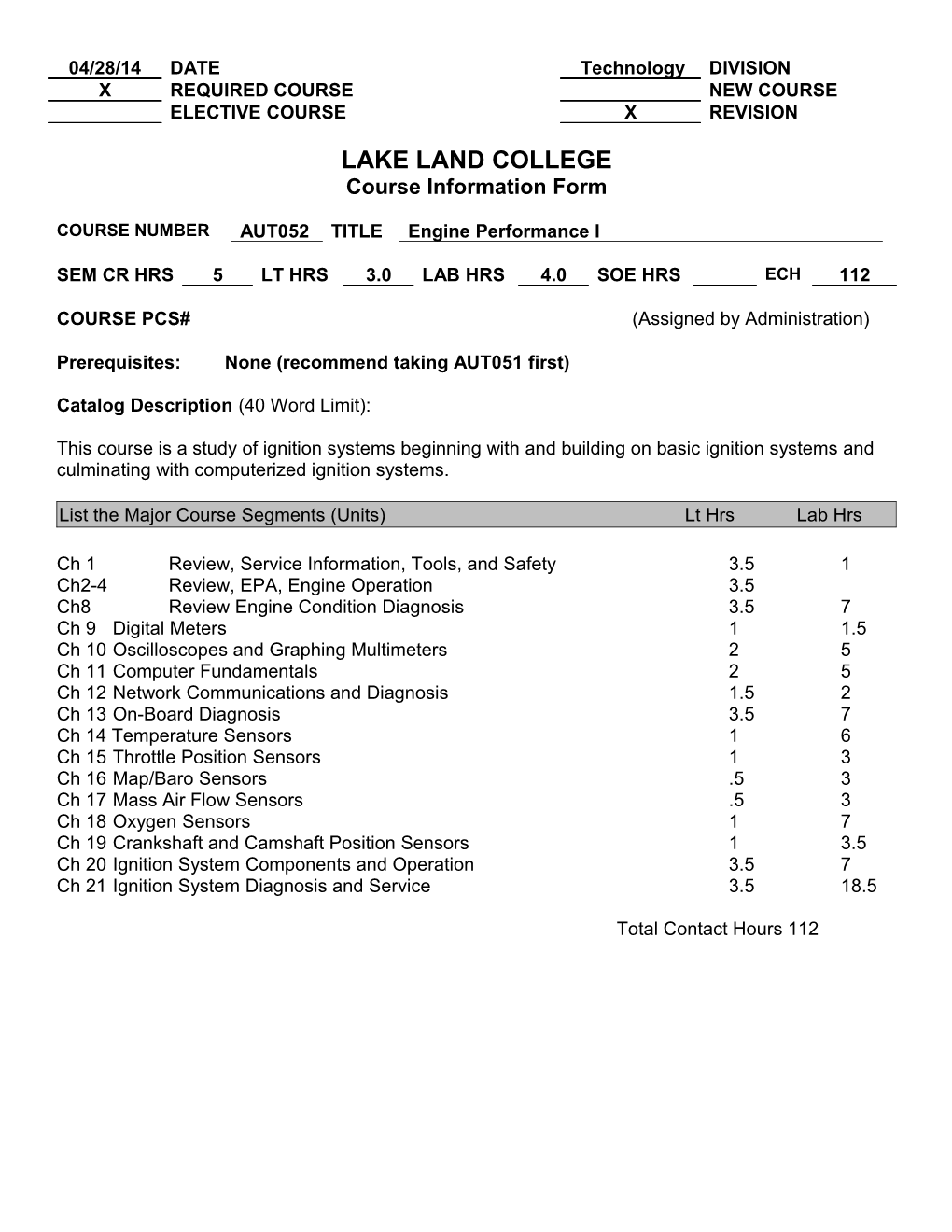

04/28/14 DATE Technology DIVISION X REQUIRED COURSE NEW COURSE ELECTIVE COURSE X REVISION

LAKE LAND COLLEGE Course Information Form

COURSE NUMBER AUT052 TITLE Engine Performance I

SEM CR HRS 5 LT HRS 3.0 LAB HRS 4.0 SOE HRS ECH 112

COURSE PCS# (Assigned by Administration)

Prerequisites: None (recommend taking AUT051 first)

Catalog Description (40 Word Limit):

This course is a study of ignition systems beginning with and building on basic ignition systems and culminating with computerized ignition systems.

