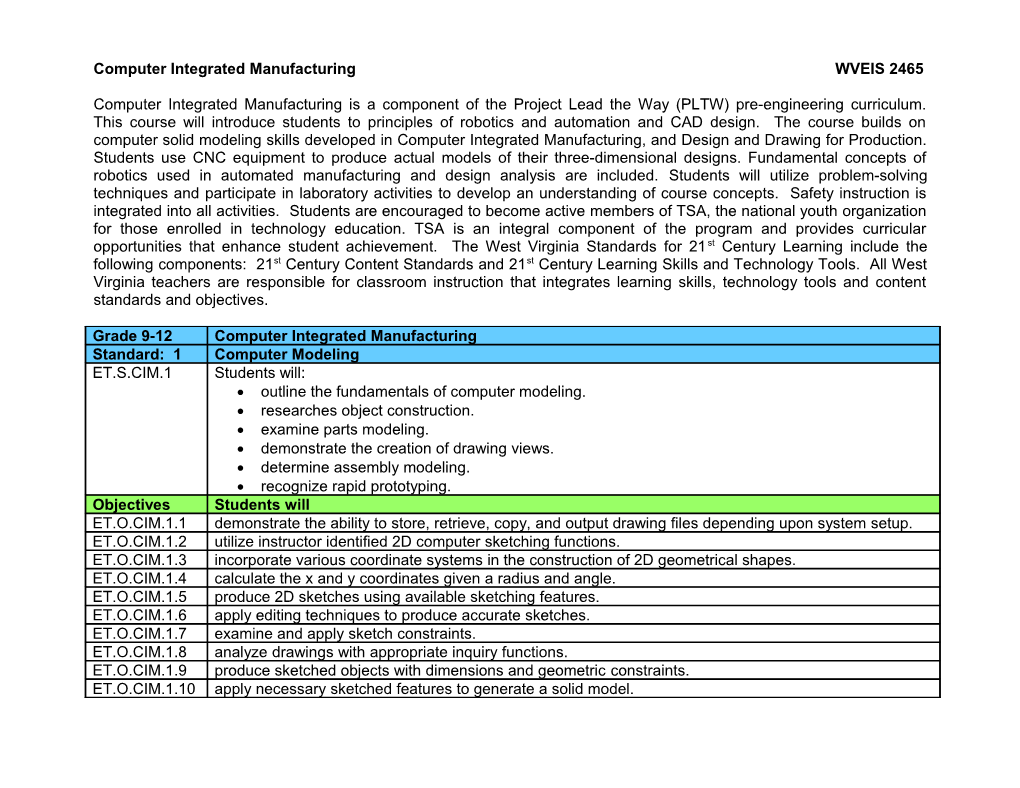

Grade 9-12 Computer Integrated Manufacturing Standard: 1 Computer Modeling ET.S.CIM.1 Students will: outline the fundamentals of computer modeling. researches object construction. examine parts modeling. demonstrate the creation of drawing views. determine assembly modeling. recognize rapid prototyping. Objectives Students will ET.O.CIM.1.1 demonstrate the ability to store, retrieve, copy, and output drawing files depending upon system setup. ET.O.CIM.1.2 utilize instructor identified 2D computer sketching functions. ET.O.CIM.1.3 incorporate various coordinate systems in the construction of 2D geometrical shapes. ET.O.CIM.1.4 calculate the x and y coordinates given a radius and angle. ET.O.CIM.1.5 produce 2D sketches using available sketching features. ET.O.CIM.1.6 apply editing techniques to produce accurate sketches. ET.O.CIM.1.7 examine and apply sketch constraints. ET.O.CIM.1.8 analyze drawings with appropriate inquiry functions. ET.O.CIM.1.9 produce sketched objects with dimensions and geometric constraints. ET.O.CIM.1.10 apply necessary sketched features to generate a solid model. ET.O.CIM.1.11 demonstrate the application and modifying of placed features. ET.O.CIM.1.12 develop multi-view drawings such as top, front, right side, isometric, section, and auxiliary views from the solid model. ET.O.CIM.1.13 demonstrate the proper application of annotations and reference dimensions while conforming to established drafting standards. ET.O.CIM.1.14 update model and drawing views using revision specification sheets provided by the instructor. ET.O.CIM.1.15 create assembly models through the integration of individual parts and sub-assemblies. ET.O.CIM.1.16 generate an assembly drawing, which include Views, Balloons, and Bill of Materials (BOM). ET.O.CIM.1.17 recognize the wide array of industry-wide prototyping methods in use. ET.O.CIM.1.18 examine the need for rapid-prototyping. ET.O.CIM.1.19 prepare a prototype model from a drawing data base. Performance Descriptors (ET.PD.CIM.1) Above Mastery Mastery Partial Mastery The student demonstrates The student demonstrates competent The student demonstrates basic but exceptional and exemplary and proficient performance and shows inconsistent performance of fundamental performance with distinctive and a thorough and effective application of knowledge and skills characterized by sophisticated application of knowledge and skills that meet the errors and/or omissions in computer knowledge and skills that exceed the standard in computer modeling. The modeling. The student can do the standard in computer modeling. The student can do the following with few following with notable errors: student can do the following with no errors: demonstrate the ability to demonstrate the ability to store, retrieve, errors: demonstrate the ability to store, retrieve, copy, and output copy, and output drawing files depending store, retrieve, copy, and output drawing files depending upon system upon system setup; utilize instructor drawing files depending upon system setup; utilize instructor identified 2D identified 2D computer sketching setup; utilize instructor identified 2D computer sketching functions; functions; incorporate various coordinate computer sketching functions; incorporate various coordinate systems in the construction of 2D incorporate various coordinate systems in the construction of 2D geometrical shapes; calculate the x and y systems in the construction of 2D geometrical shapes; calculate the x coordinates given a radius and angle; geometrical shapes; calculate the x and y coordinates given a radius and produce 2D sketches using available and y coordinates given a radius and angle; produce 2D sketches using sketching features; apply editing angle; produce 2D sketches using available sketching features; apply techniques to produce accurate sketches; available sketching features; apply editing techniques to produce examine and apply sketch constraints; editing techniques to produce accurate sketches; examine and apply analyze drawings with appropriate inquiry accurate sketches; examine and sketch constraints; analyze drawings functions; produce sketched objects with apply sketch constraints; analyze with appropriate inquiry functions; dimensions and geometric constraints; drawings with appropriate inquiry produce sketched objects with apply necessary sketched features to functions; produce sketched objects dimensions and geometric constraints; generate a solid model; demonstrate the with dimensions and geometric apply necessary sketched features to application and modifying of placed constraints; apply necessary generate a solid model; features; develop multi-view drawings sketched features to generate a solid demonstrate the application and such as top, front, right side, isometric, model; demonstrate the application modifying of placed features; develop section, and auxiliary views from the solid and modifying of placed features; multi-view drawings such as top, front, model; demonstrate the proper develop multi-view drawings such as right side, isometric, section, and application of annotations and reference top, front, right side, isometric, auxiliary views from the solid model; dimensions while conforming to section, and auxiliary views from the demonstrate the proper application of established drafting standards; update solid model; demonstrate the proper annotations and reference dimensions model and drawing views using revision application of annotations and while conforming to established specification sheets provided by the reference dimensions while drafting standards; update model and instructor; create assembly models conforming to established drafting drawing views using revision through the integration of individual parts standards; update model and drawing specification sheets provided by the and sub-assemblies; generate an views using revision specification instructor; create assembly models assembly drawing, which include Views, sheets provided by the instructor; through the integration of individual Balloons, and Bill of Materials (BOM); create assembly models through the parts and sub-assemblies; generate recognize the wide array of industry-wide integration of individual parts and an assembly drawing, which include prototyping methods in use; identify the sub-assemblies; generate an Views, Balloons, and Bill of Materials need for rapid-prototyping; and prepare a assembly drawing, which include (BOM); recognize the wide array of prototype model from a drawing data Views, Balloons, and Bill of Materials industry-wide prototyping methods in base. Performance needs further (BOM); recognize the wide array of use; examine the need for rapid- development and supervision. industry-wide prototyping methods in prototyping; and prepare a prototype use; assess the need for rapid- model from a drawing data base. prototyping; and prepare a prototype Application of knowledge and skills is model from a drawing data base. thorough and effective, and the The student can independently solve student can work independently. problems and is self-directed.

