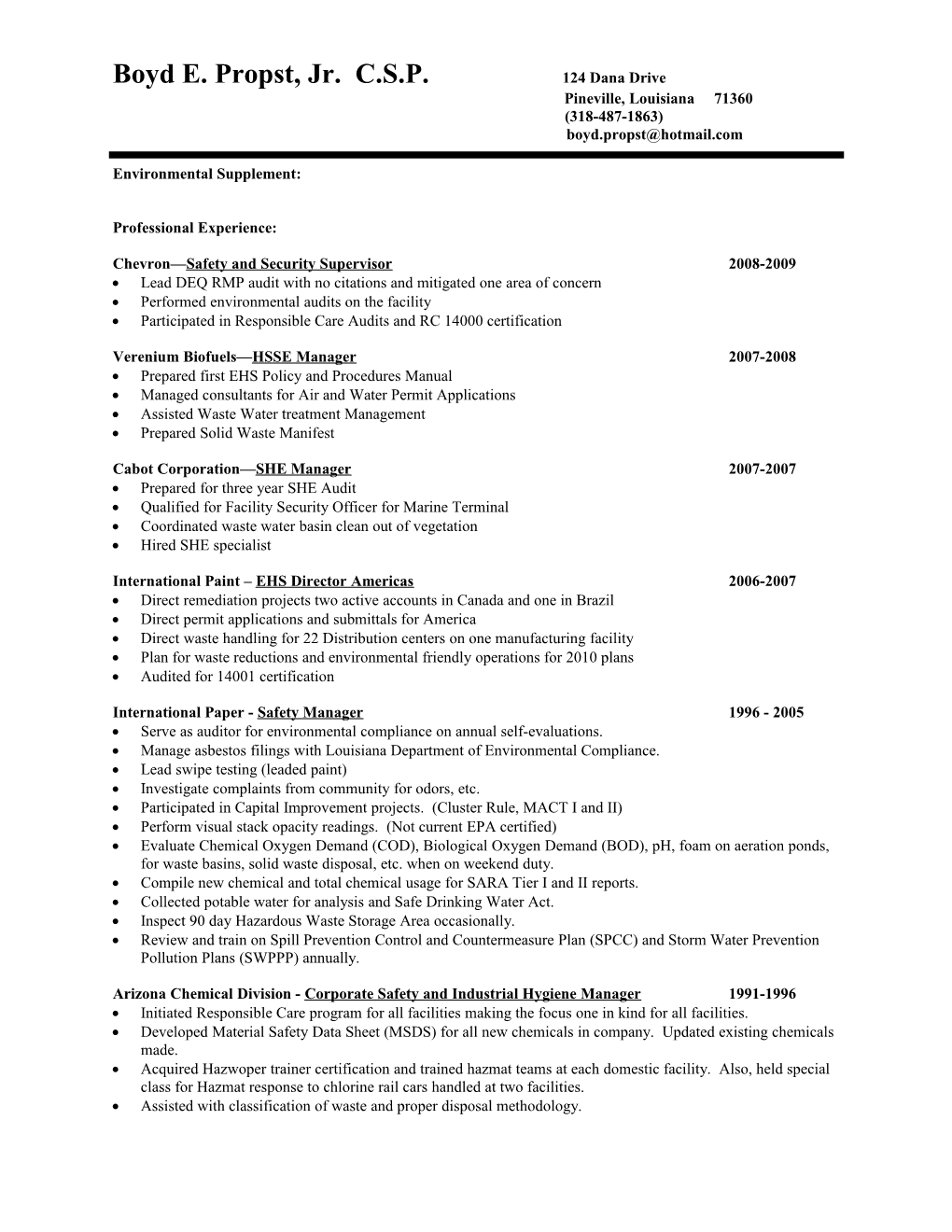

Boyd E. Propst, Jr. C.S.P. 124 Dana Drive Pineville, Louisiana 71360 (318-487-1863) [email protected]

Environmental Supplement:

Professional Experience:

Chevron—Safety and Security Supervisor 2008-2009 Lead DEQ RMP audit with no citations and mitigated one area of concern Performed environmental audits on the facility Participated in Responsible Care Audits and RC 14000 certification

Verenium Biofuels—HSSE Manager 2007-2008 Prepared first EHS Policy and Procedures Manual Managed consultants for Air and Water Permit Applications Assisted Waste Water treatment Management Prepared Solid Waste Manifest

Cabot Corporation—SHE Manager 2007-2007 Prepared for three year SHE Audit Qualified for Facility Security Officer for Marine Terminal Coordinated waste water basin clean out of vegetation Hired SHE specialist

International Paint – EHS Director Americas 2006-2007 Direct remediation projects two active accounts in Canada and one in Brazil Direct permit applications and submittals for America Direct waste handling for 22 Distribution centers on one manufacturing facility Plan for waste reductions and environmental friendly operations for 2010 plans Audited for 14001 certification

