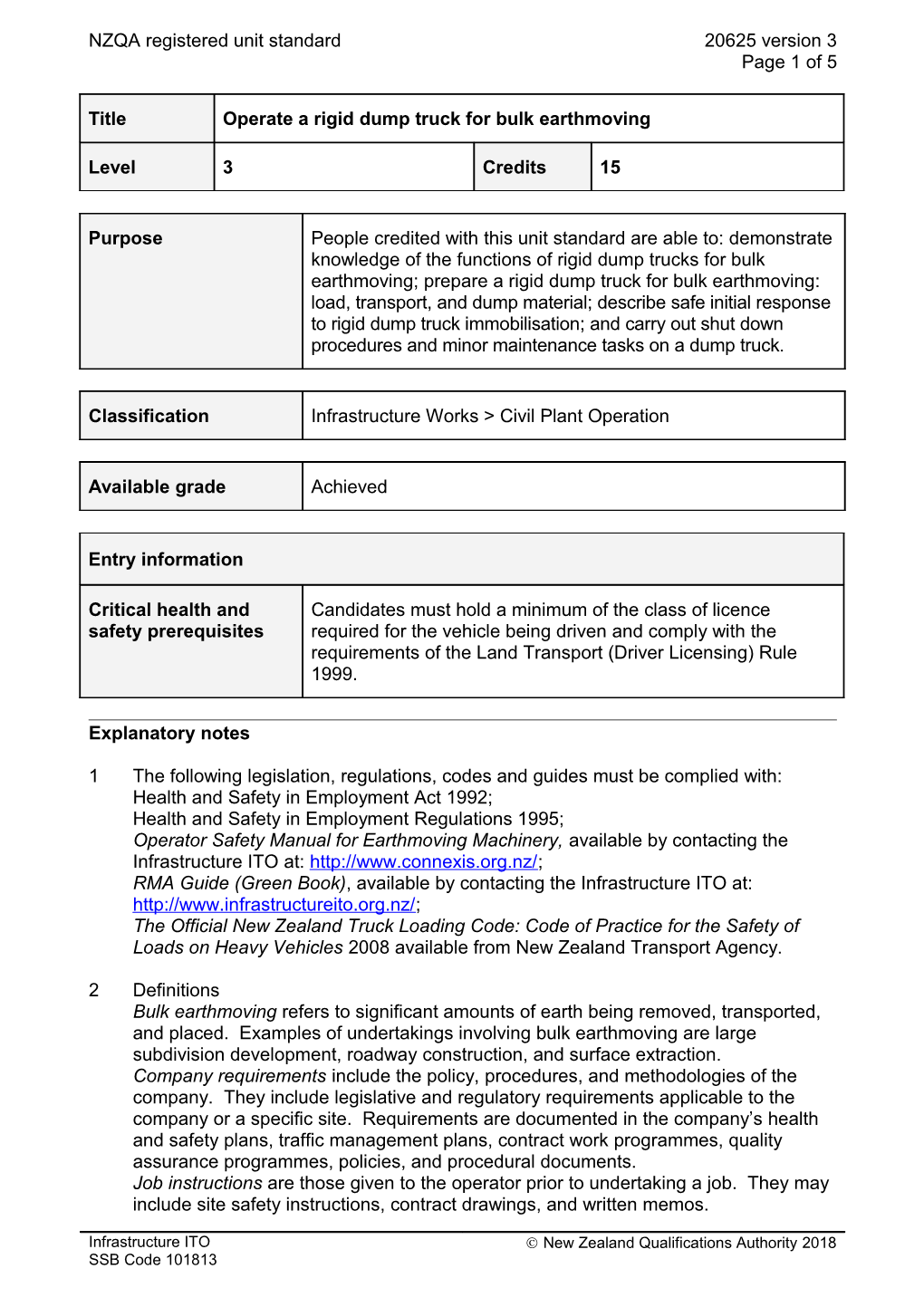

NZQA registered unit standard 20625 version 3 Page 1 of 5

Title Operate a rigid dump truck for bulk earthmoving

Level 3 Credits 15

Purpose People credited with this unit standard are able to: demonstrate knowledge of the functions of rigid dump trucks for bulk earthmoving; prepare a rigid dump truck for bulk earthmoving: load, transport, and dump material; describe safe initial response to rigid dump truck immobilisation; and carry out shut down procedures and minor maintenance tasks on a dump truck.

Classification Infrastructure Works > Civil Plant Operation

Available grade Achieved

Entry information

Critical health and Candidates must hold a minimum of the class of licence safety prerequisites required for the vehicle being driven and comply with the requirements of the Land Transport (Driver Licensing) Rule 1999.

Explanatory notes

1 The following legislation, regulations, codes and guides must be complied with: Health and Safety in Employment Act 1992; Health and Safety in Employment Regulations 1995; Operator Safety Manual for Earthmoving Machinery, available by contacting the Infrastructure ITO at: http://www.connexis.org.nz/; RMA Guide (Green Book), available by contacting the Infrastructure ITO at: http://www.infrastructureito.org.nz/; The Official New Zealand Truck Loading Code: Code of Practice for the Safety of Loads on Heavy Vehicles 2008 available from New Zealand Transport Agency.

