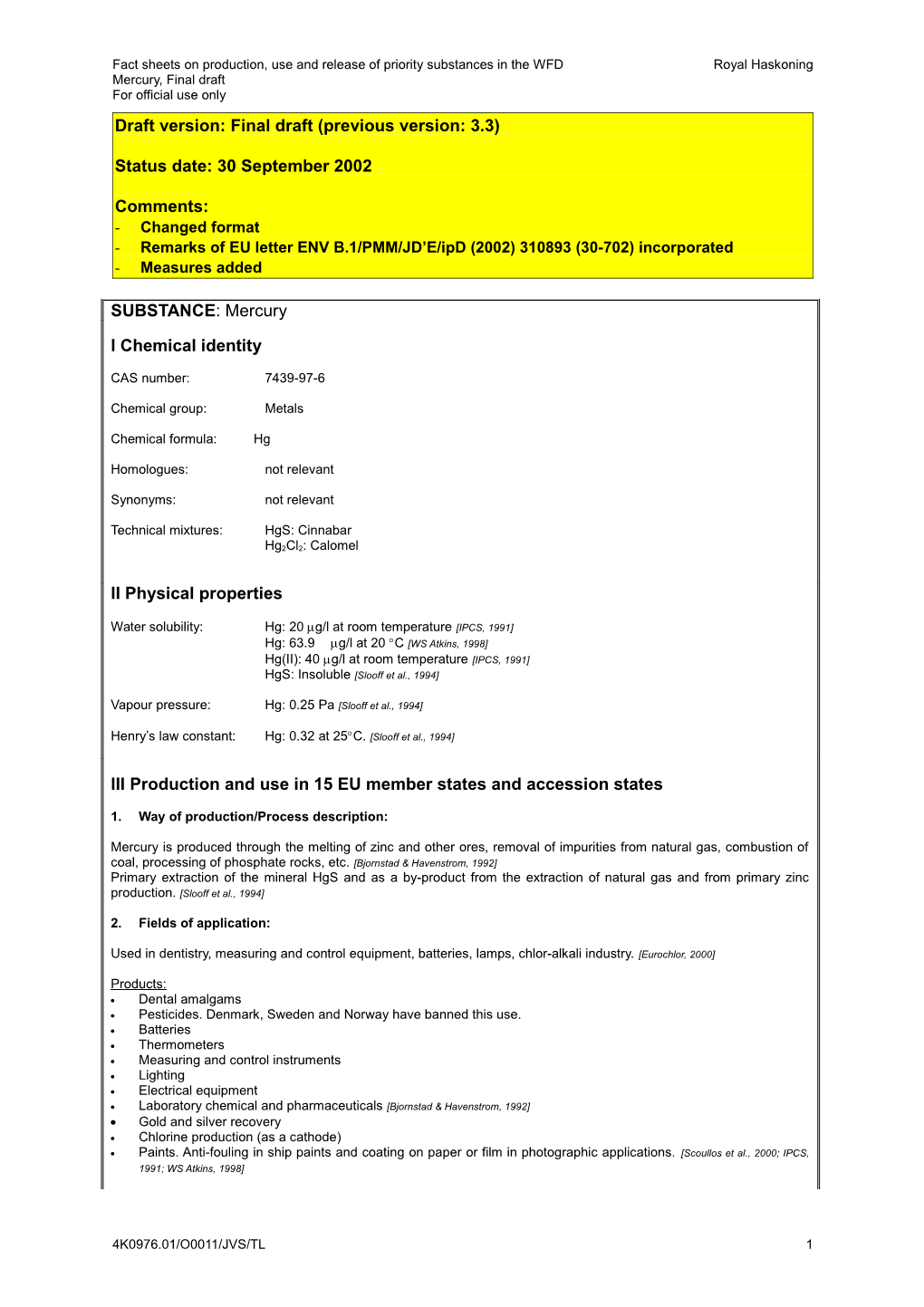

Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only Draft version: Final draft (previous version: 3.3)

Status date: 30 September 2002

Comments: - Changed format - Remarks of EU letter ENV B.1/PMM/JD’E/ipD (2002) 310893 (30-702) incorporated - Measures added

SUBSTANCE: Mercury

I Chemical identity

CAS number: 7439-97-6

Chemical group: Metals

Chemical formula: Hg

Homologues: not relevant

Synonyms: not relevant

Technical mixtures: HgS: Cinnabar

Hg2Cl2: Calomel

II Physical properties

Water solubility: Hg: 20 g/l at room temperature [IPCS, 1991] Hg: 63.9 g/l at 20 C [WS Atkins, 1998] Hg(II): 40 g/l at room temperature [IPCS, 1991] HgS: Insoluble [Slooff et al., 1994]

Vapour pressure: Hg: 0.25 Pa [Slooff et al., 1994]

Henry’s law constant: Hg: 0.32 at 25C. [Slooff et al., 1994]

III Production and use in 15 EU member states and accession states

1. Way of production/Process description:

Mercury is produced through the melting of zinc and other ores, removal of impurities from natural gas, combustion of coal, processing of phosphate rocks, etc. [Bjornstad & Havenstrom, 1992] Primary extraction of the mineral HgS and as a by-product from the extraction of natural gas and from primary zinc production. [Slooff et al., 1994]

2. Fields of application:

Used in dentistry, measuring and control equipment, batteries, lamps, chlor-alkali industry. [Eurochlor, 2000]

Products: Dental amalgams Pesticides. Denmark, Sweden and Norway have banned this use. Batteries Thermometers Measuring and control instruments Lighting Electrical equipment Laboratory chemical and pharmaceuticals [Bjornstad & Havenstrom, 1992] Gold and silver recovery Chlorine production (as a cathode) Paints. Anti-fouling in ship paints and coating on paper or film in photographic applications. [Scoullos et al., 2000; IPCS, 1991; WS Atkins, 1998]

4K0976.01/O0011/JVS/TL 1 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only The production, storage and sale or supply of pesticides containing mercury was banned in 1992. The following applications of mercury based compounds have been addressed: use in paints use in cosmetics use in agriculture Council directive 89/677/EEC regulates the following applications of mercury compounds: marine anti-fouling paints; wood preservation; textile treatment; industrial wastewater treatment. Such applications are no longer permissible and EC Member States had to implement appropriate controls eighteen moths from the date of the adoption of the Directive. It is therefore estimated that although there may be a small residual use of these products, this will keep decreasing and mercury from these products does now not represent a significant source. [OSPAR, 2000]

Contaminants: Mercury is a contaminant in fertilisers (originating from phosphate rocks and sulphuric acid), lime and sewage sludge. Fossil fuel combustion and industrial production involving the use of raw materials containing mercury (ex. zinc and copper production). [Bjornstad & Havenstrom, 1992]

3. Production volume:

European production amounted 400 tons in 1997. [Eurochlor, 2000]

Secondary and primary mercury production (tons): [Scoullos et al., 2000] 1993 1994 1995 1996 1997 1998 1999 Finland: 98 83 90 88 90 80 80 Spain: 64 393 1497 862 863 675 600

4. Number of production sites and locations of production:

In EU production in Spain and Finland. [Scoullos et al., 2000]

5. Use volume:

Consumption in western Europe in 1990 was about 900 tons. [Bjornstad & Havenstrom, 1992]

Around 37 tons of mercury enter battery waste stream in Europe annually. [EC, 2001b]

Annual flows of mercury through the EU 12 economy in 1989: [Scoullos et al., 2000] Imports extra EU 12 and prim. Production tons Imported waste and used products containing mercury - for reprocessing 0 - for disposal 40 Imported products 125 Primary (mined) mercury 967 Secondary mercury 361 Imported refined mercury 803 Imported ores, fuels, etc. 172 Reprocessed for domestic use 0 Total mercury flow 2468

Use of mercury in the Netherlands in 1990 (tons): [Slooff et al., 1994] Application mercury concentration tons reference Dentistries 50% per amalgam filling 5.5 CUWVO 1990 Laboratories 0.3 OECD 1991 Measuring devices1,5 g/thermometer <2.8 MILAD 1986/van der Poel 1990 Batteries 0.025-30% 2.4 Meijer 1991 Lamps 5-15 mg/lamp <1.3 van der Poel 1990/Bresser 1992 Chlor alkali industry 1 Total <13

Import and export (tons) of all mercury in EU15, 1997: [Eurostatt, 1997 in ERM, 1998] These figures are not representative of the amount of mercury used (lower). [Comments of Eurometaux] Country Import Export

4K0976.01/O0011/JVS/TL 2 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only France 23.0 16.8 Belgium/Lux. 70.1 10.4 Netherlands 611.9 609.8 Germany 77.7 95.6 Italy 28.2 43.3 UK 44.3 16.0 Ireland 0.1 0.2 Denmark 1.2 4.8 Greece 4.7 - Portugal 8.0 0.0 Spain 143.5 594.3 Sweden 38.5 0.0 Finland 4.7 138.7 Austria 9.6 8.6 TOTAL 1065.5 1538.5

In Sweden total use of 10 tonnes in 1999 was reported for the use of mercury in dental products, enamels and as raw material for synthesis. [Swedish EPA, 2001]

6. Relative use volumes in various applications:

Yearly net consumption of mercury due to products intentionally containing mercury in the Nordic countries is shown in appendix 1.

Usage of mercury for different product groups: [WS Atkins, 1998] Product group % of total mercury used in products Consumption of Mercury (t/y) Electrical control and switching 27 29 - Switches and relays 15 16 - Mercury vapour tubes and arc rectifiers 12 13 Measuring equipment 53 56 - medical thermometers 22 23 - Other thermometers 27 28 - Other measuring eq. 4 4 Lighting 20 21 - Fluorescent tubes 14 15 - HID lighting 6 6 Paints and coatings <1 <1 Miscellaneous <1 <1 TOTAL 100 108

Average use volumes in OECD countries for period 1988-1992: [DEPA 1998 in WS Atkins, 1998] batteries 25% Chlor-alkali industry 28% Electrical equipment 16% Paint 10% Tooth filling 7% Other uses 14% TOTAL 100% Consumption patterns has changed since in many countries use in chlor-alkali industry has stopped and use in batteries is being phased out. In Nordic countries up to 80% is used in amalgam fillings.

