Material Safety Data Sheet

ER80S-D2

Section 1: Product Information

Supplier’s Name Manufacturer’s Name Refer to Suppler

Address Address

1785 Argentia Road Refer to Supplier Mississauga, ON L5N 3A2

Telephone Number Telephone Number

(905) 826-2122 Refer to Supplier 1-800-268-4833

Trade Name: N/A

Chemical Formula: N/A Product Use: Solid welding wire for gas-shielded arc welding

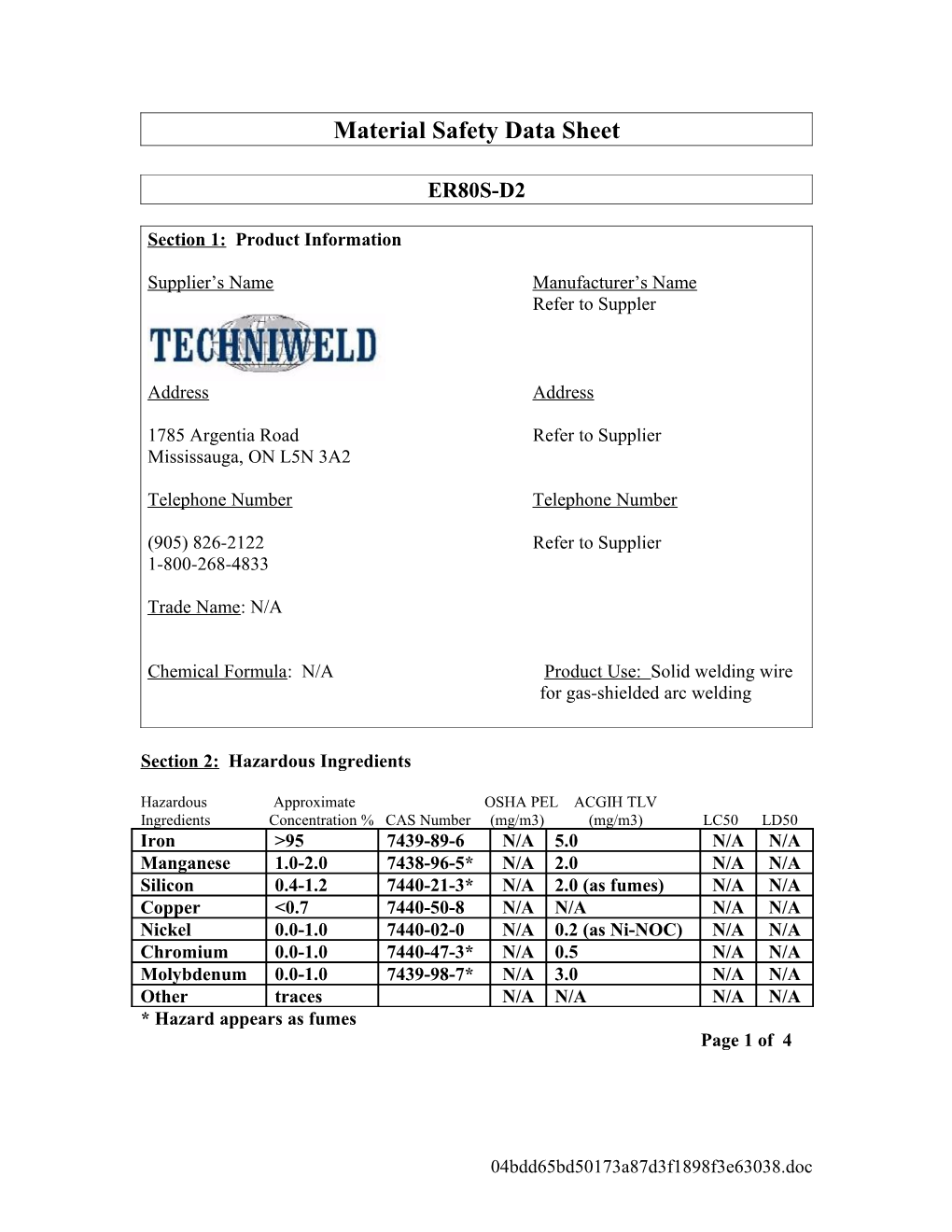

Section 2: Hazardous Ingredients

Hazardous Approximate OSHA PEL ACGIH TLV Ingredients Concentration % CAS Number (mg/m3) (mg/m3) LC50 LD50 Iron >95 7439-89-6 N/A 5.0 N/A N/A Manganese 1.0-2.0 7438-96-5* N/A 2.0 N/A N/A Silicon 0.4-1.2 7440-21-3* N/A 2.0 (as fumes) N/A N/A Copper <0.7 7440-50-8 N/A N/A N/A N/A Nickel 0.0-1.0 7440-02-0 N/A 0.2 (as Ni-NOC) N/A N/A Chromium 0.0-1.0 7440-47-3* N/A 0.5 N/A N/A Molybdenum 0.0-1.0 7439-98-7* N/A 3.0 N/A N/A Other traces N/A N/A N/A N/A * Hazard appears as fumes Page 1 of 4

