CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES CONFIRMED MINUTES OCTOBER 22 - 25, 2012 OMNI WILLIAM PENN HOTEL PITTSBURGH, PA USA

These minutes are not final until confirmed by the Task Group in writing or by vote at a subsequent meeting. Information herein does not constitute a communication or recommendation from the Task Group and shall not be considered as such by any agency.

MONDAY, OCTOBER 22 to THURSDAY, OCTOBER 25

1.0 OPENING COMMENTS - CLOSED

Call to Order / Quorum Check

The Conventional Machining as a Special Process Task Group (CMSPTG) was called to order at 1:00 p.m., 22-Oct-12.

It was verified that only SUBSCRIBER MEMBERS were in attendance during the closed session of the meeting.

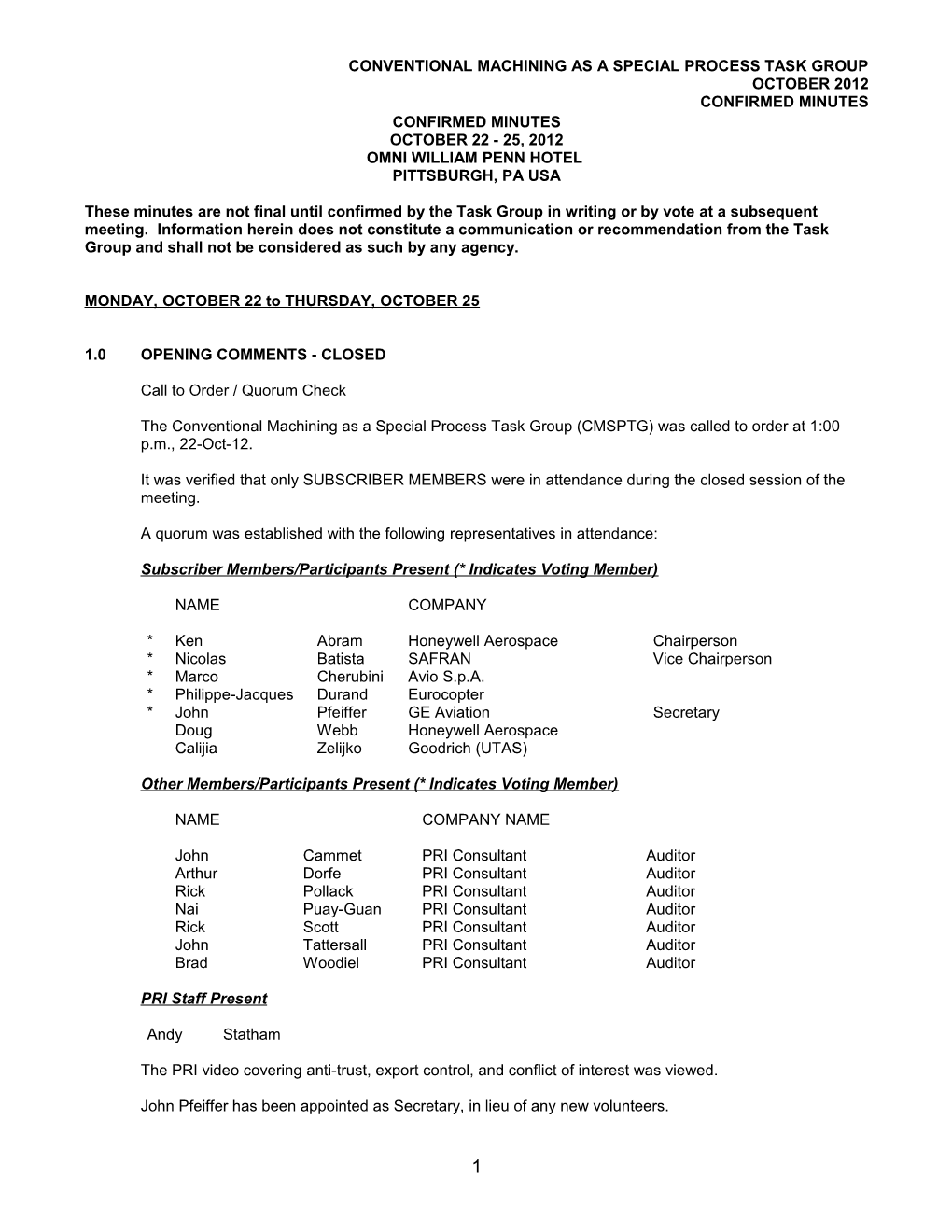

A quorum was established with the following representatives in attendance:

Subscriber Members/Participants Present (* Indicates Voting Member)

NAME COMPANY

* Ken Abram Honeywell Aerospace Chairperson * Nicolas Batista SAFRAN Vice Chairperson * Marco Cherubini Avio S.p.A. * Philippe-Jacques Durand Eurocopter * John Pfeiffer GE Aviation Secretary Doug Webb Honeywell Aerospace Calijia Zelijko Goodrich (UTAS)

Other Members/Participants Present (* Indicates Voting Member)

NAME COMPANY NAME

John Cammet PRI Consultant Auditor Arthur Dorfe PRI Consultant Auditor Rick Pollack PRI Consultant Auditor Nai Puay-Guan PRI Consultant Auditor Rick Scott PRI Consultant Auditor John Tattersall PRI Consultant Auditor Brad Woodiel PRI Consultant Auditor

PRI Staff Present

Andy Statham

The PRI video covering anti-trust, export control, and conflict of interest was viewed.

John Pfeiffer has been appointed as Secretary, in lieu of any new volunteers.

1 CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES

2.0 SUBSCRIBER CLARIFICATIONS – CLOSED

Andy Statham has created a new document to log Supplier clarifications. They will be reviewed at each meeting and then posted on eAuditNet.

ACTION ITEM: PRI Staff to remove audit numbers and other specific identifiers from the Subscriber Clarification running log. (Due Date: 30-Nov-12)

The Task Group (TG) needs to provide guidance on which devices need to be calibrated (reference AC7126/6 6.7.9), based on an audit where the need to calibrate the run-time meter on a vibratory finisher where the meter was used to set the media replenishment cycle. “Calibration” vs. “verification”? Subscribers are to add guidance to Appendix A where appropriate.

ACTION ITEM: Subscribers to update Appendix A for question AC7126/6 6.7.9, regarding which devices do or do not need to be calibrated. Also consider whether guidance should be added for similar questions on the other slash sheets. (Due Date: 15-Feb-13)

The TG needs to provide guidance on calibration requirements for coolant monitoring systems where they exist. Distinguish between “monitoring” and “alarm”.

ACTION ITEM: Subscribers to provide clarification where appropriate on calibration requirements for coolant monitoring systems (ref AC7126/1 5.5.1.2 and 5.5.2.3). (Due Date: 15-Feb-13)

ACTION ITEM: Marco Cherubini to prepare a presentation on Coolant for Pittsburgh 2013. (Due Date: 25-Oct-13)

AC7126 Base Draft Rev B was balloted. 4 approved and 1 disapproved. 6 (of 11) are required to pass the ballot. After the comments are reviewed the revision will be re-balloted.

3.0 SUBSCRIBERS METRICS – CLOSED

Delegation Review: Both Staff Engineers (Rick Sovich and Andy Statham) have reviewed about 18 audits so far towards delegation. Rick Sovich will be participating less as he focuses on other initiatives.

NCR Analysis Metrics were compiled by Melanie Petrucci.

Base Checklist AC7126: 8.2.1 (cutting fluid maintenance procedure) and 9.2.1 (machine maintenance plan) are the most common findings. The TG feels the checklist questions are clear enough. AC7126/1: 5.3.9.1 (coolant nozzle positioning in work instructions), 5.7.7 (actual process matches approved process) AC7126/2-6: Insufficient data to draw any conclusions due to the low numbers of audits to date.