Standard: 2 Programmable Machines ET.S.CIM.2 Students will: outline the history of programmable machining. research CNC characteristics. examine CNC programming. recognize CNC operations. demonstrate precision measurement. utilize CAM software. demonstrate coordinate systems. Objectives Students will ET.O.CIM.2.1 research the history of computer controlled machines charting the growth of NC and how it has been implemented into private industry. ET.O.CIM.2.2 examine how the application of CNC machines has impacted manufacturing. ET.O.CIM.2.3 compare and contrast the advantages and disadvantages of CNC Machining. ET.O.CIM.2.4 chart the evolution of machine tools, controllers, and software used in programmable machines. ET.O.CIM.2.5 outline career opportunities and educational requirements within the field of programmable machines. ET.O.CIM.2.6 identify the axis relative to various CNC machines. ET.O.CIM.2.7 contrast open and closed loop control systems. ET.O.CIM.2.8 demonstrate the types of drive systems used in CNC machines. ET.O.CIM.2.9 use the CNC control program to indicate the machine position and then contrast that position to the relative position of the part origin (PRZ). ET.O.CIM.2.10 recognize the function of the major components of a CNC machine tool. ET.O.CIM.2.11 apply various work holding devices commonly used for CNC machining. ET.O.CIM.2.12 investigate various types of tool changers used in CNC machine tools. ET.O.CIM.2.13 determine the three primary axes used in CNC machining and explore the remaining axes used in advanced machining. ET.O.CIM.2.14 research the importance of cutting tool materials and how they affect the speed and feed rates used by machine tools. ET.O.CIM.2.15 demonstrate different types of tool holding devices used in CNC machine tools. ET.O.CIM.2.16 select appropriate cutting tools to efficiently, safely, and accurately cut parts using a CNC machine. ET.O.CIM.2.17 compare the difference between reference and position points. ET.O.CIM.2.18 discover that CNC machine movements are identified by axes. ET.O.CIM.2.19 characterize that the axis system is a worldwide standard for machine movement. ET.O.CIM.2.20 plot points using absolute, relative (incremental), and polar coordinates. ET.O.CIM.2.21 demonstrate significant points on geometric shapes (ex. center point, end point). ET.O.CIM.2.22 assess the optimum location for the Program Reference Zero (PRZ) point. ET.O.CIM.2.23 outline the three categories of machine movement: straight line, curved line, and non-regular shape. ET.O.CIM.2.24 construct a preliminary planning sheet to identify necessary work holding devices, cutting tools, reference points, machining sequences, and safe operation. ET.O.CIM.2.25 research the three categories of machine movement: straight line, curved line, and non-regular shape. ET.O.CIM.2.26 produce a preliminary planning sheet to identify necessary work holding devices, cutting tools, reference points, machining sequences, and safe operation. ET.O.CIM.2.27 discover the term “Alphanumeric Coding.” ET.O.CIM.2.28 characterize the term “G codes.” ET.O.CIM.2.29 research the term “M code.” ET.O.CIM.2.30 outline the three sections of a program; Initial Commands, Program Body, and Program End. ET.O.CIM.2.31 produce a basic NC part program using necessary G and M codes, including remarks that describe the function of each code. ET.O.CIM.2.32 compare the advantages and disadvantages of shop floor programming as well as off line programming. ET.O.CIM.2.33 create a simple NC part program using a text editor and a CAM package. ET.O.CIM.2.34 utilize a CAD/CAM/CNC software solution to create a part. ET.O.CIM.2.35 analyze, identify, and correct errors found in NC part program files. ET.O.CIM.2.36 use simulation software to graphically verify NC program operation. ET.O.CIM.2.37 perform a “dry run” to verify the machine setup and program operation. ET.O.CIM.2.38 demonstrate the ability to safely setup, maintain, and operate a CNC machine center using appropriate documentation and procedures. ET.O.CIM.2.39 analyze part geometry to select appropriate cutting tools and fixturing devices needed to create the part using a CNC machine. ET.O.CIM.2.40 organize and edit the tool library of a CNC control program providing offset values and tool geometry. ET.O.CIM.2.41 calculate and verify appropriate spindle speeds and feed rates specific to each cutting tool utilized in an NC part program. ET.O.CIM.2.42 demonstrate how to fixture a part in a CNC machine and set the program reference zero (PRZ). ET.O.CIM.2.43 validate NC part programs using simulation software before machining the part on a CNC device. ET.O.CIM.2.44 demonstrate all possible methods of disabling a CNC machine in the event of an emergency. ET.O.CIM.2.45 demonstrate how to measure using standard and metric systems. ET.O.CIM.2.46 use mathematical computations to convert measurements between metric and standard inch systems. ET.O.CIM.2.47 demonstrate how to read technical drawings identifying the dimensional tolerances and limits. ET.O.CIM.2.48 demonstrate how to make precision measurements to the degree of accuracy required by plan specification using appropriate instruments. ET.O.CIM.2.49 determine how comparison instruments can be used to check dimensions, compare shapes, indicate centers, and check parallel surfaces. ET.O.CIM.2.50 research advanced and automated measurement systems that are applied in industry. (ex. Coordinate Measuring Systems, Digital Probes, and Optical scanners) ET.O.CIM.2.51 characterize the importance of precision measurement in SPC and quality control. ET.O.CIM.2.52 examine the purpose of a CAM package. ET.O.CIM.2.53 demonstrate the ability to operate the user interface of a CAM package and access help using appropriate documentation and help screens. ET.O.CIM.2.54 perform basic file operations using a CAM package such as saving, opening, printing, and editing part program files. ET.O.CIM.2.55 model how to import and export CAD files using a CAM package. ET.O.CIM.2.56 setup a CAM package by editing the material and tool libraries, defining stock sizes, selecting the appropriate post processor, and defining the units of measure to be used. ET.O.CIM.2.57 apply the fundamental and advanced milling and turning procedures used in CAM packages. ET.O.CIM.2.58 use a CAM package to generate and edit tool paths by applying appropriate machining processes to geometry imported from a CAD program. ET.O.CIM.2.59 utilize the right hand rule to identify the X, Y, and Z axes of the Cartesian Coordinate System. ET.O.CIM.2.60 apply a combination of absolute, relative, and polar coordinates to construct a three-dimensional model. ET.O.CIM.2.61 research the origin planes in the Cartesian Coordinate System. ET.O.CIM.2.62 determine the origin and planar orientations of each side of a three-dimensional model. Performance Descriptors (ET.PD.CIM.2) Above Mastery Mastery Partial Mastery The student demonstrates exceptional The student demonstrates competent The student demonstrates basic but and exemplary performance with and proficient performance and shows a inconsistent performance of distinctive and sophisticated application thorough and effective application of fundamental knowledge and skills of knowledge and skills that exceed the knowledge and skills that meet the characterized by errors and/or standard in programmable machines. standard in programmable machines. omissions in programmable machines. The student can do the following with The student can do the following with The student can do the following with no errors: research the history of few errors: examine the history of notable errors: identify the history of computer controlled machines