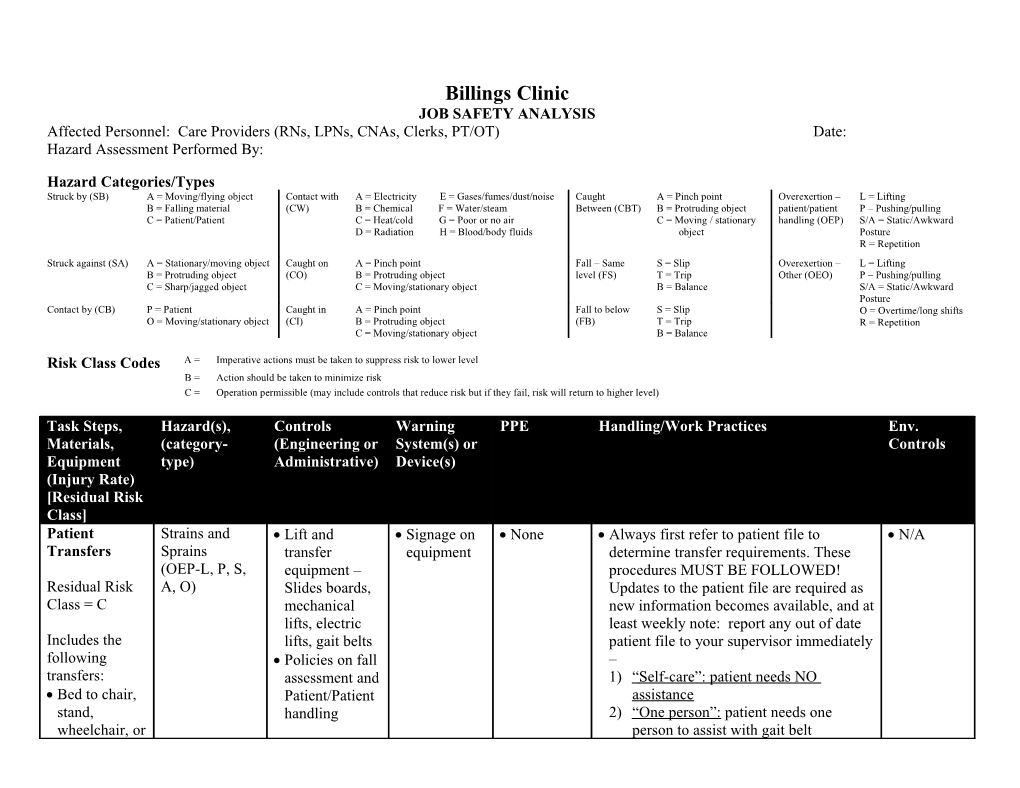

Billings Clinic JOB SAFETY ANALYSIS Affected Personnel: Care Providers (RNs, LPNs, CNAs, Clerks, PT/OT) Date: Hazard Assessment Performed By:

Hazard Categories/Types Struck by (SB) A = Moving/flying object Contact with A = Electricity E = Gases/fumes/dust/noise Caught A = Pinch point Overexertion – L = Lifting B = Falling material (CW) B = Chemical F = Water/steam Between (CBT) B = Protruding object patient/patient P – Pushing/pulling C = Patient/Patient C = Heat/cold G = Poor or no air C = Moving / stationary handling (OEP) S/A = Static/Awkward D = Radiation H = Blood/body fluids object Posture R = Repetition Struck against (SA) A = Stationary/moving object Caught on A = Pinch point Fall – Same S = Slip Overexertion – L = Lifting B = Protruding object (CO) B = Protruding object level (FS) T = Trip Other (OEO) P – Pushing/pulling C = Sharp/jagged object C = Moving/stationary object B = Balance S/A = Static/Awkward Posture Contact by (CB) P = Patient Caught in A = Pinch point Fall to below S = Slip O = Overtime/long shifts O = Moving/stationary object (CI) B = Protruding object (FB) T = Trip R = Repetition C = Moving/stationary object B = Balance

Risk Class Codes A = Imperative actions must be taken to suppress risk to lower level B = Action should be taken to minimize risk C = Operation permissible (may include controls that reduce risk but if they fail, risk will return to higher level)