Relative use volumes in the Federal Republic of Germany (in tonnes): [Balzer & Rauhut, 1996] Year 1990 1991 1992 1993 % 1993 Chlor-alkali industry 62.4 50.7 30.7 26.2 Catalists 6.0 - - - Paints 0.6 0.3 0.3 0.1 Control instruments and mechanical engineering 6.4 12.8 11.3 4.9 Chemicals and reacting agents 3.0 3.0 3.0 3.0 Medicines 20.1 32.5 31.9 29.2 Others 10.0 10.0 10.0 10.0 Total 108.5 109.3 90.5 73.4 100

Mercury Amalgam is one of the most significant product sources of mercury. It has been estimated that approximately 19 tonnes of mercury per annum are used for amalgam in the UK. Some 20 percent of this is actually put into teeth, and the remainder may either be discharged to sewer, collected in an amalgam separator

4K0976.01/O0011/JVS/TL 3 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only

device attached to a dental chair, or enter a solid waste stream for either disposal or recycling. [OSPAR, 2000]

The quantity of mercury used in the production of batteries was estimated to be 15 tonnes/year, of which 14,1 tonnes (or 94%) was used in the production of oxide cells. The quantity of mercury use in thermometers purchased for National Health Service use in the UK is approximately 1 tonne per annum. No information is available for the number of thermometers in domestic use. Data for sphygmomanometers is limited. A preliminary figure of 10,2 tonnes is estimated to be contained in these instruments. No data is currently available in the project databank regarding mercury consumption and use in barometers. Fluorescent lamps contain 20 mg mercury, metal halide lamps contain 45 mg of mercury and sodium lamps contain 9 mg of mercury. The report “Mercury in the UK” estimates the following emissions from the manufacture and use of fluorescent lamps. [OSPAR, 2000]

7. Existing regulation in member states or associated member states:

The European Union has enforced a number of regulations concerning discharges, emissions and losses of mercury. The draft UK DIFF document (DIFF 99/3/6) gives an overview on relevant directives. [OSPAR/EC, 2001]

North Sea Action Plan (NAP), Mercury, Class 1A: North Sea Ministers Conference (1990) North Sea Action Plan. National Implementation Order Third North Sea Ministers Conference. Lower Chamber, Conference year 1990-1991, 21 884 no.1-2.

UNECE POP & heavy metals, Mercury, Listed: OSPAR (1998) OSPAR 1998 List of Candidate Substances. OSPAR Strategy with regard to Hazardous Substances (Ref. nr. 1998-16), Annex 3. Sintra 22-23 July 1998.

Black List, mercury, Listed: EC (1982) List I within the framework of Directive 76/464/EEC on pollution caused by certain dangerous substances discharged into the aquatic environment of the Community. Official Journal C 176, 14.7.1982 p. 7 - 10.

Lead, cadmium and mercury containing batteries are classified as hazardous waste according to the list of hazardous waste established in 1994. According to 2000/532/EC and 2001/118/EC also unsorted batteries including lead, Cd and Hg will be classified as hazardous waste as from January 2002. Large amounts of batteries and accumulators are landfilled or incinerated with household waste. [EC, 2001b]

EC Directive 89/667 (eighth Amendment of EC Directive 79/769) which bans the use of mercury compounds in anti- fouling, wood preservative and biocidal preparations. [WS Atkins, 1998]

Environmental quality standards and emission limits have been set under amendments to Directive 76/464/EEC. Its use as a PPP was prohibited by Directive 79/117/EEC and its marketing and use has been restricted for certain applications. Mercury is included under Annex 2 to the OSPAR Stragy with regard to hazardous substances (OSPAR 2000). [RPA, 2000]

OSPAR has adopted the following measures aimed at restricting discharges/emissions of mercury from products [OSPAR/EC, 2001]: - PARCOM Recommendation 89/3 on Programmes and Measures for Reducing Mercury Discharges from Various Sources - PARCOM Decision 90/2 on Programmes and Measures for Mercury and Cadmium-Containing Batteries - PARCOM Recommendation 93/2 on Further Restrictions on the Discharge of Mercury from Various Sources - Several OSPAR Recommendations and Decisions on the Chlor-Alkali Industry - Several OSPAR Measures on Dental Amalgam

HELCOM has proposed maximum limits for the mercury content in lamps.

OSPAR-RID - The Riverine Inputs and Direct Discharges (RID) monitoring programme within OSPAR enables a quantification of all riverborne and direct inputs of selected pollutants to the Maritime Area on an annual basis, including mercury.

UN ECE LRTAP MERCURY falls under the UN-ECE-LRTAP Protocol for Heavy Metals, the aim of which is the reduction of heavy metal emissions due to human activity and with the potential of causing harmful effects at long distance from the source via transport through the atmosphere.

North Sea Conference Framework – A political commitment was made at the 2nd and 3rd North Sea Conference to take urgent and drastic measures in order to reduce the input of hazardous substances into the North Sea between 1985 and 1995 by 50%. There was an additional commitment to reduce by 70% the total input (all pathways) of a number of substances, including mercury.

EPER – Europian Pollution Emission Registry, decision of 17th July 2000. Reporting of emissions from all individual facilities with one or more activities as mentioned in Annex I of EU Directive 96/61/EC. The emission data shall be reported for each facility according to a specific format, noting a description of all activities as mentioned in Annex I of

4K0976.01/O0011/JVS/TL 4 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only Directive 96/61/EC with corresponding source categories and NOSE codes.

8. Industrial associations to be addressed:

Eurometaux, Avenue de Broqueville 12, B-1150 Brussels.

IV Releases to environment

1. General way of entrance into the aquatic environment:

Relevant main routes of release to the environment are given in appendix 11 and summarised as follows:

Production, formulation & industrial use A5-A6 S9.2; S9.3 WWT S9.2.1; S9.2.2 STP S8.4 Waste S10.1; S10.2

Consumer use (Hg ex. Thermometers, lamps etc.) A4 S8.1; S8.2; S8.3 Waste S10.1 S10.2

Agriculture (phosphate fertilisers, pesticides) A1 Soil

Waste (incineration and landfill) A7 (incineration) S10.1; S10.2 (leaching from landfill and incineration ashes)

Historic pollution A8

2. Atmospheric cycle:

a. Industrial Point Sources to the air

In 1989, mercury emissions to the air in the EC were estimated at 29 t/y for industrial production, 10 t/y for mercury mining, 5 t/y for secondary production and 6 t/y for non-ferrous metal production and refining. Due to fossil fuels 76 t/y was estimated [maxson & Vonkeman, 1991]. See also appendix 5.

In the heavy metal atmospheric emissions inventory in 1990 for EU-15 the emission of mercury to the air is estimated at 53 t/y for industrial production including non-ferrous metal processing and 33 t/y for industrial combustion. [UBA-TNO, 1990 in Entec, 2001]. See also appendix 9.

b. Municipal Collective Sources to the Air:

Europe Annual European tonnage of mercury disposed in incinerators (t/y): [WS Atkins, 1998] Product total disposed Disposed to Em. to atm. to incinerators landfill Switches, relays etc. 3.2 1.6 1.6 Mercury vapour tubes 2.6 1.3 1.3 Medical thermometers 10 5.0 5.0 Other thermometers 3.2 1.6 1.6 Other meas. Eq. 1.5 0.75 0.75 Fluorescent tubes 2.3 1.2 1.2 HID lighting 0.9 0.45 0.45 Miscellaneous <0.16 <0.08 <0.08 TOTAL 23.9 11.9 11.9

Most of the mercury containing waste enters municipal waste stream. Exceptions are: - Electrical control equipment (landfilled) - Medical thermometers enter clinical waste stream and are incinerated. - Lamps. Some is recycled, rest enter municipal waste stream - Mercury entering sewage system by breakage - Solid waste is landfilled In EU approximately 20% of municipal waste is incinerated. Estimation of the distribution of mercury from products from use and disposal of products and emission during manufacturing in appendix 3. Total EU15 losses of mercury to atmosphere from landfills is estimated to be 3.8 t/y. [WS Atkins, 1998]

4K0976.01/O0011/JVS/TL 5 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only

Around 37 tons mercury enter battery waste stream in Europe annually. [EC, 2001a]

Available national release data:

France In France in 1993, 122 tons of mercury entered the environment in the form of waste. Mercury contained in waste in France: [AGHTM 1999 in Thornthon, 2001] Activity tons % treated and recycled Zinc and lead metallurgy 18 4.8 Thermometers 9 5.6 Dentistry amalgams 9 11.4 Batteries 6.8 7.4 Laboratories 0.9 0.0 Fluorescent tubes 0.8 12.5 Barometers 0.4 10.0 High intensity lamps 0.2 10.0 Chlorine production 77 ? TOTAL 122.1 -

United Kingdom Quantification of Mercury in Waste streams in the UK [OSPAR, 2000] Source Quantity tonnes/year Municipal waste incineration2.2 Sewage sludge incineration <0.1 Clinical waste incineration 8.2 Crematoria 4.0 TOTAL 14.4

In the UK: Discharges from the manufacture of mercury oxide cells to the atmosphere and sewer were approximately 0.014 and 0.005 tonnes Hg/year respectively. Solid wastes from the manufacture of cells were landfilled together with end of life batteries returned by users. An estimated 2.05 tonnes of Hg/year was landfilled. [OSPAR, 2000]

Netherlands In the Netherlands, waste incineration causes emission to air of 1.5 tonnes/year (1992). Total mercury waste stream is 40 tonnes. [Slooff et al., 1994] The FRG, France and Italy account for 66% of emissions from incineration. [Maxson & Vonkeman, 1991]

Batteries. Emission 1994 in the Netherlands: To waste: 0.5-1 tonnes and collected fraction: 1.5-2 tonnes. [Slooff et al., 1994]

Thermometers. Emission 1994 in the Netherlands: To waste 0.29 tonnes [Slooff et al., 1994]

Chemical waste. In the Netherlands mercury release to the chemical waste stream is 0.29 tonnes [Slooff et al., 1994]

c. Diffuse sources to air and deposition

Deposition from atmosphere [Hellner 1991 and Gustafsson 1994 in WS Atkins, 1998] [EC, 2001b] Mercury in atmosphere occurs as vapour and is not associated with particulate matter. It can be transported over large distances. Estimates of residence time in atmosphere and transport distance are up to 2 years and up to 2000 km. [Hellner 1991 and Gustafsson 1994 in WS Atkins, 1998] 75% deposited by wet deposition, remainder by dry deposition. Total deposition in EU ranges 50-400 g/m2y. From this deposition re-emission can occur that can be seen as historical pollution of Mercury from terrestrial and aquatic ecosystems. [EC, 2001b] According to TGD total EU15 surface area is 3.56 x 106 km2. The total EU15 deposition is calculated to be 178 – 1424 t/y.