charting computer controlled machines charting computer controlled machines the growth of NC and how it has been the growth of NC and how it has been charting the growth of NC and how it implemented into private industry; implemented into private industry; has been implemented into private evaluate how the application of CNC examine how the application of CNC industry; identify how the application machines has impacted manufacturing; machines has impacted manufacturing; of CNC machines has impacted compare and contrast the advantages examine the advantages and manufacturing; list the advantages and disadvantages of CNC Machining; disadvantages of CNC Machining; chart and disadvantages of CNC Machining; chart the evolution of machine tools, the evolution of machine tools, chart the evolution of machine tools, controllers, and software used in controllers, and software used in controllers, and software used in programmable machines; outline programmable machines; outline career programmable machines; outline career opportunities and educational opportunities and educational career opportunities and educational requirements within the field of requirements within the field of requirements within the field of programmable machines; identify the programmable machines; identify the programmable machines; identify the axis relative to various CNC machines; axis relative to various CNC machines; axis relative to various CNC contrast open and closed loop control contrast open and closed loop control machines; contrast open and closed systems; demonstrate the types of systems; demonstrate the types of drive loop control systems; demonstrate the drive systems used in CNC machines; systems used in CNC machines; use types of drive systems used in CNC use the CNC control program to the CNC control program to indicate the machines; use the CNC control indicate the machine position and then machine position and then contrast that program to indicate the machine contrast that position to the relative position to the relative position of the position and then contrast that position position of the part origin (PRZ); part origin (PRZ); recognize the function to the relative position of the part recognize the function of the major of the major components of a CNC origin (PRZ); recognize the function of components of a CNC machine tool; machine tool; apply various work the major components of a CNC apply various work holding devices holding devices commonly used for machine tool; apply various work commonly used for CNC machining; CNC machining; examine various types holding devices commonly used for investigate various types of tool of tool changers used in CNC machine CNC machining; list various types of changers used in CNC machine tools; tools; determine the three primary axes tool changers used in CNC machine determine the three primary axes used used in CNC machining and explore the tools; determine the three primary in CNC machining and explore the remaining axes used in advanced axes used in CNC machining and remaining axes used in advanced machining; examine the importance of explore the remaining axes used in machining; research the importance of cutting tool materials and how they advanced machining; identify the cutting tool materials and how they affect the speed and feed rates used by importance of cutting tool materials affect the speed and feed rates used by machine tools; demonstrate different and how they affect the speed and machine tools; demonstrate different types of tool holding devices used in feed rates used by machine tools; types of tool holding devices used in CNC machine tools; select appropriate demonstrate different types of tool CNC machine tools; select appropriate cutting tools to efficiently, safely, and holding devices used in CNC machine cutting tools to efficiently, safely, and accurately cut parts using a CNC tools; select appropriate cutting tools accurately cut parts using a CNC machine; compare the difference to efficiently, safely, and accurately cut machine; compare the difference between reference and position points; parts using a CNC machine; compare between reference and position points; examine how CNC machine movements the difference between reference and discover that CNC machine are identified by axes; examine how the position points; identify how CNC movements are identified by axes; axis system is a worldwide standard for machine movements are identified by evaluate that the axis system is a machine movement; plot points using axes; identify how the axis system is a worldwide standard for machine absolute, relative (incremental), and worldwide standard for machine movement; plot points using absolute, polar coordinates; demonstrate movement; plot points using absolute, relative (incremental), and polar significant points on geometric shapes relative (incremental), and polar coordinates; demonstrate significant (ex. center point, end point); assess the coordinates; demonstrate significant points on geometric shapes (ex. center optimum location for the Program points on geometric shapes (ex. point, end point); assess the optimum Reference Zero (PRZ) point; outline the center point, end point); assess the location for the Program Reference three categories of machine movement: optimum location for the Program Zero (PRZ) point; outline the three straight line, curved line, and non- Reference Zero (PRZ) point; outline categories of machine movement: regular shape; construct a preliminary the three categories of machine straight line, curved line, and non- planning sheet to identify necessary movement: straight line, curved line, regular shape; construct a preliminary work holding devices, cutting tools, and non-regular shape; construct a planning sheet to identify necessary reference points, machining sequences, preliminary planning sheet to identify work holding devices, cutting tools, and safe operation; examine the three necessary work holding devices, reference points, machining categories of machine movement: cutting tools, reference points, sequences, and safe operation; straight line, curved line, and non- machining sequences, and safe research the three categories of regular shape; produce a preliminary operation; define the three categories machine movement: straight line, planning sheet to identify necessary of machine movement: straight line, curved line, and non-regular shape; work holding devices, cutting tools, curved line, and non-regular shape; produce a preliminary planning sheet to reference points, machining sequences, produce a preliminary planning sheet identify necessary work holding and safe operation; examine the term to identify necessary work holding devices, cutting tools, reference points, “Alphanumeric Coding”; characterize devices, cutting tools, reference machining sequences, and safe the term “G codes”; examine the term points, machining sequences and safe operation; discover the term “M code”; outline the three sections of a operation; define the term “Alphanumeric Coding”; characterize program, Initial Commands, Program “Alphanumeric Coding”; characterize the term “G codes”; research the term Body, and Program End; produce a the term “G codes”; define the term “M “M code”; outline the three sections of a basic NC part program using necessary code”; outline the three sections of a program, Initial Commands, Program G and M codes including remarks that