ACTION ITEM: PRI Staff to establish whether the audits/day metric represents ½ day audits. (Due Date: 30-Nov- 12)

ACTION ITEM: PRI Staff to remove the auditor-specific information from the audit finding analyses so that it can be posted on eAuditNet to help suppliers prepare for audits. Staff is also to investigate if it is possible to combine repeat Slash Sheet questions (e.g. 5.3.9.1 and 6.3.9.1) on those same documents. (Due Date: 30-Nov-12)

ACTION ITEM: PRI Staff to look into re-organizing checklists (similar to NDT) so that repeat questions for additional job audits do not appear to be separate questions in eAuditNet. This should make both loading audits and compiling metrics easier. (Due Date: 15-Feb-13)

2 CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES TABLED ITEM: Meeting review of Auditor metrics has been tabled until the next Closed session (February 2013 meeting)

Oversight Audits One oversight audit in the past quarter. There is a need for TG Subscribers to continue to support this initiative.

NUCAP There are no NUCAP CMSP audits.

4.0 REVIEW OF AUDITOR CONFERENCE – CLOSED

Auditor comments on training: ½ day was not sufficient time. Subscriber presentations were informative and technical presentations should continue to be provided.

ACTION ITEM: PRI Staff to determine if other Subscribers need to leave the meeting when a Subscriber is presenting prime-specific requirements (e.g. during auditor training). (Due Date: 30-Nov-12)

ACTION ITEM: Marco Cherubini to supply his Surface Integrity Auditor training presentation to be posted for general use. (Due Date: 25-Oct-12) Item completed 25-Oct-12

ACTION ITEM: John Pfeiffer to supply the Tool Control presentation from October 2011 to be posted for general use (if possible). (Due Date: 25-Oct-12) Item completed 25-Oct-12

Potential future technical topics: o Basics of NC program code o RoMAN failure data summary o WZL Process monitoring o Coolant control (Ken Abram) Future general topics o Specific concerns/emphasis of the Subscribers o First-time vs. re-accreditation audit findings o Edgebreak/Transitions

Auditor Suggestions: 2.2.1 should be converted to a question to enforce pre-audit discipline. Also require Suppliers to list their internal procedure references against checklist questions. Reference AC7116 paragraph 2.2.7 as an example. o Can CMSP turn this into an audit question? If so, what Subscriber requirement would it flow from? Andy Statham and Ken Abram will raise this question at the NMC meeting. o Even without making it a question, should the TG leverage the AC7116 wording regarding Specification/Procedure cross-referencing to the current 2.2.1 wording?

ACTION ITEM: PRI Staff and Ken Abram to discuss making completion of the pre-audit an AC7126 question at the February 2013 TG Chair/Staff Engineer Round Table meeting. (Due Date: 22-Feb-13)

Auditor Suggestions Cont.: Need to have the TG review the number of job audits required per slash sheets, the scope of those audits (e.g. does a single job audit include multiple operations if the feature is produced at multiple operations?), and how many days are to be allocated.

3 CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES ACTION ITEM: Task Group review the number of job audits required per slash sheets, the scope of those audits (e.g. does a single job audit include multiple operations if the feature is produced at multiple operations?), and how many days are to be allocated. – February. (Due Date: 22-Feb-13)

5.0 CLOSED NEW BUSINESS – CLOSED

No items brought forward to discuss.

6.0 OPEN SESSION OPENING COMMENTS – OPEN

Other Members/Participants Present (* Indicates Voting Member)

NAME COMPANY NAME

Michael Bath DCMA * Tim Crowe Hunting Dearborn Becky DeGutis SAE Doug Evans Janicki Industries * Brad Gould Hunting Dearborn * James Jensen Moeller Manufacturing Hubert Kern FACC AG Kyle Lindsey Danville Metal Stamping Mike Nosek Precision Aerospace David Osenar PAKO, Inc. Jack Rockstad Precision Gear, Inc. Tim Scarlett Danville Metal Bill Vaith Janicki Industries

The PRI video covering anti-trust, export control, and conflict of interest was viewed.

