TRANSPARENT ENERGY SYSTEMS PVT.LTD., "Pushpa Heights", 1st Floor, Bibwewadi Corner, Pune 411 037. Ph No.020-24211347 / 24215665 / 24212390, Fax No.24212533 E-mail : [email protected]; [email protected]; [email protected] ------ENQUIRY FORM FOR WASTE HEAT RECOVERY SYSTEMS ON ENGINE GENERATORS

CUSTOMER NAME ADDRESS:

TELEPHONE NO. : ______FAX NO. ______E – MAIL . ______

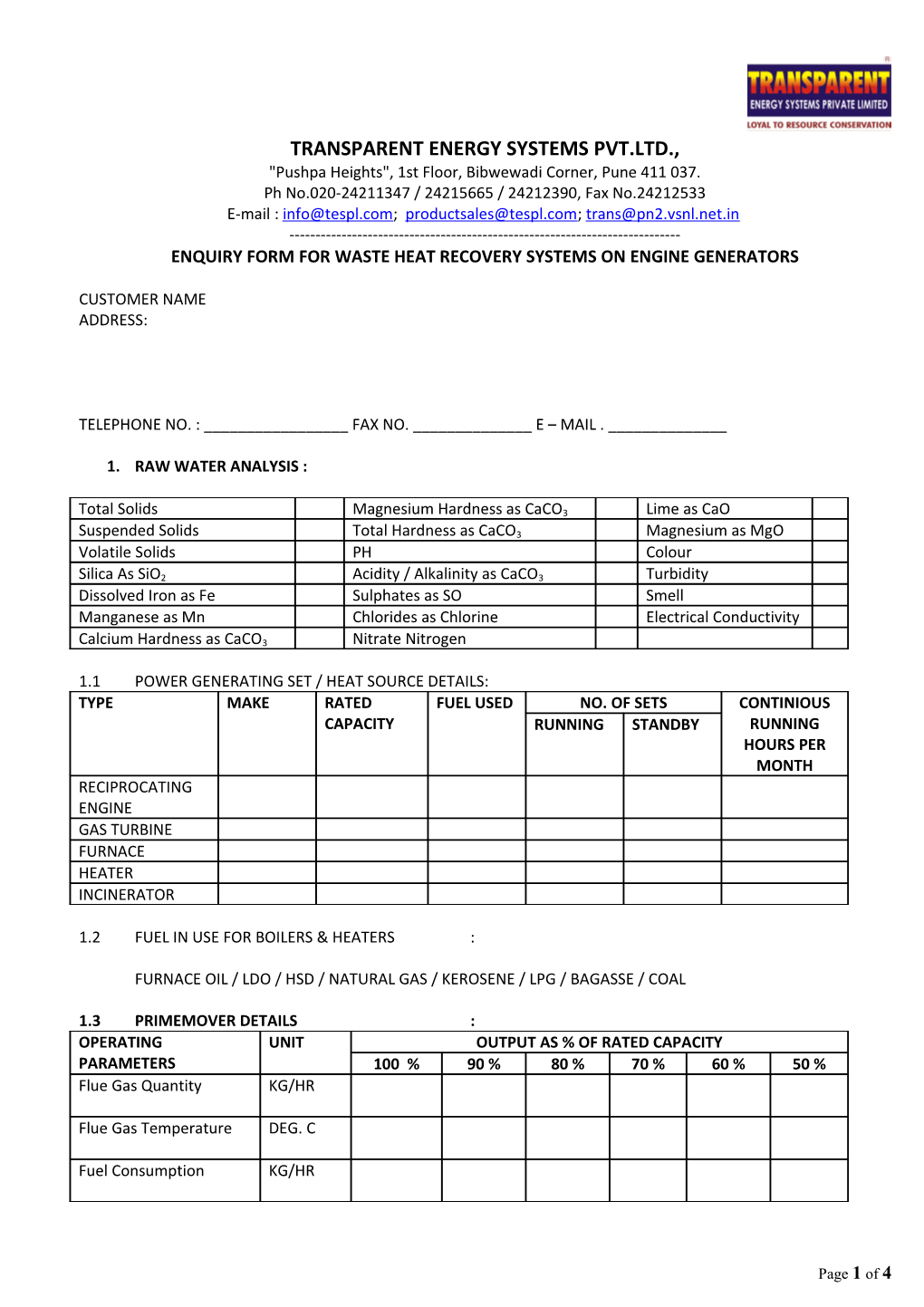

1. RAW WATER ANALYSIS :

Total Solids Magnesium Hardness as CaCO3 Lime as CaO

Suspended Solids Total Hardness as CaCO3 Magnesium as MgO Volatile Solids PH Colour

Silica As SiO2 Acidity / Alkalinity as CaCO3 Turbidity Dissolved Iron as Fe Sulphates as SO Smell Manganese as Mn Chlorides as Chlorine Electrical Conductivity

