BTEC National Diploma in Engineering Level 3

Unit 17 Computer Aided Drafting in Engineering

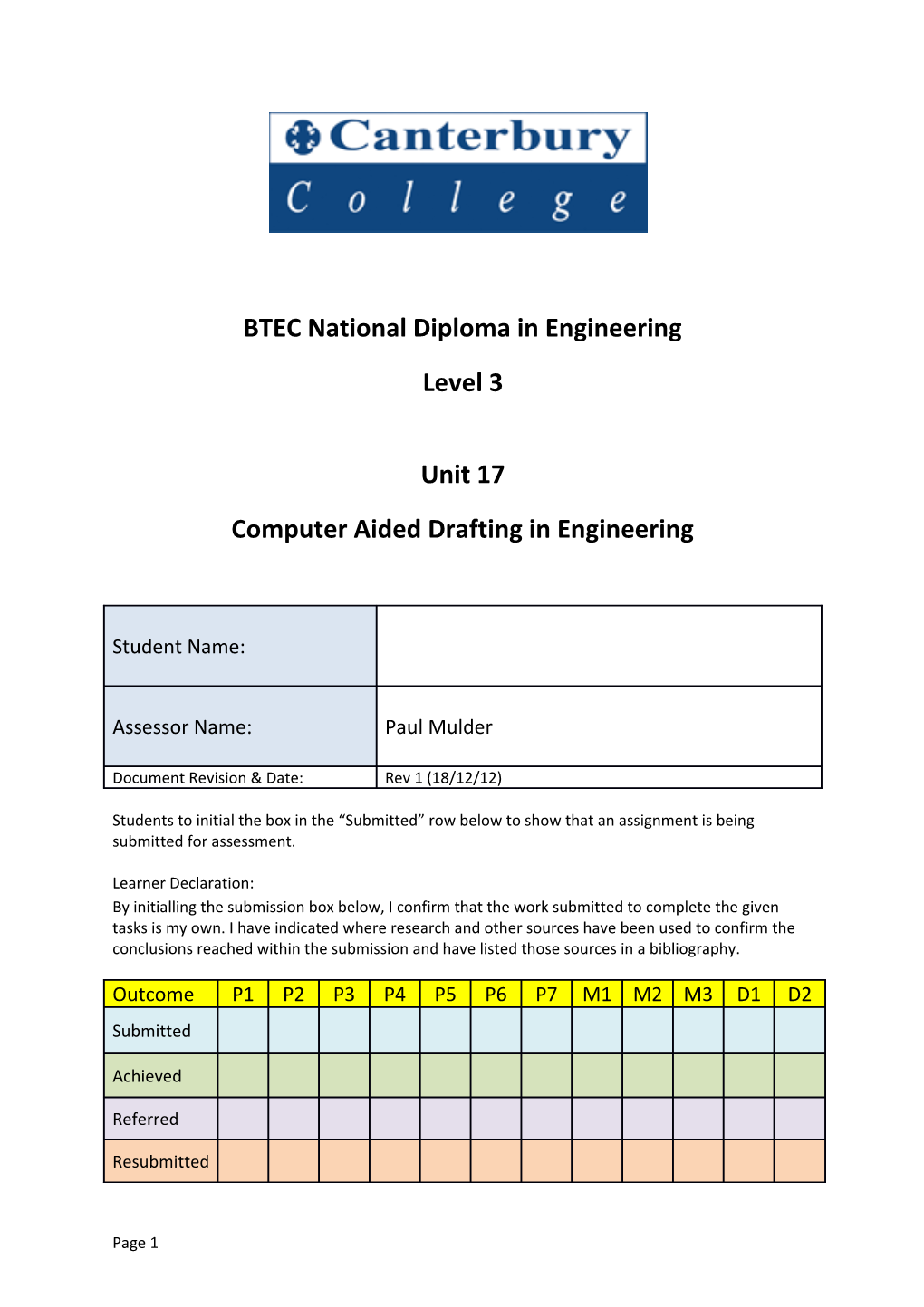

Student Name:

Assessor Name: Paul Mulder

Document Revision & Date: Rev 1 (18/12/12)

Students to initial the box in the “Submitted” row below to show that an assignment is being submitted for assessment.