Motion made by John Pfeiffer and seconded by Doug Webb to approve the minutes from the June 2012 meeting as written. Motion Passed

Brad Gould of Hunting Dearborn volunteered to serve as the CMSP representative to the SSC.

7.0 CLOSED MEETING DEBRIEF – OPEN

Ken Abram presented the major discussion points of Closed Meeting.

NCR Report-out See prior day’s minutes. Data re-presented for the benefit of the Suppliers present. No discussion from the Suppliers.

8.0 STAFF REPORT AND RAIL REVIEW – OPEN

Staff Report Oct 2012.ppt

4 CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES Task Group Metrics Andy Statham reviewed current TG membership metrics. There are currently 3 members mandating (GE Aviation, SAFRAN, and Honeywell Aerospace). As of 22 October (this meeting), we now have an SSC representative.

Changes to Procedures Andy Statham reviewed changes to Nadcap procedures. No discussion.

Discussion of Merit There are a number of companies that have already had three audits. At least one has been granted merit. There are a significant number (~20) of Suppliers that are scheduled for their third audits this year. A discussion of Merit criteria was added to the Agenda for Thursday.

RAIL Review The RAIL has been reviewed and updated.

9.0 REVIEW P&O, SSC, AND TG CHAIR AGENDA – OPEN

SSC: Review of SSC agenda P&O: Review of agenda TG &SE chair roundtable: review of agenda

No further actions or subjects identified

10.0 AC7126/7 – OPEN

Rick Scott suggested just using the current checklists, but ignoring any questions that refer to specific customer requirements rather than creating a new /7 checklist. This approach would likely result in Suppliers signing up for a number of processes (e.g. holemaking + turning + milling) which could lead to longer audits. The /7 approach might result in shorter, lower cost, audits.

Brad Gould suggested a three-tier system: the base, a /7 with common questions from each of the slash sheets, and “skinnied-down” slash sheets containing only the unique questions. Then a later audit for a Subscriber could include only the third-tier checklists, which would presumably be shorter and cheaper.

Andy Statham questioned whether there is really a need? How many Suppliers would sign up for a generic audit?

TABLED ITEM: Discussion of possible /7 checklist has been tabled until the Subscribers most likely to use this approach for their supply base are present.

ACTION ITEM: PRI Staff to send an e-mail to the team indicating that /7 has been tabled until such time as a Prime expresses a need. (Due Date: 25-Oct-12) Item was completed 25-Oct-12

Above item was closed at this meeting.

11.0 CLARIFICATION AND AUDIT HANDBOOK UPDATE – OPEN

There is only one clarification – regarding GE’s GT-193 authorizations to perform Special Processes as discussed earlier.

The Handbook needs to be updated to match the revision of the Base document. Subscribers also need to update their entries to Appendix A.

5 CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES ACTION ITEM: PRI Staff to re-order the handbook to match the revision B of AC7126. The TG will work on adjusting the guidance wording as required after the current text has been re-ordered. (Due Date: 18-Jan-13)

ACTION ITEM: Task Group to update the Handbook Appendix A to match the revisions to the Base document. (Due Date: 22-Feb-13)

12.0 REVIEW COMMENTS TO AC7126 BALLOT – OPEN

The Task Group agreed to eliminate 8.1.2 as redundant to 8.1.1. Question 8.1.3 and the accompanying guidance were updated for clarity, with no change to requirements. 11.6 & 11.7 are deleted as being redundant to 11.1 and 11.3. - editorial 7.1.7 – The TG engaged in significant discussion around the ability of a tool purchaser to require and receive information from tool Suppliers about modifications (e.g. carbide grade) to stock tools. Consensus on an effective approach was not reached, but “assure” was changed to “require” in the question, and the word “foreseen” was removed to better match the question to the ability of the Supplier to control incoming tools. - editorial 7.15 – The question was clarified with no change to requirements.

