Supplementary Materials to

Effect of Mass Disorder on the Lattice Thermal Conductivity of MgO Periclase

Under Pressure

Douglas Allen Dalton1, Wen-Pin Hsieh2,3, Gregory T. Hohensee2, David G. Cahill2, Alexander F.

Goncharov1

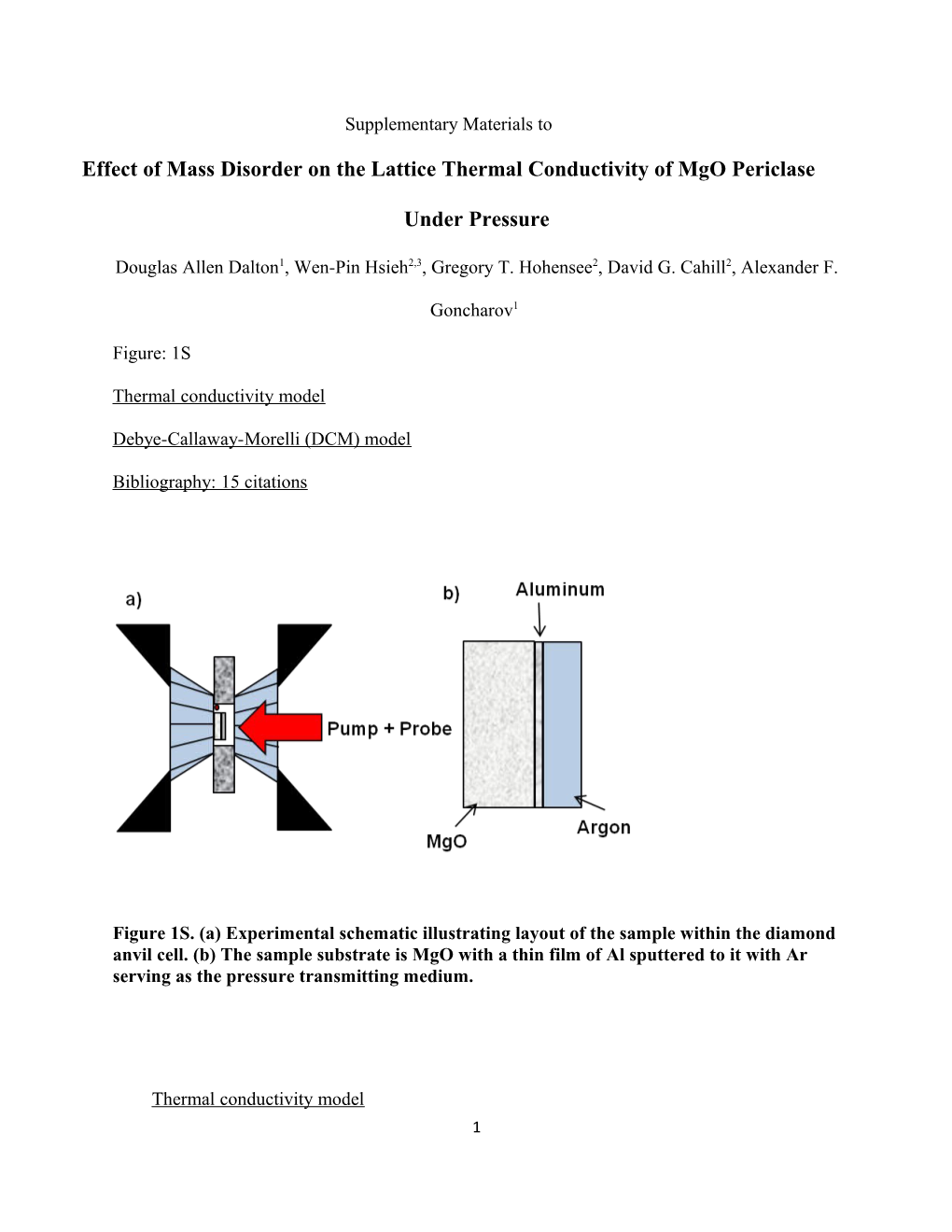

Figure: 1S

Thermal conductivity model

Debye-Callaway-Morelli (DCM) model

Bibliography: 15 citations

Figure 1S. (a) Experimental schematic illustrating layout of the sample within the diamond anvil cell. (b) The sample substrate is MgO with a thin film of Al sputtered to it with Ar serving as the pressure transmitting medium.

Thermal conductivity model 1 The thermal model has numerous parameters, including laser spot size, Al film thickness, thermal conductivity and heat capacity of all material layers. The Al film thickness hAl at ambient condition is determined using picosecond acoustics. For the pressure dependence of hAl, we calculated the changes in the volume of the Al film according to the Birch-Murnaghan equation

1 of state (EOS) for Al, KT = 73+4.54P, where KT is the isothermal bulk modulus and assumed that the Al film adheres well to the MgO substrate, allowing plastic deformation of the Al to accommodate for the mismatch in lateral compression of the Al film and MgO. The changes in the lattice constants of MgO under pressure are calculated by the EOS 2.

For purposes of the thermal calculation, the thickness of the Ar is taken to be semi-infinite, which is valid considering the spatial and temporal scales of the experiment. Thermal conductivity information on Ar is provided by molecular dynamics simulations for high P-T conditions 3 and recently validated by direct measurements 4.

Considering the relatively low Debye temperature of Ar, the heat capacity should be in good agreement with the value at the classical limit 3. From the sound speed values of Tretiakov and

Scandolo, the Debye temperature D hvm / k is calculated as 132 K at 2 GPa and 370 K at 20

GPa, where vm is the Debye frequency. With a low Debye temperature, the heat capacity per

-3 -1 atom takes on the classical value of 3 kB per atom (C= 1.36, 1.86, and 2.16 J cm K at P=2, 10, and 20 GPa) 5. At pressures beyond 30 GPa, the deviation in heat capacity from classical values is greater. The Debye temperature of Ar is 440 K, 530 K, and 600 K at P=30, 45, and 60 GPa, respectively. The deviation of the heat capacity is corrected from the classical limit by assuming a Debye-like density of states for Ar.

