Motion Control Engineering Voice: 916 463 9200 PMAC Gearless Machine Data Forms Fax: 916 463 9201 MCE Job #: Doc #: JER118 0310 LOGISTICS DATA Date Received: Page 1 of 5

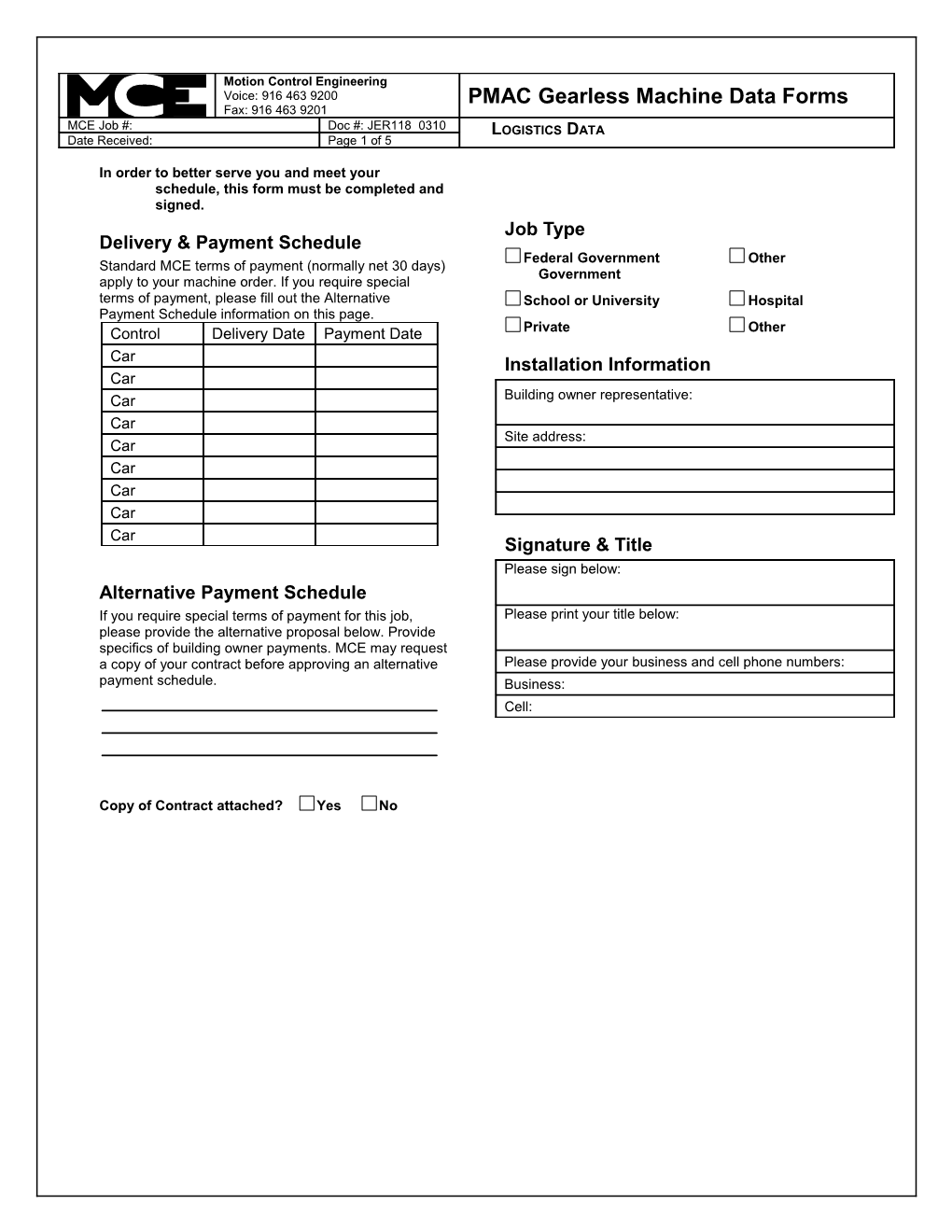

In order to better serve you and meet your schedule, this form must be completed and signed. Job Type Delivery & Payment Schedule Federal Government Other Standard MCE terms of payment (normally net 30 days) Government apply to your machine order. If you require special terms of payment, please fill out the Alternative School or University Hospital Payment Schedule information on this page. Control Delivery Date Payment Date Private Other Car Installation Information Car Car Building owner representative:

Car Site address: Car

Car

Car

Car Car Signature & Title Please sign below: Alternative Payment Schedule If you require special terms of payment for this job, Please print your title below: please provide the alternative proposal below. Provide specifics of building owner payments. MCE may request a copy of your contract before approving an alternative Please provide your business and cell phone numbers: payment schedule. Business:

Cell:

