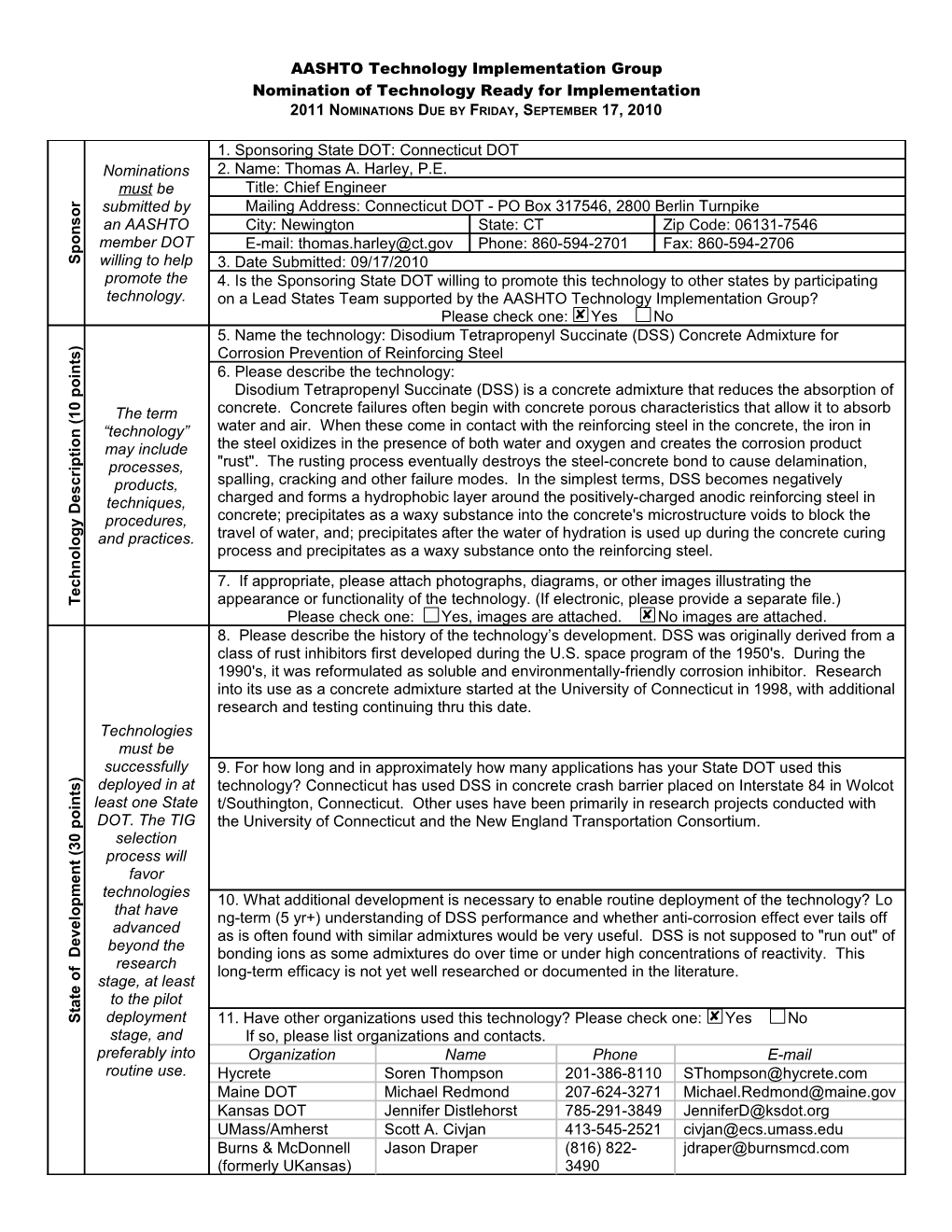

AASHTO Technology Implementation Group Nomination of Technology Ready for Implementation 2011 NOMINATIONS DUE BY FRIDAY, SEPTEMBER 17, 2010

1. Sponsoring State DOT: Connecticut DOT Nominations 2. Name: Thomas A. Harley, P.E. must be Title: Chief Engineer r submitted by Mailing Address: Connecticut DOT - PO Box 317546, 2800 Berlin Turnpike o s an AASHTO City: Newington State: CT Zip Code: 06131-7546 n o member DOT E-mail: [email protected] Phone: 860-594-2701 Fax: 860-594-2706 p

S willing to help 3. Date Submitted: 09/17/2010 promote the 4. Is the Sponsoring State DOT willing to promote this technology to other states by participating technology. on a Lead States Team supported by the AASHTO Technology Implementation Group? Please check one: Yes No 5. Name the technology: Disodium Tetrapropenyl Succinate (DSS) Concrete Admixture for )

s Corrosion Prevention of Reinforcing Steel t n i 6. Please describe the technology: o

p Disodium Tetrapropenyl Succinate (DSS) is a concrete admixture that reduces the absorption of

0 concrete. Concrete failures often begin with concrete porous characteristics that allow it to absorb

1 The term ( water and air. When these come in contact with the reinforcing steel in the concrete, the iron in n “technology” o the steel oxidizes in the presence of both water and oxygen and creates the corrosion product i

t may include p "rust". The rusting process eventually destroys the steel-concrete bond to cause delamination, i processes, r c products, spalling, cracking and other failure modes. In the simplest terms, DSS becomes negatively s e techniques, charged and forms a hydrophobic layer around the positively-charged anodic reinforcing steel in D concrete; precipitates as a waxy substance into the concrete's microstructure voids to block the y procedures, g travel of water, and; precipitates after the water of hydration is used up during the concrete curing

o and practices. l process and precipitates as a waxy substance onto the reinforcing steel. o n h

c 7. If appropriate, please attach photographs, diagrams, or other images illustrating the e