ACTION ITEM: PRI Staff to notify Rick Scott that the team eliminated three AC7126 audit questions to shorten the checklist as he requested. (Due Date: 30-Nov-12)

13.0 SUPPLIER TRAINING – DEEP DIVE ON PROCESS MONITORING – OPEN

John’s presentation is available in eAudit.net

14.0 REVIEW COMMENTS TO PLANNED EDGEBREAK SUB-SECTION – OPEN

Draft questions were circulated to the team to enhance the review of Edgebreak Processes within /1-/5 audits for cases where the Subscriber does not require a separate /6 Edgebreak audit. This would be the case, for example, where the Edgebreak/transition zone is considered part of the base feature.

The team discussed a series of proposed questions and made changes to some. A concern was raised as to whether the proposed questions are sufficient and the team was unable to re-construct the process by which they were collected. It is agreed that the /6 checklist will be reviewed at the February 2013 meeting to determine which questions might be pulled in to the other slash sheets.

ACTION ITEM: PRI Staff to add continuing discussion of potentially adding Edgebreak questions to the /1-/5 checklists to the February 2013 agenda. (Due Date: 16-Nov-12)

Topics include: If a significant number of questions are pulled forward, how will that impact the time required for the audit? Note that /1 already covers topics such as hone, abrasive flow, & jig grind for finishing of holes. This was accomplished mainly by adjusting existing questions rather than adding questions. Would a Subscriber-specific slash sheet be an appropriate tool?

15.0 REVIEW CHECKLIST REVISION SUGGESTION LIST – OPEN

The PRI video covering anti-trust, export control, and conflict of interest was viewed.

Other Members/Participants Present (* Indicates Voting Member)

6 CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES NAME COMPANY NAME

Steve Bissell Alloy Specialties Michael Graham PRI Rose Sadosky Alloy Specialties Sunder Rajan Raytheon

Grinding after Heat Treatment – Additions to AC7126/5 Sunder Rajan presented suggested additions to the grinding checklist based on information from the Metcut publication Low Stress Grinding for Quality Production. Based on TG discussion, several updates were proposed to the checklist.

ACTION ITEM: John Pfeiffer to contact TechSolve to see if the team could make copies of Low Stress Grinding for Quality Production and publish on eAuditNet. If allowed by TechSolve, Brad Gould is willing to create an electronic copy. (Due Date: 15-Feb-13)

The TG is unable to reverse-engineer the current status of the checklist drafts. Andy Statham presented a long list of comments (Excel spreadsheet), but it is unclear which may have been incorporated into drafts already. PRI staff will try to locate/identify the most recent drafts of the various slash sheets and then compare the proposed revision list to the drafts.

ACTION ITEM: PRI Staff to locate/identify the most recent drafts of the various slash sheets and then compare the proposed revision list to the drafts. (Due Date: 30-Nov-12)

16.0 MEETING REPORTS – OPEN

Andy Statham, Ken Abram, and Brad Gould summarized the activities of the Planning & Operations, TG Chair Round Table, NMC, and SSC meetings.

17.0 CHECKLIST TRANSLATION – OPEN

Currently have Chinese translations and French translations for all but /6, on which Nicolas Batista is working. Ken Abram is moving toward Spanish translations and will report out at the February 2013 meeting in Dallas.

ACTION ITEM: Ken Abram to report out in February on the status of Spanish translations. (Due Date: 22-Feb-13)

18.0 PROCEDURE REVIEW FOR TASK GROUP – OPEN

NOP-003: Staff Engineer Delegated Authority NOP-006: Supplier Advisory NOP-007: Oversight Audits – Significant discussion ensued regarding PIA implications in the case where an Observer might wish to observe an audit at a facility where another Subscriber’s parts are the only CMSP products. This will become less an issue as more CMSP Subscribers mandate more Suppliers.

19.0 VALUE PROPOSITION – OPEN

What is needed from CMSP to add more value to Subscribers? How can we make the TG meetings more impactful and attractive to potential participants? How can we make the value of the CMSP process more visible to potential mandating Subscribers?

The team generally feels that the current meeting structure/content is valuable to attendees.