List the Major Course Segments (Units) Lt Hrs Lab Hrs

Ch 1 Review, Service Information, Tools, and Safety 3.5 1 Ch2-4 Review, EPA, Engine Operation 3.5 Ch8 Review Engine Condition Diagnosis 3.5 7 Ch 9 Digital Meters 1 1.5 Ch 10 Oscilloscopes and Graphing Multimeters 2 5 Ch 11 Computer Fundamentals 2 5 Ch 12 Network Communications and Diagnosis 1.5 2 Ch 13 On-Board Diagnosis 3.5 7 Ch 14 Temperature Sensors 1 6 Ch 15 Throttle Position Sensors 1 3 Ch 16 Map/Baro Sensors .5 3 Ch 17 Mass Air Flow Sensors .5 3 Ch 18 Oxygen Sensors 1 7 Ch 19 Crankshaft and Camshaft Position Sensors 1 3.5 Ch 20 Ignition System Components and Operation 3.5 7 Ch 21 Ignition System Diagnosis and Service 3.5 18.5

Total Contact Hours 112 EVALUATION: Quizzes X Exams X Oral Pres Papers Lab Work X Projects Comp Final X Other

Textbook / Title: Automotive Engine Performance 4 th edition Author: Halderman Publisher: Prentice Hall/Pearson Education ISBN#: 9780133027754 Copyright: 2014

Workbook: Title: Engine Performance NATEF Standards Job Sheets Author: Erjavec/Pickerill Publisher: Cengage Learning ISBN#: 9781111647049 Copyright: 2015

For every task in this course, the following task must be strictly enforced as a number 1 priority:

Comply with personal and environmental safety practices associated with clothing, eye protection, hand tools, power equipment, and handling, storage and disposal of chemicals in accordance with local, state, and federal safety and environmental regulations.

At the conclusion of this course the student will, given the appropriate tools and equipment, be able to perform the following tasks safely and in a time period deemed satisfactory by the instructor.

VIII. ENGINE PERFORMANCE NATEF TASKLIST

A. General Engine Diagnosis

1. Complete work order to include customer information, vehicle identifying P-1 information, customer concern, related service history, cause, and correction.

2. Identify and interpret engine performance concern; determine necessary action. P-1

3. Research applicable vehicle and service information, such as engine P-1 management system operation, vehicle service history, service precautions, and technical service bulletins.

4. Locate and interpret vehicle and major component identification numbers. P-1

5. Inspect engine assembly for fuel, oil, coolant, and other leaks; determine P-2 necessary action.

6. Diagnose abnormal engine noise or vibration concerns; determine necessary P-3 action.

7. Diagnose abnormal exhaust color, odor, and sound; determine necessary action. P-2 8. Perform engine absolute (vacuum/boost) manifold pressure tests; determine P-1 necessary action.

9. Perform cylinder power balance test; determine necessary action. P-2

10. Perform cylinder cranking and running compression tests; determine necessary P-1 action.

11. Perform cylinder leakage test; determine necessary action. P-1

12. Diagnose engine mechanical, electrical, electronic, fuel, and ignition concerns; P-1 determine necessary action.

14. Verify engine operating temperature; determine necessary action. P-1

15. Perform cooling system pressure tests; check coolant condition; inspect and P-1 test radiator, pressure cap, coolant recovery tank, and hoses; perform necessary action.

16. Verify correct camshaft timing. P-1

VIII. ENGINE PERFORMANCE

B. Computerized Engine Controls Diagnosis and Repair

1. Retrieve and record diagnostic trouble codes, OBD monitor status, and freeze P-1 frame data; clear codes when applicable.

2. Diagnose the causes of emissions or driveability concerns with stored or active P-1 diagnostic trouble codes; obtain, graph, and interpret scan tool data.

3. Diagnose emissions or driveability concerns without stored diagnostic trouble P-1 codes; determine necessary action.

4. Check for module communication (including CAN/BUS systems) errors using a P-2 scan tool.

5. Inspect and test computerized engine control system sensors, powertrain/engine P-1 control module (PCM/ECM), actuators, and circuits using a graphing multimeter (GMM)/digital storage oscilloscope (DSO); perform necessary action.

6. Access and use service information to perform step-by-step diagnosis. P-1 7. Diagnose driveability and emissions problems resulting from malfunctions of P-3 interrelated systems (cruise control, security alarms, suspension controls, traction controls, A/C, automatic transmissions, non-OEM-installed accessories, or similar systems); determine necessary action.

8. Perform active tests of actuators using a scan tool; determine necessary action. P-1

9. Describe the importance of running all OBDII monitors for repair verification. P-1

VIII. ENGINE PERFORMANCE

C. Ignition System Diagnosis and Repair

1. Diagnose ignition system related problems such as no-starting, hard starting, P-1 engine misfire, poor driveability, spark knock, power loss, poor mileage, and emissions concerns; determine necessary action.

2. Inspect and test ignition primary and secondary circuit wiring and solid state P-1 components; test ignition coil(s); perform necessary action.

3. Inspect and test crankshaft and camshaft position sensor(s); perform necessary P-1 action.

4. Inspect, test, and/or replace ignition control module, powertrain/engine control P-2 module; reprogram as necessary.

Course Outcomes: At the successful completion of this course, students will be able to:

Students shall be able to perform task relating to engine performance/vehicle emissions, which are considered high priority by the automotive industry. Students shall be able to perform task relating to engine performance/vehicle emissions, which are considered medium priority by the automotive industry. Students shall be able to perform task relating to engine performance/vehicle emissions, which are considered low priority by the automotive industry.