Like Ar, the thickness of MgO is taken to be semi-infinite. Literature data 6-8 were used to estimate the heat capacity per atom Ca of MgO over the pressure range studied and the data were 2 2 - fit to a second order polynomial in P: Ca(P) = C0 +C1P +C2P , where C0=2.23 kB , C1= −1.38×10

2 -1 -4 -2 kB GPa , C2=1.16×10 kB GPa , and P in GPa. This was then converted to a volumetric heat capacity for MgO at high pressures.

-2 -1 The thermal conductance of the Al/Ar interface, GAl/Ar= 70+5.2P MW m K , where P is the pressure in GPa, is taken from the literature 9. The thermal conductance of the Al/MgO interface

-2 -1 at ambient pressure is high, GAl/MgO~ 480 MW m K , and the data can be fit well using G=1050

-2 -1 MW m K at P=59 GPa. Since the GAl/MgO is weakly dependent on the pressure, we linearly

-2 -1 scale the GAl/MgO= 480+9.66P MW m K , where P is the pressure in GPa.

Debye-Callaway-Morelli (DCM) model

In both the DCM and minimum thermal conductivity models, we use the MgO EOS from

Ref. 2 for the MgO density as a function of pressure and temperature, and the polycrystalline aggregate speeds of sound as defined in Ref. 10. Theses speeds of sound are derived from the bulk and shear moduli, which we take from the Jin EOS and the 11 measurement for the polycrystalline shear modulus of MgO to 130 GPa, respectively. While the bulk modulus has built-in temperature dependence through the EOS, the Murakami data does not. To apply temperature dependence to the shear modulus at arbitrary pressure, we scale it by the ratio GI(0

GPa, T) / GI(0 GPa, 300 K), where GI(0, T) is the shear modulus derived from the Cij(0, T) data of Ref. 12. The Isaak et al. data extends from 300 K to 1800 K, and has since been replicated and extended to 2500 K by a laser-heating technique (see Ref. 13). We also scale the longitudinal and transverse Gruneisen parameters according to the EOS, thereby assuming a fixed elastic anisotropy and Poisson ratio .

The ratio of the normal to Umklapp scattering rates in the DCM model is fixed by their functional forms, see Eqns. (11b), (12b), and (25) in Ref. 15, with normal scattering exponents a

3 = 2, b = 1. The point defect scattering strength ( for MgO is calculated from the natural isotopic composition 15, and found to be about 5.5x10-4. For comparison, we chose = 0.1 for the

disordered MgO model, based on a calculation of = 0.08 for mass disorder in the Mg0.5Fe0.5O alloy. With the assumption that the transverse Gruneisen parameter is a factor of 0.7 less than the longitudinal Gruneisen parameter, the latter one at 0 GPa and 300 K is the model’s only free

parameter. This was set to 2.3 to fix = DCM + min = 53.0 W/m-K for pure MgO; for comparison, the effective (longitudinal and transverse) ambient Slater Gruneisen parameter is about 2.06 2.

The minimum thermal conductivity model has three parameters: the atomic number density, and the longitudinal and transverse speeds of sound. These are all calculated as in the DCM

model, so that the combined model MgO = DCM + min is self-consistent.

1. C. Bercegeay and S. Bernard, Phys Rev B 72 (21), 214101 (2005). 2. K. Jin, X. Li, Q. Wu, H. Geng, L. Cai, X. Zhou and F. Jing, J Appl Phys 107 (11), 113518-113516 (2010). 3. K. Tretiakov and S. Scandolo, Journal of Chemical Physics 121 (22), 11177 (2004). 4. A. F. Goncharov, M. Wong, D. A. Dalton, J. G. O. Ojwang, V. V. Struzhkin, Z. Konopkova and P. Lazor, J Appl Phys 111 (11), 112609-112606 (2012). 5. H. Shimizu, H. Tashiro, T. Kume and S. Sasaki, Phys Rev Lett 86 (20), 4568-4571 (2001). 6. A. Chopelas, Phys Chem Miner 17 (2), 142-148 (1990). 7. S. Ghose, M. Krisch, A. R. Oganov, A. Beraud, A. Bosak, R. Gulve, R. Seelaboyina, H. Yang and S. K. Saxena, Phys Rev Lett 96 (3), 035507 (2006). 8. A. Chopelas and M. Nicol, J. Geophys. Res. 87 (B10), 8591-8597 (1982). 9. W.-P. Hsieh, B. Chen, J. Li, P. Keblinski and D. G. Cahill, Phys Rev B 80 (18), 180302 (2009). 10. H. M. Ledbette, J Appl Phys 44 (4), 1451-1454 (1973). 11. M. Murakami, Y. Ohishi, N. Hirao and K. Hirose, Earth Planet Sc Lett 277 (1-2), 123-129 (2009). 12. D. G. Isaak, O. L. Anderson and T. Goto, Phys Chem Miner 16 (7), 704-713 (1989). 13. S. V. Sinogeikin, D. L. Lakshtanov, J. D. Nicholas, J. M. Jackson and J. D. Bass, J Eur Ceram Soc 25 (8), 1313-1324 (2005). 14. J. C. Slater, Introduction to chemical physics. (McGraw-Hill Book Co., New York; London, 1939). 15. D. T. Morelli, J. P. Heremans and G. A. Slack, Phys Rev B 66 (19), 195304 (2002).

4