Learner Declaration: By initialling the submission box below, I confirm that the work submitted to complete the given tasks is my own. I have indicated where research and other sources have been used to confirm the conclusions reached within the submission and have listed those sources in a bibliography.

Outcome P1 P2 P3 P4 P5 P6 P7 M1 M2 M3 D1 D2 Submitted

Achieved

Referred

Resubmitted

Page 1 Task Achievement Assessor Outcome Assignment Task Evidence No. Date Signature Describe the advantages, compared to other methods, of Written P1 producing drawings 1 Assignment electronically using a CAD package Describe the software and Written P2 hardware required to produce 2 Assignment CAD drawings 3 Adj. Screw Produce 2D CAD detail 4 Jaw drawings of five components 5 Slide Locator that make up an assembly or P3 6 T Bar sub-assembly to given 7 T Bar End standards, using appropriate commands 8 Hex Screw 9 Socket Screw Produce a circuit diagram containing at least five P4 components to appropriate 10 Circuit Diagram standards, using appropriate commands Produce an assembly drawing and exploded view of an 11 Assembly P5 assembly or sub-assembly Exploded containing at least five parts, 12 using appropriate commands Assembly Interpret the properties of an engineering component or Written P6 13 circuit from a given CAD Assignment drawing Within a 3D environment Written P7 construct a 3D CAD drawing as 14 Assignment a surface and solid model Explain the relationship between CAD and other Written M1 15 software/hardware used in Assignment manufacturing Explain how the range of commands used to produce Written M2 16 CAD drawings can impact Assignment drawing production Explain how 3D CAD models Written M3 can be used in the design 17 Assignment process

Justify the use of CAD in a Written D1 18 manufacturing company Assignment

Evaluate the impact of the use Written D2 of 2D and 3D CAD models on 19 Assignment final design requirements Task(s) 1

Page 2 Assignment Deadline

Outcome P1 Describe the advantages, compared to other methods, of producing Assignment Brief drawings electronically using a CAD package Evidence Written Assignment Describe the advantages of CAD versus non-electronic drawing methods. Consider factors such as reproduction, data sharing and storage, Assignment Guidance interfacing with C.N.C. (Computer Numerical Control) production machinery.

Task Requirement Task completed to the required standard? YES NO Your assignment should describe and compare at least the points listed below: Reproduction of drawings Data sharing Interfacing with CNC machinery Accuracy Editing, making changes and updating drawings Drawing storage in terms of space, locating lost drawings, keeping back- ups in case of fire, flood, or theft. Interfacing with other production machinery via the CAD>CAM>CNC link Summary.

Assessor Feedback: Achieved? YES/NO

Page 3 Task(s) 2

Assignment Deadline

Outcome P2 Assignment Brief Describe the software and hardware required to produce CAD drawings Evidence Written Assignment As an engineer, you may work for a company already using CAD or wanting to upgrade the CAD system they are currently using. Therefore, you need to have a working knowledge of the system hardware Assignment Guidance specification required to run given CAD software. Also describe the hardware required to produce CAD drawings. Finally describe the CAD software available and evaluate the advantages and disadvantages of 2 CAD systems by comparing SolidWorks with Autodesk Inventor.

Task Requirement Task completed to the required standard? YES NO Your assignment should describe and compare at least the points listed below focussing mainly on the use of SolidWorks:

Software required such as the operating system Other software required to link to SolidWorks to ensure it runs correctly Minimum system requirements such are hard disk space, RAM, processor and video card

Hardware required to operate SolidWorks, including a monitor and printer. A brief description of at least one other input device other than a mouse. Output devices, other than a printer. Data storage options

Compare SolidWorks with a comparable 3D solid modelling package such as Autodesk Inventor highlighting good and bad area’s with each.

Assessor Feedback: Achieved?

YES/NO

Page 4 Task(s) 3-9

Assignment Deadline

Outcome P3 Produce 2D CAD detail drawings of five components that make up an Assignment Brief assembly or sub-assembly to given standards, using appropriate commands Evidence Drawings Produce 3D models for each of the parts of the Drill Vice Assembly and from them produce 2D CAD drawings for all of the parts that make up a Assignment Guidance Drill Vice except the Drill Vice Body. All drawings should be presented in 3rd angle orthographic projection and contain an isometric view of the part. Each drawing needs to be completed to BS8888.