7 CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES The team discussed the potential of launching the long-envisioned Industry Specification as a way to attract more Subscriber participation and also provide more value to the Subscribers and Suppliers. Andy Statham located a year-old e-mail from Laura Feix [email protected] describing an AMEC discussion around creating an industry standard based on CMSP.

ACTION ITEM: PRI Staff to add a recurring topic to Pittsburgh meetings to take a pulse on the value proposition of the face-to-face Task Group meeting (e.g. Continuous Improvement strategy). (Due Date: 16-Nov-12)

ACTION ITEM: PRI Staff to contact Laura Feix of SAE to see where 2011 discussions regarding the potential to launch a CMSP industry standard ended up. (Due Date: 25-Oct-12) Item was completed 25-Oct-12

Above item completed at the meeting. Laura responded that the AMEC committee is receptive to the idea of creating an Industry Standard for Special Process Conventional Machining, but that the idea has been effectively tabled because they feel their group does not have the expertise to create such a Spec. She feels that AMEC might be receptive to Nadcap CMSP providing the expertise, but this has apparently not been discussed by AMEC.

ACTION ITEM: Andy Statham and Ken Abram to add the topic of creating an Industry Specification to the NMC presentation, with the particular goal of identifying whether the existence of an industry standard might be of interest to Subscribers that are not currently active with CMSP. (Due Date: 15-Feb-13)

ACTION ITEM: PRI Staff to add a topic to the February 2013 meeting agenda to discuss launching an industry standard. (Due Date: 16-Nov-12)

20.0 AUDIT LENGTH – OPEN

Are the current time budgets for each audit appropriate? Specifically, is sufficient time allocated?

Factors that influence audit length: Redundant questions – minimizing them reduces time pressure Good pre-audits including specification references reduces time pressure. Should submission of a pre-audit be a finding-worthy requirement? Multiple operations to complete a feature (e.g. separate machining and Edgebreak operations) require additional time. Adding Edgebreak questions to /1-/5 slash sheets adds time pressure

The Task Group needs input from the Auditors as to which questions they feel are redundant.

ACTION ITEM: PRI Staff to work with the Auditors to solicit input as to which questions they feel are redundant, between now and the February 2013 meeting. Summarize and present in February. (Due Date: 15-Feb-13)

The current wording in the preamble to AC7126 does not compel Suppliers to submit the pre-audit or include Procedure cross-references. Submission “as directed by PRI” allows the Supplier an out if they do not receive a specific request from PRI. This wording needs to be improved. Reference AC7116 Rev. B paragraph 2.1.6 for an example of wording that compels the Supplier to provide specification references. This checklist also has a YES/NO question regarding whether the pre-audit has been submitted?

ACTION ITEM: PRI Staff to take the topic of pre-audit effectiveness to the SE SWAT meeting. Identify common issues and/or Best Practices around compelling 30-day audit pre-submission and adequacy of preparation. (Due Date: 30-Nov-12)

8 CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES 21.0 FLOW DOWN DOCUMENT – OPEN

Would this strategy be valuable for CMSP Suppliers Auditors? Andy Statham will poll the Auditors. If valuable, a CMSP version could be quickly created by leveraging the Welding and Coatings versions.

ACTION ITEM: PRI Staff to poll the Auditors to see if a Flow-Down Summary document would be helpful to them. (Due Date: 30-Nov-12)

22.0 OPEN NEW BUSINESS – OPEN

Review of Merit Criteria CMSP currently have (4) Suppliers that have had 3 audits and are therefore eligible for Merit. Of those, (3) have been granted Merit, the last had a potential product impact finding on their prior audit, which disqualifies them for Merit.

The current criteria are based on the Failure Criteria developed at the San Diego meeting. These will be reviewed on an ongoing basis, based on the review schedule for NOP-011.

Potential MOU with the Fluids Task Group (FLU) The FLU would consider accepting CMSP audits if we address threads and sealing surfaces. They had asked CMSP to consider adding an agenda Item for this meeting, but there was no follow-up from the FLU.