Mercury product use (NOSE 113.01; 112.09.14; 112.09.15) Estimated emission factors (g/kg) during mercury product use: [WS Atkins, 1998] Product to air (g/kg) Switches sand relays negligible Vapour tubes and arc rectifiers negligible Thermometers 50 Fluorescent tubes/HID lighting 80

4K0976.01/O0011/JVS/TL 6 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only Annual emissions of mercury during product use: [WS Atkins, 1998] Product to air (tons) Switches sand relays negligible Vapour tubes and arc rectifiers negligible Medical thermometers 1.2 Other thermometers 1.4 Other measuring equipment 0.20 Fluorescent tubes 1.2 HID lighting 0.48 Miscellaneous products <0.05 Total 4.5

Emissions from the use of Mercury in Products (tonne Hg/year): [OSPAR, 2000] Use Atmosphere Dental amalgam 0,32 Batteries 0,01 Biocides and pesticides 0,01 Industrial and control instruments nd Laboratory and medical instruments nd Lighting 0,04 Total 0,38 nd no data available in project databank

Natural sources Erosion and degassing of mineralised soils (770 t/y), volcanic eruptions (830 t/y) and geothermal activities, Earth’s subsurface crust (1,000 t/y) [Eurochlor, 2000]

Available national release data:

Netherlands: Estimated atmospheric emission due to the use of lamps in the Netherlands: 0.2 tonnes/year[Coppolse et al 1993 in Slooff et al., 1994]

3. Aquatic releases:

a. Industrial Point Sources to the aquatic environment

Mercury mining (NOSE 105.02) Mining may also be responsible for runoff to surface waters. [Maxson & Vonkeman, 1991]

Primary mercury production: [JRC, 2000a] To air: 25-35 mg Hg/Nm3; 15-30 mg Hg/tonne Hg produced To water: 1993 1994 1995 1996 1997 ppb: 4 28 66 83 67 m3: 31000 11000 32500 29000 45500

This will lead to 45500 m3 x 67 ppb = 3,048,500 mg = 3.0 kg in 1997

Total mercury discharge to water due to Mining: 4 kg in 1999 [Swedish EPA, 2001] m3: 31000 11000 32500 29000 45500 Other mining (NOSE 105.02) Most non-ferrous metal ores contain trace amounts of mercury. The roasting process is the most likely source. By-product of zinc production. In the Netherlands, annually 3 tonnes of mercurous chloride is sold out of 20 tonnes of mercury produced as by-product of zinc. Rest is waste (15 tonnes in wastewater neutralisation plaster and 1-2 tonnes waste product jarosiet which are dumped on plant). [Slooff et al. 1994]

Secondary production: [JRC, 2000a] To air: 7 mg Hg/Nm3; 0.002 kg Hg/tonne Hg produced (1997) To water (ppb): 0.3 g/tonne (1997)

Non-ferrous metal production/refining: Zinc: Average emission to air 15 mg/kg zinc production (1988b) This leads to emission of 4 tonnes in France, Italy, UK and FRG and to the EC of about 16 tonnes.

4K0976.01/O0011/JVS/TL 7 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only Lead: Emissions from smelting lead ore 0.7 mg Hg/kg. Copper: 1.0 mg Hg/kg copper production. [Maxson & Vonkeman, 1991]

Off-shore gas (NOSE 106.03.03)

Available national release data:

The Netherlands 8 tonnes of mercury was extracted in the Netherlands, of which 2-3 tonnes was sold, the rest was waste and emission [Bastin 1994 in Slooff et al. 1994]. to air: 0.02 tonnes to water: 0.005 tonnes (off-shore) to waste: 4.5-5.5 tonnes (filters and waste) Final emission to air of mercury in the Netherlands at the user of natural gas is 0.04 tonnes/year. [Slooff et al., 1994] Secondary production/recovery (from natural gas, extraction from zinc sulphide and other non-ferrous ores): Aqueous emissions from mercury recovery plants are 0.05 mg/l of effluent. Emissions to atmosphere are much higher. [Maxson & Vonkeman, 1991]

Off-shore oil (NOSE 106.02.02)

Discharges of heavy metals (tonnes) via produced water by offshore installations [Provisional data in documents SEBA 99/9/1 and SEBA 00/10/3 in OSPAR, 2000] Contracting party total amount of Hg discharged/year Netherlands 1996 0.0185 Norway 1996 0.019 Norway 1998 0.036 UK 1999 0.015 TOTAL 0.089

Available national release data:

The Netherlands Estimated is that 0.04 tonnes of mercury is dumped at sea in the Netherlands. [Bastin 1994 in Slooff et al., 1994)

Iron and Steel (NOSE 104.12/105.12)

Available national release data:

The Netherlands: The raw materials result in a total emission to air of 0.38 tonnes and to water 0.036 tons. The sinter- and pellet manufacture cause an emission to air of 0.36 tons/year and to water of 0.036 tons/year. Oxysteel factory causes an emission to air of 0.02 tonnes/year. [Slooff et al., 1994]

Sweden Total mercury discharges to water in Sweden by metal plants: 20 kg in 1995. [Swedish EPA, 2001]

Chlor-alkali industry (NOSE 105.09.02) Emission from chlor-alkali industry: < 10% of total anthropogenic emissions in W-Europe. Total emission OSPARCOM area: 8.5 tonnes in 1997 of which 0.5 to water. [Eurochlor, 2000] Chlorine and caustic soda production results to emissions to air, water and soil, most of it to waste water. In the EU in 1997 0.91 x 10 6 tons were released to air (Euro Chlor, 1998) and 1.6 t/yr in EEA countries (Hanish 1998, CBNB, 1999). Mercury discharges to water have been reduced over 85% in past decade, to 10 tons in

1997 (EuroChlor). Mercury discharge factors were reduced from 26.6 grams Hg/ton Cl2 to 8.1 in 1985, 4.1 in 1990 and 1.4 in 1997. [Scoullos et al., 2000]

Overall Chlor-alkali industry air emission factor (mercury cell process only): 0.001 kg/ton Cl2. Emission factor to water: 0.0007 kg/t Cl2. [EC, 1993]

According to Euro Chlor 6,176,000 tonnes chlor-alkali chemicals are produced using the mercury cell process. [Eurochlor, 2000] This will lead to 6,176,000 x 0.0007 = 4.32 t/y mercury discharge to the aquatic compartment.

According to Euro Chlor, mercury emissions to air and water per tonne chlorine capacity in western Europe were 27 g in 1977, 8g in 1987 and around 2 g in 1997. In the 1990s the industry moved away from the mercury process to the more efficient membrane cell process. Reported are emission factors (per tonne chlorine produced) of 0.2-2.1 g to air, 0.01-0.65 g to water and 0-84 g to waste. The three waste-brine mercury plants operating in western Europe reported total aqueous mercury emissions between 0.01-0.28 g/t chlorine capacity in 1998, as reported by Euro Chlor. Many old chlor-alkali plant sites are contaminated with mercury. [JRC, 2000b]

Losses of mercury to water in mercury cell chlor-alkali plants operated by Contracting Parties in 1997 is estimated to be 0,502 tonnes. [OSPAR, 2000]

4K0976.01/O0011/JVS/TL 8 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only

Available national release data:

The Netherlands: 1990: 0.8 tonnes to air, 0.05 tonnes to water and 0.004 tonnes to waste 1992: 0.6 tonnes to air, 0.03 tonnes to water and 0.025 tonnes to waste [Slooff et al. 1994]

Sweden. There are 10 chlorine production plants (4 are active) with mercury contaminated sediments. 4 sites are investigated with a total of 4 ton mercury. [Swedish EPA, 2001]

Total mercury discharges to water in Sweden by the chemical industry: 6 kg in 1995. [Swedish EPA, 2001]

Phosphorous Fertilizer (NOSE 105.09.26) Mercury is a contamination of the phosphate ore and sulphuric acid. The mercury contamination ends up in

water (0.1-1g/ton P2O5 produced) and fertiliser (0.01 g/ton P2O5 produced). Annual emission to water in the Netherlands is 0.37 tonnes/year. [Slooff et al., 1994] Mercury emissions due to production and use of phosphate fertilisers are depicted in table appendix 2. [Maxson & Vonkeman, 1991] In 1996, EU15 production of phosphorous fertiliser was 2.341 x 106 t/y [IFA 1998 in Oosterhuis et al., 2000]. This leads to an annual discharge of 0.2341 – 2.341 t/y to the aquatic compartment.

Product manufacturing (NOSE 104/105) Estimated emission factors (g/kg) for mercury product manufacture: [WS Atkins, 1998] Product to air to sewer In solid waste Switches and relays 0.0003 0.03 5 Vapour tubes and arc rectifiers 0.0003 0.03 5 Measuring equipment 0.0003 0.03 140 Fluorescent tubes/HID lighting 22 0.03 140

Estimated European annual emission during product manufacture: [WS Atkins, 1998] Product to air (g/y) to sewer (kg/y) In solid waste (t/yr) Switches and relays 4.8 0.48 0.08 Vapour tubes and arc rectifiers 3.9 0.39 0.065 Medical thermometers 6.9 0.69 3.2 Other thermometers 8.4 0.84 3.9 Other measuring equipment 1.2 0.12 0.56 Fluorescent tubes 330 (kg/y) 0.45 2.1 HID lighting 130 (kg/y) 0.18 0.84 Miscellaneous products <0.3 <0.03 <0.14 Total 490 kg/y 3.2 11

Dental amalgams (NOSE 111.03.02)

Available national release data:

The United Kingdom: Mercury Amalgam is one of the most significant product sources of mercury. It has been estimated that approximately 19 tonnes of mercury per annum are used for amalgam in the UK. Some 20 percent of this is actually put into teeth, and the remainder may either be discharged to sewer, collected in an amalgam separator device attached to a dental chair, or enter a solid waste stream for either disposal or recycling. [OSPAR, 2000]

The Netherlands: Wastewater: 2.3 tonnes/year, resulting in 0.3 tonnes in surface water. [CUWVO 1990 in Slooff et al., 1994]

Crematories & Cemetries (release route to soil) (NOSE 109.05.01)

Available national release data:

United Kingdom [OSPAR, 2000]: It has been estimated in the UK, crematoria give rise to approximately 1.32 tonnes of Hg/year being emitted to atmosphere and 0.03 tonnes of Hg/year being disposed on land as ash.

Germany [OSPAR, 2000]: Germany reports that releases from the crematoria sector are in the range of 0.048 – 0.168 tonnes per year.

Netherlands [Slooff et al., 1994]:

4K0976.01/O0011/JVS/TL 9 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only - Crematories. Mercury from amalgam fillings. Estimated (inaccurate) emission to air counts 0.05 tonnes. [van de Meer 1990 in Slooff et al., 1994] - Cemeteries. Release to soil: 0.1 tonnes in 1991. [Slooff et al., 1994]

Sweden [IPCS, 1991]: - Crematories. Emission to air: 0.3 t/y (1984)

Refineries (NOSE 105.08)

Available national release data:

Netherlands [OSPAR, 2000]: Mercury releases from oil refineries in the Netherlands calculated to be 0.2 t/y to air and 0.04 t/y to water.

