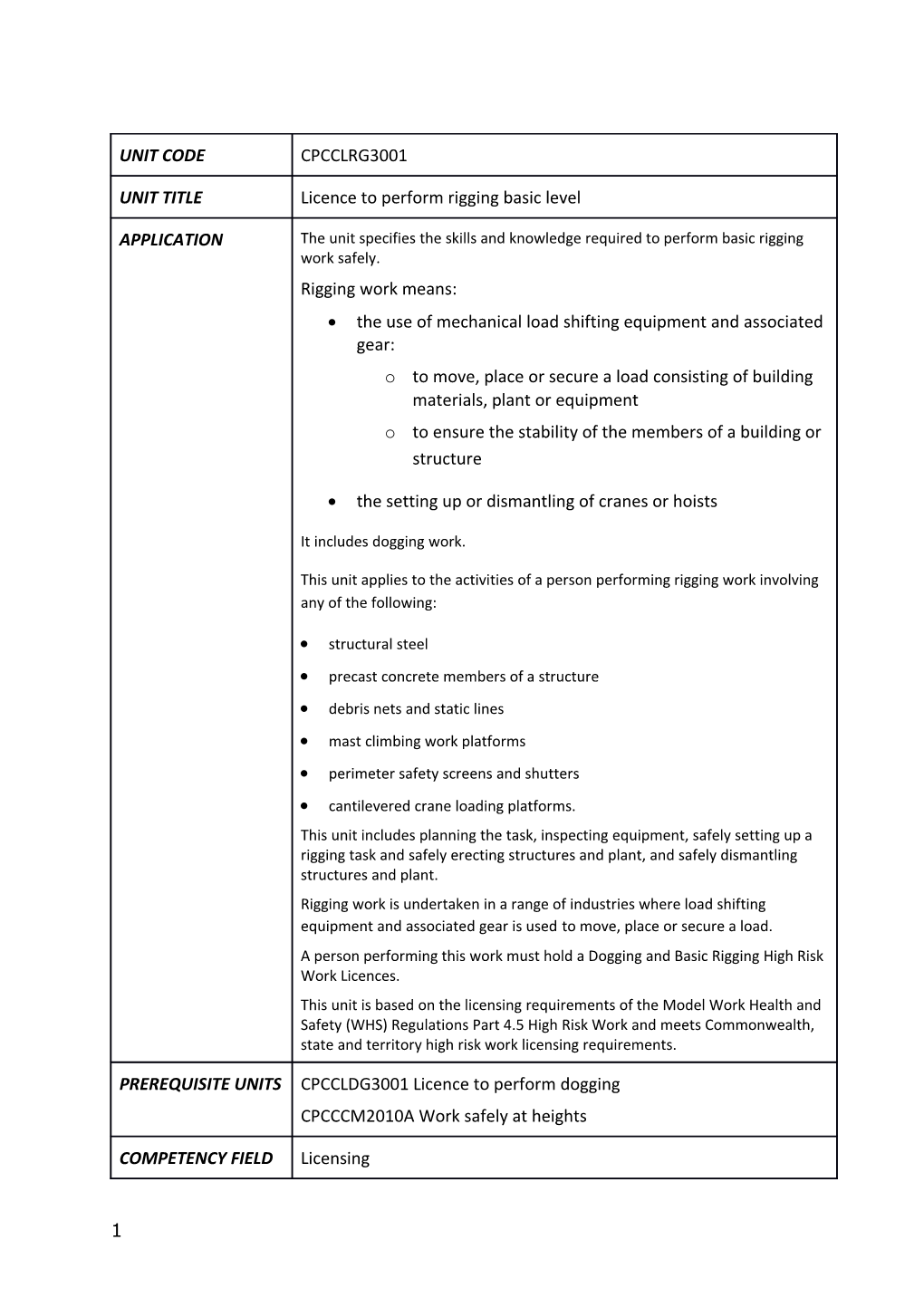

UNIT CODE CPCCLRG3001

UNIT TITLE Licence to perform rigging basic level

APPLICATION The unit specifies the skills and knowledge required to perform basic rigging work safely. Rigging work means: the use of mechanical load shifting equipment and associated gear: o to move, place or secure a load consisting of building materials, plant or equipment o to ensure the stability of the members of a building or structure

the setting up or dismantling of cranes or hoists

It includes dogging work.

This unit applies to the activities of a person performing rigging work involving any of the following:

structural steel precast concrete members of a structure debris nets and static lines mast climbing work platforms perimeter safety screens and shutters cantilevered crane loading platforms. This unit includes planning the task, inspecting equipment, safely setting up a rigging task and safely erecting structures and plant, and safely dismantling structures and plant. Rigging work is undertaken in a range of industries where load shifting equipment and associated gear is used to move, place or secure a load. A person performing this work must hold a Dogging and Basic Rigging High Risk Work Licences. This unit is based on the licensing requirements of the Model Work Health and Safety (WHS) Regulations Part 4.5 High Risk Work and meets Commonwealth, state and territory high risk work licensing requirements.