Task Steps, Hazard(s), Controls Warning PPE Handling/Work Practices Env. Materials, (category- (Engineering or System(s) or Controls Equipment type) Administrative) Device(s) (Injury Rate) [Residual Risk Class] Patient Strains and Lift and Signage on None Always first refer to patient file to N/A Transfers Sprains transfer equipment determine transfer requirements. These (OEP-L, P, S, equipment – procedures MUST BE FOLLOWED! Residual Risk A, O) Slides boards, Updates to the patient file are required as Class = C mechanical new information becomes available, and at lifts, electric least weekly note: report any out of date Includes the lifts, gait belts patient file to your supervisor immediately following Policies on fall – transfers: assessment and 1) “ Self-care”: patient needs NO Bed to chair, Patient/Patient assistance stand, handling 2) “ One person”: patient needs one wheelchair, or person to assist with gait belt walker 3) “ Two Person”: patient needs two Wheelchair to people to transfer toilet, chair, 4) “Equipment Assist”: patient is to be or tub moved via lift assist equipment Chair to stand All employees, including new employees, or walker are to be trained and their skills reviewed Bed prior to doing transfers, AND prior to use positioning of equipment. All patient files are to be kept current to assure proper transfer assistance is provided. Do pre-use check of equipment (Slings, hooks, cables, etc.) to assure it MAKE SURE YOUR PATH OF TRAVEL AND SET-POINT ARE PREPARED BEFORE YOU START TO MOVE PATIENT Always stay clear of suspended person Know weight limits of gear and do not exceed them

Patient Patient Gait belt None None Do not wear chains, loose ear-rings, ties, None interaction ambulation nametags, etc. that patients could grab falls Always use gait belt for assistance Residual Risk (OEP-L, A) DO NOT “CATCH” patient if he/she falls. Class = C Assist / support patient to the floor. Ensure that patient is not injured before attempting to move them from floor. Seek assistance from co-workers to move patient from the floor using appropriate lift techniques or device. Patient Potentially Restraints None None Always first refer to patient file to N/A interaction combative determine their behavior issues, needs, patients and “Handling Requirements”. These Residual Risk (SB-C), (CB-P) MUST BE FOLLOWED! Class = C Updates to the patient file are required as new information becomes available, and at least weekly note: report any out of date patient file to your supervisor immediately Assure staffing levels are adequate and report inadequate staffing immediately DO NOT BE ALONE WITH POTENTIAL COMBATIVE INDIVIDUALS Do not wear chains, loose ear-rings, ties, nametags, etc. that patients could grab Approach patients with caution Always use a paired (two person) approach Use calm and non-confronting approach If there is any indication with any patient that they may become combative, step out, and get assistance from other trained individuals; wait for patient to calm down before re-entering

Patient Needle Sticks, Safety sharps Warning Gloves Always first refer to patient file to All sharps interaction Exposure to Sharps signage on Face masks determine patient’s background. Assure must be blood and other containers devices or shields all immunizations are current for patients disposed Residual Risk potentially Admin. Policy Gowns and staff of in Class = C contaminated on Universal Respirator DO NOT RECAP NEEDLES. DISPOSE approved materials Precautions OF THEM IMMEDIATELY IN SHARPS sharps (CW-H)] CONTAINERS containers Do not recycle needles and then Updates to the patient file are required as removed new information becomes available, and at from the least weekly note: report out of date facility by patient files to your supervisor an immediately approved Always use sharps container and assure hazardous container is located in area where sharps materials are used waste Assure that ALL POTENTIALLY hauler to EXPOSED STAFF ARE current on an universal precautions and procedures authorized training (attendance at training is disposal mandatory!) site. Use standard precautions and procedures for any potential exposure to blood or other bodily fluids; and when exposure to other communicable diseases is possible (e.g., scabies or pediculosis) Always use gloves and wash hands thoroughly with antibacterial soap for at least 2 minutes pre-shift, and 30 seconds minimum between patients General Strains and None None None Use legs, not back – keep back vertical N/A lifting, and Sprains during lift Material (OEO-L, P, A, Do Not twist when lifting; move your handling R) whole body instead Set work area up such that weights are at Residual Risk waist level Class = C Pre-shift and post-break stretching exercises are encouraged Limit weights lifted as much as possible and report any difficult lifts for re-design Use two-person lift for heavier and awkward loads; and assist equipment (scissor lifts, dollies, forklifts etc.) to eliminate lifts Rotate to other tasks throughout the shift

General Duties Slip/Trip/Falls Admin. Policy None None Housekeeping is CRITICAL to our safety! Recycle (FS-S, T, B), titled “Waste Keep work areas organized and free from materials Residual Risk (FB-S, T, B) Stream debris and trip hazards (extension cords, as possible Class = C Management files, papers, debris); Plan” Report any areas that are continual problems Keep file drawers closed when not in use Clean-up work area(s) prior to all breaks and at the end of each shift IMMEDIATELY place “Wet Floor” signs liberally in area of spills/hazards Assure IMMEDIATE clean-up/mop-up of spill or wet area DO NOT WALK BY A HAZARD, take responsibility to correct it

General Duties Falling Admin. Policy Labels on Hard-toed Keep file drawers closed when not in use None Material titled “Personal hard hats or shoes Do not wear open-toed shoes Residual Risk (SB-A, B) Protective bump caps Hard hat Wear hard-toed shoes as appropriate. Class = C Equipment” Bump cap Ensure that all unstable and top heavy items (e.g., files cabinets, etc.) are secured (e.g. attached to wall) to prevent them from tipping over Wear appropriate head protection wear objects may fall from above