Sweden Mercury discharges to water in Sweden for Refineries: 2 kg in 1995 [Swedish EPA, 2001]

Pulp and Paper (NOSE 104.07/ 105.07)

Available national release data:

Sweden (soil). Between 1941-1968 around 650 ton of phenylmercuryacetate (PMA), corresponding to 360 ton mercury, was used in the pulp and paper industry as slimicide and for impregnation of the pulp. In the paper mill effluents a lot of contaminated fibers were released resulting in fibre rich sediments, contaminated with mercury, outside the mills. In the early 1970s many of these sites were investigated and around 4 ton of mercury were found in 26 sites which is half of the sites where PMA has been used. From the contaminated sites there is a continuous release of mercury. From one site the release was measured to be 1 kg per year. [Swedish EPA, 2001] Mercury discharges to Water in Sweden for the Pulp and paper industry: 7 kg in 1995 [Swedish EPA, 2001]

b. Municipal Collective Sources to the aquatic environment:

Discharges to municipal sewer (S8.1; S8.2; S8.3; S8.4)

European Union Calculated total discharge to water (kg) from households after treatment: [Herrera & Knudsen, 2000] Country 1985 1990 1991 1992 1993 1994 1995 EU15 19463 12772 11831 10879 10041 9243 8501 B 568 382 354 327 303 281 259 DK 265 167 153 138 125 113 104 D 4270 2522 2347 2150 1974 1805 1647 EL 583 397 369 344 311 284 258 E 2202 1465 1339 1245 1147 1056 971 F 3014 2069 1920 1756 1629 1510 1399 IRL 206 135 124 115 106 97 89 I 3184 2093 1933 1784 1652 1530 1415 L 19 13 12 12 11 10 9 NL 744 505 468 433 396 361 319 A 406 271 243 228 211 195 180 P 581 385 353 325 300 277 256 FIN 217 145 134 124 115 107 99 S 366 249 231 213 198 183 170 UK 2838 1972 1850 1686 1563 1434 1325

Emissions from the use of Mercury in Products (tonne Hg/year): [OSPAR, 2000] Use Sewer Dental amalgam 6.9 Batteries <0.01 Biocides and pesticides <0.01 Industrial and control instruments nd Laboratory and medical instruments nd Lighting - Total 6.91 nd : no data available in project databank

The Netherlands - In the Netherlands emission by the use of lamps is 0.01 tons/year to water, [Slooff et al. 1991] - Wastewater. Total estimated emission in the Netherlands in 1990 to water: 0.1 tonnes which results in a

4K0976.01/O0011/JVS/TL 10 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only

emission of the surface water of 0.02 tonnes. [Slooff et al. 1994] - Thermometers. In the Netherlands, emission to sewer < 0.25 tonnes (equals emission surface water < 0.06 tonnes) [Slooff et al., 1994]

Emissions to surface water (t/y) from household sources in the Netherlands: 0.3 from household sources, 2.3 from dentistry and 0,01 from utility building. [SPEED 1993 in Thornthon, 2001]

Sweden Total mercury discharges to water by municipal waste water treatment plants: 304 kg in 1998. [Swedish EPA, 2001]

Germany Mercury load in wastewater from 13 monitored municipal WWTP in Germany (1998): ~0 kg/y (total annual dirty water quantity: 2.72107 m3/y). Mercury load in wastewater from 13 monitored industrial plants (1998): 0.010 kg/y From these data the total emission due to point sources in German Baltic Sea catchment area was calculated to be 0.012 kg/y. [Gluschke, 1999]

c. Diffuse sources to water

Runoff from soil Residence time in soil is 100-1000 years. About 15% of the deposited mercury reaches the surface water during the course of a year. [Hellner 1991 in WS Atkins, 1998] Applying the 15% over the above estimated 178 – 1424 t/y gives 27 – 214 t/y is entering to water by the atmospheric cycle.

Diffuse sources (A1; S3.1; S4.2)

Agriculture (NOSE 110) Mercury emissions due to production and use of phosphate fertilisers are depicted in table appendix 2. [Maxson & Vonkeman, 1991]

Available national release data:

Scandinavia. Amounts of mercury spread by sewage sludge in environment for agricultural purposes are estimated to be about 0.2 t/y in Sweden and Finland and about 0.4-0.5 t/y in Denmark and Norway. [Bjornstad & Havenstrom, 1992]

The Netherlands. Mercury on agricultural grounds in the Netherlands (tons/year). [Slooff et al., 1994] Manure: 0.5 Artificial fertiliser: 0.5 Sludge: 0.2 Deposition: 1.9

Members of the OSPAR maritime area Appendix 6 gives the load of mercury entering the OSPAR maritime area and the greater north sea [OSPAR/EC, 2001]

4. Overall releases and summary

Total Anthropogenic emission of Hg in Europe since 1980 (in tpa) [EC, 2001b] Source Category 1980 1985 1990 1995 Combustion of fuels 350 296 195 186 Industrial combustion 460 388 390 93 Other sources 50 42 42 59 Total 860 726 627 338

In appendix 9 a detailed overview is given of European emission figures of all industrial sectors. The following ratio can be used for all industrial sectors: [UBA-TNO, 1990 in Entec, 2001]: Sector tpa % of tot Iron and steel 7 3 Ferrous metal processing 0 0 Non-Ferrous 3 1 Petroleum refineries - Chlor-alkali production 28 12 Cement and lime production38 15 Glass production 0 0 Waste treatment and disposal 39 16

4K0976.01/O0011/JVS/TL 11 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only Transport 0 0 Public power, cogen and d. heating 43 18 Comm, instit and res combustion 13 5 Industrial combustion 33 13 Other sectors 39 16 TOTAL 245 100%

Relative anthropogenic Hg Emissions in Europe in 1995 (to the air compartment) [EC, 2001b] T o t a l a n t h r o p o g e n i c G a s e o u s e l e m e n t a l G a s e o u s b i v a l e n t V a r i o u s s o u r c e s o f

H g e m i s s i o n H g e m i s s i o n H g e m i s s i o n H g e m i s s i o n

b y a n t r o . s o u r c e s b y a n t r o . s o u r c e s b y a n t r o . s o u r c e s

P o w e r p l a n t s /C o a l C o m b u s t i o n 2 6 % 2 1 % 3 3 % 3 4 %

R e s i d e n t i a l h e a t i n g 2 6 % 2 1 % 3 3 % 3 4 %

O i l c o m b u s t i o n 2 % 2 % 3 % 3 %

C e m e n t p r o d u c t i o n 8 % 1 1 % 4 % 6 %

L e a d 1 % 1 % 0 % 0 %

Z i n c 4 % 5 % 2 % 3 %

P i g & I r o n 3 % 5 % 2 % 2 %

C a u s t i c S o d a 1 2 % 1 4 % 1 1 % 0 %

W a s t e D i s p o s a l 3 % 1 % 5 % 8 %

O t h e r 1 5 % 1 9 % 7 % 1 0 %

European Union Calculated emissions (t/y) to air and water (1991, insecure data): [Maxson et al., 1991 in Slooff et al., 1994] Country Air Water Belgium/Luxembourg 11 3 Denmark 8.1 1 Germany 52 9.7 Greece 1.2 1 Spain 8.9 6 France 42 8.3 Ireland 0.6 1 Italy 24 8.4 Portugal 1.4 1 England 25 7.4

Calculated releases of mercury to the compartments: [OSPAR, 2000] Compartment Quantity (tonnes mercury per annum) Atmosphere 0,04 Landfill 2,4 Municipal waste 1,6 TOTAL 4,04

Mercury in dredged material (DM) [OSPAR, 2000] Contracting 1995 1996 party DM Hg DM Hg (tonnes) total load harbours estuary & (tonnes) total load harbours estuary & sea channels sea channels BE 31189436 6.1 1.6 4.5 29264498 6.5 1.4 5.1 DK 500256 0.03 0.03 0.0 562784 0.2 0.2 0.0 FR* 28792778 1.8 0.9 0.9 28792778 1.8 0.9 0.9 GE** 26462000 0.5 0.5 0.0 19123000 0.3 0.2 0.0 IC 131721 220698 IR 620207 0.0 0.0 0.0 1372734 0.2 0.1 0.1 NL 14199240 4.8 4.8 8016381 2.5 2.5 NO 288647 0.0 0.0 399716 0.0 0.0 SP 2890800 2.1 0.6 1.5 2055148 4.0 2.2 1.8 SW 1748600 0.0 0.0 3308608 0.1 0.1 UK 20254200 8.7 7.3 1.3 24105334 7.6 7.2 0.4 TOTAL 127077885 23.6 15.7 8.2 117221679 23.2 14.8 8.3 * 1994 data used as an indication of approximate figures for 1996 ** including 381000 tonnes of DM from the Netherlands

Mercury emissions (t/yr) from various sources in the EC (1989) are shown in appendix 5. Emissions to air,

4K0976.01/O0011/JVS/TL 12 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only water and soil are given. Past accumulation of mercury in the environment is one of the sources of pollution today. [Maxson & Vonkeman, 1991]

Available national release data:

The Netherlands In the Netherlands, annually (1990) 40 tonnes of mercury is dumped as waste. The emission to air was ca. 4 tonnes (mainly by waste incineration and chlor-alkali industry), to water 1 ton (mainly phosphorous fertiliser industry and dentistry’s), to soil ca. 1.2 ton (mainly by application of fertilisers on agricultural grounds). 75% (year base 1990) of the mercury load of the surface water is coming from abroad. [Slooff et al., 1994] Changes in mercury content of EU12 (minus former German Democratic republic) territory and the Netherlands in 1995 (tons) is depicted in appendix 4. [Scoullos et al., 2000]

Main industrial sources of mercury in the Netherlands: [OSPAR, 2000] Source Air (t/year) Water (t/year) Chlor-alkali Industry 0.8 0.05 Phosphorus fertilisers 0.37 Natural gas 0.06 Oil extraction 0.04 Processing metal ores 0.38 0.036 Oil refineries 0.2 0.04 Coal combustion 0.4 – 0.7 Other 0.09 TOTAL 1.8 – 2.1 0.63

A mercury flow diagram for the Netherlands in 1995 is given in appendix 8.

