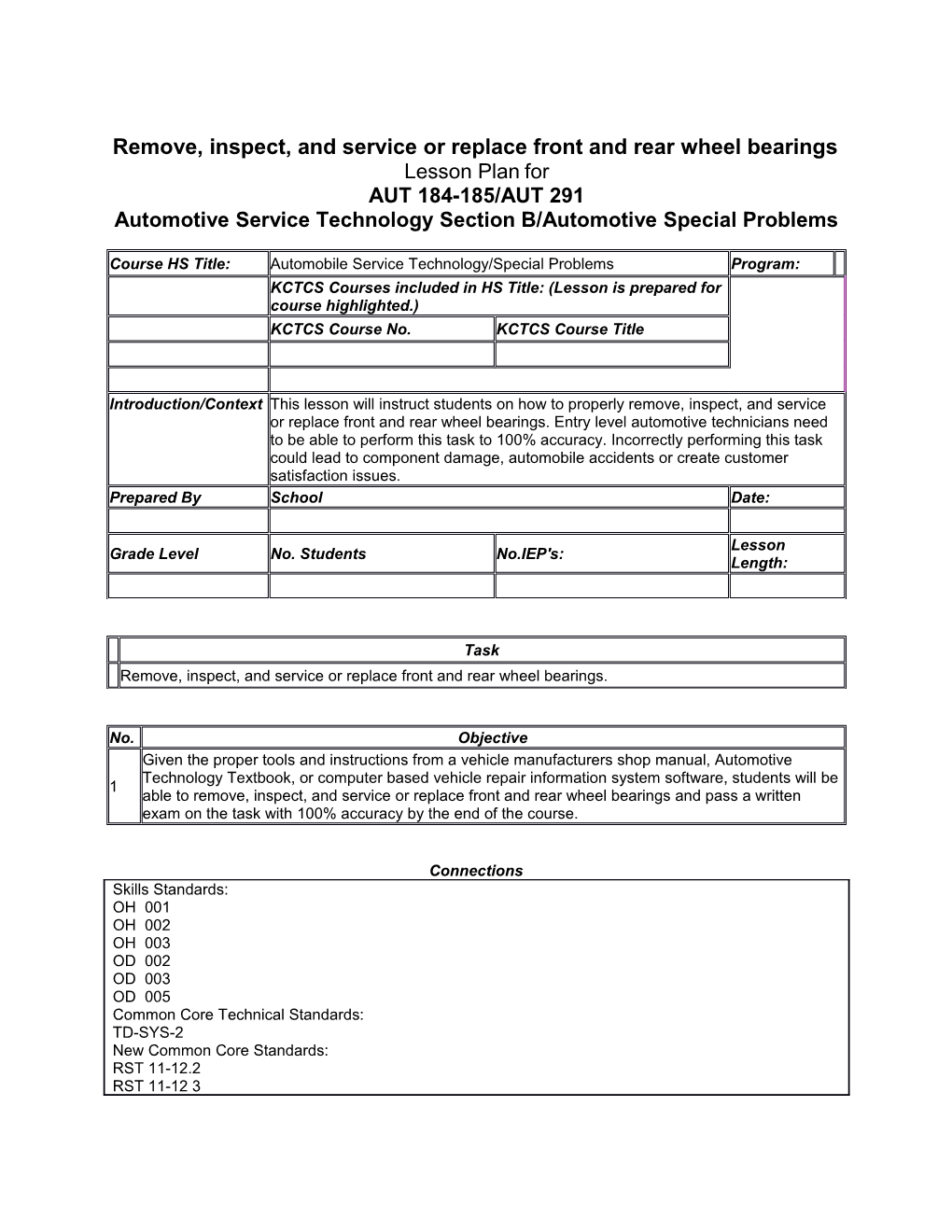

Remove, inspect, and service or replace front and rear wheel bearings Lesson Plan for AUT 184-185/AUT 291 Automotive Service Technology Section B/Automotive Special Problems

Course HS Title: Automobile Service Technology/Special Problems Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title

Introduction/Context This lesson will instruct students on how to properly remove, inspect, and service or replace front and rear wheel bearings. Entry level automotive technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task could lead to component damage, automobile accidents or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Remove, inspect, and service or replace front and rear wheel bearings.

No. Objective Given the proper tools and instructions from a vehicle manufacturers shop manual, Automotive Technology Textbook, or computer based vehicle repair information system software, students will be 1 able to remove, inspect, and service or replace front and rear wheel bearings and pass a written exam on the task with 100% accuracy by the end of the course.

Connections Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-SYS-2 New Common Core Standards: RST 11-12.2 RST 11-12 3 INSTRUCTIONAL MATERIALS/TECHNOLOGY

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Various Automotive Excellence Vol. 1 2007 Glencoe SS-560,561

Supplies Quantity Item Source As Needed Hand Towels Various As Needed Wheel Bearing grease (1lb tub) Various As Needed Cotter pins (assortment) Various

Equipment Quantity Item Source As Needed Four Post Lift (12,000 lb minimum) Various

Content/Presentation/Demonstration Outline Instruct students that safety rules concerning proper use of tools, vehicle lifting equipment, and jack stands, must be adhered to, as well as the Material Safety Data Sheets for any chemicals used (such as wheel bearing grease). Instruct students that there are basically two types of automotive wheel bearings, adjustable (that require service) and nonadjustable (that cannot be serviced, and must be replaced when defective). Inform students that a wheel bearing consists of three basic parts, an inner race, an outer race and a row of bearings (which can be either roller type or ball type). Instruct students that wheel bearings are further classified as adjustable and non-adjustable. The adjustable bearings have been historically installed on the front of rear wheel drive vehicles and require packing with wheel bearing grease, the seals replaced, and the preload properly adjusted. With the move to front wheel drive cars in the mid 80's, the non-adjustable, permanently lubricated wheel bearings became more popular. Manufacturers have almost eliminated adjustable wheel bearings in passenger cars and light duty trucks and most rear wheel drive vehicles now use non-adjustable bearings. When these bearings become defective, or fail, they are simply replaced. Demonstrate the proper procedure for checking for "play" in the front wheels by raising and properly supporting vehicle, grasping the wheel at the top and bottom and rocking the tire in and out. Proper preload will only give 0''-0.003" of play, so any movement indicates a need for service. Demonstrate removal of the wheel bearing/hub assembly. Remove and support caliper assembly. Remove cap, cotter pin, nut, washer and outer wheel bearing. Remove inner wheel bearing seal and bearing. Demonstrate proper cleaning and inspection of races inside the hub assembly, and both wheel bearings. Instruct students that bearings and races should be washed with soapy water and air dried before repacking. All grease should be removed from hub assembly with a shop towel and inspected under a light for signs of metal particles. Instruct students that new grease must not be mixed with old due to incompatibility issues. Demonstrate proper procedures for packing wheel bearings (both by hand, and with a bearing packer should be covered). Demonstrate proper packing and reinstallation of rear wheel bearing and wheel bearing seal in the hub assembly. Install the hub, front bearing, washer and nut, and demonstrate the proper assembly for adjusting the bearing preload. (This needs to be researched to be vehicle specific). Instruct students that nonadjustable wheel bearings, which are factory lubricated and sealed, must be replaced when noisy or defective. Some vehicles require removal of the spindle, the wheel bearing pressed out and a new one pressed in, while some are designed to allow the wheel bearing and hub to be replaced as an assembly. Specific vehicle service information must be followed. Additionally front wheel drive vehicles typically have an axle nut that must be removed and replaced.

Applications/Practice 1 Refer to content.

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 2 accommodations for special needs students will be added if required.

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)