Copy of Contract attached? Yes No Motion Control Engineering Voice: 916 463 9200 PMAC Gearless Machine Data Forms Fax: 916 463 9201 MCE Job #: Doc #: JER118 0310 Date Received: Page 2 of 5

Timely delivery and trouble-free installation begin Signature: with these data forms. Accurate, complete information is essential. Non-response to a yes/no question will be defined as meaning Machine Data that the item does not apply. Job location (city/state): Date: Number of cars: Job Name (please do not abbreviate): Contract date: Project Type: New construction Modernization Duty: Passenger Service Freight Customer Job #: PO#: Measurements: U.S./English S.I./Metric

Contractor Information Roping Contact: Rated car speed: Feet Per Minute Phone: Fax: 1:1 2:1 Other: Email: Overslung Underslung Company name and address: Number of ropes:

Wrapping: Single Double Rope diameter: 8mm 10mm 1/2” 5/8” 9/16” Rope type: Traction steel City State Zip Code Extra high strength traction steel

Shipping Information Load Rated live load (lbs): Contact: Empty car weight (crosshead label, lbs.): Phone: Fax: Total suspended weight: lbs: kg: Company name and address: Total suspended weight is the sum of: Capacity Cab weight including sling, platform, doors & operator Rope weight, Traveling cable Counterweight frame and fillers City State Zip Code Compensation chain Notice required: 24 hours 48 hours Other Counterweight percentage (typically 45%): Compensation Type: Rope Chain Compensation assumed to be 100%. Check if lift gate truck needed Machine Surveyor Machine location: Overhead Basement Side Contact: Options Phone: Fax: Rope guards: Sheave guard: Company name: Isolation pads: Dead end Hitch plates (2:1 only):

Sub base w/deflector sheave in machine room Does job have specifications? Yes No Seismic Zone 2 or greater? Breakdown crating required: No Yes Specifications being sent to MCE? Yes No (Machine is separated into major components to reduce size and weight for easier handling.) Form Completed By Option 1: Sheave & brake shipped separately. Option 2: Sub base broken down and shipped separately. Name/Title: Option 3: Sheave, brake, rotating assembly shipped Phone: Fax: separately (requires extensive customer technical Email: expertise to re-assemble correctly and safely) MCE to provide on-site technician to re-assemble Company name: machine Additional charges apply to all options. Motion Control Engineering Voice: 916 463 9200 PMAC Gearless Machine Data Forms Fax: 916 463 9201 MCE Job #: Doc #: JER118 0310 Date Received: Page 3 of 5 Motion Control Engineering Voice: 916 463 9200 PMAC Gearless Machine Data Forms Fax: 916 463 9201 MCE Job #: Doc #: JER118 0310 Date Received: Page 4 of 5

Sheave and Rope Drop Information Standard: Deflector in hoistway Deflector in machine room

Machine sheave Machine sheave diameter diameter

Main sheave to floor Center line to center line distance Slab thickness Deflector sheave diameter Deflector sheave to floor Base with deflector Center line to center line distance Center of deflector sheave to floor Deflector sheave Slab thickness diameter Rope Drop Indicate Alignment: RL Rope Drop SHEAVE LOCATION DRAWING RR Swung Left Swung Right Aligned R2 Sheave Sheave Sheave

R2

= D1

RL RR

Machine Room This information is required to help determine how much Clearance at Machine Location space is available for machine installation, sub base Distance from mounting surface requirements, and structural conditions. Please FAX to to first overhead obstruction: MCE. Provide a sketch of the floor plan within a 10-foot radius of the machine site. Show all objects that will be in place when machine is installed. Indicate clearances. Motion Control Engineering Voice: 916 463 9200 PMAC Gearless Machine Data Forms Fax: 916 463 9201 MCE Job #: Doc #: JER118 0310 Date Received: Page 5 of 5

LAYOUT. REAR COUNTERWEIGHT / FRONT OPENING CENTER PARTING HOISTWAY Floors Ceiling Labels Heights P Top MR Height Machine C D Floor Thickness Floor Room CWT A Beams x Beams D.B.R. E H x W

Overhead HW Depth # Floors Top Floor this Riser F CAR D.B.R. H B G Finished Travel Sill I Pit x W x H J K

HW Width Add floors if needed Machine Room Width:

L Hatch Below M Rail Dimension Car Cwt Back N R Q Height Face Lbs / Foot

DIMENSION @ TIGHTEST POINT w o l A B e B

h C D c t a

H E F G H I J K L Machine Room M N Depth O P O Q R MR Beam size x Call for additional layout diagrams: F/R opening, left side counterweight. MACHINE ROOM Indicate door location with X ’s F/R opening, right side counterweight. F only, left close, right side counterweight. XXXXXXXXXXXX F only, right close, left side counterweight. F only, left close, left side counterweight. F only, right close, right side counterweight.