Task Task Requirement Task completed to the required standard? YES NO Task 3 Drill Vice Adjuster Screw Task 4 Drill Vice Jaw Task 5 Drill Vice Slide Locator Task 6 Drill Vice T Bar Task 7 Drill Vice T Bar End Task 8 Drill Vice Hexagon Head Screw Task 9 Drill Vice socket Cap Head Screw Assessor Feedback: Achieved?

YES/NO

Page 5 Page 6 Page 7 Page 8 Task(s) 10

Assignment Deadline

Outcome P4 Produce a circuit diagram containing at least five components to Assignment Brief appropriate standards, using appropriate commands Evidence 2D CAD Drawing Produce a drawing of an electronic circuit diagram for a transistor switch Assignment Guidance circuit, using the correct symbols and annotate as necessary.

Task Requirement Task completed to the required standard? YES NO Is the circuit diagram neatly laid out? Does the circuit diagram show the Bill of Materials? Does the circuit diagram show the required information in a title block? Are all the components identified by an alpha-numeric identification? Are each of the components drawn clearly and correctly?

Assessor Feedback: Achieved?

YES/NO

Page 9 Task(s) 11-12

Assignment Deadline

Outcome P5 Produce an assembly drawing and exploded view of an assembly or sub- Assignment Brief assembly containing at least five parts, using appropriate commands Evidence Drawings Produce a 3D assembly model containing the required number of each of the parts of the Drill Vice Assembly. From the assembly model produce a 3D exploded assembly. Then produce 2D CAD drawings for the Drill Vice Assembly and Drill Vice Exploded Assembly, including Bill of Materials and Assignment Guidance identification balloons for each part. The assembly drawing should be presented in 3rd angle orthographic projection and contain an isometric view of the part. The Exploded Assembly drawing should contain just an exploded isometric view of the part. Each drawing needs to be completed to BS8888.

Task Task Requirement Task completed to the required standard? YES NO Task 11 Drill Vice Assembly

Task 12 Drill Vice Exploded Assembly

Assessor Feedback: Achieved?

YES/NO

Page 10 Task(s) 13

Assignment Deadline

Outcome P6 Interpret the properties of an engineering component or circuit from a given Assignment Brief CAD drawing Evidence Written Assignment Interpret the properties of the Drill Vice Adjuster Screw shown on the next page. State whether it is drawn in 1st or 3rd angle orthographic projection and describe how you know this. Detailed information as shown in the table below should be included. Don’t Assignment Guidance just copy what’s on the drawing verbatim, it is important to show that you can interpret this information into text. Eg. If a thread size is stated as M4x0.7, describe the thread type, including its diameter and pitch. This assignment also counts for P3 of Unit 16 – Engineering Drawing for Technicians.

Task Requirement Task completed to the required standard? YES NO Are the following points adequately interpreted, described and explained?: The overall sizes of the part. The sizes of each element of the part, both length and diameter. Chamfers Thread Cross-drilled hole The orthographic view of the drawing The details of the information contained in the drawing data block

Assessor Feedback: Achieved?

YES/NO

Page 11 Page 12 Task(s) 14

Assignment Deadline

Outcome P7 Within a 3D environment construct a 3D CAD drawing as a surface and Assignment Brief solid model Evidence Written Assignment As evidence of the drill vice parts being created as 3D models, provide screen dumps as printed documents showing each of the Drill Vice parts which have been modelled in 3D using SolidWorks. Assignment Guidance Each part should be captured from at least two viewpoints, one of which should be the isometric view and the other should show the opposite 3 sides of the model from the isometric view. Describe each of the views from the list below.

Task Requirement Task completed to the required standard? YES NO Does the assignment contain the following 3D models: Drill Vice Adjuster Screw Drill Vice Jaw Drill Vice Slide Locator Drill Vice T Bar Drill Vice T Bar End Drill Vice Hex Head Screw Drill Vice Socket Cap Head Screw Drill Vice Body Drill Vice Assembly Drill Vice Exploded Assembly Assessor Feedback: Achieved?