PREREQUISITE UNITS CPCCLDG3001 Licence to perform dogging CPCCCM2010A Work safely at heights

COMPETENCY FIELD Licensing

1 UNIT SECTOR Not applicable

ELEMENTS PERFORMANCE CRITERIA Elements describe Performance criteria describe what needs to be done to demonstrate actions or outcomes achievement of the element. that are demonstrable and assessable.

1. Plan basic rigging 1.1 Review the task to task. be undertaken and obtain relevant workplace-specific information.

1.2 Identify task and workplace hazards.

1.3 Identify risk control measures and equipment in accordance with workplace-specific information and hazard management principles (i.e. the hierarchy of control).

1.4 Calculate load weight, dimensions and centre of gravity in consultation with other personnel involved in the task.

1.5 Select slinging method and lifting gear appropriate to the load.

2 1.6 Calculate rated capacity of lifting equipment resulting from selected slinging techniques.

1.7 Determine lifting and slinging points.

1.8 Determine communication methods with plant operators and other personnel involved in the task.

2. Select and inspect 2.1 Select and inspect equipment. safety equipment, and select and fit personal protection equipment (PPE) in accordance with workplace requirements.

2.2 Select lifting equipment and gear and make sure it is clean enough to be inspected for defects.

2.3 Inspect lifting equipment and gear for defects, including nicks, cracks, tears, corrosion, stretching, distortion and chemical damage.

3 2.4 Select communication equipment and inspect to make sure it is working and fit for use.

2.5 Isolate, report and record defective equipment in accordance with workplace requirements.

3. Set up basic rigging 3.1 Communicate task. information about the task to workplace personnel.

3.2 Put risk control measures and equipment in place.

3.3 Prepare lifting equipment and gear for safe use.

3.3 Inspect ground and foundation and assess suitability for task in consultation with other personnel involved in the task.

3.4 Position rigging equipment and associated gear for work application and stability in accordance with workplace requirements.

4 3.5 Apply temporary connections.

4. Erect rigging 4.1 Erect rigging structures and structures and plant. plant in accordance with workplace requirements and workplace-specific information.

4.2 Maintain stability of rigging structures and plant during erection in accordance with workplace requirements.

4.3 Use communication methods to coordinate the rigging task.

4.4 Use rigging plant and rigging equipment in accordance with workplace requirements.

4.5 Connect temporary supports to safely meet rigging task requirements.

4.6 Check completed rigging task against task requirements.

4.7 Remove excess materials from the work area in accordance with workplace requirements.

5 5. Dismantle rigging 5.1 Conduct rigging structures and dismantling task plant. safely in accordance with workplace requirements.

5.2 Maintain stability of structures and associated plant during dismantling in accordance with workplace requirements.

5.3 Inspect rigging structures, plant, equipment and gear and safety equipment for defects, and isolate and report defective items in accordance with workplace requirements.

5.4 Store rigging structures, plant, equipment and gear and safety equipment in accordance with workplace requirements.

5.5 Remove risk control measures and equipment.

6 FOUNDATION SKILLS A person demonstrating competency in this unit must have the following language, literacy, numeracy and employment skills: numeracy skills to: o estimate and calculate loads associated with erecting and dismantling structures o interpret and use working load limit (WLL) o interpret numerical data from structural and design charts, plans and drawings reading skills to interpret: o equipment manuals and manufacturer specifications o written workplace requirements, including emergency plans o written task instructions, plans, and schedules o written information from structural and design charts, plans and drawings o safe work method statements (SWMS) o permits and certifications o workplace signs and labels writing skills to complete equipment checklists and maintenance and incident reports communication skills at a level sufficient to communicate with other personnel: o speaking and listening skills o questioning to confirm understanding o vocabulary specific to basic rigging tasks and for workplace procedures o hand signals o two-way radios self-management skills to implement risk control measures and follow emergency plans UNIT MAPPING Supersedes and is equivalent to CPCCLRG3001A Licence to INFORMATION perform rigging basic level.