Spain According to de Ministry of Spain the following industrial sectors potentially discharges Mercury to the environment: Metallic minerals mining; Metallic minerals mining (non-ferrous); Pulp, paper and paperboard manufacturing; Gold and Silver Recovery, Non-ferrous metals manufacturing and processing. [Ministerio de Medio Ambiente, 2001]

Sweden Emissions of mercury to the atmosphere in Sweden in 1984 in kg/year: [IPCS 1991] 3300 incineration of household waste 900 smelting 400 chloralkali industry 300 crematories 200 combustion of coal and peat 200 other sources [Swedish Environmental Protection Board, 1986 in IPCS, 1991]

Mercury discharged to Land or Landfill in the UK [OSPAR, 2000] Sector Quantity (tonnes of Hg/year) Estimation Landfill Land Method Chlor-alkali production 22.8(a) - MB Paper and pulp industry 0.05 - EF Phosphate production 0.02 0.08 EF Primary lead and zinc smelting 10.2(b) - MB Coal-fired power stations 3.4(c) - EF Industrial coal combustion 0.3(d) - EF Domestic coal combustion 0.2 - EF Total 37.0 0.08 EF: Estimate produced using emission factors MB: Estimate produced using a mass balance method (a) Precise nature of disposal is dependent upon the mercury content and other characteristics of the particular waste stream (b) Mercury may be recovered from calomel or the material is disposed to landfill after appropriate pre-treatment (c) An additional 2.7 tonnes of Hg present in ash is not disposed to landfill as the ash may be used (d) Assumes that all ash is landfilled

United Kingdom Emissions of mercury to the atmosphere in the UK in 1984 in kg/year: 25500 fossil fuel combustion 10100 production and use of articles containing mercury 5900 municipal waste incineration 5000 non-ferrous metal production 2500 cement manufacture 1800 iron and steel production

4K0976.01/O0011/JVS/TL 13 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only

500 sewage sludge incineration [Dean & Suess, 1985 in IPCS, 1991]

Denmark, the Netherlands and Sweden Emission of cadmium in Denmark, the Netherlands and Sweden reported by VKI is shown in the table in appendix 7. [VKI, 1999 in Herrera & Knudsen, 2000]

V Environmental fate of releases to environment

1. Adsorption to solids (sediment, sludge, soil):

HgS is practically insoluble in water. HgS is stable under anaerobe circumstances, under aereobe conditions it is slowly oxidised to Hg2. Hg2+ can form complexes with other compounds and form soluble and insoluble complexes. In sediment, Hg can be transformed in organic mercury compounds such as methyl mercury (CH3HgOH) which is stable in water and can evaporate. Elementary mercury can evaporate and dissolve in water. [Slooff et al., 1994]

Runoff from soil Residence time in soil is 100-1000 years. About 15% of the deposited mercury reaches the surface water during the course of a year. [Hellner, 1991 in WS Atkins, 1998] Solids-water partition coefficients in soil are 15-8-316 l/kg. [Slooff et al., 1994 in WS Atkins, 1998]

2. Volatilisation:

Most important gas phase oxidation pathways are the reaction with ozone and OH radicals. Oxidation of Hg 0 (elemental vapour) leads to Hg(II) species that are notably less volatile and will tend to condense onto the atmospheric particulate matter or be deposited. Or Hg0 May be dissolved in atmospheric water and can the be oxidised by ozone or OH radicals. [EC, 2001b]

Deposition from atmosphere Mercury in atmosphere occurs as vapour and is not associated with particulate matter. It can be transported over large distances. Estimates of residence time in atmosphere and transport distance are up to 2 years and up to 2000 km. [Hellner, 1991 and Gustafsson, 1994 in WS Atkins, 1998] 75% deposited by wet deposition, remainder by dry deposition. Total deposition in EU ranges 50-400 g/m2a. From this deposition re-emission can occur that can be seen as historical pollution of Mercury from terrestrial and aquatic ecosystems. [EC, 2001a]

3. Degradation:

In landfill, mercury compounds are reduced to mercury which is stable for about 10 years. After this time it can leach out. Mercury can also be emitted to air which is probably a shorter term effect. Mercury entering landfill from sewage sludge or incineration clinker can be leached to groundwater. Estimates for concentrations in municipal waste are 1-1.5 mg/kg and in incineration ash higher. This produces concentration in landfill gas from 0.13-14 g/m3. A review by LDAI of published data on the composition of leachates from domestic waste in landfill sites, demonstrated that heavy metals are not generally present at significant concentrations in landfill leaches. [LDAI, 1995]

4. Partition to compartments:

Mercury in soil (Hg2+) is mainly bound to sediment. Acid can increase the solubility of mercury considerably and cause transport in soil. In soil mercury is mainly in the anorganic form.

In freshwater ca. 1-10% of mercury is present as methyl mercury. In acidic chloride containing water, HgCl 2 is the most 2- important form. In seawater HgCl4 is the dominant soluble mercury ion. Metallic mercury can evaporate to the air and is the dominant form of atmospheric mercury. It can be mobilised over long distances and stays in atmosphere for a long time. Oxidation products such as HgO or HgCl 2 can dissolve in rainwater and precipitate to soil or rainwater. [Slooff et al., 1994]

5. Behaviour:

Uptake by biota BCF for fish range from 5-800 depending on type of fish and compound of mercury.

VI Evaluation

1. Relevant NOSE-codes of point sources

NOSE-code Sources IPPC-code 104.07/105.07 Characteristic processes in the manufacture of pulp and paper and paper products, publishing and printing 104.12/105.12 Characteristic processes in the manufacture of basic metals, fabricated metal products and machinery 104/105 Production processes in manufacturing industry and water supply

4K0976.01/O0011/JVS/TL 14 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only 105.02 Characteristic processes in the mining and quarrying industry, except of energy-producing materials 105.08 Characteristic processes in the manufacture of coke, refined petroleum products and nuclear fuel 105.09.02 Chlorine production 105.09.26 Phosphate fertilisers 106.02.02 Off-shore activities (liquid fossil fuels) 106.03.03 Off-shore activities (gaseous fossil fuels) 109 Pollution control, treatment and waste disposal 109.05.01 Incineration of corpses 110.05 Manure management, incl. Mineral fertilisers 110.06 Use of pesticides and limestone 110.07 Other equipment (wood, oil and coal combustion) 113.1Household consumption and similar processes (batteries and other lead containing products) 111.03 Medical and veterinary care (chemicals and instruments) 111.03.02 Dentists (amalgam) 112.02.04 Batteries 112.03 Laboratories (chemicals and instruments) 112.09.14 Leakage/spillage of mercury thermometers 112.09.15 Leakage/spillage of mercury vapour lamps 101 Combustion processes (production of heat and electricity) 104.07/105.07 Manufacture of pulp, paper and paper products, publishing and printing 104.8Characteristic processes in the manufacture of coke, refined Petroleum products and nuclear fuel, involving fuel combustion 104.09/105.09 Manufacture of chemicals, chemical products and man-made fibres (production of paint and enamel) 104.12.03 Reheating furnaces of steel and iron 104.12.05 Primary lead production 104.12.06 Primary zinc production 104.12.07 Primary copper production 104.12.10 Secondary copper production 104.12.11 Aluminium production 104.12.12 Aluminium production (SF6 use) 104.12.15 Nickel production 105.09.24 Ammonium phosphates 105.09.26 Phosphate fertilisers 105.09.43 Calcium carbide production 104.11/105.11 Characteristic processes in the manufacture of other non-metallic mineral products (cement, glass etc.) 105.12.41 Ferro alloys (except SF6 use) 105.12.42 Ferro alloys (only SF6 use) 106 Extraction and distribution of fossil fuels and geothermal energy (offshore activities – produced water, product activities and raw materials containing lead) 109.02 Wastewater treatment (incl. Storm water runoff and sewage sludge) 109.03 Waste incineration pyrolysis 109.05 Cremation 109.06 Solid waste disposal on land n.a.* Contaminated sediments/ dredged spoil * n.a. = not applicable [OSPAR/EC, 2001]

2. Evaluation of emission data:

a. Emission to water

Discharges to the aquatic environment by industrial point sources (t/y) Route NOSE-code EU15 National Factor Year Source Mercury mining 0.003 1997 JRC, 2000a Other mining 0.3 g/t 1997 JRC, 2000a Off-shore gas 0.005 (NL) 1991 Slooff et al., 1991 Off-shore oil 0.089 96-99 OSPAR, 2000 Iron and steel 0.036 (NL) Slooff et al., 1994 0.020 (S) 1995 Swedish EPA, 2001 Chlor-alkali industry 4.32 EC, 1993 & Eurochlor, 2000 Phosphorous fertiliser 0.2341-2.341 1996 Slooff et al., 1994 & IFA, 1994 in Oosterhuis et al., 2000 Product manufacturing 0.0032 WS Atkins, 1998 Dental Amalgams* 2.3 (NL) CUWVO, 1990 in Slooff et al., 1994 <15.2 (UK) OSPAR, 2000

4K0976.01/O0011/JVS/TL 15 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only

Crematories & cemetries (soil) 0.03 (UK) OSPAR, 2000 0.1 (NL) 1991 Slooff et al., 1994 Refineries 0.04 (NL) OSPAR, 2000 0.002 (S) 1995 Swedish EPA, 2001 Pulp & paper 0.007 (S) 1995 Swedish EPA, 2001

* this source may be counted in the municipal sewage route as well

Discharges to municipal sewer S8.4: 8.501 t/y (1995) [Herrera & Knudsen, 2000] Amount of mercury discharge before treatment is not known Remark 1: The routes S8.1 (direct discharge not connected to municipal sewer); S8.2 (sewered, but no treated by STP) & S8.3 (sewered but occasional emission via bypass of STP via stormwater overflow) are not included (data gap) Remark 2: Declining trend from 1985 – 1995, no actual data >2000

Agriculture Sewer to agriculural soil: 8.3 t/y (EU15) [WS Atkins, 1998]

Historic pollution (S11.1) Harbour sludge: 14.8 t/y (1996) [OSPAR, 2000] Estuary’s and sea channels: 8.3 t/y (1996) [OSPAR, 2000]

b. Emission to air

A5 / A6: 338 t/y (1995) [EC, 2001b] A4: 4.5 t/y [WS Atkins, 1998] S3.2 / S4.2: 15% of deposited mercury reaches surface water during the course of 1 year [WS Atkins, 1998] Runoff from soil: 0.15 x 178 – 1424 t/y = 27 – 214 t/y

Waste:

* Incineration to air (50%) = 11.9 t/y 20% / 23,9 t/y from landfill (50%) = 11.9 t/y [WS Atkins, 1998]

* Landfill air = 3.8 t/y 80% / 99,6 t/y [WS Atkins, 1998] soil = 95.8 t/y (of which unknown amount of leachate)

* Recycling (gap of knowledge)

c. Deposition

Deposition estimated at: rate: 50-400 g/m2y [EC, 2001b] surface area EU15: 3.56 x 106 deposition 178 – 1424 t/y

3. Gaps and questions:

- The following discharges of industrial point sources are unknown for the EU15: other mining, off-shore gas, iron and steel, dental amalgams, crematories and cemetries, refineries and pulp and paper. In stead of European discharge figures, national figures or discharge rates are known. - The amount of leachate of landfill to water is unknown. - The recycling rate of mercury in the solid waste stream is not known. - The routes S8.1 (direct discharge not connected to municipal sewer); S8.2 (sewered, but no treated by STP) & S8.3 (sewered but occasional emission via bypass of STP via stormwater overflow) are not included in the discharges to the municipal sewer. - There is no actual data of discharges to the municipal sewer.