program, Initial Commands, Program Body, and Program End; produce a describe the function of each code; Body, and Program End; produce a basic NC part program using necessary examine the advantages and basic NC part program using G and M codes including remarks that disadvantages of shop floor necessary G and M codes including describe the function of each code; programming as well as off line remarks that describe the function of compare the advantages and programming; create a simple NC part each code; list the advantages and disadvantages of shop floor program using a text editor and a CAM disadvantages of shop floor programming as well as off line package; utilize a CAD/CAM/CNC programming as well as off line programming; create a simple NC part software solution to create a part; programming; create a simple NC part program using a text editor and a CAM analyze, identify, and correct errors program using a text editor and a package; utilize a CAD/CAM/CNC found in NC part program files; use CAM package; utilize a software solution to create a part; simulation software to graphically verify CAD/CAM/CNC software solution to analyze, identify, and correct errors NC program operation; perform a “dry create a part; analyze, identify, and found in NC part program files; use run” to verify the machine setup and correct errors found in NC part simulation software to graphically verify program operation; demonstrate the program files; use simulation software NC program operation; perform a “dry ability to safely setup, maintain, and to graphically verify NC program run” to verify the machine setup and operate a CNC machine center using operation; perform a “dry run” to verify program operation; demonstrate the appropriate documentation and the machine setup and program ability to safely setup, maintain, and procedures; examine part geometry to operation; demonstrate the ability to operate a CNC machine center using select appropriate cutting tools and safely setup, maintain, and operate a appropriate documentation and fixturing devices needed to create the CNC machine center using procedures; analyze part geometry to part using a CNC machine; organize appropriate documentation and select appropriate cutting tools and and edit the tool library of a CNC control procedures; define part geometry to fixturing devices needed to create the program providing offset values and tool select appropriate cutting tools and part using a CNC machine; organize geometry; calculate and verify fixturing devices needed to create the and edit the tool library of a CNC appropriate spindle speeds and feed part using a CNC machine; organize control program providing offset values rates specific to each cutting tool and edit the tool library of a CNC and tool geometry; calculate and verify utilized in an NC part program; control program providing offset appropriate spindle speeds and feed demonstrate how to fixture a part in a values and tool geometry; calculate rates specific to each cutting tool CNC machine and set the program and verify appropriate spindle speeds utilized in an NC part program; reference zero (PRZ); validate NC part and feed rates specific to each cutting demonstrate how to fixture a part in a programs using a simulation software tool utilized in an NC part program; CNC machine and set the program before machining the part on a CNC demonstrate how to fixture a part in a reference zero (PRZ); validate NC part device; demonstrate all possible CNC machine and set the program programs using a simulation software methods of disabling a CNC machine in reference zero (PRZ); validate NC part before machining the part on a CNC the event of an emergency; programs using a simulation software device; demonstrate all possible demonstrate how to measure using before machining the part on a CNC methods of disabling a CNC machine in standard and metric systems; use device; demonstrate all possible the event of an emergency; mathematical computations to convert methods of disabling a CNC machine demonstrate how to measure using measurements between metric and in the event of an emergency; standard and metric systems; use standard inch systems; demonstrate demonstrate how to measure using mathematical computations to convert how to read technical drawings standard and metric systems; use measurements between metric and identifying the dimensional tolerances mathematical computations to convert standard inch systems; demonstrate and limits; demonstrate how to make measurements between metric and how to read technical drawings precision measurements to the degree standard inch systems; demonstrate identifying the dimensional tolerances of accuracy required by plan how to read technical drawings and limits; demonstrate how to make specification using appropriate identifying the dimensional tolerances precision measurements to the degree instruments; examine how comparison and limits; demonstrate how to make of accuracy required by plan instruments can be used to check precision measurements to the degree specification using appropriate dimensions, compare shapes, indicate of accuracy required by plan instruments; assess how comparison centers, and check parallel surfaces; specification using appropriate instruments can be used to check research advanced and automated instruments; examine how comparison dimensions, compare shapes, indicate measurement systems that are applied instruments can be used to check centers, and check parallel surfaces; in industry (ex. Coordinate Measuring dimensions, compare shapes, indicate research advanced and automated Systems, Digital Probes, and Optical centers, and check parallel surfaces; measurement systems that are applied scanners); characterize the importance research advanced and automated in industry (ex. Coordinate Measuring of precision measurement in SPC and measurement systems that are Systems, Digital Probes, and Optical quality control; examine the purpose of applied in industry (ex. Coordinate scanners); characterize the importance a CAM package; demonstrate the ability Measuring Systems, Digital Probes, of precision measurement in SPC and to operate the user interface of a CAM and Optical scanners); characterize quality control; evaluate the purpose of package and access help using the importance of precision a CAM package; demonstrate the appropriate documentation and help measurement in SPC and quality ability to operate the user interface of a screens; perform basic file operations control; identify the purpose of a CAM CAM package and access help using using a CAM package such as saving, package; demonstrate the ability to appropriate documentation and help opening, printing, and editing part operate the user interface of a CAM screens; perform basic file operations program files; model how to import and package and access help using using a CAM package such as saving, export CAD files using a CAM package; appropriate documentation and help opening, printing, and editing part setup a CAM package by editing the screens; perform basic file operations program files; model how to import and material and tool libraries, defining stock using a CAM package such as saving, export CAD files using a CAM package; sizes, selecting the appropriate post opening, printing, and editing part setup a CAM package by editing the processor, and defining the units of program files; model how to import material and tool