T appearance or functionality of the technology. (If electronic, please provide a separate file.) Please check one: Yes, images are attached. No images are attached. 8. Please describe the history of the technology’s development. DSS was originally derived from a class of rust inhibitors first developed during the U.S. space program of the 1950's. During the 1990's, it was reformulated as soluble and environmentally-friendly corrosion inhibitor. Research into its use as a concrete admixture started at the University of Connecticut in 1998, with additional research and testing continuing thru this date. Technologies must be successfully 9. For how long and in approximately how many applications has your State DOT used this ) s deployed in at technology? Connecticut has used DSS in concrete crash barrier placed on Interstate 84 in Wolcot t n i least one State t/Southington, Connecticut. Other uses have been primarily in research projects conducted with o DOT. The TIG p the University of Connecticut and the New England Transportation Consortium.

0 selection 3 ( process will t n favor e

m technologies

p 10. What additional development is necessary to enable routine deployment of the technology? Lo

o that have l ng-term (5 yr+) understanding of DSS performance and whether anti-corrosion effect ever tails off e advanced v as is often found with similar admixtures would be very useful. DSS is not supposed to "run out" of e beyond the D

bonding ions as some admixtures do over time or under high concentrations of reactivity. This

f research long-term efficacy is not yet well researched or documented in the literature. o stage, at least e t to the pilot a t

S deployment 11. Have other organizations used this technology? Please check one: Yes No stage, and If so, please list organizations and contacts. preferably into Organization Name Phone E-mail routine use. Hycrete Soren Thompson 201-386-8110 [email protected] Maine DOT Michael Redmond 207-624-3271 [email protected] Kansas DOT Jennifer Distlehorst 785-291-3849 [email protected] UMass/Amherst Scott A. Civjan 413-545-2521 [email protected] Burns & McDonnell Jason Draper (816) 822- [email protected] (formerly UKansas) 3490 Submit Submit Market Readiness (30 points) Payoff Potential (30 points) commensurate effort cost,and combinationof adopted adopted a with with the payoffthe with and significant defined as definedas the technologies. formto technologies processwill applicability reasonable can bethat advantage over other over amount amount of benefitor potential. selection available Completed currently Payoffis The The TIG broad favor the and concrete prevent waterfurther penetration. (typicallylaced chlorides) with penetratemay intothe concrete, toacting fillmicrostructure the of steeland blocks oxidation processof steel. the also Material actsprecipitate as a wherever water organizationshave that it?used 12. the does How technologymeet customer or stakeholderneedsyour in Stateor DOT other ofpatents. ofDSS-based products. Prior disclosure of DSS the compoundtohas, date, prevented issuance mightaffect ofease implementation. 19. describeanyPlease legal,environmental, social, intellectual property, barriersother or that Carlstadt, NJ 07072 462 Ave Barell Hycrete,Inc. organizations18. What currently supplyand providetechnical for support technology?the possiblyother sources such as researchinstitutions other and (toDOT's state bedetermined). dprocess support.Additional informationbackground available Connecticut from DOT, and already toavailable assist deployment? resources—such17. What technical as specifications,training and materials, user guides—are placementonDSS-entrained concrete. the admixturesupplier;thefrom trainingand properconstruction in technique for preparation and odified design process DSS-entrainedto accountfor concrete's lowerstrengths;cost of acquiring anotherorganization? isthe16. estimated What cost,effort, lengthand ofrequired time theto deploy technologyin usesalt for weather winter maintenance, toareasprone ocean/salt fog). penetrationshould beminimized (foundations in waters,salt/brackish bridge states decks in that concretepermeability;organizational commitment toprojects use in water/chloride where stateconcretespecifications for to include as admixture;additionDSS performance criteriaof for actions15. wouldWhat another organization need to taketo adopt this technology? corrosionseen age at this begreatlywill retarded due to DSS the additive. deckstypically reach useful possibly in life, 20+ cycle.the Ityear isbelieved the that typical rebar beliefthat realthe savingspotential for DSS-entrained comes concrete atage the whenbridge nbridgedecks, parapetcrash walls, etc.would barrier, potentially benefit usage.fromIt isour factors. broadlymightHow technologythe bedeployed? type (includingbranchesother of government and private industry) size,and other or relevant 14. describethePlease potentialextent of implementation in termsof geography, organization construction, sizable reductionand; in materialbuilding waste products. increase costincreased in savings; safety spallingfromconcrete; reduced delaysdue to beable increase to reinforcedlife the of bridgedecks 50%, by wouldit providecorresponding advantage other over anti-corrosionadditives isthat has modesthreeof protection. might If DSS hepersistent problem of extending lifespanthe all of almost concrete.reinforced primary Its benefits, anyadvantagesor other over existingothertechnologies. costsavings, improvements, safety transportation or efficiency effectiveness, environmental type13. scaleWhat and of benefits hasyour realizedDOT from technology? usingthis Include http://transportation1.org/tig_solicitation/Submit.aspx Low: of modifyingspecifications Cost allowance for of costadmixture; of m Material a acts layer protection as of around anodic the reinforcing Hycrete owns copyrightsHycrete ona brandnamecreated familyfor a One company,One Hycrete, canofferavailable all technical an All stateAll that DOT's use reinforcingsteeli DSSisenvisioned to address t Revision of Revision