Calcium Hardness as CaCO3 Nitrate Nitrogen

1.1 POWER GENERATING SET / HEAT SOURCE DETAILS: TYPE MAKE RATED FUEL USED NO. OF SETS CONTINIOUS CAPACITY RUNNING STANDBY RUNNING HOURS PER MONTH RECIPROCATING ENGINE GAS TURBINE FURNACE HEATER INCINERATOR

1.2 FUEL IN USE FOR BOILERS & HEATERS :

FURNACE OIL / LDO / HSD / NATURAL GAS / KEROSENE / LPG / BAGASSE / COAL

1.3 PRIMEMOVER DETAILS : OPERATING UNIT OUTPUT AS % OF RATED CAPACITY PARAMETERS 100 % 90 % 80 % 70 % 60 % 50 % Flue Gas Quantity KG/HR

Flue Gas Temperature DEG. C

Fuel Consumption KG/HR

Page 1 of 4 Permissible Back Pressure on primemover MM of at Outlet Manifold WC Engine Cooling Water Flow Rate CU.M/HR (High Temp, Circuit) Engine Cooling Water Outlet Temperature DEG. C (High Temp. Circuit) Engine Cooling Water DEG. C Return Temperature (High Temp. Circuit)

2. HEAT MODES USED IN PLANT :

STEAM / HOT WATER / HOT AIR / THERMIC FLUID / REFRIGERATION / CHILLING

2.1 TYPE OF BOILER :

SMOKE TUBE / FINNED TUBE / WATER TUBE / COIL TYPE / COMPOSITE

2.2.1 STEAM REQUIRREMENT : ( KG/HR ) STEAM QUALITY – DRY & SATURATED / SUPERHEATED

PRESSURE TEMP. MAXIMUM MINIMU NORMAL Kg / sq.cm (g) ( DEG. C ) M High Pressure PRESENT Low Pressure Medium Pressure High Pressure FUTURE Low Pressure Medium Pressure

3.1 CONDENSATE RETURN : %

Condensate Temperature at Inlet to Feed Water Tank - Deg.C

Condensate Flow Rate -

TEMPERATURE MAXIMUM MINIMUM NORMAL MAXIMUM PRESENT MINIMUM NORMAL MAXIMUM FUTURE MINIMUM NORMAL

3.2.1 HOT WATER REQUIREMENT :

Page 2 of 4 A) OPEN LOOP : Feed Temp. Outlet MAXIMUM MINIMUM NORMAL Temp.

PRESENT

FUTURE

B) CLOSED LOOP : kcal/hr Inlet Temp. Outlet MAXIMUM MINIMUM NORMAL Temp.

PRESENT

FUTURE

3.2.2 HOT AIR REQUIREMENT :

A) OPEN LOOP : Feed Temp Outlet Temp MAXIMUM MINIMUM NORMAL

PRESENT

FUTURE

B) CLOSED LOOP : kcal/hr Inlet Temp Outlet Temp. MAXIMUM MINIMUM NORMAL

PRESENT

FUTURE

3.2.3 THERMIC FLUID REQUIREMENT : kcal/hr

Inlet Temp. Outlet MAXIMUM MINIMUM NORMAL Temp.

PRESENT

FUTURE

3.2.4 CHILLED WATER REQUIREMENT :

Inlet Temp. Outlet MAXIMUM MINIMUM NORMAL Temp.

PRESENT

FUTURE 4. WASTE WATER EVAPORATION / DESALINATION LOAD :

Waste Water / Desalination Water Composition:

Page 3 of 4 PH Ammonical Nitrogen Heaxavalent Chromium Temp. Chlorides Total Chromium Total Suspended Solids Sulphates Copper Total Dissolved Solids Sulphides Lead BOD (3days at 27 Deg.C) Cyanides Arsenic COD Nitrate Cadmium Oil & Grease Phosphate Colour Phenolic Compounds Insecticides / Pesticides Bio-Assay test Total Dissolved Gases

QUALITY OF EFFLUENT TO BE HANDLED : PROPOSED USE OF EVAPORATOR WATER : PROPOSED DISPOSAL OF CONCENTRATE:

MATERIAL OF CONSTRUCTION OF PLANT : Carbon Steel AISI 304 AISI 316 OTHERS

5.0 ACCESSORIES & INSTRUMENTATION NEEDED :

ACCESSORIES INSTRUMENTATION Feed Water Tank Recorders & Meters For : Pressurised Deareator Tank Steam Flow Continious Blowdown System Water Flow Chimney Flue Gas Flow Soot Blower Water Level Dust Collector in Flue Gas Steam Pressure Chemical Dosing System Fuel Pressure Water Softner Flue Gas Temperature Any Other Oxygen in Flue Gas Any Other

Special requirements/remarks:

______

______

Questionnaire filled by:

Name : ______

Designation : ______

Signature : ______

Date : ______

Page 4 of 4