libraries, defining measure to be used; apply the and export CAD files using a CAM stock sizes, selecting the appropriate fundamental and advanced milling and package; setup a CAM package by post processor, and defining the units turning procedures used in CAM editing the material and tool libraries, of measure to be used apply the packages; use a CAM package to defining stock sizes, selecting the fundamental and advanced milling and generate and edit tool paths by applying appropriate post processor, and turning procedures used in CAM appropriate machining processes to defining the units of measure to be packages; use a CAM package to geometry imported from a CAD used; apply the fundamental and generate and edit tool paths by program; utilize the right hand rule to advanced milling and turning applying appropriate machining identify the X, Y, and Z axes of the procedures used in CAM packages; processes to geometry imported from a Cartesian Coordinate System; apply a use a CAM package to generate and CAD program; utilize the right hand rule combination of absolute, relative, and edit tool paths by applying appropriate to identify the X, Y, and Z axes of the polar coordinates to construct a three- machining processes to geometry Cartesian Coordinate System; apply a dimensional model; research the origin imported from a CAD program; utilize combination of absolute, relative, and planes in the Cartesian Coordinate the right hand rule to identify the X, Y, polar coordinates to construct a three- System; and determine the origin and and Z axes of the Cartesian dimensional model; research the origin planar orientations of each side of a Coordinate System; apply a planes in the Cartesian Coordinate three-dimensional model. Application of combination of absolute, relative, and System; and determine the origin and knowledge and skills is thorough and polar coordinates to construct a three- planar orientations of each side of a effective, and the student can work dimensional model; research the three-dimensional model. The student independently. origin planes in the Cartesian can independently solve problems and Coordinate System; and determine the is self-directed. origin and planar orientations of each side of a three-dimensional model. Performance needs further development and supervision. Standard: 3 Robotics ET.S.CIM.3 Students will: research the technology of robotics. compare and contrast robotics and automated systems. outline robotic characteristics. discover mechanical components. research control systems. demonstrate programming methods. apply industrial robot applications. Objectives Students will ET.O.CIM.3.1 outline the chronological development of automation leading to robotics. ET.O.CIM.3.2 discover career opportunities in the robotics career fields. ET.O.CIM.3.3 investigate the development of robotics from science fiction. ET.O.CIM.3.4 compare and contrast a minimum of four dangerous and repetitive jobs that robots are used. ET.O.CIM.3.5 formulate a definition of a robot. ET.O.CIM.3.6 classify different types of robots. ET.O.CIM.3.7 evaluate the positive impact robots have on manufacturing. ET.O.CIM.3.8 research the social implications of robots. ET.O.CIM.3.9 compare the four classifications of robots. ET.O.CIM.3.10 examine a classification of robot. ET.O.CIM.3.11 design and build a working model of a robot. ET.O.CIM.3.12 report specifications and work envelopes of robots. ET.O.CIM.3.13 sketch the mechanical components to a robot. ET.O.CIM.3.14 design and develop an end effector. ET.O.CIM.3.15 demonstrate an understanding of the way end effectors are specific to a process. ET.O.CIM.3.16 examine the various drive systems used in robotics and analyze the advantages and disadvantages of each. ET.O.CIM.3.17 outline the basic components of robot controllers. ET.O.CIM.3.18 demonstrate an understanding of control techniques and computer simulations. ET.O.CIM.3.19 design and build a feed system with sensors. ET.O.CIM.3.20 program a robot to perform several tasks. ET.O.CIM.3.21 program a robot to solve a materials handling problem. ET.O.CIM.3.22 recognize the need for end of arm tooling and how this tooling affects the robots operation. ET.O.CIM.3.23 determine the necessity for specialty tooling applications in robotics. ET.O.CIM.3.24 prepare and document a presentation on end of arm tooling. ET.O.CIM.3.25 analyze and generate the solution to a robotic manufacturing problem. Performance Descriptors (ET.PD.CIM.3) Above Mastery Mastery Partial Mastery The student demonstrates exceptional The student demonstrates competent and The student demonstrates basic but and exemplary performance with proficient performance and shows a inconsistent performance of distinctive and sophisticated application thorough and effective application of fundamental knowledge and skills of knowledge and skills that exceed the knowledge and skills that meet the characterized by errors and/or standard in robotics. The student can standard in robotics. The student can do omissions in robotics. The student do the following with no errors: outline the following with few errors: outline the can do the following with notable the chronological development of chronological development of automation errors: outline the chronological automation leading to robotics; leading to robotics; examine career development of automation leading discover career opportunities in the opportunities in the robotics career fields; to robotics; list career opportunities robotics career fields; investigate the examine the development of robotics in the robotics career fields; identify development of robotics from science from science fiction; examine a minimum the development of robotics from fiction; compare and contrast a of four dangerous and repetitive jobs that science fiction; list a minimum of four minimum of four dangerous and robots are used; formulate a definition of dangerous and repetitive jobs that repetitive jobs that robots are used; a robot; classify different types of robots; robots are used; formulate a formulate a definition of a robot; examine the positive impact robots have definition of a robot; classify different classify different types of robots; on manufacturing; research the social types of robots; list the positive evaluate the positive impact robots implications of robots; examine the four impact robots have on have on manufacturing; research the classifications of robots; examine a manufacturing; research the social social implications of robots; compare classification of robot; design and build a implications of robots; identify the the four classifications of robots; working model of a robot; report four classifications of robots; evaluate a classification of robot; specifications and work envelopes of describe a classification of robot; design, and build a working model of a robots; sketch the mechanical design and build a working model of robot; report specifications and work components to a robot; design and a robot; report specifications and envelopes of robots; sketch the develop an end effector; demonstrate an work envelopes of robots; sketch the mechanical components to a robot; understanding of the way end effectors mechanical components to a robot; design and develop an end effector are specific to a process; examine the design and develop an end effector; with no errors; demonstrate an various drive systems used in robotics, demonstrate