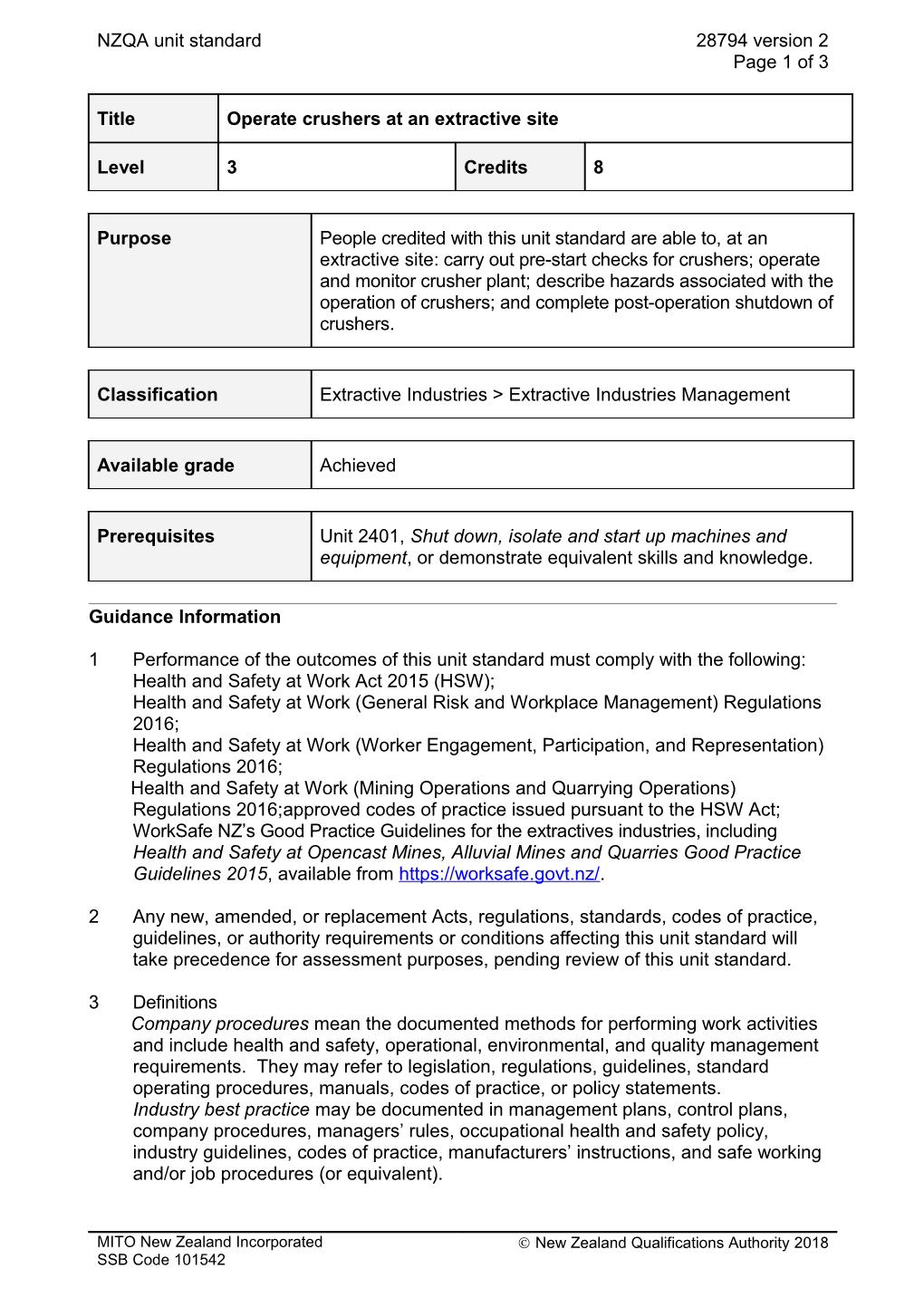

NZQA unit standard 28794 version 2 Page 1 of 3

Title Operate crushers at an extractive site

Level 3 Credits 8

Purpose People credited with this unit standard are able to, at an extractive site: carry out pre-start checks for crushers; operate and monitor crusher plant; describe hazards associated with the operation of crushers; and complete post-operation shutdown of crushers.

