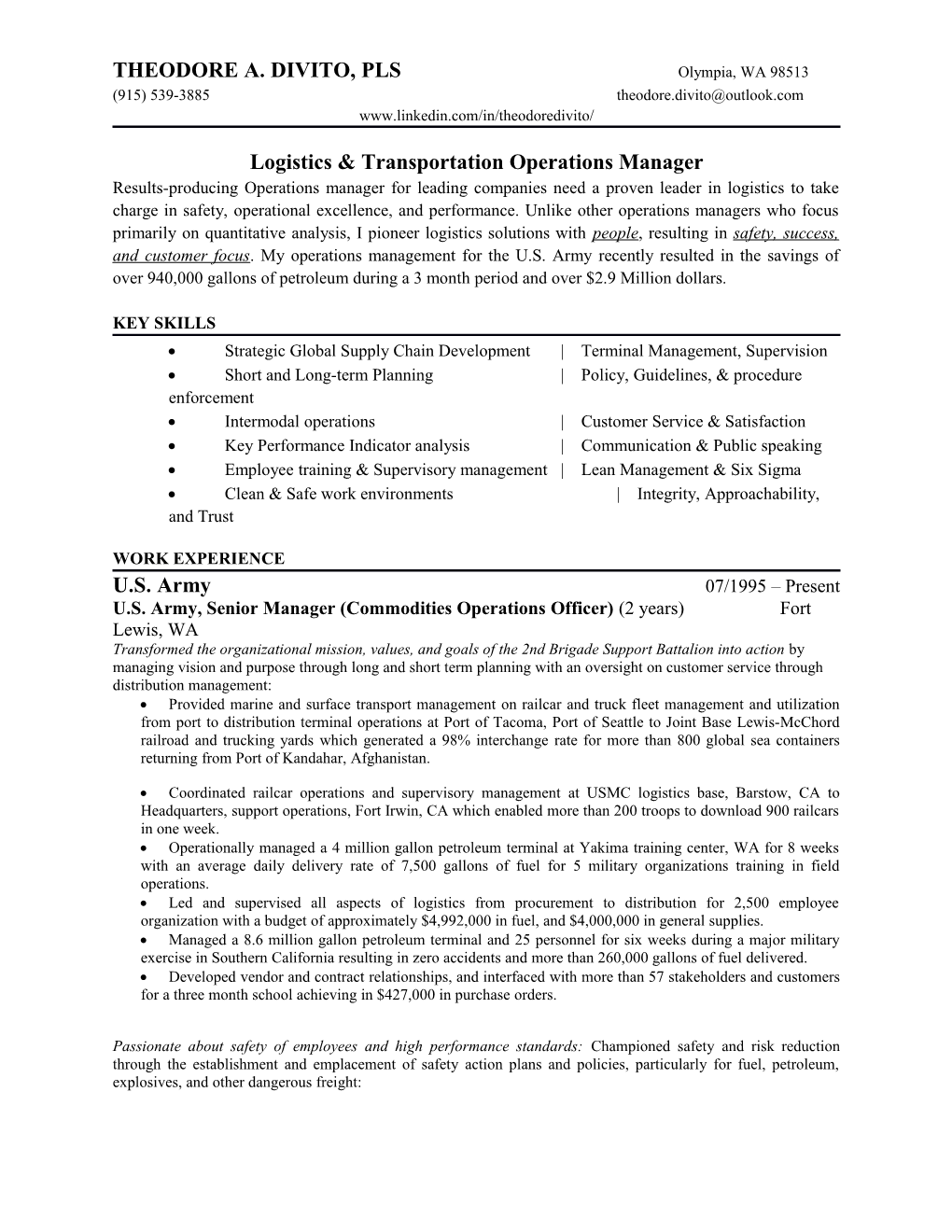

THEODORE A. DIVITO, PLS Olympia, WA 98513 (915) 539-3885 [email protected] www.linkedin.com/in/theodoredivito/

Logistics & Transportation Operations Manager Results-producing Operations manager for leading companies need a proven leader in logistics to take charge in safety, operational excellence, and performance. Unlike other operations managers who focus primarily on quantitative analysis, I pioneer logistics solutions with people, resulting in safety, success, and customer focus. My operations management for the U.S. Army recently resulted in the savings of over 940,000 gallons of petroleum during a 3 month period and over $2.9 Million dollars.