an understanding of the understanding of the way end effectors determine the advantages and way end effectors are specific to a are specific to a process; evaluate the disadvantages of each; outline the basic process; identify the various drive various drive systems used in robotics components of robot controllers; systems used in robotics and list the and analyze the advantages and demonstrate an understanding of control advantages and disadvantages of disadvantages of each; outline the techniques and computer simulations; each; outline the basic components basic components of robot controllers; design and build a feed system with of robot controllers; demonstrate an demonstrate an understanding of sensors; program a robot to perform understanding of control techniques control techniques and computer several tasks; program a robot to solve a and computer simulations; design simulations; design and build a feed materials handling problem; recognize the and build a feed system with system with sensors; program a robot need for end of arm tooling and how this sensors; program a robot to perform to perform several tasks; program a tooling affects the robots operation; several tasks; program a robot to robot to solve a materials handling examine the necessity for specialty solve a materials handling problem; problem; recognize the need for end of tooling applications in robotics; prepare recognize the need for end of arm arm tooling and how this tooling affects and document a presentation on end of tooling and how this tooling affects the robots operation; evaluate the arm tooling; and analyze and generate the robots operation; describe the necessity for specialty tooling the solution to a robotic manufacturing necessity for specialty tooling applications in robotics; prepare and problem. Application of knowledge and applications in robotics; prepare and document a presentation on end of arm skills is thorough and effective, and the document a presentation on end of tooling; and analyze and generate the student can work independently. arm tooling; and analyze and solution to a robotic manufacturing generate the solution to a robotic problem. The student can manufacturing problem. independently solve problems and is Performance needs further self-directed. development and supervision.

Standard: 4 Computer Integrated Manufacturing ET.S.CIM.4 Students will: characterize the rationale for CIM. compare and contrast the types of CIM systems. outline the components of a CIM system. demonstrate the CIM system applications. Objectives Students will ET.O.CIM.4.1 compare and contrast how the individual components of a flexible manufacturing system are interrelated. ET.O.CIM.4.2 outline the benefits and problems associated with CIM technology and how they affect the manufacturing process. ET.O.CIM.4.3 characterize some basic characteristics of a manufacturing operation that lend themselves to computer integrated manufacturing. ET.O.CIM.4.4 research some of the typical components and sub systems that make up an automated machining, assembly, and process-type manufacturing operation. ET.O.CIM.4.5 determine the three categories of CIM manufacturing systems. ET.O.CIM.4.6 compare and contrast the benefits and drawbacks of the three categories of CIM manufacturing systems. ET.O.CIM.4.7 compare and contrast the working relationship between the CNC mill and the robot. ET.O.CIM.4.8 outline the components of a FMS. ET.O.CIM.4.9 assess the relationship between a CNC milling machine interface and a jointed arm robot interface through a communication handshaking process. ET.O.CIM.4.10 discover the individual components used in selected CIM systems. ET.O.CIM.4.11 analyze and select components for a CIM system for a specific industrial application. ET.O.CIM.4.12 examine the various applications of a Programmable Logic Controller as related to its use in a CIM system. ET.O.CIM.4.13 compare and contrast the difference between a PLC and a computer with interface. ET.O.CIM.4.14 recognize and understand the necessary safety precautions associated with a fully automated CIM system. ET.O.CIM.4.15 demonstrate the significance of teamwork and communication when they combine the designs of the individual groups into a complete miniature FMS. ET.O.CIM.4.16 recognize how their individual components work together to form a complete CIM system. ET.O.CIM.4.17 assemble and test individual component designs by integrating them into a complete miniature FMS built from the Fischertechnik models. Performance Descriptors (ET.PD.CIM.4) Above Mastery Mastery Partial Mastery The student demonstrates exceptional The student demonstrates competent The student demonstrates basic but and exemplary performance with and proficient performance and shows inconsistent performance of distinctive and sophisticated application a thorough and effective application of fundamental knowledge and skills of knowledge and skills that exceed the knowledge and skills that meet the characterized by errors and/or standard in computer integrated standard in computer integrated omissions in computer integrated manufacturing. The student can do the manufacturing. The student can do manufacturing. The student can do the following with no errors: compare and the following with few errors: following with notable errors: compare contrast how the individual components compare and contrast how the and contrast how the individual of a flexible manufacturing system are individual components of a flexible components of a flexible manufacturing interrelated; outline the benefits and manufacturing system are system are interrelated; outline the problems associated with CIM interrelated; outline the benefits and benefits and problems associated with technology and how they affect the problems associated with CIM CIM technology and how they affect manufacturing process; characterize technology and how they affect the the manufacturing process; some basic characteristics of a manufacturing process; characterize characterize some basic characteristics manufacturing operation that lend some basic characteristics of a of a manufacturing operation that lend themselves to computer integrated manufacturing operation that lend themselves to computer integrated manufacturing; research some of the themselves to computer integrated manufacturing; research some of the typical components and sub systems manufacturing; research some of the typical components and sub systems that make up an automated machining, typical components and sub systems that make up an automated machining, assembly, and process-type that make up an automated assembly, and process-type manufacturing operation; determine the machining, assembly, and process- manufacturing operation; determine the three categories of CIM manufacturing type manufacturing operation; three categories of CIM manufacturing systems; compare and contrast the determine the three categories of CIM systems; compare and contrast the benefits and drawbacks of the three manufacturing systems; compare and benefits and drawbacks of the three categories of CIM manufacturing contrast the benefits and drawbacks categories of CIM manufacturing systems; compare and contrast the of the three categories of CIM systems; compare and contrast the working relationship between the CNC manufacturing systems; compare and working relationship between the CNC mill and the robot; outline the contrast