International Paper - Safety Manager 1996 - 2005 Serve as auditor for environmental compliance on annual self-evaluations. Manage asbestos filings with Louisiana Department of Environmental Compliance. Lead swipe testing (leaded paint) Investigate complaints from community for odors, etc. Participated in Capital Improvement projects. (Cluster Rule, MACT I and II) Perform visual stack opacity readings. (Not current EPA certified) Evaluate Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), pH, foam on aeration ponds, for waste basins, solid waste disposal, etc. when on weekend duty. Compile new chemical and total chemical usage for SARA Tier I and II reports. Collected potable water for analysis and Safe Drinking Water Act. Inspect 90 day Hazardous Waste Storage Area occasionally. Review and train on Spill Prevention Control and Countermeasure Plan (SPCC) and Storm Water Prevention Pollution Plans (SWPPP) annually.

Arizona Chemical Division - Corporate Safety and Industrial Hygiene Manager 1991-1996 Initiated Responsible Care program for all facilities making the focus one in kind for all facilities. Developed Material Safety Data Sheet (MSDS) for all new chemicals in company. Updated existing chemicals made. Acquired Hazwoper trainer certification and trained hazmat teams at each domestic facility. Also, held special class for Hazmat response to chlorine rail cars handled at two facilities. Assisted with classification of waste and proper disposal methodology. Boyd E. Propst, Jr. C.S.P. 124 Dana Drive Pineville, Louisiana 71360 (318-487-1863) [email protected]

Performed some site assessments as an additional auditor for International Paper Corporate. Assisted in the underground storage tank (UST) evaluations.

Berwind Railway Services, Inc. Corporate Environmental, Safety and Industrial Hygiene Manager 1990-1991 Prepared and submitted SARA reports Tier I and II Advised for clean up of all chemical that are transported by rail and proper disposal methodology. Prepared first environmental policy manual for the corporation and trained management on applicable standards and policy requirements.

Mason Chamberlin, Inc. – Safety Engineer and Industrial Hygienist 1986-1990 Respond to fires, spills, gas releases, explosions, etc. and coordinate evacuations, containment, and control measures. Monitor and review analyze methods/procedures, construction, engineering projects/drawings, environmental and health problems. Quantitatively evaluate physical and chemical agents/hazards by surveys, analysis, sampling, medical surveillance, toxicology, MSDS’s, etc. Administer programs and perform training on: hazard communication, respiratory protection, heat stress, and first response for hazardous material spills and containment.

Republic Refining, Ltd. – Safety Coordinator and Plant Chemist 1982-1986 Developed SPCC Plan Managed hazardous waste disposal and manifest. Negotiated air permits with state of Mississippi Environmental Group and converted Title V permit. Contracted air modeling using CRYSTLR Method.

Pursue Gas Processing, Inc. - Assistant Plant Chemist 1981-1982 Perform quality and process control analysis for this sour gas processing facility. Including hazardous waste determinations.

Mississippi Power and Light – Project Chemist 1978-1981 Directed and coordinated Environmental Impact Statement (EIS) for DeSoto Coal Fired Power Plant. Handled NPDES permitting and reporting for all five fossil fuel units. Performed stack testing for regulatory requirements (SO2, NOx, etc.) Performed lab test for Water Discharge requirements (NPDES), BOD, COD, SS, pH, etc.

Specific Environmental Specialized Skills: Clean Air Act and Community Right to Know Water and Waste Water permits and monitoring and reporting ISO 14001 standards Gas Chromatography Analysis using Flame Ionizing Detector (FID) and Thermal Conductivity Detector (TCD) ASTM test methods and many other instruments and testing methods, spectrophotometers, etc. Monitor and participate in state or regional rule making. Have lead plant-level business planning activities from an environmental perspective. Advised Management on environmental compliance issues; report regulatory issues, including spills, releases and emergencies, as required by law and internal procedures. Participate in development and implementation of emerging environmental programs. Develop and write sampling and testing procedures. Responsible for developing environmental reports and maintaining environmental records. Boyd E. Propst, Jr. C.S.P. 124 Dana Drive Pineville, Louisiana 71360 (318-487-1863) [email protected]

Independently develop construction and operating permit applications and negotiate permit terms and conditions. Coordinate and respond to environmental assessments as a member of a team. Participate in cross-functional teams on special projects as assigned. Assist in budgeting for environmental activities. Independently assist in the providing of environmental input to the Capital Improvement Projects. Independently interact with environmental regulators; accompany government inspectors on agency inspections and complaints and lead the negotiation of any violations. Lead or contribute to the development of environmental permit applications. Schedule and participate in monitoring, sampling, and testing of permitted process and pollution control equipment for compliance. Assess the need for and arrange for appropriate environmental training. Provide input to regarding pollution control equipment operation and maintenance programs as related to permit requirements. Self-directed management of environmental contracts.