KEY SKILLS Strategic Global Supply Chain Development | Terminal Management, Supervision Short and Long-term Planning | Policy, Guidelines, & procedure enforcement Intermodal operations | Customer Service & Satisfaction Key Performance Indicator analysis | Communication & Public speaking Employee training & Supervisory management | Lean Management & Six Sigma Clean & Safe work environments | Integrity, Approachability, and Trust

WORK EXPERIENCE U.S. Army 07/1995 – Present U.S. Army, Senior Manager (Commodities Operations Officer) (2 years) Fort Lewis, WA Transformed the organizational mission, values, and goals of the 2nd Brigade Support Battalion into action by managing vision and purpose through long and short term planning with an oversight on customer service through distribution management: Provided marine and surface transport management on railcar and truck fleet management and utilization from port to distribution terminal operations at Port of Tacoma, Port of Seattle to Joint Base Lewis-McChord railroad and trucking yards which generated a 98% interchange rate for more than 800 global sea containers returning from Port of Kandahar, Afghanistan.

Coordinated railcar operations and supervisory management at USMC logistics base, Barstow, CA to Headquarters, support operations, Fort Irwin, CA which enabled more than 200 troops to download 900 railcars in one week. Operationally managed a 4 million gallon petroleum terminal at Yakima training center, WA for 8 weeks with an average daily delivery rate of 7,500 gallons of fuel for 5 military organizations training in field operations. Led and supervised all aspects of logistics from procurement to distribution for 2,500 employee organization with a budget of approximately $4,992,000 in fuel, and $4,000,000 in general supplies. Managed a 8.6 million gallon petroleum terminal and 25 personnel for six weeks during a major military exercise in Southern California resulting in zero accidents and more than 260,000 gallons of fuel delivered. Developed vendor and contract relationships, and interfaced with more than 57 stakeholders and customers for a three month school achieving in $427,000 in purchase orders.

Passionate about safety of employees and high performance standards: Championed safety and risk reduction through the establishment and emplacement of safety action plans and policies, particularly for fuel, petroleum, explosives, and other dangerous freight: Theodore A. DiVito, PLS 915-539-3885 Page 2

Managed several complex railhead operations at Joint-Base Lewis-McChord with over 100 employees for trans-loading operations over two years with zero accidents or injuries. Delivered over 260,000 gallons of petroleum over a three month period and saved the life and eyesight of one employee from a pressurized container through the enforcement of protective equipment such as safety glasses and hearing protection. Developed and implemented more than four safety policies, guidelines, and operational standard operating procedures utilizing Federal regulations which resulted in zero injuries in two years.

Implemented lean management processes that initiated budget and capital spending optimization measures:

Monitored Key Performance Indicators (KPI) and managed spending and consumption which generated savings of over $2.9 million dollars over a 3 month period by identifying over-projection of fuel use.

Built and maintained positive relationships with customers and interchange partners: Facilitated process and change improvements in equipment resources where applicable and filled in for team members during personnel shortages that resulted in food, ammunition, and medical supply delivery.

Developed and implemented commodity sources for five internal and three global stakeholders for a multi- national training exercise in Asia that enabled 600 foreign troops to train in the United States over six weeks.

Connected Sales and operational planning (S&OP) by establishing vendors and contractors through the supply chain process.

Floated more than 25 contracts and purchases in order to procure several tons of commodities ranging from break-bulk to general freight for 57 stateside and one foreign national organization which ensured 3,000 troops to train during a three-month summer ROTC camp. U.S. Army, International Consultant (Army Logistics & Security Advisor) (6 mo.) Afghanistan operationally managed logistics operations:

Mobilized and planned more than 20 international shipping containers for customs compliance and air shipment at the logistical staging yard located at Forward Operating Base Walton (A major logistics hub) resulting in a 100% pass rate and the savings of over $140,000 in potential fines.

Equipped a small 5-man expeditionary logistics advisory team for six months in Kandahar province, Afghanistan. Was solely responsible for procurement of American logistics requirements.

Provided supply chain expertise, mentorship, and leadership to senior Afghan police officials. Served as the link/facilitator between coalition forces and the Afghan government in order to resource 1000 police officers.

Delivered change management through problem resolution and partnership cooperation:

Smashed through cultural and logistical barriers through the coaching and mentoring of 18 foreign government officials over six months which improved supply chain treaty compliance by 60%.