the working relationship mill and the robot; outline the components of a FMS; assess the between the CNC mill and the robot; components of a FMS; assess the relationship between a CNC milling outline the components of a FMS; relationship between a CNC milling machine interface and a jointed arm assess the relationship between a machine interface and a jointed arm robot interface through a communication CNC milling machine interface and a robot interface through a handshaking process; discover the jointed arm robot interface through a communication handshaking process; individual components used in selected communication handshaking process; discover the individual components CIM systems; analyze and select discover the individual components used in selected CIM systems; analyze components for a CIM system for a used in selected CIM systems; and select components for a CIM specific industrial application; examine analyze and select components for a system for a specific industrial the various applications of a CIM system for a specific industrial application; examine the various Programmable Logic Controller as application; examine the various applications of a Programmable Logic related to its use in a CIM system; applications of a Programmable Logic Controller as related to its use in a CIM compare and contrast the difference Controller as related to its use in a system; compare and contrast the between a PLC and a computer with CIM system; compare and contrast difference between a PLC and a interface; recognize and understand the the difference between a PLC and a computer with interface; recognize and necessary safety precautions associated computer with interface; recognize understand the necessary safety with a fully automated CIM system; and understand the necessary safety precautions associated with a fully demonstrate the significance of precautions associated with a fully automated CIM system; demonstrate teamwork and communication when automated CIM system; demonstrate the significance of teamwork and they combine the designs of the the significance of teamwork and communication when they combine the individual groups into a complete communication when they combine designs of the individual groups into a miniature FMS; recognize how their the designs of the individual groups complete miniature FMS; recognize individual components work together to into a complete miniature FMS; how their individual components work form a complete CIM system; and recognize how their individual together to form a complete CIM assemble and test individual component components work together to form a system; and assemble and test designs by integrating them into a complete CIM system; and assemble individual component designs by complete miniature FMS built from the and test individual component designs integrating them into a complete Fischertechnik models. The student by integrating them into a complete miniature FMS built from the can independently solve problems and miniature FMS built from the Fischertechnik models. Performance is self-directed. Fischertechnik models. Application of needs further development and knowledge and skills is thorough and supervision. effective, and the student can work independently. Standard: 5 Participating in the Student Organization ET.S.CIM.5 Students will participate in a local student organization. Objectives Students will ET.O.CIM.5.1 assess the purpose and goals of student organizations. ET.O.CIM.5.2 demonstrate leadership skills through participation in student organization activities such as meetings, programs, projects, and competitions. ET.O.CIM.5.3 evaluate the benefits and responsibilities of participation in student, professional, and civic organizations as an adult. Performance Descriptors (ET.PD.CIM.5) Above Mastery Mastery Partial Mastery The student demonstrates exceptional The student demonstrates competent The student demonstrates basic but and exemplary performance with and proficient performance and shows inconsistent performance of distinctive and sophisticated application a thorough and effective application of fundamental knowledge and skills of knowledge and skills that exceed the knowledge and skills that meet the characterized by errors and/or standard in participating in the student standard in participating in the student omissions in participating in the student organization. The student can assess organization. The student can organization. The student can identify the purpose and goals of a student examine the purpose and goals of a the purpose and goals of a student organization; demonstrate leadership student organization; demonstrate organization; demonstrate leadership skills through participation in student leadership skills through reporting skills through reading about student organizations activities such as about student organizations activities organizations activities such as meetings, programs, projects, and such as meetings, programs, projects, meetings, programs, projects, and competitions; and evaluate the benefits and competitions; and examine the competitions; and define the benefits and responsibilities of participation in benefits and responsibilities of and responsibilities of participation in student, professional, and civic participation in student, professional, student, professional, and civic organizations as an adult. The student and civic organizations as an adult. organizations as an adult. can independently solve problems and Application of knowledge and skills is Performance needs further is self-directed. thorough and effective, and the development and supervision. student can work independently. Standard: 6 Literacy and Numeracy ET.S.CIM.6 Students will demonstrate the literacy and numeracy skills required to solve complex, real-world problems associated with their career/technical content area and improve their thinking and reasoning skills. Objectives Students will ET.O.CIM.6.1 utilize a variety of technical sources (e.g., Internet, manuals, journals, directions, reports, etc.) to complete career/technical assignments and projects. ET.O.CIM.6.2 demonstrate writing skills required to complete career/technical assignments and projects. ET.O.CIM.6.3 demonstrate accuracy in calculating and measuring graphical work required to complete career/technical assignments and projects. ET.O.CIM.6.4 analyze tables, charts, graphs and multiple data sources to complete career/technical assignments and projects. Performance Descriptors (ET.PD.CIM.6) Above Mastery Mastery Partial Mastery The student demonstrates exceptional The student demonstrates competent The student demonstrates basic but and exemplary performance with and proficient performance and shows inconsistent performance of fundamental distinctive and sophisticated application a thorough and effective application of knowledge and skills characterized by of knowledge and skills that exceed the knowledge and skills that meet the errors and/or omissions in literacy and standard in literacy and numeracy. The standard in literacy and numeracy. The numeracy. The student selects a variety student chooses a variety of technical student utilizes a variety of technical of technical sources (e.g., Internet, sources (e.g., Internet, manuals, sources (e.g., Internet, manuals, manuals, journals, directions, reports, journals, directions, reports, etc.) to journals, directions, reports, etc.) to