VII Measures

1. Measures at production level:

a. Contribution to water at production level

Total emission to water at production level without mining (inknown) is less then 1 t/y. Total amount including emission to air and land is estimated on 51 t/y [MAXSON & VONKEMAN, 1991].

b. Relevant IPPC sector, documents and available emission criteria

4K0976.01/O0011/JVS/TL 16 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only

Relevant IPPC sectors are: - 1. Energy industries (1.2 mineral oil and gas refineries and 1.3 coke ovens) - 2. Production and processing of metals (2.2 installations for the production or pig iron or steel, 2.3 installation for the processing of ferrous metals, 2.4 ferrous metal foundries, 2.5 installations for the production and smelting of non-ferrous metals); - 3. Mineral industry; - 4. Chemical industry (4.2 chemical installations for the production of inorganic chemicals, 4.3 chemical installations for the production of fertilisers; - 5. Waste management (5.2 installations for the incineration of municipal waste, 5.4 landfills); - 6.1 Industrial plants for the production of pulp and paper.

c. Voluntary agreements

The European chlor-alkali industry is committed to continue mercury emissions reduction [Eurochlor, 2000]

d. Substitution

Substitution is mentioned for dental amalgam, batteries, biocides and pesticides, industrial and control instruments, laboratory and medical instruments and lighting containing mercury [OSPAR, 2000] and [ERM, 1998].

e. Process control, modifications

BAT in the (ferrous and) non-ferrous metal industry: - Materials handling and storage: long list of BAT is mentioned in the BREF document and in addition because of the vapour pressure of mercury, storage of the product in sealed and isolated flasks is considered to be BAT. - Process selection: Herreschoff furnace is considered to be BAT for primary mercury production from cinnabar. For other production it is not possible to conclude that a single production process is BAT. - Gas collection and abatement: list of BAT is given in the BREF document; - Process residues: Roasted rock free from mercury is used for construction purpose and other raw materials are used in precious metal recovery processes. Pelletisation and return sludge from waste water to the furnace for primary production. For secondary purposes this is not always possible and small quantities are disposed.

f. Effluent treatment

BAT in (ferrous and) non-ferrous metal industry: - Neutralise waste water with caustic soda and treat with sodium sulphide. The effluent will pas through a carbon filter before discharge.

BAT in common waste water treatment in chemical sector: - Precipitation with sodium sulphide or polyorganosulphides. - Ion exchange - Chemical oxidation

2. Measures at use level:

a. Contribution to water at use level

Total emission to water at use level is estimated to be 35 t/y on a total amount of 710 t/y [MAXSON & VONKEMAN, 1991].

Total emission to water due to industry is about 9 t/y [UBA-TNO, 1990 in Entec, 2001]

b. Use by IPPC sectors

A possibility to decrease Hg emission would be Fuel switching: [EC, 2001b] - Modernisation of existing utility and industrial heat producing plants; - Development of new methane burning boilers; - Modernisation of coal mines with respect to better exploitation of coal bed methane. An overview of the cost effectiveness of mercury control measures in utility boilers and waste incinerators is given in appendix 10.

BAT in mineral oil and gas industry: - Removal from gas in a cold trap and recovered as Hg containing sludge which is treated in vacuum distillation unit.

BAT in chlor-alkali industry: Mercury cell plants - monitoring of leakage’s and recovery of Hg (for example monitoring of Hg in cell room), good housekeeping (like cell room concrete coated with material resist to Hg absorption), human factors (cleaning of clothes), end of pipe measures (removal from hydrogen gas, caustic soda etc), process integrated measures.

BAT in cement and lime industry: - Lower the exhaust temperature or absorption on activated carbon in kiln.

4K0976.01/O0011/JVS/TL 17 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only

c. Use by SME groups

See substitution VII 1d.

d. Use by consumers

Possible measure to decrease Hg emission would be Fuel switching: [EC, 2001b] - Increase the use of natural gas or oil - Increase the use of alternative fuels or imported electricity to meet base load electric generation requirements.

e. Use in agriculture

Monitoring of mercury content of sewage sludge and prevent use of sewage sludge containing mercury.

3. Measures at community level:

a. Sewage treatment

Large variations of removal of mercury in waste water treatment plants is to be expected: 0% for no treatment, 10 to 30% for primary treatment, 20 to 60% for biological treatment and 50 to 90% for advanced treatment [VKI in Herrera & Knudsen 2000]

b. Waste disposal

BAT for waste going into landfills is covered by relevant EC legislation dealing with waste [OSPAR, 2000]

c. Incineration

Relevant EC Directives cover BAT for municipal waste incinerators and hazardous waste incinerators. [OSPAR, 2000]

Incineration of sewage sludge: wet flue gas treatment and active carbon treatment.

d. Recycling

In general, mercury used in product can very easily be recovered for recycling or safe disposal. However, it seems that national and EU regulations governing the movement of hazardous waste prevent manufacturers from recovering the mercury used in their products [ERM, 1998].

4. Measures at regulatory level:

a. EU level: IPPC emission control

The European Union has enforced a number of regulations concerning discharges, emissions and losses of mercury. The draft UK DIFF document (DIFF 99/3/6) gives an overview on relevant directives. [OSPAR/EC, 2001]

b. EU level: Substitution or outphasing

Black List, mercury, Listed: EC (1982) List I within the framework of Directive 76/464/EEC on pollution caused by certain dangerous substances discharged into the aquatic environment of the Community. Official Journal C 176, 14.7.1982 p. 7 – 10.

Lead, cadmium and mercury containing batteries are classified as hazardous waste according to the list of hazardous waste established in 1994. According to 2000/532/EC and 2001/118/EC also unsorted batteries including lead, Cd and Hg will be classified as hazardous waste as from January 2002. Large amounts of batteries and accumulators are landfilled or incinerated with household waste. [EC, 2001b]

EC Directive 89/667 (eighth Amendment of EC Directive 79/769) which bans the use of mercury compounds in anti- fouling, wood preservative and biocidal preparations. [WS Atkins, 1998]

Environmental quality standards and emission limits have been set under amendments to Directive 76/464/EEC. Its use as a PPP was prohibited by Directive 79/117/EEC and its marketing and use has been restricted for certain applications. Mercury is included under Annex 2 to the OSPAR Strategy with regard to hazardous substances (OSPAR 2000). [RPA, 2000]

c. EU level: Limitations of use in certain applications

(See VII 4a and 4b).

4K0976.01/O0011/JVS/TL 18 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only d. Other regulatory and/or national policy measures

Other measures in general: - Input tax on the use of mercury in products; - Labelling of products.

North Sea Action Plan (NAP), Mercury, Class 1A: North Sea Ministers Conference (1990) North Sea Action Plan. National Implementation Order Third North Sea Ministers Conference. Lower Chamber, Conference year 1990-1991, 21 884 no.1-2.

UNECE POP & heavy metals, Mercury, Listed: OSPAR (1998) OSPAR 1998 List of Candidate Substances. OSPAR Strategy with regard to Hazardous Substances (Ref. nr. 1998-16), Annex 3. Sintra 22-23 July 1998.

OSPAR has adopted the following measures aimed at restricting discharges/emissions of mercury from products [OSPAR/EC, 2001]: - PARCOM Recommendation 89/3 on Programmes and Measures for Reducing Mercury Discharges from Various Sources - PARCOM Decision 90/2 on Programmes and Measures for Mercury and Cadmium-Containing Batteries - PARCOM Recommendation 93/2 on Further Restrictions on the Discharge of Mercury from Various Sources - Several OSPAR Recommendations and Decisions on the Chlor-Alkali Industry - Several OSPAR Measures on Dental Amalgam

HELCOM has proposed maximum limits for the mercury content in lamps.

OSPAR-RID - The Riverine Inputs and Direct Discharges (RID) monitoring programme within OSPAR enables a quantification of all riverborne and direct inputs of selected pollutants to the Maritime Area on an annual basis, including mercury.

UN ECE LRTAP MERCURY falls under the UN-ECE-LRTAP Protocol for Heavy Metals, the aim of which is the reduction of heavy metal emissions due to human activity and with the potential of causing harmful effects at long distance from the source via transport through the atmosphere.

North Sea Conference Framework – A political commitment was made at the 2nd and 3rd North Sea Conference to take urgent and drastic measures in order to reduce the input of hazardous substances into the North Sea between 1985 and 1995 by 50%. There was an additional commitment to reduce by 70% the total input (all pathways) of a number of substances, including mercury.

EPER – Europian Pollution Emission Registry, decision of 17th July 2000. Reporting of emissions from all individual facilities with one or more activities as mentioned in Annex I of EU Directive 96/61/EC. The emission data shall be reported for each facility according to a specific format, noting a description of all activities as mentioned in Annex I of Directive 96/61/EC with corresponding source categories and NOSE codes.

Switzerland: Sensitising chemicals, Quecksilber, Listed SUVA (2001) Swiss Occupational Exposure Limits 2001 (Grenzwerte am Arbeitsplatz 2001). SuvaPro, 1903.d.

France: Tableaux de maladies Professionelles (TMP), mercure, 55: Les Fiches Toxicologiques (FT), mercure, 2: INRS (1999) French Occupational Exposure Limits (Valeurs limites d'exposition professionelle aux agents chimiques). ND 2098-174-99, Cahiers de notes documentaires – Hygiène et sécurité du travail – No. 174.

The Netherlands: Reprotic Chemicals, mercury, Development Cataegory:2 SZW (2001) Nederlandse lijst van voor de voortplanting vergiftige stoffen. Niet-limitatieve lijst van voor de voortplanting giftige stoffen waarop de aanvullende registratieplicht van toepassing is als bedoeld in artikel 4.2, vijfde lid van het Arbeidsomstandighedenbesluit. Februari 2001.