Developed a soft-sell approach of mentorship through listening which generated a partnership rather than competitive relationship. Kept a strategic focus on long-term business which led to permanent friendships. Theodore A. DiVito, PLS 915-539-3885 Page 3

Implemented Lean management processes and financial responsibility through supply chain operations: Connected distribution center capabilities to American and Afghan inventory requirements through a 100% monthly inventory and supply chain analysis which led to a 97% improvement in product flow. Leveraged recycling and re-use of government materials possible in order to reduce purchasing costs. Cleared out 4 supply warehouses full of excess inventory in one month and recovered three tons of ammunition.

Ensured adequate resources and compliance in support of treaty agreements: Captured the real logistics situation by identifying the capabilities and accountability of the foreign logistics supply chain in order to tactically procure 1900 liters of petroleum. Established compliance standards by ensuring commodities were accounted and signed for properly. Supervised supply chain channels to procure 500 tons of fortification material from the coalition warehouse to the Afghan distribution yard.

U.S. Army, Company Vice-President (Army Executive Officer) (2 years) Fort Stewart, GA Drove results through team building and supervision:

Supervised 40 personnel for on-loading operations from the Fort Stewart rail yard to the Port of Savannah. Worked with cranes, fork-lifts, vessels, and trains in order to transport more than 60 shipping containers, break- bulk, and roll on/ roll off (RORO) from the army logistics terminal to the port with a 100% shipment rating.

Managed four subordinate leaders and more than 200 employees by evaluating performance, promotions, and disciplinary actions which optimized task priorities, communication, scheduling, and work assignments.

Developed training process improvements to petroleum supply chain personnel which culminated in the set up and establishment of a 250,000 gallon bulk petroleum farm.

Implemented lean and quality management processes continuously for a petroleum supply company: Developed training initiatives measured through Key Performance Indicators (KPI) and Unit Status Reporting (USR) which tracked performance, equipment, personnel, and mission readiness. Performed long and short planning to improve deficiencies. Communicated briefings to senior management weekly. Supervised warehouse delivery issues through weekly meetings with key section leaders. Advocated solutions which resulted in a 97% improvement in the maintenance ready rate.

Passionate about financial accountability and inventory loss prevention: Hand selected as Chief Investigating Officer for lost government property totaling over $240,000 spanning a three year time frame which recovered 75% of the property and the remaining 25% written off due to erroneous paperwork.

U.S. Army, Manager (Army Platoon Leader) (2 years) Tallil, Iraq Established safe and reliable transportation: Successfully oversaw, and operationally managed 40 employees on more than 100 transportation missions (convoys) from Tallil, Iraq (on the Kuwaiti border) to Baghdad logging more than 400 incident-free miles each trip with an average daily shipment of 600 tons.

U.S. Army Executive Advisor (Battle Staff NCO) (3 years) El Paso, TX Theodore A. DiVito, PLS 915-539-3885 Page 4

Directed, coordinated comprehensive logistical and reverse logistical functions for product life cycles: Acted as the local contact for purchases and swap tonnage (recycling). Purchased $85,000 worth of equipment over one year and disposed and reallocated over $60,000 worth of obsolete equipment in two months. Translated and motivated executive direction and technical requirements into a system process that labor could understand through public speaking and technical explanation.

EDUCATION Master of Arts: Transportation & Logistics Management | American Military University Bachelor of Science: Business Marketing | University of Maryland, University College Associate of Science: Electrical & Mechanical Technology | Community College of the Air Force

CREDENTIALS & CERTIFICATIONS Professional Designation in Logistics (PLS) - American Society of Transportation & Logistics (ASTL) Environmental Compliance - U.S. Army Lean Six Sigma -Aveta Business Institute Lean Six Sigma for Manufacturing - Defense Acquisition University Transportation Workers Identification Card (TWIC) - Department of Homeland Security Hazardous Materials Management - U.S. Army Safety & Risk Management - U.S. Army SECRET Security Clearance - Department of Defense

PROFESSIONAL ASSOCIATIONS American Society of Transportation & Logistics (ASTL) 2014 American Production & Inventory Control Society (APICS) 2014 Public Fleet Managers Association (PFMA) 2015 Transportation Club of Tacoma (TCT) 2015 Transportation Club of Seattle (TCS) 2015

TECHNICAL SKILLS Microsoft office: Microsoft Word, Microsoft Excel, Microsoft PowerPoint, Microsoft Outlook Logistics Management and Transportation management system software (TMS) PBUSE, BCS3, BFT, AIMS-TC RFID tracking