etc.) to complete career/technical complete career/technical assignments complete career/technical assignments assignments and projects; reproduces and projects; performs writing skills and projects; demonstrates writing skills writing skills required to complete required to complete career/technical required to complete career/technical career/technical assignments and assignments and projects; assignments and projects; projects; illustrates accuracy in communicates accuracy in calculating demonstrates accuracy in calculating calculating and measuring graphical work and measuring graphical work required and measuring graphical work required required to complete career/technical to complete career/technical to complete career/technical assignments and projects; and explains assignments and projects; and assignments and projects; and tables, charts, graphs and multiple data evaluates tables, charts, graphs and analyzes tables, charts, graphs and sources to complete career/technical multiple data sources to complete multiple data sources to complete assignments and projects. Performance career/technical assignments and career/technical assignments and needs further development and projects. The student can independently projects. Application of knowledge and supervision. solve problems and is self-directed. skills is thorough and effective and the student can work independently. Standard: 7 21st Century Learning Skills ET.S.CIM.7 The student will access and manipulate information for use in oral, written, or multimedia format using appropriate technology skills. apply sound reasoning processes to solve complex real-world problems and develop new ideas. exhibit leadership and ethical behavior in planning and executing tasks, as an individual or a group member. Objectives Students will ET.O.CIM.7.1 search online using a range of technology tools and media to access relevant information needed for problem solving. ET.O.CIM.7.2 create information for oral, written, and multimedia communications, adhering to copyright laws. ET.O.CIM.7.3 engage in problem solving and critical thinking processes to create and evaluate complex strategies in order to independently solve problems. ET.O.CIM.7.4 adapt to new situations by considering multiple perspectives and a commitment to continued learning. ET.O.CIM.7.5 exhibit ethical behavior and positive leadership while working collaboratively in the school and/or community. ET.O.CIM.7.6 model legal and ethical behaviors in the use of technology. Performance Descriptors (ET.PD.CIM.7) Above Mastery Mastery Partial Mastery The student demonstrates exceptional The student demonstrates competent The student demonstrates basic but and exemplary performance with and proficient performance and shows inconsistent performance of fundamental distinctive and sophisticated application a thorough and effective application of knowledge and skills characterized by of knowledge and skills that exceed the knowledge and skills that meet the errors and/or omissions in 21st century standard in 21st century learning skills. standard in 21st century learning skills. learning skills. The student explains The student assesses online technology The student searches online using a online technology tools and media to tools and media to access relevant range of technology tools and media to access relevant information needed for information needed for problem solving; access relevant information needed for problem solving; identifies information for critiques information for oral, written, and problem solving; creates information for oral, written, and multimedia multimedia communications, adhering to oral, written, and multimedia communications, adhering to copyright copyright laws; integrates problem communications, adhering to copyright laws; discusses problem solving and solving and critical thinking processes to laws; engages in problem solving and critical thinking processes to create and create and evaluate complex strategies critical thinking processes to create and evaluate complex strategies in order to in order to independently solve evaluate complex strategies in order to independently solve problems; discusses problems; interprets new situations by independently solve problems; adapts new situations by considering multiple considering multiple perspectives and a to new situations by considering perspectives and a commitment to commitment to continued learning; multiple perspectives and a continued learning; reviews ethical incorporates ethical behavior and commitment to continued learning; behavior and positive leadership while positive leadership while working exhibits ethical behavior and positive working collaboratively in the school collaboratively in the school and/or leadership while working collaboratively and/or community; and describes legal community; and reinforces legal and in the school and/or community; and and ethical behaviors in the use of ethical behaviors in the use of models legal and ethical behaviors in technology. Performance needs further technology. The student can the use of technology. Application of development and supervision. independently solve problems and is knowledge and skills is thorough and self-directed. effective and the student can work independently. Standard: 8 Entrepreneurship Skills ET.S.CIM.8 Students will access the opportunities, concepts, processes, and personal traits/behaviors associated with successful entrepreneurial performance. Objectives Students will ET.O.CIM.8.1 assess global trends in entrepreneurship that are related to their career/technical program. ET.O.CIM.8.2 determine entrepreneurial opportunities in venture creation related to their career/technical program. ET.O.CIM.8.3 examine desirable entrepreneurial personality traits. Performance Descriptors (ET.PD.CIM.8) Above Mastery Mastery Partial Mastery The student demonstrates exceptional The student demonstrates competent The student demonstrates basic but and exemplary performance with and proficient performance and shows inconsistent performance of fundamental distinctive and sophisticated application a thorough and effective application of knowledge and skills characterized by of knowledge and skills that exceed the knowledge and skills that meet the errors and/or omissions in standard in entrepreneurship skills. The standard in entrepreneurship skills. The entrepreneurship skills. The student lists student critiques global trends in student assesses global trends in global trends in entrepreneurship that are entrepreneurship that are related to their entrepreneurship that are related to related to their career/technical program; career/technical program; evaluates their career/technical program; describes entrepreneurial opportunities in entrepreneurial opportunities in venture determines entrepreneurial venture creation related to their creation related to their career/technical opportunities in venture creation related career/technical program; and identifies program; and assesses desirable to their career/technical program; and desirable entrepreneurial personality entrepreneurial personality traits. The examines desirable entrepreneurial traits. Performance needs further student can independently solve personality traits. Application of development and supervision. problems and is self-directed. knowledge and skills is thorough and effective and the student can work independently.