FIRST ASSIGNMENT ______Course Code : MS 05 Course Title : Management of Machines and Materials Assignment No.: 05/TMA-1/SEM-I/2005 Coverage : Blocks 1 and 2 ______Note : There are three questions . Answer all and submit to the coordinator of the study centre, you are attached with.

Q.1. (a) Describe five major types of materials handling methods and name some advantages of each.

(b) Why are many offices being built as multi-story buildings whereas single-story factories are more common?

Q.2. (a) How is the capacity planning problem different for mature products that have relatively stable growth pattern than for products that are new or involve risky situations?

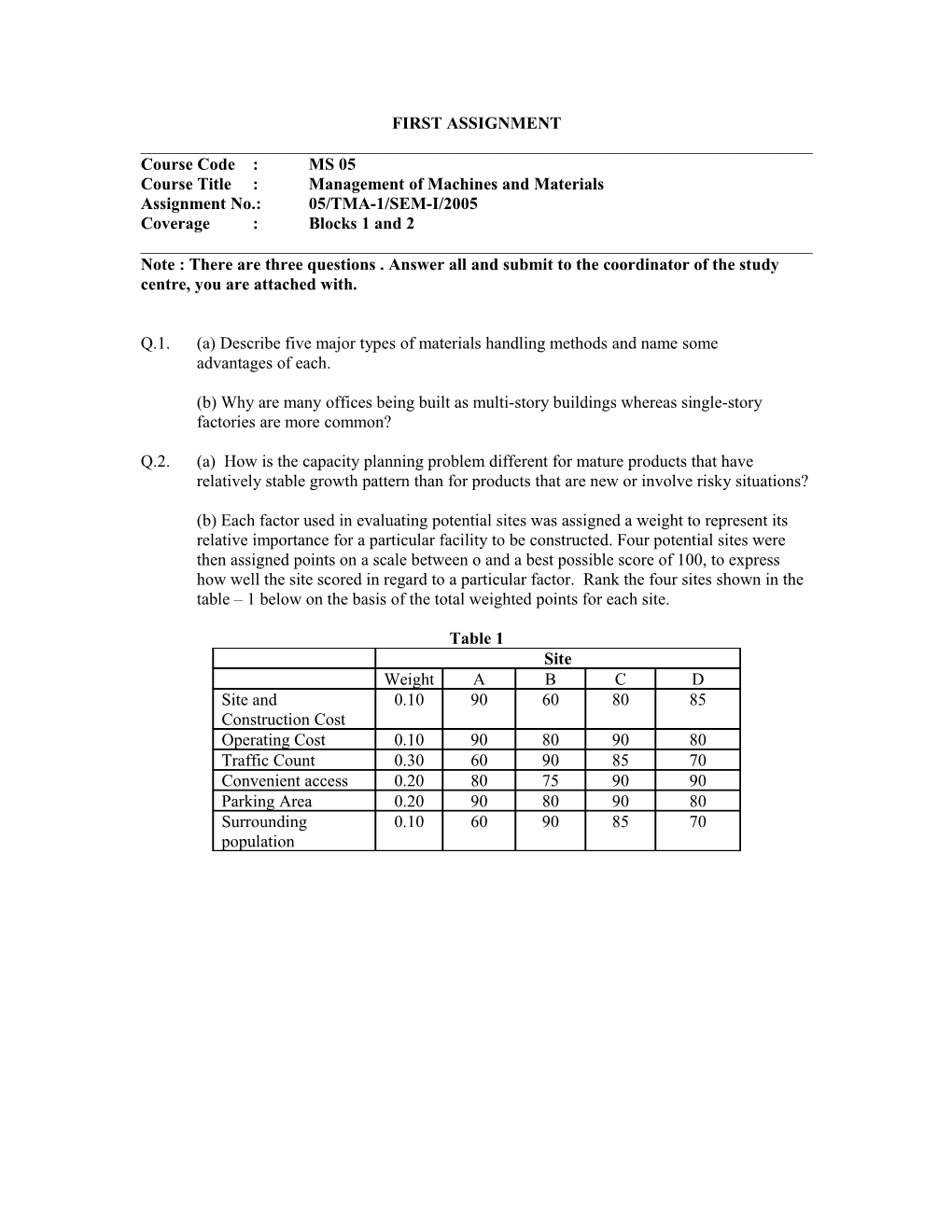

(b) Each factor used in evaluating potential sites was assigned a weight to represent its relative importance for a particular facility to be constructed. Four potential sites were then assigned points on a scale between o and a best possible score of 100, to express how well the site scored in regard to a particular factor. Rank the four sites shown in the table – 1 below on the basis of the total weighted points for each site.

Table 1 Site Weight A B C D Site and 0.10 90 60 80 85 Construction Cost Operating Cost 0.10 90 80 90 80 Traffic Count 0.30 60 90 85 70 Convenient access 0.20 80 75 90 90 Parking Area 0.20 90 80 90 80 Surrounding 0.10 60 90 85 70 population Q. 3. (a) Your company is considering expanding into the Sun Belt. Your industry is heavily dependent on water transportation, so the preliminary research has narrowed the location to three sites near port facilities in Kolkata, Chennai and Vishakhapatnam on the basis of the following data, which site is preferable? Show your computations.