04bdd65bd50173a87d3f1898f3e63038.doc Section 3: Physical Data

Physical State: Solid Boiling Point: N/A Odour and Appearance: Odourless Melting Point: 1600ºC Odour Threshold(PPM): N/A Solubility in Water: No Specific Gravity: 5-8 g/cm3 % Volatile (by Volume): N/A Vapour Pressure(MM): N/A PH: N/A Vapour Density (Air =1): N/A Coefficient of Water/Oil Distribution: N/A Evaporation Rate: N/A

Section 4: Fire or Explosion Hazard

Flammable: No . Keep flammable materials away from the work area. Means of Extinction: N/A Flashpoint: N/A Upper Flammable Limit (% by volume): N/A Lower Flammable Limit (% by volume): N/A Auto ignition temperature: N/A Hazardous Combustion Products: N/A Explosion data-sensitivity to mechanical impact: N/A Explosion data-sensitivity to static discharge: N/A

Section 5: Reactivity Data

Chemical Stability: Yes Incompatibility to other substances: Yes If so, which ones? Strong acids and bases . Hazardous decomposition products: When the filler metal is consumed, the fume and gas decomposition products generated are different in percent and form from the ingredients listed in Section 2 plus those from the base metal, coating, etc. Reasonably expected fume constituents of this product would include: oxides of iron. Secondary complex oxides of manganese, silicon, chromium and molybdenum. The present OSHA permissible limits for exavalent chromium are .05mg/m3 that will result in significant reduction from the 5mg/m3 general fume level. Gaseous reaction products may include carbon monoxide and carbon dioxide. Ozone and nitrogen oxides may be formed by the radiation from the arc, in addition to the shielding gases like argon and helium whenever they are employed. One recommended way to determine the composition and quantity of fumes and gases to which workers are exposed is to take an air sample from inside the welder’s helmet, if worn, or in the worker’s breathing zone.

Page 2 of 4

04bdd65bd50173a87d3f1898f3e63038.doc Section 6: Toxicological Information

Over exposure to welding fumes may result in discomfort such as dizziness, nausea, dryness or irritation of nose, throat and eyes. Pre-existing respiratory conditions may be aggravated in some individuals. Welding arc from the electric welding process creates fumes as well as intense radiation that produce ozone. Over exposure to ozone can result in mucous membrane irritation as well as pulmonary changes including congestion and edema. Pulmonary edema can be delayed in onset. Long term overexposure may lead to siderosis (iron deposits in lungs) and is believed by some investigators to affect pulmonary function. The potential for overexposure to copper fumes may exist when welding on alloys containing amounts of copper greater than 2.5%. Exposure to copper fumes can result in upper respiratory tract irritation, nausea and Metal Fume Fever.

Exposure Limits 5 mg/M3 Reproductive Toxicity N/A Irritancy of Material N/A Teratogenicity N/A Sensitization to Material N/A Mutagenicity N/A Carcinogenicity N/A Toxicologically synergistic products N/A

Section 7: Preventive Measures

Personal Protective Equipment:

Eye Protection: Wear helmet or use face shield with appropriate filter lens. Provide protective screens and goggles, if necessary, to shield others.

Respiratory Protection: Use NIOSH approved or equivalent fume respirator or air supplied respirator when welding in confined spaces or where local exhaust or ventilation does not keep exposure limit below TLV.

Protective Clothing: Wear hand, head, and body protection that help to prevent injury from radiation, sparks, and electrical shock. At a minimum this includes welder’s gloves and protective face shields with filter lens, and may include arm protectors, aprons, hats, shoulder protection, as well as dark substantial clothing. Ultraviolet radiation can cause irritation or flash burns to eyes and skin. Train the welder not to touch live electrical parts and to insulate himself from others.

Engineering Controls: Use enough ventilation, local exhaust at the arc or both to keep the fumes and gases below TLV’S in the worker’s breathing zone and the general area. Train the welder to keep his/her head out of the fumes. Endeavor to control the total welding fumes to below 5 mg/m3. Refer to Health Hazard Data Section 6. Train the welder to deep his head out of the fumes. Page 3 of 4

04bdd65bd50173a87d3f1898f3e63038.doc Section 7: Preventive Measures (continued)

Leak or Spill Procedure: N/A

Handling Procedures and Equipment: Wash hands thoroughly after using these products.

Waste Disposal: Dispose of residue from cutting, grinding or welding operations into suitable containers. Ferrous scrap-do not dispose of in the environment.

Storage Requirements: N/A

Special Shipping Information: N/A

Section 8: First Aid Measures

Eye Contact: Flush with water for at least 15 minutes. Get medical attention if irritation persists.

Inhalation: Remove from exposure. Get medical attention if experiencing breathing difficulty. If breathing has stopped, perform artificial respiration.

Skin Contact: Remove particles by thoroughly washing with soap and water. In case of thermal burns, flush with water for at least 15 minutes.

Ingestion: Ingestion is not likely to occur. To further reduce the possibility, maintain good hygiene habits

Section 9: Preparation Information

Prepared by: Techniweld (905) 826-2122 1-800-268-4833

Date Prepared: January 1, 2007

The manufacturer believes this data to be accurate and to reflect qualified expert opinion regarding current research. However, the manufacturer cannot make any express or implied warranty as to this information.

Page 4 of 4

04bdd65bd50173a87d3f1898f3e63038.doc