LINKS Hyperlink to Companion Volume Implementation Guide

7 Assessment Requirements

UNIT CODE CPCCLRG3001

NIT TITLE Licence to perform rigging basic level

PERFORMANCE EVIDENCE safely perform rigging tasks at a basic level including rigging: o a structural steel erection

o pre-cast concrete members of a structure

o debris net and static line

o hoists or mast climbing work platform

o a perimeter safety screen or shutter

o a cantilevered crane loading platform

To be competent in this unit, a KNOWLEDGE EVIDENCE person must demonstrate knowledge of:

the requirements of Commonwealth, state or territory and local government WHS/OHS legislation, standards and codes of practice for undertaking basic rigging activities workplace-specific information: o safe work method statements (SWMS) o local conditions including access and egress o permits and certifications o task plans and schedule and structural plans o workplace procedures, including emergency plans

8 o equipment manuals and manufacturers’ specifications workplace information-keeping requirements, including legislative requirements: o equipment and maintenance checklists o record system where service and maintenance history is kept o incident reports the systematic process of eliminating and reducing risk to health and safety through the application of the hierarchy of control hazards: o ground instability o overhead hazards o lighting o traffic o weather o pedestrian traffic o work required at heights minimum clearance distance from powerlines or electrical equipment as determined by relevant state authority or electrical supply authority risk control measures and equipment: o traffic barricades and control o pedestrian barricades o personal protective equipment o adequate illumination basic rigging structures and plant: o static lines

9 o debris nets o hoists o mast climbers o cantilever crane loading platforms associated personnel: o other riggers o doggers o load-shifting plant operators o engineers o supervisors o colleagues types and functions of basic rigging equipment and gear and safety and personal protection equipment, including selection, inspection, care, handling, manufacturers’ specifications, application, storage and limitations: o rigging equipment: • elevated work platforms • cantilevered crane loading platforms • mast climbers • safety screens and shutters • non-slewing cranes • mobile slewing cranes • vehicle loading cranes • tower cranes • self-erecting tower cranes

10 • portal boom cranes • derrick cranes • bridge and gantry cranes o associated gear: • power and manually operated lifting gear • lifting clutches • tag lines • flexible steel wire rope (FSWR) • chains • wire and synthetic slings • shackles • terminations • wedge sockets • eye bolts • beam clamps • plate clamps • rope grips • turnbuckles • rigging screws • chain blocks • lever blocks • lever-action winches • sheaves • spreader bars • lifting beams • jacks

11 • levers • skates • wedges • rollers • girder trolley o safety equipment: • safety harness • energy absorber • lanyard • inertia reel • static safety lines o personal protective equipment (PPE): • hard hat • safety boots • gloves • high-visibility clothing • breathing, hearing, sight, skin and sun protection o communication equipment: • two-way radios • whistles • reasons for not using mobile phones for signalling purposes ground and foundation suitability: o rough, uneven ground o backfilled ground

12 o soft soils o hard compacted soil o rock o bitumen o concrete o suspended concrete floors o building roofs o landings o ground bearing pressure workplace policies, procedures and practices applicable to basic rigging including: o installation of a fall arrest system (static line) o use of a safety harness and fall arrest system o installation of crane loading platforms o installation of a debris net o installation of a shutter and safety screen o working safely at heights o erection of structural steel o erection of precast panel o set-up and operation of a winch for load movement o installation of a materials hoist o installation of a mast climber the application, limitation, operation and safety requirements of: o structural steel erection o hoists o safety nets and static lines o mast climbing work platforms o perimeter safety screens and shutters o cantilevered crane loading

13 platforms mathematical processes for estimation and measurement of loads for basic rigging principles of plant, equipment and structural stability relating to basic rigging work techniques for tying bends and hitches and their application in basic rigging, including: o sheet bend o becket hitch o running bowline o double bowline methods of creating splices and their application in basic rigging, including: o eye splice o back splice

ASSESSMENT CONDITIONS Assessments must be conducted by an assessor accredited for the Basic Rigging High Risk Work Licence class in the Commonwealth/state/territory where the licence will be obtained (i.e. an assessor authorised by a Commonwealth/state/territory WHS/OHS regulator). Assessors must satisfy applicable regulatory requirements which must include requirements in the Standards for Registered Training Organisations current at the time of assessment. Assessment processes and techniques must be appropriate to the language, literacy and numeracy requirements of the work being performed. Assessment of performance must be undertaken in the workplace or under realistic workplace conditions which reflect: the use of full-scale, industry-standard equipment performing tasks within timelines

14 expected in a workplace standard and authorised work practices, safety requirements and environmental constraints. Assessment of this unit of competency must include the use of the National Assessment Instruments (NAI) issued by Safe Work Australia. These instruments include the requirement for assessments to be conducted in the English language. Simulators must not be used in the assessment of this unit of competency. Assessment must include access to: rigging equipment and associated equipment in a safe condition to meet the basic rigging specified in the Performance Evidence safety equipment in safe condition personal protective equipment (PPE) communication equipment including fixed-channel two-way radios associated personnel to assist with basic rigging task workplace information applicable to basic rigging, including: o equipment and maintenance checklists o record system where service and maintenance history is kept o incident reports o workplace procedures, including emergency plan o equipment manuals and manufacturers’ specifications risk control measures and equipment.

LINKS Hyperlink to Companion Volume Implementation Guide

15