Black list, mercury, Applies to Soil, Water, Air: Min. VROM (1986) Dutch black-listed substances. Indicative Environmental Multi-Year Programme 1986 – 1990.

Priority Chemicals, mercury, Listed: Min. VROM (1986) List of Dutch priority substances. Indicative Environmental Multi-Year Programme 1986 – 1990.

Hazardous Waste (BAGA), mercury, A: Min. VROM (2000) Decree concerning hazardous waste substances (Besluit van 12 december 2000, houdende aanwijzing van gevaarlijke afvalstoffen). Publication series of the Dutch Ministry of Housing, Spatial Planning and the Environment (VROM). Netherlands Bulletin of Acts and Decrees 2000, 592.

4K0976.01/O0011/JVS/TL 19 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only Norway: Sensitising Chemicals, Mercury Listed Arbeidstilsynet (1996) Norwegian Occupational Exposure Limits (Administrative normer for forurensning i arbeidsatmosfære). Arbeidstilsynet. Veiledning til arbeidsmiljøloven nr. 361.

Priority List: Mercury Listed. Discharges to be reduced substantially before 2010. Environmental Policy for a Sustainable Development. Report Nr. 58 (1996-97) to the Storting.

Observation List: Mercury Listed. Norwegian Pollution Control Authority (2000): The observation List. TA 1711/2000

Regulation on handling of photochemicals in photo, x-ray and graphical industry (T-0913 (1992))

Regulation relating to waste water contaminated with amalgram and waste from dental clinics and dental surgeries (T- 1014 (1994)) [SFT, 2001]

Austria: Existing regulation: BGBI.Nr. 169/1996 ST0052 [Anonymous, 2001]

4K0976.01/O0011/JVS/TL 20 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only LITERATURE

Anonymous, 2001. Austrian Legislation on Priority Chemicals of the Water Framework Directive. Balzer, D., Rauhut, A., 1996. Eintrag von Blei, Cadmium und Quecksilber in die Umwelt – Bilanzen über Verbrauch und Verbleib. Band 2. Landesgewerbeanstalt Bayern, Bereich Technische Information. Forschungsbericht 106 01 047, im Auftrag des Umweltbundesamtes, Berlin. Bjornstad, S. and G. Havenstrom, 1992. Assessment of possibilities for reducing the use of mercury. Scandpower A/S, Nordic Council of Ministers, Norway. Braun, M., et al., 1999. Rhein Bestandsaufnahme der Einträge Prioritäter Stoffe 1996. IKSR/CIPR. EC (European Commission), 1993. Identification and brief description of the emissions from different sectors of the manufacture of basic inorganic chemicals and non-metallic mineral products. EC (European Commission) 2001a. Draft Directive on batteries and accumulators. Draft of 30 March 2001. Brussels. EC (European Commission), 2001b. Ambient air pollution by Mercury (Hg), Position Paper. Entec (Entec UK Limited), 2001. Economic Evaluation of air targets for heavy metals. ERM (Environmental Resources Management), 1998. Analysis of the advantages and drawbacks of restricting the marketing and use of mercury in certain products. European Commission – Directorate General for Industry (DG III). Reference 5260. Eurochlor, 2000. Information sheet on Mercury. Gluschke, M., 1999. Emission inventory of the German Baltic Sea catchment area. Umweltbundesamt (UBA). Germany. Herrera, R.J. and L. Knudsen, 2000. Water discharges from municipalities and industries. European Commission, ESTAT. Joint Eurostat/EFTA Group, Doc. no. IES/00/6.3B. IPCS (International Programme on Chemical Safety), 1991. Inorganic mercury. Environmental Health Criteria 118. WHO. Geneva. JRC (Joint Research Centre), 2000a. Integrated pollution prevention and control, Reference document on best available techniques in the non-ferrous metals industries. EIPPCB. Seville, Spain. JRC (Joint Research Centre), 2000b. Integrated pollution prevention and control, Reference Document on best available techniques in the chlor-alkali manufacturing industry. EIPPCB. Seville, Spain. LDAI, 1995. Composition of leachates from domestic waste in landfill sites. Maxson, P.A. and G.H. Vonkeman, 1991. Mercury. Rational paths through uncharted territory. Realistic Regulatory Strategies for Risk Reduction within the European Community. Global Environment Research Centre. Ministerio de Medio Ambiente, 2001. Spanish comments on the 2nd meeting of Experts Advisory Forum (EAF). Oosterhuis, F.H., F.M. Brouwer, H.J. Wijnants, 2000. A possible range on cadmium in phosphate fertilisers: Economic and environmental implications. Institute for environmental Studies (IVM), Vrije Universiteit Amsterdam. The Netherlands. OSPAR, 2000. OSPAR Background document on mercury and organic mercury compounds. OSPAR Commission. ISBN 0 946956 54 5. OSPAR/EC, 2001. HARP-HAZ Prototype. HARP-HAZ Contact Group. RPA (Risk and Policy Analysts), 2000. Socio-Economic Impacts of the Identification of Priority Hazardous Substances under the Water Framework Directive.

4K0976.01/O0011/JVS/TL 21 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only Scoullos, M., G. Vonkeman, I. Thornton, 2000. Towards an integrated EU policy for heavy metals (EUPHEMET). Contract no. ENV4-CT97-0614. Chapter 4, p. 87-287. SFT, 2001. WFD, Sources and measures for priority substances. Slooff, W., P. Bont, M. van Ewijk, 1991. Exploratory report Mercury. RIVM Report no. 710401006. Bilthoven, The Netherlands. Slooff, W., P. van Beelen, J.A. Annema, J.A. Janus, 1994. Basisdocument kwik. RIVM Report no. 710401023. Bilthoven, The Netherlands. Swedish EPA (Environmental Protection Agency), 2001. Information on emission sources for priority substances. Naturvårdsverket, Sweden. Thornthon, I., 2001. Pollutants in urban waste water and sewage sludge. I C Consultants Ltd (ICON), London, United Kingdom. WS Atkins International Ltd, 1998. Assessment of the Risks to Health and to the Environment of Mercury Contained in Certain Products. Final Report, AFS5704/2091 E-052. Under the authority of Directorate-General III.

4K0976.01/O0011/JVS/TL 22 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only APPENDIX 1, YEARLY NET CONSUMTION OF MERCURY DUE TO PRODUCTS INTENTIONALLY CONTAINING MERCURY IN THE NORDIC COUNTRIES [Miljøgifter i produkter,

1999 in SFT, 2001]

Yearly net consumption of mercury (tons/year) Products Norway Sweden Denmark Finland (1999) (1991) (1990) (1991) Dental amalgams 0.507 1.7 2 1 Batteries 0.130 0 1.2 1.5-2 Alkalinemanganese 2 Button cell Thermometers Fever 0.005 1.4 (1986) 0.5 1.2-1.8 (1987) Industrial 1.0 Measuring instruments 0.040 0.2-0.9 Electrical equipment and instruments 0 2-2.5 (1988) 0.1-0.3 - Discharge lamps, including fluorescent 0.114 0.3 (1988) 0.3 0.1 tubes Laboratorial chemicals and 0.040 0.1 (1988) 0.5 2 (1987) pharmaceuticals Pesticides Paints 0 - 0 - Seed dressing 0 -1) 0 42) Others 0.001 - - - Total ~0.837 8 6 11 1) Banned from 1/7/1988 2) Banned from 30/9/1992

4K0976.01/O0011/JVS/TL 23 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only APPENDIX 2, MERCURY EMISSIONS DUE TO PRODUCTION AND USE OF PHOSPHATE FERTILISER

[maxson & Vonkeman, 1991]

EU12 B/L DK D GR E F IRL I NL P UK

Phosphate rock imports 14818 1793 0 1387 566 2801 3699 50 1294 1906 312 832 (103 tons)

Hg contents (tons) 41 4.0 - 3.1 2.1 8.1 10.3 0.3 3.6 5.1 0.8 3.1

Hg in gypsum waste (tons) 4.0 0.4 - 0.3 0.2 0.8 1.0 - 0.3 0.6 - 0.3 - to air min. ------to land 2.6 0.3 - 0.2 min. 0.5 0.7 - 0.2 0.2 - 0.2 - to water 1.3 min. - min. min. 0.3 0.3 - min. min. - min.

Equivalent P2O5 use 4499 113 107 683 164 519 1402 150 759 91 79 432 (103 tons)

Hg application in fertiliser (tons) 0.3 0.1 1.7 0.4 1.3 3.4 0.4 1.9 0.2 0.2 1.0 - to land 11

4K0976.01/O0011/JVS/TL 24 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only APPENDIX 3, DISTRIBUTION OF MERCURY FROM PRODUCTS TO ENVIRONMENTAL COMPARTMENTS (T/Y)

[WS Atkins, 1998]

Product Losses to air Losses to Losses to Disposal to landfill watercourses agriculture * Switches and relays 1.6 negligible Negligible 15 vapour tubes and arc rectifiers 1.3 negligible Negligible 11 Medical thermometers 6.2 1.8 3.5 12 other thermometers 3.0 2.2 4.2 18 Other measuring equipment 0.95 0.32 0.61 2.1 Fluorescent tubes 2.7 negligible Negligible 12 HID lighting 1.1 negligible Negligible 5.0 Miscellaneous products <0.13 negligible Negligible 0.82 Total 17 4.3 8.3 75

* Losses to agriculture is based on an assumption that 47.5% of sewage sludge will be used in agriculture

4K0976.01/O0011/JVS/TL 25 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only 1. APPENDIX 4, CHANGES IN MERCURY CONTENT OF EU12 IN 1995 (TONS)

[Scoullos et al., 2000]

Economic compartment Environment Source Input Source Output Source Input Ores etc. 1100 Emissions 761 Emissions 761 Import products 1328 ‘safe’ disposal 170 Mobilisation1) 18 Recovery 35 Recovery -35 Exports 444 Trabsboundary -14

Total 2463 1375 730

Accumulation 1088 730 Net result from input (18) and output (0)

Accumulation of mercury within EU12 territory in 1995 (tons):

Economic compartment Environment Form Amount Form Amount Materials 218 Soil localised 440 Product 435 Soil diffused 258 Stored waste 435 Sediemnts 5 Other 27

Accumulation 1088 730

CHANGES IN MERCURY CONTENT OF DUTCH TERRITORY IN 1995 IN MTONS

Economic compartment Environment Source Input Source Output Source Input Ores, fossil fuel 31.8 Exported waste 2 Export emission -5 Natural gas 8.5 Exports (prod.) 9 IImport emission 6 Imports 16.5 Emiss. + waste 42 Emiss. + waste 42 Reprocessing 2 Reprocessing 8 Reprocessing -6

