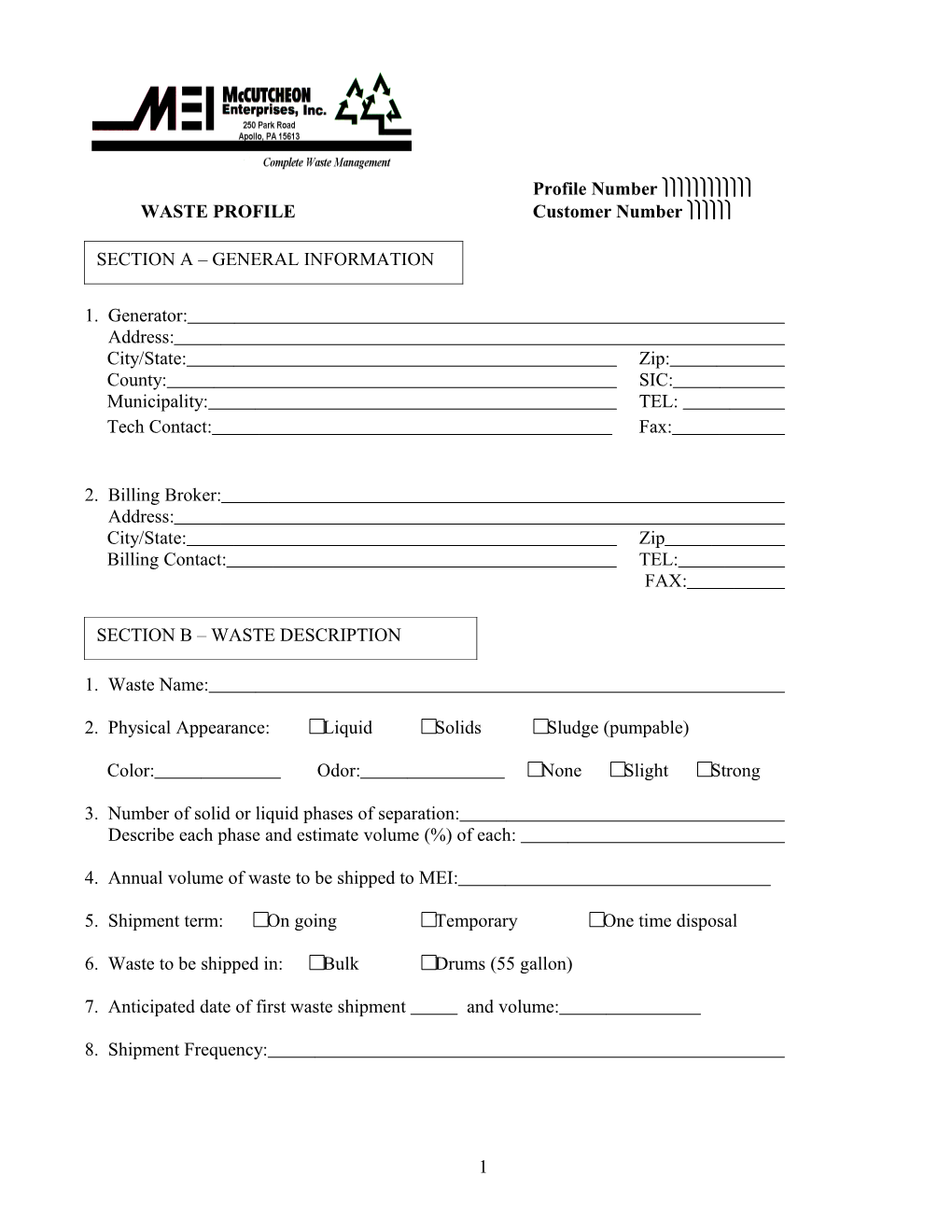

Profile Number WASTE PROFILE Customer Number

SECTION A – GENERAL INFORMATION

1. Generator: Address: City/State: Zip: County: SIC: Municipality: TEL: Tech Contact: Fax:

2. Billing Broker: Address: City/State: Zip Billing Contact: TEL: FAX:

SECTION B – WASTE DESCRIPTION

1. Waste Name:

2. Physical Appearance: Liquid Solids Sludge (pumpable)

Color: Odor: None Slight Strong

3. Number of solid or liquid phases of separation: Describe each phase and estimate volume (%) of each:

4. Annual volume of waste to be shipped to MEI:

5. Shipment term: On going Temporary One time disposal

6. Waste to be shipped in: Bulk Drums (55 gallon)

7. Anticipated date of first waste shipment and volume:

8. Shipment Frequency:

1 SECTION C – CHEMICAL ANALYSIS

1. Waste sample type: Grab Composite Other

Provide a detailed description of the sampling method and a diagram of the sample collection area.

Diagram of sample collection area:

2. List the results of the analysis of the waste below: Please attach laboratory report

3. Check below if results are in PPM or PPB and note if results are by TCLP vs. Totals.

4. Please analyze for the following parameters indicated by (), or contact MEI to perform analysis for you.

PARAMETER METHOD TEST RESULT RANGE PARAMETER METHOD TEST RESULT RANGE PREFERENCE PPM PPB (TYPICAL) PREFERENCE PPM PPB (TYPICAL) Check if by TCLP pH 150.1/9040 Arsenic 6010/7060 Oil and Grease 413.1/9070 Barium 6010/7080 PCB 608/8080 Cadmium 6010/7130 TVS 160.4 Chromium 6010/7190 TSS 160.2 Lead 6010/7420 Total Solids 160.3 Mercury 7470 Flash Point 1010 Selenium 6010/7740 TCLP 1311 //////////// ////////// Silver 6010/7760 COD 410.1/410.2 RCRA Volatile Organics 8260 Cyanide 9010 RCRA Semi-Vol Organics 8270 Sulfide 9030 Spec. Gravity D1298-99 BOD 05 SM5210B

5. Is the waste a hazardous waste as defined in 40 CFR 261? Yes No IF THE WASTE IS HAZARDOUS IT CANNOT BE DISPOSED AT MEI

6. Is the waste subject to any specific Federal pre-treatment standards? Yes No If yes, identify industrial category and subpart. Attach copy of PSES/PSNS if available.