YES/NO

Page 13 Task(s) 15

Assignment Deadline

Outcome M1 Explain the relationship between CAD and other software/hardware used Assignment Brief in manufacturing Evidence Written Assignment Describe the relationship between a typical CAD system and other software/hardware in a production environment. Consider how 3D models Assignment Guidance interface directly with CNC machining work centres and how that reduces time and errors.

Task Requirement Task completed to the required standard? YES NO Your assignment should describe the interface between SolidWorks and other software/hardware as a minimum covering the examples listed below: CAM software CNC machinery Finite Element Analysis (FEA) Other CAD software Savings in time and errors

Assessor Feedback: Achieved?

YES/NO

Page 14 Task(s) 16

Assignment Deadline

Outcome M2 Explain how the range of commands used to produce CAD drawings can Assignment Brief impact drawing production Evidence Written Assignment Produce a written evaluation, to demonstrate how the use of a range of commands can affect the efficiency of drawing production in terms of speed, accuracy and repeatability. Comparisons should be made between best practice and less efficient methods. Particular mention should be made of the use of the rectangle, polygon Assignment Guidance and mirror commands, although others should be considered. These commands should be compared with less efficient methods. In the case of rectangles, drawing 4 separate lines versus using the rectangle tool. Speed, accuracy and repeatability should feature strongly with the role they play in the preferred methods.

Task Requirement Task completed to the required standard? YES NO Your assignment should explain, evaluate and compare a range of commands in SolidWorks as a minimum covering the examples listed below: Rectangle Polygon Mirror At least one other

Assessor Feedback: Achieved?

YES/NO

Page 15 Task(s) 16

Assignment Deadline

Outcome M3 Assignment Brief Explain how 3D CAD models can be used in the design process Evidence Written Assignment Produce a written assignment describing the commonly used 3D Assignment Guidance commands, include screen dumps of your own work to demonstrate and describe the advantages of using 3D models in the design process

Task Requirement Task completed to the required standard? YES NO Your assignment should describe the advantages of a range of 3D commands in SolidWorks as a minimum covering the examples listed below: A range of at least 4 3D commands of your choice 1. 2. 3. 4. Plus at least the following: Rotating the view Zooming Cross-sectioning Assembly Exploded Assembly

Assessor Feedback: Achieved?

YES/NO

Page 16 Task(s) 18

Assignment Deadline

Outcome D1 Assignment Brief Justify the use of CAD in a manufacturing company Evidence Written Assignment As the user cost for a modern CAD system is not cheap, justify the use of Assignment Guidance CAD in a manufacturing company.

Task Requirement Task completed to the required standard? YES NO Your assignment should justify and evaluate the use of SolidWorks in industry as a minimum covering the examples listed below: Costs Training requirements Advantages Disadvantages

Please note. This assignment should draw from many of the topics discussed in previous assignments, but analysing them from the perspective of this assignment, as described in the assignment guidance above

Assessor Feedback: Achieved?

YES/NO

Page 17 Task(s) 19

Assignment Deadline

Outcome D2 Evaluate the impact of the use of 2D and 3D CAD models on final design Assignment Brief requirements Evidence Written Assignment Complete a written assignment describing the advantages of using 3D models in the 3D assembly process. Produce a written evaluation of the difference between 2D drawings and 3D models from a customer’s perspective, including how customers might Assignment Guidance interpret this information for their final design requirements. Compare the use of a 2D CAD package, such as AutoCAD, with the use of a 3D CAD package, such as SolidWorks, when completing a design task from inception to completion. You may use the Drill Vice Assembly and it’s components as your example.

Task Requirement Task completed to the required standard? YES NO Your assignment should evaluate the use of SolidWorks in industry as a minimum covering the examples listed below: Evaluate the advantages and disadvantages of 2D drawings versus 3D models How customers might interpret 2D and 3D information for their final design requirements Compare the use of a 2D CAD package, such as AutoCAD, with the use of a 3D CAD package, such as SolidWorks, when completing a design task from inception to completion.

Note. Use Youtube tutorials to gain an understanding of AutoCAD 2D before attempting the last element of the assignment.

Assessor Feedback: Achieved?

YES/NO

Page 18