2 Definitions Bulk earthmoving refers to significant amounts of earth being removed, transported, and placed. Examples of undertakings involving bulk earthmoving are large subdivision development, roadway construction, and surface extraction. Company requirements include the policy, procedures, and methodologies of the company. They include legislative and regulatory requirements applicable to the company or a specific site. Requirements are documented in the company’s health and safety plans, traffic management plans, contract work programmes, quality assurance programmes, policies, and procedural documents. Job instructions are those given to the operator prior to undertaking a job. They may include site safety instructions, contract drawings, and written memos.

Infrastructure ITO Ó New Zealand Qualifications Authority 2018 SSB Code 101813 NZQA registered unit standard 20625 version 3 Page 2 of 5

Manufacturer’s instructions refer to the manufacturer’s operating manuals. Rigid dump truck for the purposes of this unit standard, are heavy rigid dump vehicles with load capacity of at least 20 tonnes and used for the purpose of bulk earthmoving. Walk-around – refers to walking around the machine inspecting it and its environment for hazards and removing hazards that may impair start-up.

3 Operators must use the hand and horn signals endorsed by their company.

Outcomes and evidence requirements

Outcome 1

Demonstrate knowledge of the functions of rigid dump trucks for bulk earthmoving.

Evidence requirements

1.1 Rigid dump trucks are identified and described in terms of their types and components.

Range types may include but are not limited to – 2WD, 4WD, 6WD, rock deck, wide-body deck, heated deck, coal deck; evidence of five types is required; components – power train, hydraulic system, production monitors.

1.2 Rigid dump trucks are described in terms of the operations they perform.

Range civil, extractive.

1.3 Rigid dump trucks handling on varying surfaces is described in accordance with company requirements.

Range laden, unladen, slippery, uneven, uphill, downhill.

Outcome 2

Prepare a rigid dump truck for bulk earthmoving.

Evidence requirements

2.1 Job instructions are confirmed in accordance with company requirements.

2.2 Walk-around is completed prior to starting work and any adjustments required are made in accordance with manufacturer’s instructions and company requirements.

Infrastructure ITO Ó New Zealand Qualifications Authority 2018 SSB Code 101813 NZQA registered unit standard 20625 version 3 Page 3 of 5

2.3 Rigid dump truck operation is checked prior to starting work in accordance with manufacturer’s instructions and company requirements.

Range visibility, seat belt, engine controls and gauges, throttle position, hydraulic controls, engine oil, water, battery fluid, hydraulic oil, fuel, transmission oil, cab cleanliness, grease system, tyre pressure and condition, engine warm-up, engine oil pressure, transmission oil pressure, park brake, electrical charging, hydraulics operating, braking systems, warning systems, lights, emergency systems, communications equipment; may include – air tanks, air pressure, rock ejectors.

2.4 Surrounding area is checked for hazards, before moving off in accordance with company requirements.

Outcome 3

Load, transport, and dump material.

Evidence requirements

3.1 Rigid dump truck is positioned in relation to loading equipment in accordance with manufacturer’s instructions and company requirements.

Range queuing, off-side loading, on-side loading, loading through the rear, reversing, communication with loading operator.

3.2 Load is transported in a controlled manner in accordance with rigid dump truck capability, company requirements, and site road rules.

Range uphill, downhill.

3.3 Tiphead procedures are explained and demonstrated in accordance with company requirements.

Range approach, visual check, positioning, exit.

3.4 Load is dumped in accordance with manufacturer’s and site instructions.

Range may include – bin, waste area, stockpile, structural fill.

3.5 Unladen rigid dump truck is driven in a controlled manner in accordance with truck capability, company requirements, and site road rules.

Range uphill, downhill.

3.6 Emergency braking is demonstrated in accordance with manufacturer’s instructions and company requirements.

Range laden, unladen.

Outcome 4

Infrastructure ITO Ó New Zealand Qualifications Authority 2018 SSB Code 101813 NZQA registered unit standard 20625 version 3 Page 4 of 5

Describe safe initial response to rigid dump truck immobilisation.

Evidence requirements

4.1 Safe initial response to rigid dump truck immobilisation is described in accordance with company requirements.

Outcome 5

Carry out shut down procedures and minor maintenance tasks on a dump truck.

Evidence requirements

5.1 Dump truck is parked and shut down in accordance with manufacturer’s instructions and company requirements.

Range may include but is not limited to – engine run-down, checks, refuelling, hoist position, documentation (including reporting any faults).

5.2 Scheduled minor maintenance tasks are carried out in accordance with manufacturer’s instructions and company requirements.

Range may include but is not limited to – housekeeping, routine servicing, lubrication.

Planned review date 31 December 2019

Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 25 February 2004 31 December 2014 Review 2 17 September 2010 31 December 2016 Review 3 19 February 2015 N/A

Consent and Moderation Requirements (CMR) reference 0101 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do.

Please note Providers must be granted consent to assess against standards (accredited) by NZQA before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment.

Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards.

Infrastructure ITO Ó New Zealand Qualifications Authority 2018 SSB Code 101813 NZQA registered unit standard 20625 version 3 Page 5 of 5

Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards.

Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMRs). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

Comments on this unit standard

Please contact the Infrastructure ITO [email protected] if you wish to suggest changes to the content of this unit standard.

Infrastructure ITO Ó New Zealand Qualifications Authority 2018 SSB Code 101813