Relevant Factors Kolkata Chennai Vishakhapatnam

Variable Costs per Rs. 18.00 Rs. 20.00 Rs. 19.50 unit Fixed Costs/year Rs. 15,00,000.00 Rs. 30,00,000.00 Rs. 40,00,000.00 Price per unit Rs. 30.00 Rs. 30.00 Rs. 30.00 Volume (units/year) 3,00,00.00 2,50,000.00 Rs. 3,25,000.00

(b) Home computers are now on the market. They are quite powerful, involving keyboard input video output, and very substantial memory capacities and they are designed to use rather capable languages such as C++. Price ranges from Rs. 30,000 to Rs. 60,000 and are declining.

If you were tooling up to produce such a product, how would you go about assessing the market for the next five years? What kinds of capacity strategies would you generate? What decision methodology would you use? SECOND ASSIGNMENT ______Course Code : MS 05 Course Title : Management of Machines and Materials Assignment No.: 05/TMA-2/SEM-I/2005 Coverage : Blocks 3 and 4 ______Note : There are three questions. Answer all and submit to the coordinator of the study centre, you are attached with.

Q.1. (a)(i) Which view of job design do you think is most practical ? Most humane ? Most likely to succeed in the long term ?

(ii) Under what conditions is a group incentive plan generally more appropriate than an individual incentive plan ?

(b) The Apollo toy company is a small new toy manufacturer. The company is to produce a toy rocket and can assign three people to its assembly.

Task Time (seconds) Predecessor (s)

A 30 None B 20 None C 8 A D 14 A E 16 B F 20 B, D G 25 E H 6 G I 16 E J 20 H K 12 H L 6 J

i) Develop a three-station assembly line for the above task. ii) What is the cycle time ? iii) What is the efficiency of the line ? iv) What would be the expected output of the line per 8 hour production shift (assume the line is run at its minimum cycle time ? Q.2. (a) Consider a flow shop that has only two processor. A job is completed on processor 1and then on processor 2. The data for 10 jobs are as follows:

Job Processing Time (Minutes) 1 2 3 4 5 6 7 8 9 10 Processor 1 2 7 9 0 3 10 1 5 6 8 Processor 2 6 8 4 10 9 7 5 1 2 3 Due Date 25 19 30 25 16 55 60 32 45 39

i) Determine the schedule that minimizes the maximum flow time. ii) What is the maximum flow time for your schedule ? iii) How many jobs are tardy in your schedule ?

(b) The Shivkumar word processing centre has accepted several jobs that are due in next few days. A batch of these jobs is assigned to Ms. Seema. The pertinent data for these jobs are given below:

Job 1 2 3 4 5 6

Time to process 5 4 3 1 ½ 2 (days) Due in (days) 11 10 16 2 1 3

i) Can Ms. Seema finish all her jobs on time ? ii) Give the schedule that Ms. Seema should follow in processing these jobs. Justify your choice of a schedule. iii) If the company pays a penalty of Rs. 100 per day for a job that is tardy but receives no reward for jobs finished early, what schedule would you recommend to Ms. Seema ? Q.3. (a) (i) What are the characteristics of large-scale projects that focus managerial efforts on the detailed scheduling of activities and on project completion dates ?

(ii) What are the general conditions for which preventive maintenance is appropriate ?

(b) Table provides data for the project of installing a gas-forced air furnace.

Immediate Time Activity Code Activity Description Predecessor (Days) Activity A Start - 0 B Obtain Delivery of furnace unit A 10 C Delivery of piping A 5 D Delivery of dampers and grillers F 14 E Delivery of duct work F 10 F Design duct layout A 2 G Install ducts and dampers D, E 12 H Install grills G 1 I Install furnace unit B 1 J Install gas piping C 5 K Connect gas pipes to furnace I, J 0.5 L Install electric wiring B 2 Install controls and connect to M I, L 1 electrical system N Test Installation H, K, M 0.5 O Clean up N 0.5

(i) Develop the network diagram for the project. (ii) Using the manual computation algorithm, compute the following statistics for the furnace installation project

ES, EF, LS, LF for each activity Total slack for each activity Critical path Project Completion time. THIRD ASSIGNMENT

______Course Code : MS 05 Course Title : Management of Machines and Materials Assignment No. : 05/TMA-3/SEM-I/2005 Coverage : Blocks 5 and 6 Note : There are three questions. Answer all and submit to the coordinator of the study centre, you are attached with.

Q.1. (a) What is the major difference between aggregate planning in manufacturing and aggregate planning in services ?

(b) What do you understand by automated storage and retrieval? For what kinds of goods and in which companies in India do you think such systems would be appropriate?

Q.2. (a) An item is demanded at the rate of 2000 units per year at a uniform rate. Ordering cost is Rs. 350 per order. Inventory earning cost is 24 % of the unit price per year. The supplier has offered a unit price of Rs. 100 per item but he is willing to reduce it to to Rs. 95 per item if a purchase order of 1000 units or more is placed. Should you accept this offer? Justify your answer.

(b) Product M is made of two units of N and three of P. N is made of two units of R and four units of S. R is made of one unit of S and three units of T. P is made of two units of T and four units of U

(i) Show the bill of materials (product structure tree) (ii) If 100 M are required, how many units of each component are needed ? (iii) Show both single level parts list and an intended part list.

Q.3. (a) What is FMS ? What is the general field of FMS application? Is the field of FMS application significant in terms of the potential market size for its capability? State with reference to any production unit.

(b) A manufacturer is attempting to set the production lot size for a particular item that is manufactured only periodically. The incremental cost of setting up machines for production is Rs 400. The inventory holding cost is Rs 10 unit per year. The annual requirements for the item are 52,000 and the production rate is 5000 units per week.

(i) What is the most economical manufacturing lot size? (ii) How many production runs are needed per year to satisfy the requirement? (iii) What considerations should influence the actual lot size selected?