General Duties Emergency Admin. Policy None None Emergent conditions can result in Collect Preparedness titled unpredictable hazards. Alertness is a key. hazardous Residual Risk (All categories- “Emergency Seek assistance regarding hazards during waste for Class = C All types) Management emergency situations. off-site Plan” Participate in emergency drills and be disposal aware of evacuation routes; and eye wash, first aid station and staff locations Keep all emergency exit routes unobstructed and accessible. Know the evacuation routes for your area. Know the location and contents of the Safety and Emergency Procedures Kardex. Assure fully charged, inspected, and proper extinguishers are in your work area Ensure that there are supplies on-site that are adequate for chemical and physical hazards present; and that MSDS’s are available Make sure that medical emergency numbers are posted

Chemical Irritation of Admin. Policy Some areas Gloves Know the contents of MSDS’s for all Collect (soaps, eyes and skin titled may have an Eyewear hazardous materials you are assigned to hazardous cleaners, (CW-B) “Hazardous air Face mask / use. waste for disinfectants) Materials monitoring shield Review the hazard assessment for the off-site Use Management system to Gowns tasks to determine protective equipment disposal Plan” warn of poor Respirator needs. Check date of assessment for Collect all Residual Risk air quality. Review currency. regulated Class = C Confined MSDS for Always wash prior to leaving the work waste for spaces must area appropriat be checked each Never eat, drink, or smoke in a chemical e storage for air chemical use or storage area and off- quality involved to Inspect equipment daily for wear or site using a determine deterioration and replace as needed. disposal calibrated appropriate Clean and maintain in a sanitary condition gas monitor PPE. and ready for use Container Contact Personal protective equipment is a last label supervisor resort for protecting your health and Warning or Safety safety. All feasible engineering controls signs Office for and work practices must be used before assistance relying upon personal protective equipment to reduce exposure Chemical Use Irritation of Admin. Policy Some areas Gloves Assure that all primary and secondary Collect (Corrosives, eyes and skin, titled may have an Eyewear containers are labeled indicating the hazardous Toxics) burns, “Hazardous air Face mask / contents and hazards waste for asphyxiation, Communica- monitoring shield Know the contents of MSDS’s for all off-site Residual Risk death tions Plan – system to Gowns hazardous materials you are assigned to disposal Class = C (CW-B, G) Chemical warn of poor Respirator use. Collect all Safety” air quality. Review Review the hazard assessment for the regulated Confined MSDS for tasks to determine protective equipment waste for spaces must each needs. Check date of assessment for appropriat be checked chemical currency. e storage for air involved to Always wash prior to leaving the work and off- quality determine area site using a appropriate Never eat, drink, or smoke in a chemical disposal calibrated PPE. use or storage area gas monitor Contact Inspect equipment daily for wear or Container supervisor deterioration and replace as needed. label or Safety Clean and maintain in a sanitary condition Warning Office for and ready for use signs assistance Assure that eyewash facilities and a quick drench shower are functional where corrosive materials are used. Assure that all primary and secondary containers are labeled indicating the contents and hazards Personal protective equipment is a last resort for protecting your health and safety. All feasible engineering controls and work practices must be used before relying upon personal protective equipment to reduce exposure

Chemical Use Fire, burns, Admin. Policy Signage on None Perform an assessment of the area and N/A smoke titled cylinders assure that ignition hazards are Compressed inhalation, “Compressed eliminated gasses-Oxygen cryoburns, cuts, Gases – Assure that equipment (including contusions, Handling and connectors, hoses, fittings, valves, Residual Risk fractures, death Storage” regulators, gauges, etc.) is routinely Class = C (SB-A), (CW- Vertical inspected and in good condition and free C) cylinder stands from leaks, rust, wear, deteriorated parts Cylinder Assure that oxygen cylinders are stored transports with cylinder caps in place and cylinders kept in an upright position, and secured Keep “no smoking/ignition sources” signs posted in cylinder storage area Keep proper and fully charged fire extinguisher in storage area Assure fire extinguisher is in cylinder storage area and fully charged Assure all ignition sources are removed from area of flammables storage and use Assure that fittings/connections are tight Store flammables separate from oxidizers including oxygen cylinders Know by memory, procedures for response to oxygen enhanced fires or environments

Certification: This document has been completed in conjunction with representatives of the department(s) or workgroup(s) listed above and serves as a comprehensive assessment of the hazards present in the covered task, activity, or work area.

Applicable Billings Clinic or department specific standards: Applicable outside agency regulations or accrediting standards

Supervisor/Employee Review: My Supervisor has reviewed this JSA with me, I have read the material, and I agree to follow the protective measures outlined above.

Employee (Print Name): ______

Employee: ______Date: ______(Signature)

Supervisor (Print Name): ______

Supervisor: ______Date: ______(Signature)