Total 59 61 37

Accumulation 3 36

4K0976.01/O0011/JVS/TL 26 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only APPENDIX 5, MERCURY EMISSIONS IN THE EC (T/Y) IN 1989 [maxson & Vonkeman, 1991]

Source Air Water Land Total Mercury mining 10 ? 20 30 Secondary production 5 <1 15 21 Non-ferrous metal production/refining - Zinc/cadmium 4 <1 16 20 - Lead 1 <1 2 3 - Copper 1 <1 1 2 Subtotal 6 1 19 26 Fossil fuels - Coal 48 <1 12 60 - Oil 24 - - 24 - Natural gas 4 - - 4 Subtotal 76 <1 12 88 Industrial production - Iron/steel 4 2 28 34 - Chlorine/caustic 23 5 150 178 - Industrial catalysts ? <1 ? <1 - Cement 2 - 26 28 - Phosphate fertiliser <1 1 3 4 - Mercuric oxide, other chem. ? ? ? ? - Other, (esp. sulphiric acid) Subtotal 29 8 207 244 product use - Batteries 33 <1 100 133 - Dental amalgams 8 14 24 46 - Electr. Lighting and equipment 10 <1 30 40 - Measuring/control instr. 6 <1 19 25 - Laboratory applications 1 1 6 8 - Phosphate fertiliser - - 11 11 - industrial catalysts 4 <1 12 16 Subtotal 63 17 202 282 Cremation/burial 4 - 6 10 Sludge waste disposal 3 2 28 33 Dredging <1 6 20 26 Total 197 35 529 761

4K0976.01/O0011/JVS/TL 27 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only APPENDIX 6, LOAD OF MERCURY ENTERING THE OSPAR MARITIME AREA AND THE GREATER NORTH SEA

[OSPAR/EC, 2001]

Inputs from geographical area tons 1990 tons1995 OSPAR contracting parties Total OSPAR Maritime Area 35-48 17-27 OSPAR contracting parties Greater North Sea 25-30 15-18 UK Greater North (channel + north sea) 1.8-4.5 0.72-2.6 UK Channel 0.06-0.2 0.02-0.08 UK North Sea 1.7-4.3 0.7-2.5

ATMOSPHERIC INPUTS OF MERCURY TO THE NORTH SEA FROM 1987-1995

Year 1987 1988 1989 1990 1991 1992 1993 1994 1995 mercury (t) 9 9 7 5 6 6 3 3 4

4K0976.01/O0011/JVS/TL 28 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only APPENDIX 7, EMISSION (T/A) OF MERCURY IN DENMARK, THE NETHERLANDS AND SWEDEN

[VKI in Herrera & Knudsen 2000]

Denmark (1993) MWWTP 0.8 Industries rainwater overflows Scattered houses 0.03 Total 0.83 Netherlands (1994) Refineries and energy sector 0.01 Industries 0.27 Waste treatment 0.21 Agriculture 0 Transport 0 Households 0.31 Others 0.12 Total 0.92 Sweden (1995) Mining 0.36 Pulp&Paper and Printing 0.02 Refineries 0.00 Chemical 0.01 Mfr. of fabricated metal products : Prim. metal works 0.02 Sec. metal works : MWWTP 0.53 Total 0.95

4K0976.01/O0011/JVS/TL 29 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only APPENDIX 8, MERCURY FLOW DIAGRAM FOR THE NETHERLANDS IN 1995

[Scoullos et al., 2000]

838.5

Imported bulk primary mercury reprocessing industry Exports and secondary Hg 2 838.5 raw Hg Sludge/waste/emissions 6 6 domestic gas sludge/waste 90 reprocessed 850 tons 2 domestic product waste 4 lamps 8.5 domestic gas 85 imported sludge/waste 5 calomel 85 imported 93 total 2 gas sludge 20 other 90 940 total 113.5 total 12 2 0 Imported (raw Hg for) products 2 etc. Accumulation in economy 3 products 3 raw Hg for TL lamps Occurance in the Dutch economy 2 electrodes 0 reprocessed Total mercury flow 3 total 1 fertiliser Reprocessed: through 0.5 agricultural products 2 amalgam 2 amalgam Dutch economy 20.5 2 total reprocessed 1 2 batteries/accumulators 143.8 Accumulation in the Dutch 6 measuring instruments Other direct applic.: environment Environmental 16.5 total 5 calomel 7 solid waste burden 3 fabr. TL lamps 36 2.5 large batteries 16.3 domestic burden ores, fuels etc. 6 measuring instruments 2 agricultural soils 4.5 imported emissions 25 zinc ores 2 imported amalgam 1 other soils 21.5 zinc waste etc. 3 coal 2 batteries/acc. 0.7 surf. water/sediment 42.3 total 18.5 natural gas 2.5 chemical compounds 0.7 waste watersystem 1.1 phosphate ores 20.5 total direct 0.6 groundwater 0.8 iron ores 1.8 roads/comstr. materials 16.3 4.5 6 1.9 petrochemicals Indirect applic.: 20 zinc waste 40.3 total 2 fertilisers and agricultural 36.3 total products 2 electrodes 2 coal electric generation 1.5 iron and steel 0.3 import coal, households From third countries Exported emissions 3 air Imported waste and 7.8 total indirect 3 surface water, North sea used prod. containing 6 total Hg

85 diverse 85 total

4K0976.01/O0011/JVS/TL 30 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only Appendix 9. Heavy Metal Atmospheric Emissions Inventory in 1990 for EU-15

[UBA-TNO, 1990 in Entec, 2001]

Sector Arsene Cadmium Mercury Nickel tpa % tpa % Tpa % tpa % Iron and steel 35 6% 37 18% 7 3% 142 3% Sinter plants 4 1% 5 2% 1 0% 27 1% Pelletisation plants 0% 0% 0% 0% Coke oven plants 2 0% 3 1% 2 1% 4 0% Blast furnaces 16 3% 1 1% 1 1% 19 0% Basic oxygen steelmaking 2 0% 2 1% 0 0% 5 0% Electric steelmaking and casting 11 2% 26 13% 3 1% 88 2% Ferrous metal processing 0 0% 0 0% 0 0% 0 0% Non-ferrous 16 3% 29 14% 3 1% 13 0% Aluminium 0 0% 0 0% 0 0% 13 0% Copper production 7 1% 2 1% 0 0% 0 0% Nickel production - - - - Metallurgical processes (in alloys) 0% 0% 0% 0% Cobalt 0% 0% 0% 0% Lead production (primary) 9 2% 8 4% 3 1% 0% Zinc production (primary) - 19 9% 1 0% - Cadmium & mercury 0% 0% 0% 0% Petroleum refineries - - - 1 0% Chlor-alkali production - - 28 12% - Cement and lime production4 1 2% 1 38% 15 20% 0 Glass production 7 1% 1 0% 0 0% 10 0% Waste treatment and disposal 3 0% 16 8% 39 16% 27 1% Waste incineration 3 0% 16 8% 36 15% 27 1% Cremation - 0 0% 2 1% - Hg thermometers and vapour lamps - - 1 1% - Transport 2 0% 44 22% 0 0% 1759 36% Road transport combustion - 34 17% 0 0% 270 6% Road transport non-combustion - 3 1% - 9 0% Other transport combustion 2 0% 8 4% 0 0% 1480 30% Public power, cogen and d. heating 38 7% 10 5% 13 5% 129 3% Public power etc. brown coal 20 4% 3 2% 9 4% 24 0% Public power etc. hard coal 130 23% 4 2% 21 9% 94 2% Public power etc. fuel oils 117 20% 10 5% 1 1% 1560 32% Public power etc. other fuels 10 2% 1 1% 12 5% 3 0% Comm, instit and res combustion 177 31% 29 14% 33 13% 970 20% Commercial etc. brown coal 2 0% 0 0% 4 2% 16 0% Commercial etc. hard coal 23 4% 1 1% 3 1% 38 1% Commercial etc. fuel oils 9 2% 2 1% 0 0% 73 2% Commercial etc. other fuels 3 0% 6 3% 6 2% 2 0% Industrial combustion 177 31% 29 14% 33 13% 970 20% Industrial combustion brown coal 66 11% 9 4% 14 6% 81 2% Industrial combustion hard coal 52 9% 2 1% 9 4% 70 1% Industrial combustion fuel oils 51 9% 12 6% 2 1% 805 17% Industrial combustion other fuels 9 2% 6 3% 9 4% 15 0% Other sectors 17 3% 17 8% 39 16% 108 2% Total 575 100% 203 100% 245 100% 4860 100%

4K0976.01/O0011/JVS/TL 31 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only Appendix 10: Cost effectiveness of Mercury control measures in utility boilers and water incinerators [EC, 2001a] Control option Mercury Co sts Removal Investment Operating and Efficiency Maintenance (%) 1. Powerplant in 1000US$/MWh in 1000US$/MWh - ESP (only) 10 1.6 0.2 - FFs (only) 29 28.9 5.8 - ESP or FF + wet FGD 85 59 2.5 - Dry absorber SDA + ESP 67 143 5 - ESP + carbon filter beds 90-95 264 62 -Activated carbon injection + FF 50-90+ 34.6 8.1 2. Municipal Waste Combustor in 1000US$/tonne in 1000US$/tonne - ESP and FFs - as above - ESP or FF+carbon filter beds 99 31.7/80.0 6.5/15.6 - Activated carbon injection +ESP or FF 50-90+ 0.3/0.8 0.25/1.3 - Polishing wet scrubber + ESP or FF 85 10.3/22.9 1.9/4.9 3. Medical Waste incinerators in 1000US$/tonne in 1000US$/tonne - ESP and FFs - as above - Activated carbon injection +FF 50-90+ 56.5/127 89.0/84.0 - Polishing wet scrubber +FF 85 400 100

4K0976.01/O0011/JVS/TL 32 Fact sheets on production, use and release of priority substances in the WFD Royal Haskoning Mercury, Final draft For official use only Appendix 11. Scheme of release routes for Mercury

AIR

A5 A6 A7 A4

Production Formulation Consumer Buildings Historic Agriculture Deposition Traffic Materials Industrial use use pollution 101/ 104/ 105/ 106/ 112 113.01 110.05/-06/-07

S9.2 S9.3 S11.1

S8.1 Waste S8.2 SOIL 109 S8.3 S1 Erosion & S9.2.2 Runoff WWT STP S3.2 S4.2 GROUNDWATER Leaching S9.2.1 Drain S3.3 S8.4 S4.3 WWT Drainage S2 S10.1 S10.2

SURFACE WATER

4K0976.01/O0011/JVS/TL 33