2 SECTION D – PROCESS DESCRIPTION AND SCHEMATIC

1. Give a detailed description of the manufacturing or waste generating process and a description (if applicable) of waste treatment and stabilization including treatment/stabilization monitoring:

2. Please attach any MSDS sheets if available.

3. Draw a schematic of the manufacturing or waste generating process here or attach:

4. Additional comments or information:

SECTION E – CERTIFICATION OF GENERATOR

I certify under penalty of law that I have personally examined and am familiar with the information submitted in this and all attached documents and that based upon my inquiry of those individuals immediately responsible for obtaining the information, I believe that the submitted information is true, accurate, and complete.

COMPANY

AUTHORIZED REPRESENTATIVE

TITLE

SIGNATURE DATE / /

3

Generator/Broker Special Waste Processing Warranty Statement

Please initial statement 1, 2 & 3. Consultants, Brokers or other parties may initial and sign on behalf of the generator only if a notarized letter of authorization from the generator permits such party to sign documents on their behalf and legally binds the generator in submission with the Waste Profile (WP).

____ 1. I hereby warrant that the waste described in the attached waste processing application (WP) is not a listed hazardous waste pertinent to 40 CFR 261 and 25 PA Code 261. Furthermore, the described waste is not a mixture of a listed hazardous waste or residue derived from the treatment of a listed hazardous waste (or if it is a residue of a listed hazardous waste, it has been stabilized and meets the requirements of this waste profile) nor is the described waste an excluded hazardous waste unless it meets the conditions of the Waste Analysis and Classification Plan. _____ 2. I hereby specifically warrant that (in lieu of analytical testing and therefore based upon my knowledge of the waste stream and manufacturing process described in the attached waste processing application, WP) the parameters specified in the application and those parameters listed below are not equal to or greater than the allowable levels indicated on the approved Residual Waste Permit for the receiving facility. _____ 3. I hereby certify that (in lieu of analytical testing and therefore based upon my knowledge of the waste stream and manufacturing process described in the attached waste processing application, WP) any parameter of the waste (listed in MEI’s Table R-4 of the Residual Waste Permit Waste Analysis Plan) does not exceed the Table R-4 limit for that parameter unless it meets the conditions of the Waste Analysis and Classification Plan.

Acceptable Facility Limits (AFL) for Residual Waste (Except Waste Oil)

PARAMETER CONCENTRATION UNITS PARAMETER CONCENTRATION UNITS

Ignitability – FlashPoint >140 ºF Organics Group Corrosivity – pH >2 / <12.5 D018 – Benzene <0.5 mg/l Reactive Cyanide <250.0 mg/l D019 – Carbon Tetrachloride <0.5 mg/l Reactive Sulfide <250.0 mg/l D021 – Chlorobenzene <100.0 mg/l PCB <0.2 mg/l D022 – Chloroform <6.0 mg/l D023 – o-Cresol <200.0 mg/l Toxicity – TCLP D024 – m-Cresol <200.0 mg/l Metals Group D025 – p-Cresol <200.0 mg/l D004 – Arsenic <5.0 mg/l D026 – Cresol <200.0 mg/l D005 – Barium <100.0 mg/l D027 – 1,4 Dichlorobenzene <7.5 mg/l D006 – Cadmium <1.0 mg/l D028 – 1,2 Dichloroethane <0.5 mg/l D007 – Chromium <5.0 mg/l D029 – 1,1 Dichloroethylene <0.7 mg/l D008 – Lead <5.0 mg/l D030 - 2.4 Dinitrotoluene <0.13 mg/l D009 – Mercury <0.2 mg/l D032 – Hexachlorobenzene <0.13 mg/l D010 – Selenium <1.0 mg/l D033 – Hexachloro – 1,3 – butadiene <0.5 mg/l D011 – Silver <5.0 mg/l D034 – Hexachloroethane <3.0 mg/l Copper <250.0 mg/l D035 – Methyl Ethyl Ketone <200.0 mg/l Iron <100.000.0 mg/l D036 – Nitrobenzene <2.0 mg/l Managanese <25.000.0 mg/l D037 – Pentachlorophenol <100.0 mg/l Nickel <250.0 mg/l D038 – Pyridine <5.0 mg/l Zinc <1,000.0 mg/l D039 – Tetrachloroethylene <0.7 mg/l D040 – Trichloroethylene <0.5 mg/l Pesticides & Herbicides Group: D041 – 2,4,5 – Trichlorophenol <400.0 mg/l D012 – Endrin <0.02 mg/l D042 – 2,4,6 – Trichlorophenol <2.0 mg/l D013 – Lindane <0.4 mg/l D043 – Vinyl Chloride <0.2 mg/l D014 – Methoxychlor <10.0 mg/l Ethylbenzene <10.0 mg/l D015 – Toxaphene <0.5 mg/l Toluene <100.0 mg/l D016 – 2,4-D <10.0 mg/l Xylene <100.0 mg/l D017 – 2,4,5 – TP <1.0 mg/l D020 – Chlordane <0.03 mg/l D031 – Heptachlor <0.008 mg/l

Please check one: Generator Broker Print Name: Title:

Signature: Date: 4