Classification Extractive Industries > Extractive Industries Management

Available grade Achieved

Prerequisites Unit 2401, Shut down, isolate and start up machines and equipment, or demonstrate equivalent skills and knowledge.

Guidance Information

1 Performance of the outcomes of this unit standard must comply with the following: Health and Safety at Work Act 2015 (HSW); Health and Safety at Work (General Risk and Workplace Management) Regulations 2016; Health and Safety at Work (Worker Engagement, Participation, and Representation) Regulations 2016; Health and Safety at Work (Mining Operations and Quarrying Operations) Regulations 2016;approved codes of practice issued pursuant to the HSW Act; WorkSafe NZ’s Good Practice Guidelines for the extractives industries, including Health and Safety at Opencast Mines, Alluvial Mines and Quarries Good Practice Guidelines 2015, available from https://worksafe.govt.nz/.

2 Any new, amended, or replacement Acts, regulations, standards, codes of practice, guidelines, or authority requirements or conditions affecting this unit standard will take precedence for assessment purposes, pending review of this unit standard.

3 Definitions Company procedures mean the documented methods for performing work activities and include health and safety, operational, environmental, and quality management requirements. They may refer to legislation, regulations, guidelines, standard operating procedures, manuals, codes of practice, or policy statements. Industry best practice may be documented in management plans, control plans, company procedures, managers’ rules, occupational health and safety policy, industry guidelines, codes of practice, manufacturers’ instructions, and safe working and/or job procedures (or equivalent).

MITO New Zealand Incorporated Ó New Zealand Qualifications Authority 2018 SSB Code 101542 NZQA unit standard 28794 version 2 Page 2 of 3

4 Range Evidence is required for two different types of crushing plant.

Outcomes and performance criteria

Outcome 1

Carry out pre-start checks for crushers at an extractive site.

Performance criteria

1.1 Pre-start checks are carried out in accordance with industry best practice and company procedures.

Range may include but is not limited to – feeder, wear and tear, guards, safety devices, emergency stop, fire protection, drive equipment, size reduction mechanism, stone boxes, cut out and isolating switches, trips, platforms, exits, entrances, walkways and handrails, housekeeping.

Outcome 2

Operate and monitor crusher plant at an extractive site.

Performance criteria

2.1 Crusher plant is operated and monitored in accordance with industry best practice and company procedures.

Range may include but is not limited to – dry run, guards, safety devices, fire protection, feeder, drive equipment, stone boxes, platforms, exits, entrances, walkways and handrails, housekeeping, dust control, drive couplings and/or belts, noise and vibration, wet and dry conditions.

2.2 Crusher plant is adjusted to ensure correct product specification is achieved.

2.3 Blocked crushers are cleared in accordance with industry best practice and company procedures.

Outcome 3

Describe hazards associated with the operation of crushers at an extractive site.

Range hazards must include but are not limited to – nip and/or pinch points, stored energy, fire, spillage, moving parts, falling objects, working at heights, poor housekeeping.

MITO New Zealand Incorporated Ó New Zealand Qualifications Authority 2018 SSB Code 101542 NZQA unit standard 28794 version 2 Page 3 of 3

Performance criteria

3.1 Significant hazards associated with the operation of crushers are described.

3.2 Methods of controlling the hazards are described in accordance with industry best practice and company procedures.

Range includes but is not limited to – isolation and lock-out procedures.

Outcome 4

Complete post-operation shutdown of crushers at an extractive site.

Performance criteria

4.1 Plant is shut down after operation in accordance with industry best practice and company procedures.

Range may include but is not limited to – lubrication points, housekeeping, drive systems, skirting, wear.

4.2 Documentation is completed in accordance with industry best practice and company procedures.

Replacement information This unit standard replaced unit standard 8897, unit standard 8898, and unit standard 8911.

Planned review date 31 December 2022

Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 18 June 2015 N/A Rollover and 2 25 January 2018 N/A Revision

Consent and Moderation Requirements (CMR) reference 0114 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do.

Comments on this unit standard

Please contact MITO New Zealand Incorporated [email protected] if you wish to suggest changes to the content of this unit standard.

MITO New Zealand Incorporated Ó New Zealand Qualifications Authority 2018 SSB Code 101542