TABLED ITEM: The potential MOU with FLU has been tabled until there is further interest indicated by FLU participants.

Potential MOU with the Coatings Task Group (CT) CT has expressed a casual interest in an MOU related to machining after coating. No Action Item for CMSP until further consideration and contact by CT.

23.0 PLAN NEXT MEETINGS – OPEN

The next Nadcap meeting is in Dallas, Texas, USA from Monday Feb 18th – Thursday Feb 21st. CMSP will meet for three days from Tuesday through Thursday.

ACTION ITEM: PRI Staff to send an e-mail to Suppliers to encourage attendance in February 2013 meeting. (Due Date: 31-Dec-12)

The June 2013 meeting will be in Paris, France, June 3rd -7th.

Teleconferences Wednesday 9-Jan-13 at 10:00 EST (US) Wednesday 6-Feb-13 at 10:00 EST (US)

Potential Topics for Future Meetings Include a slot for Supplier training at February 2013 meeting. If a number of new Suppliers are present, John Pfeiffer could re-present the process monitoring topic. If Marco Cherubini is able to attend, re-present the surface enhancement topic (John Pfeiffer could cover this is Marco Cherubini is not available). Launching an industry standard Chair and SE to schedule a presentation on an Overview on CMSP to NMC for February 2013 meeting. Other TG members can attend in support. Verification of off-the-shelf cutting tools

9 CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES ACTION ITEM: PRI Staff to add discussion of incoming cutting tool control to the February 2013 agenda. Specifically, how do suppliers influence the cutting tool vendors to notify them of changes to catalog tools. (Due Date: 16-Nov-12)

ACTION ITEM: PRI Staff and Ken Abram to schedule a presentation on an Overview on CMSP to NMC for February 2013 meeting. (Due Date: 22-Feb-12)

ACTION ITEM: PRI Staff to collect data from eAuditNet to examine the overlap in Suppliers between CMSP, NM, and SE, to prepare for potential discussions from the NMC. (Due Date: 15-Feb-13)

24.0 POTENTIAL AUDITOR EXAMINATIONS – OPEN

It will likely be mandated by NMC that new Auditors pass an on-line TG-specific test. NDT, for example, has an initial general theory examination, followed by interviews, followed by training, followed by a second on-line exam on checklist requirements. The CMSP TG feels that a less extensive process would be appropriate for this TG.

Once NOP-012 is released the TG will review the requirements in it related to Auditor Training and formulate an Action Plan.

ACTION ITEM: PRI Staff to add a February 2013 agenda Item to review NOP-012. (Due Date: 16-Nov-12)

25.0 REVIEW PARKING LOT – OPEN

Completion of the potential AC7126/7 generic checklist was added to the Parking Lot. “Checklist on Cutting Tools” has been removed from the Parking Lot “Waterjet Cutting” has been removed from the Parking Lot Update of handbook to address “Procedure” questions has been closed as being worked. MOU with NM has been removed from the Parking Lot “Creation of a Job Audit policy similar to NMSE” has been removed from the Parking Lot because no one can remember the need driving it. “Creation of an MOU with Chemical Processes regarding nital etch” has been removed from the Parking Lot. Composite Machining has been removed from the Parking Lot based on the lack of interest displayed during a discussion in San Diego with the Composites Task Group. All other Parking Lot items are unchanged.

26.0 REVIEW NEW ACTION ITEMS – OPEN

Action Items were reviewed.

ADJOURNMENT – 25-OCT-12 – Meeting was adjourned at 5:00 p.m.

Minutes Prepared by: John Pfeiffer from GE Aviation, [email protected].

***** For PRI Staff use only: ******

Are procedural/form changes required based on changes/actions approved during this meeting? (select one)

10 CONVENTIONAL MACHINING AS A SPECIAL PROCESS TASK GROUP OCTOBER 2012 CONFIRMED MINUTES

YES* NO

*If yes, the following information is required:

Documents requiring Who is responsible: Due date: revision: None N/A N/A

11